Seam roofing is considered one of the best solutions for roofs with a slight slope. It is sealed, durable and easy to install. Initially, the fold was assembled only by hand. This took a lot of time, the quality of the joints depended on the qualifications of the worker. After the advent of professional equipment for assembly, the speed of installation increased, and it became possible to make smooth connections of any length. Therefore, the demand for such finishing is growing. Let's look at all the intricacies of self-installation of a seam roof.

Installation of seam roofing

Seam roofing is a roof covering in which adjacent structural parts connected using special seams.

The painting is one of the elements of a modern roof covering, in which all the edges and edges are previously prepared for the installation of a seam joint.

Seam roofing is popular because, subject to high-quality professional installation, it ensures complete tightness of the under-roof space. And with a modern protective polymer coating, a seam roof will last a long time with minimal maintenance costs.

Among the main advantages of the roof is the possibility of long-term use of the coating , based on the presence of a modern anti-corrosion coating.

The folded covering elements are lightweight and have a smooth surface. Thanks to this, snow and water do not linger on the surface.

The installation of a seam roof begins with the choice of fastening - the seam. The folds can be standing or lying, but they differ in that with the help of horizontal folds you can effectively connect all the elements that are in the same position. Standing elements can be used to connect the roof along the entire length of the slope.

Rebates are characterized by different types of joints produced, which can be single and special double . In the first case, there is one classic bend; a double bend is distinguished by its ability to ensure maximum tightness. Such folds are used in those areas of the roof where there is a danger of moisture accumulation due to leakage, which is typical for gutters.

types of locks

For proper installation, you may need many tools and different attachments for certain elements. Before installation, you should prepare the following roofing tools for standing seam roofing:

- All possible measuring devices - plumb line, level, levels.

- A tool for identifying the difference between the height of all surface points in relation to a particular set level. Equipment is required to measure possible increases in levels.

- Manual and more modern electric scissors, which are needed for cutting and neatly cutting out roofing elements.

- Nibbler for carrying out the operational sharpening process.

- A hacksaw and construction jigsaw for efficient lathing.

- Standard grinder.

- Household drill and hammer drill.

- Fastening gun for pressing out. Rubber and wooden mallets.

Rebate panels can be cut using angle grinders. The main thing is that all untreated areas should be carefully protected from sawdust, and the cut areas should be treated with special anti-corrosion compounds.

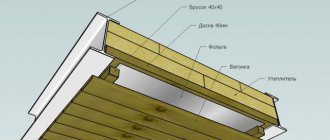

Roofing pie

The seam roofing pie is characterized by a special multi-component system, which, in addition to the roofing itself, consists of various other elements. This includes sheathing, insulation, and high-quality waterproofing. Hence the name roofing pie - it consists of a large number of layers. If the pie is arranged correctly, a large number of different problems can be avoided. This is an ideal opportunity to prevent the appearance of icicles, the accumulation of condensation and heat loss.

The arrangement of the pie requires special attention, since errors in the design process of a particular layer will seriously reduce the overall strength and durability of the structure.

A competent ventilation system is of great importance in the process of designing and arranging a roof. It removes excess moisture from the entire roofing pie. To discharge water through the membranes into the equipped ventilation, it is worth leaving several holes in the roof during the installation process. Wooden sheathing will cope with this process perfectly.

Clamp - what is it and what is it for?

In the process of installing seam roofing, fastening devices such as clamps are used. Essentially, this is a special device that is designed for fastening roofing sheets . You don’t have to use nails, which can disrupt the integrity and complete tightness of the coating.

The use of a clamp greatly simplifies the process of installing the roof covering and ensures the overall durability of the system. Finishing the roof with similar elements makes it aesthetically pleasing and as airtight as possible.

clamp

Sheathing for standing seam roofing

The fastening of the seam roof is carried out strictly to the pre-installed sheathing. This will help prevent sagging of the steel sheets, but only if the required pitch range is fully observed.

The following materials are used as lathing:

- Galvanized metal profile.

- Eco-friendly wooden beam 50 to 50.

- Board 100 by 32.

These elements are attached strictly from below and upward, that is, from the eaves to the roof ridge. If you are installing metal sheathing or loose wood sheathing, you should use a high-quality anti-condensation film before installing it along the rafters. When using a special continuous sheathing or other completely continuous base, a special vapor diffusion film will need to be laid over the entire flooring.

The sheathing pitch is 20 centimeters ; it is allowed to use a pitch in the range of 20-40 centimeters.

The material provides the following advantages:

- Installation of a permanent ventilation duct , which will remove condensed moisture appearing on the back side of the roof made of metal;

- Effective prevention of destructive corrosion of metal elements, as well as rotting of wood elements;

- Significant reduction in noise from precipitation .

