Ideas about the aesthetics and comfort of home are constantly changing. Just a couple of decades ago, balconies and loggias were perceived as additional utility rooms that did not require any special repairs. They were glazed for the sole purpose of insulating the apartment as a whole. Nowadays, balconies are often converted for growing flowers and used as recreation rooms. Much more attention is paid to their appearance. Finishing the outside of the balcony with siding is an excellent solution to the problem of external cladding. Let's look at how to choose the right material and master the installation technology yourself.

- What to look for when purchasing

- Stage #1: preparing the balcony

Why is it worth covering a balcony with siding?

There are several advantages of this cladding:

- Insulation. Under the panels, the balcony can be insulated and made comfortable at any time of the year.

- Easy to install. Covering a balcony with siding is a simple task. You can handle it on your own.

- Practicality. The finish is unpretentious to use. Easy to clean, not afraid of frost, moisture and fungi.

- Price. Siding is one of the most affordable facing materials today.

- Durability. This cladding will last at least 3 decades.

- Individuality of your home. There are a lot of options - different colors, textures, from different materials. You can choose the optimal balcony covering for your home.

Features of cladding a wooden house

When covering a wooden house with siding, it is necessary to take into account the characteristics of the materials:

- finishing of the facade, as well as interior work, must begin after the house has settled;

- for the lathing, it is advisable to use a wooden beam (seasoned and treated with an antiseptic);

- It is mandatory to treat the surface of the walls with an antiseptic, since after installing the sheathing it is impossible to control the condition of the wood and promptly carry out preventative measures for areas affected by fungus;

- for additional protection, you can lay a waterproofing membrane;

- Even if the walls are smooth and the siding is installed without insulation, the panels cannot be attached to the wall - for proper use of the wood, a gap is required that the sheathing creates.

Cladding a wooden houseSource elka-palka.ru

The ease of installation of siding does not exclude care and accuracy when carrying out work. An error when installing the starting profile, fasteners that are “tightened” or incorrectly installed in the hole, non-compliance with recommendations for the size of the temperature gap - all this can lead to serious consequences for the skin, which will not be so easy to eliminate.

Which siding to choose for a balcony?

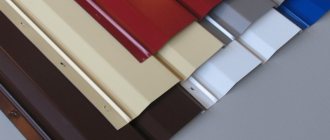

On the market you can find siding that looks like wood, brick or stone. You can choose any texture and color. But the material from which the siding is made needs to be selected more carefully.

Balcony, decorated with brick panels in the color of the walls of the house. (photo No. 1)

Today, four inexpensive and easy-to-use materials can be distinguished:

- Metal siding. This is a thin steel sheet coated with a protective polymer layer.

- Vinyl panels. Made from PVC. Can be classic or foam siding; "shipboard", "herringbone" or "blockhouse" type.

- Acrylic siding. It is also made from PVC, but with the addition of Acrylnitril-Styrol-Acrylester (ASA) polymer, which changes the properties of the material.

- Facade panels. Made from polypropylene, they look like brick or stonework.

There are also wood and fiber cement siding available. But they are not suitable for a balcony: wood is heavy and impractical - it needs regular protection from moisture and fungi. Fiber cement siding is expensive and very heavy. Balcony ceilings and fences will not withstand such a load.

A comparison of metal, vinyl and acrylic siding and siding panels is given below.

| Metal | Vinyl | Acrylic | Facade panels | |

| Weight | The heaviest type of siding. | Easy | Easy | Lungs |

| Strength | The most durable. | Medium strength. | Medium strength. | Thicker and stronger than siding. |

| Water resistance | Resistant to water thanks to a polymer protective coating. | Water resistant. | Water resistant. | Waterproof |

| Scratch resistance | If the protective layer is damaged in the rain it will rust. | Scratches do not affect the performance characteristics of the panels. | Scratches do not affect the performance characteristics of the panels. | Scratches do not affect the performance characteristics of the panels. |

| Resistance to fungi and mold | Stable. | Stable. | Stable. | Stable. |

| Resistant to fading | Fades moderately in the sun. | Fades moderately in the sun. | Does not fade. | Does not fade. |

| Features of use | Not recommended in coastal regions and areas near industrial facilities, with a high content of salts in the air. | Recommended for regions with temperate and cold climates. | Recommended for regions with hot climates and a lot of sunny days. | Recommended for all climate zones. |

!

