Although a brick house already looks attractive, many owners of such real estate are thinking about the question of how to decorate the outer walls. Such a need may also arise when the brick has served its purpose and no longer looks as attractive as it did after building a house.

Another argument for cladding exterior brick walls is that cladding helps make the living space more comfortable to live in in terms of temperature. The facade can be sheathed using ventilated wall technology, using brick in combination with insulation, wind and vapor barriers. But before finishing a brick house, you should select the material, having considered all the features of modern market offers.

Requirements for finishing a brick house outside

External finishing must resist moisture.

Not all possible types of finishing are suitable for cladding brick facades. Their purpose is to protect walls from rain, snow and wind.

Requirements for finishing a brick house:

- Resistance to moisture. Porcelain tiles or clinker are low-porosity materials. Sheathing with such stone does not absorb moisture and does not allow it to pass to the brick walls.

- Repairability - if to replace a damaged defect you need to dismantle the entire facade, this option can hardly be considered successful.

- Decorative - they decide to sheathe the facade to give it a beautiful look.

Finishing also solves secondary problems, for example, repels rodents and insects, and allows you to additionally insulate the house.

Description of the construction process

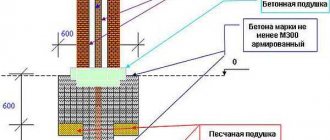

The construction of any building begins with laying the foundation, which is responsible for its stability and strength. The process of pouring it has many subtleties, one of which is waterproofing. To accomplish this task, it is necessary to cover the top layer of the foundation with an insulating material that ensures the preservation of the qualities of the foundation. Such products can be various materials, ranging from special bitumen impregnations to ordinary roofing felt.

During their installation, the main support points of the building are created, on which a full-fledged roof can be laid. First, 2 corner bricks are laid on the insulated foundation.

In the future, it is from them that the wall will be formed. As a rule, its construction is done from left to right. To install the first row, you first need to tighten the thread to control the evenness of the plane. Each subsequent brick, starting from the corner, is placed on cement mortar and compacted well. This should be done carefully, since excessive pressure on the material can lead to plane distortion. The joints between two bricks are also filled with mortar.

The second row is also laid from the corner of the building so that the joint between the bricks of the first layer is covered by half. Every few rows it is necessary to reinforce the brickwork, which consists of laying a metal mesh between the bricks. Its installation is carried out inside the cement mortar, which is covered with the next row of material. This method of dressing will improve the load-bearing characteristics of the wall and give it a colorful appearance.

Sheathing options

Finishes are chosen for attractiveness and moisture resistance. The latter is important for buildings made of porous materials, such as sand-lime brick.

Tile

The façade tiles give the building an attractive appearance:

- Clinker - differs from brick in its low thickness, but has other advantages of clinker. The material does not absorb moisture at all, is not afraid of the most severe frosts or heat, and is resistant to aggressive chemicals.

- I find terracotta tiles durable, but also moisture resistant and resistant to the harshest frosts. The material is more reminiscent of ceramic in color and texture, so it looks interesting on the facade. Ceramics are durable, beautiful, and weigh less. Disadvantage: complicated installation.

- Decorative - cement or concrete. The material is light and hard, although it is inferior in strength to clinker. The main advantage of finishing is the variety of textures and colors. It imitates any natural or artificial stone.

An interesting option is flexible tiles. It is glued to the facade and allows you to change the appearance of the building in a couple of days. However, it does not differ in high moisture resistance or strength.

Thermal panels

This is the name of a building element that includes all layers of conventional cladding: insulation, hydro- and vapor barrier and decorative tiles. Some also include an additional fire-resistant backing to reduce the risk of fire.

The top layer of the panel is made of clinker, decorative tiles, and porcelain stoneware. The assembled panels form a normal wall surface, which in appearance cannot be distinguished from clinker or artificial stone cladding.

Siding

The exterior of a brick house can be finished using any type of siding:

- Metal - steel or aluminum. The lamellas are durable, lightweight, and do not corrode. Steel ones should be painted and protected from rust. Aluminum ones do not rust.

- Vinyl - the material is produced both in the form of lamellas and in the form of facade panels. Plastic is lightweight, but provides wind protection, does not allow moisture to pass through, but is wary of extreme cold. Vinyl siding imitates wood, stone, and ceramics.

- Wooden - made from wood chips, therefore much more resistant to water than lining.

- Fiber cement - not afraid of water, sun, cold, rust. Non-flammable, resistant to mechanical damage. This siding is quite heavy, so cladding takes a lot of time.