Where the installation of roof assemblies is carried out - valleys, roofing eaves, as well as connections and abutments to various protruding elements of the structure, a second sheathing profile element is mounted . This gives increased strength and rigidity to the installed panels.

Requirements for the rafter system and sheathing

A special feature of a seam roof is the rigid, non-removable fastening of metal sheets to each other. Also, metal sheets do not have additional longitudinal bends that would allow adjusting the joint between the already fixed and mounted sheet. Therefore, it is important to strictly adhere to the calculated linear dimensions and diagonals when constructing the frame.

The plane on which the seam roof will be mounted must be almost ideal, since the metal sheets do not have additional stiffeners, but must fit tightly to the sheathing so that unnecessary noise is not created during precipitation or strong winds.

The frame for a seam roof can be made of metal (in utility or industrial premises, as well as if a self-locking seam is used), however, wood would be preferable for residential premises.

The rafters are subject to general construction requirements for strength and design snow load. If the slope of the seam roof is large, the distance between them can be increased, since the metal sheets are large and light in weight, and the snow load will also be small. If it does not exceed 20⁰, the use of a self-locking fold is not recommended, since it has less tightness. For the same reason, in this case it is unacceptable to use a single lock - only a double one.

The sheathing for a seam roof can be made of 50x50 timber, 32x100 boards with or without a calculated pitch between the boards, or solid sheet material.

The lower the roof slope, the smaller the pitch. The need for a continuous sheathing arises in cases where a copper seam roof, aluminum or zinc-titanium will be installed, since they have less rigidity, and zinc-titanium is more fragile. Continuous sheathing is also preferable for complex roof configurations.

In places of cornices, valleys, abutments to protruding structures (smoke ventilation ducts, parapets), as well as along the perimeter, it is advisable to maintain a continuous sheathing with a width of 500 to 700 millimeters. There is also a need for additional lathing with a width of at least 120 millimeters in places where the paintings are transversely joined.

It is important not to forget to treat the wood with antifungal and fireproofing agents. This can be done on the ground before installing the frame, or after installing it, but before installing the roof.

Description and features of seam roofing

A seam is a seam formed by joining two adjacent covering elements. It is obtained by pressing the panels with their edges, followed by bending and pressing. The performance qualities of the roof depend on the joining technique used.

Types of folds:

- Standing connections are used for vertical fixation of panels. They come in single and double. In the first case, two edges have a right angle bend, and only one has a 180 degree bend. The double fold is more reliable and airtight; it best protects the roof from leaks. It is created by rolling up the edges using a hand or power tool. In this case, characteristic elevations are formed above the roof surface in the areas where the elements meet. The minimum slope angle for structures with a single connection is 10 degrees, with a double connection - 3.

- Lying seams are used for horizontal fastening of panels. Since they are not as reliable as standing ones, they are rarely used in practice.

- Klikfalts are distinguished by their simplicity and ease of installation, but they are used only on roofs with a sufficient slope (at least 16 degrees). The usual seaming is not used. The canvases are simply inserted into the seam and snapped together. Such panels have a top lock on one of the edges and a counter lock (as well as a perforated strip for discreet fixation to the sheathing) on the other.

Seam roof is an old type of construction. It was widespread in Europe and the Russian Empire, so such roofs are often used in the reconstruction of buildings.

Installation of ventilation systems- Pipes for internal sewerage

How to choose a window sill?

Over time, technologies have emerged that make installation easier and more convenient. Nowadays, to create such roofs, thin panels with a protective coating, supplied in rolls, are used . This material allows you to cover a simple structure with one or two slopes and a roof of complex or unusual shape.

Characteristics

Seam roofing machine

For the production of seam panels, rolled metal . During production, sheets are cut lengthwise, a protective coating is applied to them, and then they are sent to a rolling machine. There, seam locks are made and the panels are cut crosswise to obtain panels of the required sizes. Such elements with edges ready for joining are also called paintings.

Typically the panels have a thickness of 0.45-0.7 mm and a length of 1.2-9 m.

The width depends on the type of side folds. They distinguish between general and useful . For products with a double fold, the first is 62.5 cm, the second is 55 cm. For panels with a click fold, the values are 54.5 and 51 cm, respectively.

The weight of 1 m² of finishing coating is from 2 to 5 kg. It depends on the type of metal used and its thickness.

Installation of connections to pipes

Which exact method of framing the pipe to choose depends on how the paintings fit the pipe, i.e. from the location of the vertical locks. We'll look at the principle.

Bottom connection

Bottom and side paintings must be mounted to the pipe. It is desirable to bend the metal of the paintings onto the pipe from below and from the sides. Vertical locks approaching the pipe from below must be bent to a distance of at least 200 millimeters, and on the part of the picture that will be placed on the pipe, they can first be bent to the plane of the picture.