Vinyl siding is good for homes in northern regions and on the shady side of the building. Acrylic - for southern regions and balconies facing the sunny side.

Acrylic siding and facade panels will cost a little more than their analogues. But these options win in some respects.

Characteristics of translucent aluminum structures

The aluminum profile used in the assembly of translucent enclosing structures is manufactured according to the standards established by GOST 22233-2001, its main provisions:

1. In the production of frames, types of profiles are used:

- solid, there are no closed air chambers in their cross-section;

- hollow - the internal structure has one or more chambers, closed on all sides;

- combined - include hollow and solid chambers made of the same type of profile aluminum, connected to each other through an insert with high heat transfer resistance.

2. Profiles are divided according to the condition of the material (aluminum) from which it is made, they are:

- hardened and naturally aged (indices T, T4 in aluminum marking);

- hardened and artificially aged (T64, T6, T1);

- artificially aged and partially hardened (T5);

- high-strength hardened and artificially aged (T1, T22, T25, T66).

3. Based on dimensional deviations during manufacturing, aluminum profiles are divided into types with normal (N), increased (P) and precision (PR) accuracy.

4. Types of coating of finished aluminum profiles:

- An - anodic oxide;

- Zhl - liquid paint or electrophoresis;

- P - single-layer or multi-layer polymer powder application method;

- K - complex, consisting of two layers, combining the above types of coatings.

- According to heat transfer resistance, aluminum profiles are divided into 7 classes: the first has the highest value from 0.5 to 0.55 m2*°C/W, the rest have lower values in increments of 0.5, the last 7th class has a resistance of less than 0.2 m2* °C/W.

- The profile from which frames for facade glazing are assembled has a length from 2000 to 7000 mm.

- Aluminum profiles are made from alloys with silicon and magnesium alloying additives; in combined systems, polyamide glass-filled inserts are additionally used.

- In accordance with the norms of the Eurasian Council for Standardization, Metrology and Certification (EASC), the following requirements are observed in the manufacture of façade glazing elements:

- in heated buildings, heat-saving double-glazed windows must be used;

- the area of the glazing sashes for the rigidity and strength of the structural unit should not be higher than 2.5 m2, the weight of the finished profile structure with a double-glazed window should not exceed 100 kg;

- overall dimensions of doorways no more than 2100x900 mm;

- the sash must withstand a static load in the plane of at least 1200 N, in the corners at least 400 N, the assembled structure must withstand a stress of 500 N;

- The service life of the aluminum profile together with its component parts should not fall below 40 years.

Glued double-glazed windows for general construction use, used in the manufacture of sashes for external façade glazing, are subject to GOST 24866-99, its main provisions:

1. Type of design by number of chambers:

- with one (SPO);

- two (SPD).

2. Filling the chambers:

- dry atmospheric air;

- gases (krypton Kr, argon Ar and others);

- fluoride sulfur SF6.

3. According to purpose, they are divided into general construction or special with increased characteristics according to:

- impact resistance (Ud);

- noise protection (Ш);

- frost resistance (M);

- sun protection (C);

- energy saving (E).

4. The thickness of assembled glass bags is from 14 to 60 mm, the gap between glass sheets is 8 - 36 mm, the cross-section of a glass sheet is from 3 to 6 mm.

5. Overall dimensions of packages are up to 3200x3000 mm, aspect ratio no more than 5:1.

6. Heat transfer resistance from 0.28 to 0.8 m2*°C/W.

How much siding should I buy?

→ In order not to make a mistake with the quantity, you need to calculate the area of all surfaces that are to be covered. As a rule, these are three walls of the balcony. Or more if the balcony has sloping corners and is of irregular shape. We sum up the data obtained and divide the result by the area of one panel. And if we add 10-15%, we will definitely have waste.

→ Let's look at an example. The balcony is being covered with siding from the outside.