A lower connection is placed on top of them, having a bend with an obtuse angle and a 20-millimeter edge in the upper part. This rib will go into the groove, which must be cut out in the brick of the pipe using a grinder.

The width of this junction should be greater than the lower dimension of the pipe by two bends, each bend 200 millimeters. The height of the overlap at the junctions: on the pipe - at least 150 millimeters, on the roof - at least 200 millimeters.

Marking for the groove on the brick is done with a construction marker, and bending lines are also marked along the edges of the pipe, and cutting lines along the bend of the junction from the ends to the edges of the pipe. A cutting line is marked at the angle of inclination of the roof from the ribs of the pipe to the ends of the junction. An edge of 20 millimeters is also cut off from the ends to the edge of the pipe, since it will interfere with the tight fit of the bent petal to the pipe.

After all the excess parts are cut off and the petals are bent towards the pipe, the junction is attached with dowels to the bottom of the pipe in the desired position. The dowels are placed not far from the groove, but at a distance of several centimeters to avoid chipping the brick. The holes for the dowels are drilled with an impact drill.

Lateral connections

The side connections must have an overlap at the bottom and under the top connection of at least 200 millimeters.

Similarly to the bottom connection, we mark lines - for the groove, for cutting and for bending. We will bend a petal of several centimeters towards the lower junction, and the entire petal towards the upper junction. The excess length of the lower petal can also be cut off. Both petals are pressed against the pipe, after which the side connections can be secured with dowels in the area of the lower edge of the pipe and along the groove.

It is necessary to step back from the edge of the pipe and from the groove a few centimeters to avoid chipping the brick.

Manufacturing materials

Seam roofing differs in relief and type of metal used. Typically the panels have a wavy surface . You can find canvases with a seamless texture , which have an attractive appearance and can be easily mounted on the roof.

Among the materials for seam structures are used:

Installation of PVC windows- Covering the drain hole with your own hands

- How to lay flexible tiles on the roof?

- Galvanized steel with a protective polymer coating. Cold-rolled sheets are used for panels. Galvanizing is performed using the hot method. The material adheres well to other layers of the roofing pie and is not prone to corrosion and peeling. It is durable and retains its attractive appearance for a long time. For additional protection and to give a certain color, the products are coated with a polymer layer on top. This could be, for example, pural, plastisol, polyester.

- Aluminum products are lighter than those made of iron, are not subject to corrosion, and are ductile. They are also available in different colors. Such panels are suitable for finishing arched, domed and other non-standard structures.

- Copper roofing has an attractive appearance and good performance. One of its features is the color change over time. After 2-3 years of operation, the roof becomes darker and has a chocolate tint. Later, the surface becomes black, and after 13-15 years a patina appears on it, and the color begins to resemble malachite. This roof looks interesting and expensive. Sometimes copper panels are patinated artificially.

- The alloy of zinc and titanium is ductile, lasts a long time, and has a very attractive appearance. But installing such a roof requires skill, so it is better to entrust it to professional craftsmen.

Criterias of choice

The most budget option is panels made of thin steel without a protective coating, but they do not have a long service life. It would be more practical to buy paintings coated with pural or polyurethane (polyester protects less well, although it is more common).

the most expensive . The price is influenced by durability, quality and thickness of galvanization, and the characteristics of the metal itself.

When buying panels, you should also take into account climatic features - precipitation, temperature changes, wind strength, air humidity. Affects the choice and purpose of the building.

Features and difficulties of installation

The traditional method of construction involves covering it with sheets of metal . Over time, it was replaced by the use of small-sized paintings , so the old method is gradually becoming a thing of the past due to the complexity of installation. Panels made from rolled metal are especially convenient. Their installation helps prevent leaks, as the number of lying seams is minimized. Before work, it is recommended to calculate the required number of panels. This is not difficult if you know the dimensions of the roof and its slope.

The main factor forcing people to abandon seam roofing is insufficient sound insulation : residents will hear the rain drumming. This can be corrected if you use high-quality noise and heat insulating materials . The thickness of the insulation depends on the climatic characteristics of the region. Sound insulation is laid under each element of the sheathing and counter-lattice. This protects the structure from redirecting vibration through the rafter system from the outside to the inside. In the assemblies of the ridge and cornices, it is necessary to install seals that level out noise. They are also mounted from the inside of the paintings along the central axis. This helps to attenuate the noise wave as it passes through areas where the metal is sagging.

How to properly lay a vapor barrier on the ceiling?- Is it possible to glue wallpaper on whitewashed walls?

- Imitation of a brick wall made of gypsum plaster

The roofing cake includes the following components:

- vapor barrier material and ceiling lining;

- waterproofing;

- timber for raising, laid on the rafters;

- insulation;

- counter rails;

- lathing made of durable and stable wood;

- metal paintings connected by folds and fixed on sheathing boards with clamps.

If the sheets used are made of zinc alloy or copper , it is necessary to organize a continuous plane of boards, thick waterproof plywood or chipboard under them. It is stuffed on top of the lathing, and then the paintings are fixed.

Before laying the panels on the frame, it is necessary to install a drainage system and eaves strips, as well as arrange the valleys. When the covering is laid, proceed to the installation of the ridge.

Fixed and sliding clasp

Clamps make the fastening more reliable and help hide the fasteners. Their number depends on the strength of the winds in the region. When installing the ridge and cornice units, they are placed twice as densely. Elements of the sheathing and counter-lattice need to be fixed only with self-tapping screws . Then the drying of the wood will not weaken the fixation. Also for installation you need a viscous one-component sealing composition based on polyurethane . It is laid along the entire length of the seam. The composition must be resistant to UV rays and also adhere well to metal. When it hardens, it will take the form of a rubber strip glued to the panels. The use of sealant is necessary to prevent roof leaks. Sometimes aluminum strips are used for this purpose. They are rolled with a roller and painted in the required shade.

Installation of a ventilated ridge

The main elements of a ventilated ridge are: the upper ridge profile, the ventilation grille and the supporting elements.

The ventilated ridge design, which is simple and reliable, was installed by user nekorsakov.

The upper cornice profile was purchased ready-made. The lower (support) profile was made of galvanized steel using sheet bending equipment. Its perforation was carried out directly on the construction site.

nekorsakov

I decided to place the lower (support) strips between the sheathing and the picture, without securing anything else. I mounted the upper planks on top of them (with some overlap). The support strip is ultimately held not by individual screws, but by an entire roofing sheet, fixed with clamps and pressed together with adjacent sheets. In this mounting option, the perforated wall of the support bar was pushed deep from the edge, which seemed to me both aesthetically and functionally better (away from the “aggressive” external environment with its precipitation).

Installation and repair of seam roofing

| Types of jobs | Unit | Cost, rubles | |||

| gable roof | hip roof | complex roof | copper/titanium-zinc roofing | ||

| Installation of seam panels | sq.m. | 485 | 537,6 | 700,2 | 750,8 |

| Installation of connections to a wall/pipe | linear meters | 420 | 504 | 588 | 672 |

| Installation of junction drip line | linear meters | 140 | 168 | 196 | 224 |

| Installation of skates, hips | linear meters | 420 | 504 | 588 | 672 |

| Valley device | linear meters | 420 | 504 | 588 | 672 |

| Installation of end strips | linear meters | 350 | 400 | 450 | 500 |

| Installation of cornice strips | linear meters | 350 | 400 | 450 | 500 |

Prices for all types of roofing installation work are presented on the “Price List” page.

Today, seam roof repair is one of the most popular types of roofing work in Moscow. has significant experience in carrying it out in any buildings and offers its services on terms favorable to the customer. The use of materials from trusted suppliers ensures the durability and tightness of each repaired area.

What is a clamp and why is it needed?

In the process of installing seam roofing, fastening devices such as clamps are used. Essentially, this is a special device that is designed for fastening roofing sheets . You don’t have to use nails, which can disrupt the integrity and complete tightness of the coating.

The use of a clamp greatly simplifies the process of installing the roof covering and ensures the overall durability of the system. Finishing the roof with similar elements makes it aesthetically pleasing and as airtight as possible.

Klyammer

When is a standing seam metal roof repair needed?

As a rule, repairing a seam metal roof with your own hands or with the help of specialists is carried out if its installation was not done well enough or serious violations were committed during operation. It is necessary to fix the leaking coating, through which moisture accumulates inside the roof space and destroys the insulation.

Leaks often occur in single-seam joints or in places where the coating is mechanically damaged. Contaminated areas and clogged drains contribute to corrosion and moisture transmission at seams.

Installation of sheathing

A counter-lattice is mounted on top of the waterproofing membrane. These are 50 by 50 wooden blocks that are laid along the rafters and secured with self-tapping screws.

Perpendicular to the counter-lattice structure, the sheathing is installed. For this, boards 30 mm thick are used, which are laid parallel to each other with a certain pitch.

Seam roofing works: capital and current

Routine seam roofing and other work is carried out using professional tools and equipment by qualified roofers. Annually or as needed:

- Individual sections are replaced, including mechanically damaged ones (with an area of no more than 10% of the total roof surface).

- The parapet fence is being replaced.

- Snow guards are installed.

- The sheathing is partially replaced (no more than 20%).

- Patches are made and cracks are sealed.

- Rafters are repaired (no more than 10% of the entire structure).

- The joints of the seams and at the eaves are sealed.

- Gutters, cornices, dormer windows and shafts, and safety pipes on the ridge are installed.