→ Area of the front wall for cladding: 2.4 m x 1.1 m = 2.64 sq. m.

→ Area of one end wall: 0.8 m x 2.7 m = 2.16 sq. m.

→ Total area for cladding: 2.16 + 2.16 + 2.64 = 6.96 sq. m.

→ Add 10% for waste: 6.96 x 1.1 = 7.66 sq. m.

And we divide by the area of one panel (let’s say it will be “Canada Plus Lux” color “Beech”, its area is 0.69 sq. m): 7.66: 0.69 = 11.1 panels.

We always round up. It turns out that for our example we need 12 panels of Canada Plus siding from Alta-Profile.

In addition, a facade fastening system is needed. For metal siding - metal. For vinyl or acrylic, metal, wood and plastic are suitable. The latter is even preferable. It reacts to temperature changes in the same way as the panels themselves, so the system will be more reliable.

And finally, you will need additional strips (starting, finishing, j-profile, outer corner and others - depending on the configuration and size of your balcony). A siding sales manager will help you choose a complete set. Do not neglect additional materials - not only the ease of use, but also the service life of the entire balcony depends on this.

If insulation is planned under the sheathing, you also need to purchase insulation in slabs. For example, mineral wool, polystyrene foam or extruded polystyrene foam.

Material calculation

Let us now consider what features siding installation has. First of all, you should correctly calculate the amount of material needed.

To do this, we determine the size of the strips of material and measure the surface area for the cladding. Dividing the area of the surface to be finished by the area of a unit of material, we obtain the number of required strips.

It is necessary to purchase material with a small reserve, since during installation some scraps are formed for which there is no further use.

In addition to siding, you need to purchase material for lathing, fasteners and a drill.

Install it yourself or call a professional?

A neat balcony covered with wood siding. (photo No. 2)

In some situations, you can install siding on the balcony yourself, in others you will have to call in specialists.

You can cover your balcony yourself if:

- it is located no higher than the 2nd floor. You can carry out installation directly from the street by installing scaffolding;

- there is no continuous fencing - for example, it is made of metal rods, and you have the opportunity to line it from the inside.

!

You can line a balcony with siding yourself if it is open with a fence made of metal rods or is located on the 1st or 2nd floors.

Accordingly, you will have to resort to the help of professionals with permission to perform high-altitude work if:

- the balcony is located above the second floor;

- The balcony railing is solid and you do not plan to dismantle it.

Let's take a closer look at how to proceed if the balcony fencing is made of metal rods. In this situation, you can do the work yourself, armed with our instructions.

Security measures

Since work is carried out at height, it is necessary to follow some safety rules. These include the following provisions:

- Before carrying out installation work, you need to make sure that the metal parapet is reliable.

- When working on balconies located above the second floor, you should use special safety belts. According to existing rules, the belt must be worn on the body, and the safety end must be securely attached to the metal fence.

- If you don’t have a belt, you can use ropes or other equipment, including climbing equipment.

- When carrying out work, the area under the balcony must be fenced off to prevent injury to passers-by if concrete pieces, tools or siding elements accidentally fall.

- It is recommended to use ladders to work on the first and second floors.

- If there is no metal balcony parapet, then it is recommended to use the services of qualified installers, since in order to attach the sheathing to the concrete fence it is necessary to perform some dangerous types of work while being outside the balcony.

- When working with power tools, you must follow electrical safety rules.

In order to fasten the panels efficiently and correctly with your own hands, you must follow the recommendations of specialists. Helpful Tips:

- Before installation, the siding must be left outdoors for some time so that it takes on its operational dimensions.

- Do not force the panels when installing them. They must fit freely into the corresponding grooves of other elements.

- Also, do not tighten the panels when installing them.

- Fasteners must be installed in specially provided holes. Under no circumstances should they be mounted into the body of the panels.

- Installation must begin from the side. This will give you the opportunity to gain some experience before installing the panels from the front.

- The fasteners should not be over-tightened; it is recommended to even leave a small gap.

- All measurements must be taken carefully and panels must be cut with the utmost precision.

- The gap between the end of the siding panel and the fastening element must be at least 5 mm.

- The fastener is installed strictly in the center of the hole provided for it.

Finishing the balcony with siding from the outside: preparatory stage

We will prepare the necessary set of tools. We will need:

- building level

- roulette

- metal scissors or grinder

- drill

- screwdriver

- pencil

- fishing line or cord.

Let's get to work. External cladding of the balcony with siding begins with the preparatory stage:

- We remove furniture and interior items from the balcony - everything that can be taken out.

- We inspect the ceilings and balcony railings. If necessary, we clean off old paint and traces of rust. After this, we apply an anti-corrosion coating or paint to the metal structures.

- If the fences are dilapidated, it is better to dismantle them and install new ones.

- If there are cracks on the balcony slab, they need to be widened and filled with concrete. If there is damage, you need to install wooden formwork and fill it with concrete. Further work will have to be postponed until the concrete gains strength.

Upper belt

If the balcony slab is not skewed and the lower belt is not needed immediately, we now make it from timber onto the sheathing, as described above. Again, the height of the lower belt is at least 80 mm, i.e. it needs to be made from two or three rows of timber.

We measure how many WHOLE strips of siding will fit along the height of the fence, from the top edge of the bottom chord. Siding, unlike lining, cannot be cut lengthwise to size. THE TOP EDGE OF THE TOP SIDING MUST APPLY EXACTLY TO THE TOP EDGE OF THE FENCE. Please note that to install the casing you will need at least 20 mm of board.

Therefore, along the upper connection of the balcony railing, you need to make an upper belt from boards 60-100 mm wide. Its outer edge should protrude outward by the thickness of the sheathing, and the inner edge will support the window sill. The upper chord is fastened through the existing holes (through which the railings were attached) with self-tapping screws 6 mm long, 3/4 of the thickness of the upper beam, or, if the upper chord comes out thin, with bolts with heads flush through. It is better to take bolts with wide thin heads (press washers).

But what to do if the edge of the top strip of siding ends up protruding only 10-15 mm, or “falls short” by the same amount? If you don’t fence 200-250 mm of the upper belt, it’s a monkey’s work, and it will be inconvenient later.

In this case, you need to lay another beam below on top of the one already laid. The small space between the lower edge of the starting belt and the bottom of the wooden belt will then be painted over along with the balcony slab, but it will not be visible from below.

Do-it-yourself balcony siding: installation of sheathing

Installation of wooden sheathing under siding. (photo No. 3)

When the preparatory stage is completed, the paint has dried, and the concrete has gained strength, you can move on to the second stage: installing the sheathing.

- We install the lower horizontal belt of the sheathing. You can use a special plank or wooden blocks as it. In the second case, they must be treated with antiseptic agents. The plank or beam is installed strictly horizontally, attached to a steel corner, which is located at the bottom of the parapet, or directly to the balcony slab. We fix the belt to the walls using metal corners.

- We mount the upper horizontal belt. To do this, measure the height at which the panels will be installed. We make markings. We stretch the cord or fishing line, measure the horizontal line so that the outer siding of the balcony is even. We fix the upper belt on the parapet. We carry out the work by analogy with the lower belt.

- We install vertical sheathing profiles. The step is 30-40 cm. In some cases it can be 50 cm. We check that each profile is aligned strictly vertically. We attach them to the wall and horizontal belts using self-tapping screws or corners.

By the way, the sheathing can be assembled on the ground, and only then lifted using strong cables and secured in place.

!

The sheathing pitch is 30-50 cm. It is convenient to assemble the sheathing on the ground, and then lift it with cables and secure it.

Material consumption

Calculating the required number of panels, timber and additional elements allows you to purchase exactly as much material as needed. The footage of the timber frame is summed up from the length of the vertical and horizontal elements. We must remember that the pitch of the racks is 600 mm. The amount of timber is equal to the perimeter of the railings multiplied by two, plus the number of posts multiplied by the length of one.

The footage of the starting and finishing strips is calculated according to the length of the perimeter of the balcony railing. The number of panels is determined by dividing the total area of the balcony railing by the area of one.