- The roof surface is painted.

- All construction waste is removed.

carries out seam roofing work by connecting panels using a double vertical seam, which ensures the highest tightness and reliability. The seams are sealed with silicone, which increases the roof’s impermeability to moisture.

During a major overhaul, the coating is replaced almost completely. As a result, the building requires the installation of a seam roof, a full range of work for which the company’s craftsmen carry out in Moscow in strict compliance with all safety and reliability standards for building structures.

Major repairs and installation of seam metal roofing:

- The old roof covering is being replaced.

- The parapet grating and sheathing are being replaced.

- The parapet grating is painted.

- Rafters are being repaired (up to 60% of the entire structure).

- Wooden structures are cleaned and treated with several layers of fire protection.

- The installation of standing seam metal roofing is carried out by specialists.

- Double-seam joints in the seams and on the eaves are sealed.

- Ventilation ducts, cornices, gutters are installed.

- Dormer windows, shafts, and a ridge safety pipe are installed and trimmed.

- Construction waste is removed.

Post-accident repair and installation of seam roofing by specialists is carried out in cases of sudden damage, for example, in winter. The efficiency and coordination of the working group’s actions allows us to urgently restore the roof and further maintain its condition.

Types of seam connections

The tightness of the roofing covering, as well as the complexity of its installation, depends on what type of seam is used in a particular case.

Based on the installation method, there are two types of roofing elements: self-latching panels and pictures made for mechanical rolling (bending) of seam joints.

Panels for mechanical seam rolling make it possible to obtain fairly rigid joints that differ from each other both in appearance and in the degree of tightness.

The photo shows the main types of folds made for rolling. Double folds are rightfully considered more airtight (compared to single folds). This applies to both recumbent and standing connections.

Standing (longitudinal) seams allow you to create stronger connections. Therefore, the fewer transverse recumbent locks in the roof structure, the more reliable the roof covering.

Also, on open and clearly visible surfaces, L-shaped (corner) folds are often created. These seams are considered more aesthetically pleasing, but less airtight connections. Therefore, they can be installed on slopes of 25º or more (for example, on cornices or gables).

Source

Seam roofing: installation price

Depending on the complexity and configuration of the future seam roof, the installation price may include a different amount of work and quantity of building materials. It is quite difficult to calculate these indicators on your own. In this regard, a company specialist visits the site to draw up a detailed estimate.

Established price for standing seam roof repair:

- Installation of seam panels – from 448 RUR/m².

- Installation of connections to a pipe/wall – from 420 rubles/linear meter.

- Installation of skates, hips - from 420 rubles per linear meter.

- Installation of drip joints - from 140 rubles/linear meter.

- Installation of cornice strips - from 280 rubles/linear meter.

- Installation of valleys - from 420 rubles per linear meter.

- Installation of end strips - from 280 rub./linear meter.

The total price of repair and installation of seam roofing includes the cost of a measurement visit - 1,600 rubles. and drawing up a detailed estimate (including calculation of the cost of building materials) - 1600 rubles.

Those wishing to do their own repairs to a standing seam metal roof should remember that aluminum and copper materials can be patched. Finished copper patches, strengthened by soldering, are treated with a special liquid so that they do not stand out against the background of the old coating. Aluminum plates are secured with self-tapping screws and glue.

Articulation of paintings in the ridge part

The installation of a metal roof in the ridge part will differ depending on the need for ventilation of the roofing pie.

Roof with ventilation

If the roof has ventilation vents, then the air rises upward along the roof, and for its free release into the atmosphere it will be necessary to form an opening in the ridge part of the roof - in this case, the paintings are mounted without articulation with each other. A certain gap is left between them, which will subsequently be covered with a ridge strip. In this case, you can bend the edges up 2 - 3 centimeters to reduce wind blowing.

The simplest solution for installing a ridge strip would be to attach it to the end of a standing double lock using a tapping metal screw with a rubber gasket. To prevent this self-tapping screw from going to the side, it would be logical to first mark the hole with a thin drill. However, this method may cause the drill to come off and damage the surface of the ridge or painting, so you should work carefully.

The minimum overlap of the ridge unit on the paintings is 20 centimeters. The lower the slope of the roof, the greater this overlap should be.

A slightly more complex option for installing a ridge strip is to make an additional sheathing for the ridge along the diffusion gap:

This method is described in more detail in the video below:

Roof without ventilation

If roof ventilation is not required, then instead of a ridge, a locking connection between the panels along the upper edge of the roof is used. To do this, the paintings are first moved above the line of intersection of the planes by at least 25 millimeters and bent upward. To prevent this bend from being interfered with by the folded longitudinal lock, it is bent into a lying position. After the transverse seam lock has been formed, connecting the patterns of different roof planes, you can treat with sealant those places where the longitudinal lock was bent.