Finishing a balcony with siding: instructions for installing panels

Installation of siding panels. (photo No. 4)

Installation of the panels themselves is carried out in the following sequence:

- We install the starting bar along the lower belt. We fix it with self-tapping screws.

- We install a j-profile along the walls. In the corners there is an outer corner.

- We measure and cut the siding panels to the required size.

- We install the panels from bottom to top. We secure it with self-tapping screws to each vertical plank of the sheathing. In this case, we tighten the screws strictly in the center of the perforation, at right angles to the panel itself. We twist them to the end, and then do half a turn back.

Covering a balcony with siding: the process. (photo No. 5)

- Before installing the last panel, we mount the finishing strip and insert the last panel into it.

- Now you can install waterproofing and insulation.

- Next we move on to the interior decoration. Don't forget to choose the facing material for this in advance. You can also use siding for the interior decoration of the balcony. The work is performed in the same way: first the sheathing is installed, then additional profiles and the panels themselves.

Schematic representation of a balcony insulation cake. (photo No. 6)

If you are doing work from inside the balcony, follow the instructions described above. If you work from the street, then after installing the sheathing, the insulation is installed, then the waterproofing, and only after that the siding panels themselves.

Balcony covered with siding, up to the internal cladding. (photo No. 7)

Selection of double-glazed windows

The exterior decoration of the balcony will not fully fulfill its function without good glazing. The best options would be double-glazed windows.

Since windows are long and take up a lot of space, good energy-saving packages are needed, preferably inexpensive ones.

Single-chamber double-glazed windows are installed when the balcony is used for household needs: storing cans, drying clothes.

Their sound-proofing and heat-insulating properties are quite sufficient for such purposes. Plus they are relatively inexpensive.

Double-chamber packages have high energy savings. They make it possible to equip a separate workplace on an insulated balcony.

We invite you to watch the video:

Their installation is necessary when connecting a balcony to an apartment room.

Important nuances when installing vinyl siding

If you are lining your balcony with metal siding, you can skip this point. But finishing the balcony with vinyl siding suggests that the panels will expand in hot weather and contract in cold weather. Therefore it is important:

- Leave a gap of 5-8 mm between the panels and slats in winter, 4-5 mm in summer.

- Do not tighten the screws all the way. You can screw them all the way in and make a half turn back, or insert a coin between the panel and the screw head. It should hold tightly, but be removed without effort. There is no need to tighten the screw any more.

Life hack: use a coin to properly install self-tapping screws. (photo No. 8)

Color

Color plays a huge role when choosing finishing material for a balcony. It must completely fit the overall interior design. Each manufacturer has different siding coloring and structure. At the same time, when covering the walls of the balcony, it is necessary to select a color that would harmoniously combine with the roof and windows. Most often they prefer natural contrasting shades, dark and pastel colors.

If the design contains wooden decorative elements, it is recommended to purchase material of terracotta or eggplant color. The shades of spring foliage, in brown, olive and chestnut, also look no less beautiful.

Most designers recommend taking into account the climate zone when choosing a siding palette. For areas where rainy weather prevails, bright and warm colors are perfect. For hot areas, gray shades are the best option.

Common Mistakes

When installing siding panels, the following mistakes are most often made:

- Non-galvanized fasteners are used. These can rust in the first years of operation.

- The panels are fixed too tightly with self-tapping screws. This error leads to deformation of the siding.

- No allowance is left for thermal expansion. This also leads to deformation of the coating.

- Self-tapping screws are inserted into the body of the panel, and not into the perforated allowances for installation.

All these mistakes lead to a reduction in the service life of the cladding and can force the apartment owner to replace the panels with new ones in just a few years. Avoid these shortcomings, and your siding will serve you for many years.

Interior finishing work

Of course, a balcony covered with sading on the outside will look unfinished if the same is not done on its inner surface.

Interior decoration of the balcony

First you need to prepare the room for work. For this purpose, the walls are cleaned and primed. Next, install the sheathing system. If this is required, level the planes under the beams with additional planks. The wooden frame must undergo antiseptic treatment. Before installing the siding, the structure is checked again with a level and the necessary communications are laid.

The lathing steps should be approximately 70 cm. The upper planks are attached using dowels (and on the wall and ceiling).