It is desirable that the longitudinal locks of different planes do not overlap each other. If this happens, then they need to be bent in different directions in the direction of the roof.

Since the ridge is the highest point, and the water will flow down from it, a single seam lock will be sufficient. The video below shows this method in detail:

An interesting solution for drainage may be the formation of a drainage gutter during the installation of a seam roof, without the use of hanging gutters. In this case, there will also be an articulation of the transverse ends of the paintings with the longitudinal end of the sheet from which the gutter was formed. This joint is performed using a recumbent lock, since a double lock in this case will be very difficult to make. To protect against leakage along this lock, the drip line must extend onto the roof above this lock.

Installation instructions for seam roofing

Work is carried out in dry weather. A separate part of the roof is the picture, the edges of which are already prepared for the seam connection. Standard instructions for installing a seam roof include:

- Strengthening row strips along the small bend.

- Pulling the strips to the sheathing with a clamp (at least two clamps on each side of the sheet).

- Fastening with screws or nails to the side edges of the sheathing beams.

- Bend the edge of a small bend.

- Joining paintings with a single fold using a tool.

- Performing a double fold using special frames.

More detailed instructions for installing metal seam roofing are available upon request from the company’s craftsmen.

You can order roofing work on seam roofing in Moscow by calling the website. will do everything to fulfill all your requirements!

Design of the roof in areas of eaves overhangs

The ridges of folded paintings, located in places where the eaves overhang, should be trimmed (literally by 2...3 cm).

After this, the remaining (protruding) part of the picture will easily bend under the eaves overhang, forming a reliable and airtight eaves overhang.

It is not necessary to completely remove the outermost part of the ridge. It can be folded, forming a neat decorative plug at the end of the fold.

Installation of side end strips

We present the installation diagram for the side gable profile.

Where:

- The beam on which the wind strip is attached (the dimensions of the beam are selected based on the geometry of the wind profile).

- Roofing screw “metal-wood”.

- Side end strip.

- Start/finish seam roofing panel.

- Self-tapping screw with press washer.

- Klyammer.

At the junction of the roof slopes, the end strips are connected as follows.

Seam roof: features and installation rules

The roof performs a very important function, regardless of its type and purpose of the building. It is this that protects the house from penetration of moisture, snow, wind, and also retains heat inside the living quarters. There are a large number of roofing materials that help the roof perform its function, but the seam type has a special place. And there are reasons for this - the reliability of the design, its long service life, and the ability to install it yourself.

Recommendations for use

In order for the Klikfaltz roof to serve for a long time, the roof is regularly inspected from the ground. Every year - with a rise to the level of the cornice, on each slope. After abnormal natural phenomena - hail, hurricane winds, heavy snowfalls - an extraordinary inspection of the roof from the ground is carried out. If scratches appear on the roofing material, they are repaired with metal paint (preferably a corrector for repairing scratches and paint with a brush, an aerosol is acceptable). Clearing snow from the roof in winter is not practiced. On a properly designed roof equipped with snow retention systems, there is no need to clear snow from metal tiles. There is no technology that allows you to clear snow from the roof without denting or scratching the panels. Snow removal is resorted to only when the accumulated snow mass threatens to destroy the roof.

Tools for installing seam roofing

You can install a seam roof yourself only if you have the following special tools:

- Folding machine. It is used only if the length of the seam is more than 10 m. The tool can be manual, semi-automatic or electric. For self-installation, the first two options are most often used.

You won’t be able to do without a folding machine when installing a metal roof.

A folding hammer is needed for working in hard-to-reach places

The length of the fold frame corresponds to the seam processing step

A mandrel spatula will help you bend the edges of paintings without using a machine

Video: sheet bending machine for seam roofing

Waterproofing

In insulated attics, to protect the insulation, as well as to increase the efficiency of insulation, use superdiffusion membranes, for example Folder Classic, Delta Vent N, Tyvek Solid.

For a cold attic, if there is a separating layer, an additional waterproofing layer is not required. For step lathing, a waterproofing layer, which is mounted directly on the rafters, is required. It is allowed to use convection films, for example Grand Line D98.

Seam roofing material

Seam roofing involves the use of metal sheets. More recently, it was only galvanized steel, which still serves some home owners due to its resistance to corrosion. Now the list for arranging a seam roof is much wider:

- Galvanized steel with polymer coating. It protects the folds from the harmful effects of ultraviolet rays on the metal, and also performs an aesthetic function, because the tone of the material can be matched to the color of the overall landscape design idea.

Galvanized steel with polymer coating can be of any color

A copper roof has a typical shade for this metal

Aluminum is absolutely not subject to corrosion

Zinc-titanium requires extreme care during installation

A metal sheet with curved edges for a seam roof has a very unusual name. Experts call them paintings.

Laying a seam roof with your own hands

You can make a seam roof with your own hands, provided that the technology is fully followed. It is equally important to properly prepare the roof for installation . This process includes:

- Installation of sheathing. Before installation, all wooden elements must be thoroughly treated with antiseptic agents and mixtures that prevent rotting and burning. The type of sheathing depends on the material used. For galvanized steel it should have a step of 20–25 cm, for copper it should be solid. In the first case, additional boards are laid along the edge of the roof; there should be several of them and they must be fastened without gaps. Similar masonry should be placed along the ridge joint.

The sheathing for a seam roof should be installed with a minimum pitch or be continuous

Each type of seam roof connection is suitable for a certain slope of the slopes and the junction point

It is not recommended to take paintings with uneven edges or curved ones for work. Such a roof will lack aesthetics.

Seam roofing technology

Technologies do not stand still. This also applies to the method of laying seam roofing. At the moment, the so-called roll technology is used. Its peculiarity is to create a picture along the entire length of the roof. In this case, the rolls are lifted onto the roof with the edges already prepared for fixation, and this greatly simplifies the installation process.

Metal sheets are attached directly to the sheathing using clamps; it is advisable to use so-called wandering clamps, which significantly increases the reliability of the fastening.

It is considered more reliable to use a floating clamp for a seam roof

In problem areas, it is recommended to use a double folded edge . This applies to valleys, gutters, valleys and other places where snow and water can accumulate. Recessed seams can be used if you want virtually no visible seams on the roof. For roofs with a slope angle of more than 25 degrees, it is recommended to choose a corner standing seam, for which you just need to correctly bend the upper edge of the metal sheet.

Video: installation of click seam roofing

Stages of installation of a seam roof

The process of laying a seam roof is as follows:

- Installation of the eaves overhang, after which it is necessary to install a drainage system in the form of gutters. They should be installed at a slight angle. This will allow water from the roof to flow by gravity to the funnel.

You need to start installing a seam roof by installing the eaves overhang

Seam roof paintings should be laid in a vertical direction

The paintings are secured using clamps

It is recommended to use a special gun for sealant

Video: do-it-yourself seam roof installation

Installation of seam roof elements

After laying the metal sheets, you can proceed to the installation of roofing elements, namely the valley and ridge.

To install the first element you need:

- It is impossible to purchase a special profile that you can make yourself. It can be replaced with a sheet of metal of such a width that this strip is enough to give a special shape, while the valley must extend onto both slopes by at least 20 cm. The profile or metal strip must be laid at the joint and secured with self-tapping screws.

Endova can prevent roof leaks

A special metal pad is suitable for the skate. It has curved edges, thanks to which it easily fits with metal roofing sheets. The ridge can be ventilated or unventilated, and the first option is preferable, since this will save on installing aerators to prevent condensation under the roofing material.

You can make a ridge for a seam roof yourself

Video: valley liner

Selection of design and material

To make it more convenient for you, we suggest that you first understand the concepts a little.

Pictures are rectangular metal elements with folds, which are mounted on the roof. The standard shape is steel sheets in the form of a rectangle with cut-out corners. The seam roof is made from paintings.

A fold is a specific seam that is obtained by fastening different sheets of metal together. The advantage is that with such a connection the density is quite high, and neither sealants nor adhesives are needed to ensure complete tightness. And, in addition to their main task, the folds also play the role of stiffening ribs for the entire roof.

A clasp is a special fastener that is nailed directly to the base of the roof. A simple clamp has the same shape as the future rebate blank, and a movable one ensures the future thermal expansion of the metal (compression and expansion at different times of the year).

As you can see, everything is simple and you don’t need to worry about anything.

Material for making paintings

Seam roofing is made from both galvanized steel and various non-ferrous metals. Here are the materials that seam roofing is most often made from today:

Option #1 - steel

The most common option. Steel seam roofing can be galvanized, non-galvanized, or additionally coated with polymer. The advantages are corrosion resistance, low cost and durability (60 years of service).

But over time, steel, unfortunately, noticeably tarnishes. Therefore, to install a seam roof, steel paintings should only be taken that are covered with a colored multi-layer coating. And when purchasing these, make sure that they have a special protective film on them - this is the only way the material will not get scratched during transportation.

But in any case, even a high-quality polymer coating on the roof will not be durable: due to sunlight, acid rain and the most important enemy - the humid maritime climate.

Option #2 - copper

This is the most beautiful roof that simply lights up on a sunny day. Its main advantage is that no biological life will take root on it, especially moss. But there are also many disadvantages - such metal is soft, requires careful handling and is quite expensive.

Over time, copper also becomes covered with patina - a layer of oxides, and becomes dark brown. And after a while - green, and nothing needs to be restored. And it is precisely because of the oxides that copper cannot be combined with other materials on a seam roof.