Advice. If using dowels makes work difficult, use liquid nails. When installing siding, constantly check the surfaces with a level, especially at the initial stage of work.

What to finish with?

Today, there are a large number of different materials intended for the external decoration of balcony blocks. Each specimen has its own distinctive characteristics, advantages and disadvantages.

Plastic panels

Most often on city streets you can see balconies decorated with plastic panels. Otherwise, they are also called plastic or vinyl lining. Such materials are durable and wear-resistant. Plastic is used for both external and internal decoration.

Another significant advantage of plastic balcony design is its affordable cost. This economical option is the best in terms of price and quality.

The plastic panels look very neat. They refresh the balcony block, and it looks much more attractive.

Installation of such facing materials is very simple and easy. To cover the balcony, you don’t have to hire specialists, but do it yourself.

Siding

Another common material is siding. They decorate not only houses, but also balcony rooms. It is also suitable for internal and external cladding.

Siding can be metal, wood (made of wood-polymer composite) or vinyl. The last option is in greatest demand. This material is not subject to corrosion. It does not deform over time and does not lose its attractive appearance.

It is worth noting that siding is very difficult to stain, so it will not require special and frequent maintenance. It is also environmentally friendly and absolutely safe. Siding is fireproof and comes in a variety of colors.

To install such material, you still need to have some skills and knowledge.

An equally promising material is metal siding. It has an affordable price and beautiful appearance.

Metal siding is very wear-resistant. Its top layer is not paint, but a special polymer coating that does not need to be constantly updated or repainted. He is not afraid of temperature changes.

Corrugated sheet

Many apartment owners are turning to external finishing with corrugated sheets. This material consists of thin corrugated sheets of steel. They can have a variety of sizes and colors.

People are often skeptical about this design option because of its subtlety and lightness. And in vain. In fact, the corrugated sheet is reliable and very durable. Such characteristics are provided by the relief surface, which gives the sheets increased rigidity.

Mineral and silicone plaster

Less often, apartment owners turn to finishing with mineral and silicone plaster. Such solutions not only look very beautiful, but also have soundproofing properties.

High-quality plaster is vapor-permeable. It does not absorb large amounts of water, so a favorable microclimate will always be maintained on the balcony. This finishing material is not afraid of mechanical damage. Also, it will not require special care from its owners.

Wooden lining

Wood-based materials are less practical. For example, ordinary lining looks attractive on a balcony block, but does not tolerate dampness and moisture well.

From time to time it will have to be treated with special impregnations that add life to the lining, so it is recommended to choose plastic panels.

Results

As a conclusion, let’s talk about some important things that were not discussed in this article - and completely in vain. First of all, you must understand that you can only finish the balcony façade yourself on the second or third floor without appropriate insurance. If you live higher up, it’s better to think about your own safety once again and make every effort to minimize the likelihood of an accident. In general, the higher you have to work, the more skill is required from the master.

Only qualified craftsmen with insurance and permission can carry out high-altitude work

Thus, if your floor is not the second or third, it is better to think again about involving real professionals in such responsible and risky work. Such people have the necessary equipment for insurance and appropriate permission to work at height. However, you will have to pay for high-altitude work - and we are talking about decent sums of money.

However, who will finish the outside of your balcony is up to you to decide. Draw your own conclusions, we have analyzed all the work that will have to be done here in detail, so any owner can make a decision - whether he can handle it personally, or whether it is better to attract outside help.

Options for style ideas

Let's consider several interesting style solutions for decorating the outside:

External cladding can significantly extend the life of the structure.

This is an opportunity not only to decorate the facade of a building, in any color, but also to improve the technical characteristics of the structure.

If you glaze it, you can get a small, but full-fledged room.

A wide range of finishing materials will allow you to choose an option for everyone.

Options for finishing the balcony outside with siding and plastic.

If you decide to do the sheathing yourself, follow all safety precautions.

Once you have completed the exterior finishing, you can begin interior cladding.

To fit into the planned renovation budget and bring design ideas to life.

This is interesting: Furniture for the balcony: practical ideas and unusual solutions (23 photos)