Copper seam roofing is also valuable for its flexibility - it is easy to create roofing architectural masterpieces, not to mention simple roofs:

Option #3 - zinc

The zinc seam roof is additionally covered with a protective layer – zinc carbonate. Over time, such a roof acquires a chic silver-gray color. A zinc roof lasts for about 50 years, which is relatively short, and therefore in Europe such material is no longer used for making paintings.

Option #4 - aluminum

This type of roofing is the most resistant to mechanical damage and corrosion, and can last more than 100 years! And the pleasant silver shine will only please the eye.

In addition, this material is lighter than steel and more resistant to corrosion. But aluminum is bad because it expands and contracts much more strongly with temperature changes. That is why the installation of such a roof has its own characteristics:

Option #5 - zinc-titanium

This is a strong, successful alloy of zinc and titanium: zinc does not corrode, and titanium has both strength and ductility. This coating is also valuable for designers, because over time it becomes covered with a noble patina. The roof looks great!

Option #6 - aluzinc

Aluzinc is steel paintings with an aluminum-zinc coating, which has valuable self-healing properties and perfectly protects scratches and cuts from corrosion.

Option #7 - an alloy of three metals

Titanium-zinc-copper alloy. There is not much copper here, only 0.005%, but this is enough to give the roofing material plasticity, which makes profiling easier.

Special coating

If your house is located in a coastal area or an area with poor environmental conditions, or simply a hot and humid climate, then purchase folded paintings covered with pural. Only this polymer is capable of protecting at a high level from sea air, rain with acidic impurities and scorching ultraviolet radiation.

Production technology

Seam roofing is also divided according to production technology - into cast and roll.

Cast roofing has long been used in Russia, and its reliability has already been tested. It is easy to install such a seam roof with your own hands and without special tools, there are no transverse seams, and the surface is complete and durable. But rolled seam roofing is a new technology with its own advantages and disadvantages. These are metal strips for the entire length of the slope, and immediately with prepared edges using a special machine. The fold is formed double.

And according to the width of the patterns and the presence of stiffeners, seam roofing is divided into the following types:

- Double fold and two stiffening ribs. This type of roofing is most in demand in the industrial sector. It is used to destroy warehouses and large buildings with very different roof slopes. Standard width – 5.57 m, working width – 5.45 m.

- Double fold and two stiffening ribs, but smaller width - 35.2 m (working 3.4 m). This type of roofing is used to cover the roofs of cottages, large residential buildings and historical monuments.

- Double fold without stiffeners. There are also two types of such roofs, based on the actual width - 5.57 m and 3.52 m. Both are quite suitable for residential buildings and ordinary private houses.

And folded panels can also be ordinary and starting, trapezoidal and parallel:

Market offers

If we talk about brands, in Russia, as well as abroad, the most popular Finnish seam roofing is from the Ruukki company, with self-latching seams.

Better prices for domestic materials. It has been on the market for more than 16 years, and is quite pleased with the quality of its products. In production there are both ordinary glossy and matte paintings, as well as unique ones for creating a special roof design.

Errors in installing a seam roof

When installing a seam roof yourself, errors are possible. The most common are:

- Large pitch of sheathing. Ideally it should be continuous. This will prevent deformation of the metal sheets during roof operation.

- Lack of treatment of wooden roof elements with antiseptic agents and anti-rotting mixtures. Ignoring this rule will reduce its service life. Despite the strength of metal roofing, an unprotected roof will only last as long as the sheathing.

- Lack of ventilation clearance in the roofing pie. This can lead to condensation accumulating under the paintings, which will cause corrosion, since all the protective layers are on the outside.

- Using fasteners made of metal that is incompatible with the metal of the roofing material. If you use copper for coating, then the clamp must also be copper, otherwise the seams will come apart.

- Using a simple clamp when installing long paintings. Metal expands and contracts under the influence of temperature changes, and a simple clamp is not able to withstand this. Therefore, it is recommended to use a floating element that has a free movement reserve.

- The use of a single method of attaching paintings in difficult places, which leads to deformation and divergence of the seam.

Video: mistakes that can be made when installing a seam roof

Important nuances

In order to avoid additional loss of time and difficulties due to the need to adjust the length, it is necessary to take the dimensions of the roof according to the dimensions of the sheathing with particular accuracy. This is important if the paintings will not be produced at the installation site on a special machine, but will be ordered from a third-party manufacturer. It is better if this operation is carried out by a specialist who can take into account the need for additional overlaps at the joints and spacing of transverse recumbent seams on large lengths of the paintings.

If the customer purchased the roofing material from a good manufacturer, a manual will be included with it. It must be studied before installation, since it may cover nuances unique to this type of product.