When finishing a brick wall, only the degree of protection from water and wind that the siding provides is important.

Stone

Facing with artificial or natural stone is the most expensive option, but also the most effective. Natural materials, like granite and marble, are very beautiful, strong, and durable. But the stone weighs a lot. This finish should be taken into account at the design stage as it creates significant loads. In addition, stone cladding is difficult.

Artificial stone slabs weigh much less. In terms of strength and durability, they are not always inferior to natural ones. Porcelain tiles are stronger and less absorbent than real ones. Concrete conglomerates are more fragile, but they are easier to replace.

Plaster

The simplest finishing option is plastering. Since the facade has a large area, smooth plaster mixtures are used infrequently - they are too simple. They prefer structural plaster, which, due to the displacement of granules during application, forms an unusual relief surface.

Mosaic plaster for exterior use is impressive. This mixture contains small colored pebbles. The frozen layer is, as it were, formed from them.

Masonry mortar

If the external masonry of the wall is carried out “for jointing”, then how aesthetically pleasing the brick wall will look depends on the quality, composition and correct use of the mortar. The thickness of the seams must be the same everywhere, and they must be filled completely; voids are not allowed. The solution must be prepared before starting work and applied within two hours. For plasticity, clay, lime or marble pulp is added to it.

For horizontal seams, a thickness of 10 to 15 mm is used, for vertical seams - from 8 to 10 mm.

When constructing a brick building, you need to know that any deviation from the project can subsequently lead to unpredictable consequences. The stability and strength of brick load-bearing walls can be easily reduced if:

- reduce their thickness;

- increase their height;

- increase the area or number of openings;

- reduce the width of the walls between the openings;

- arrange additional niches or channels in the walls;

- use heavier floors.

A brick wall whose thickness is less than the design thickness must be additionally reinforced.

All changes to the project must be made by specialists; this cannot be done independently.

Brick buildings have obvious advantages that put them one step above houses made of any other materials. Made according to original designs, they have their own style and charm. This is also a good option for investing funds and transferring real estate to descendants by inheritance.

Thermal insulation and rough finishing

Insulation from the outside often turns out to be a more profitable solution than from the inside. The brick wall and cladding do not prevent this.

There are 2 options:

- Frameless - slab insulation, like polystyrene foam or polystyrene foam, can simply be glued onto a flat brick surface. Such a wall can be easily plastered and tiled.

- Frame - for cladding with siding, clapboard, natural or artificial stone, a metal frame is often installed. Its structure forms an excellent basis for insulation. Slab heat insulators are mainly used, but mineral and basalt wool can also be used.

When covering with thermal panels, no additional insulation is provided. If the house is finished with clinker, all thermal insulation work is carried out inside.

Internal load-bearing walls

Buildings with a length or width of more than five and a half meters are separated along the long side by internal load-bearing walls. They are used for end support of the ceilings or coverings of the structure.

The thickness of internal brick walls is made smaller than external ones, because insulation is not required here, but not less than 250 mm (brick laying). The load-bearing walls, both external and internal, are interconnected and, along with the foundation and roof, form a single structure - the skeleton of the building. All loads acting on the structure are evenly distributed over its area. The junctions of the external and internal walls are reinforced with meshes or separate reinforcement through 5 rows of masonry. The walls are at least 510 mm wide and they are also reinforced. If it is necessary to install pillars as load-bearing supports, then the cross-section of the structures must be at least 380x380 mm (one and a half brick masonry). They are also reinforced with 3–6 mm wire every 5 rows along the height of the masonry.

Required tools and materials

Tools for finishing a house with siding

Different methods require a variety of materials and tools. The most popular option is siding. For this you need:

- vinyl, metal, wooden slats;

- steel profile;

- self-tapping screws, dowels for fastening;

- drill, screwdriver, hammer drill;

- metal scissors, hacksaw, hammer, pliers;

- tape measure, plumb line or rule.

Additional materials may be required, such as reinforcing mesh or polyurethane foam.

How to lay brickwork correctly, basic techniques

An important condition for a high-quality wall is the correct composition of the solution. For 1 part of M400 cement, 3 parts of sand (fraction 2 mm) are required, or 4 parts if M500 cement is used. As a measure, a 10-liter bucket is usually used (12 kg of sand or 14 kg of cement is placed in it). Add 0.5 - 0.7 liters of water per 1 kg of cement - the solution should not be too liquid.

During the laying process, the following rules are observed:

the base is laid out of red ceramic brick (it is more resistant to moisture) to the level of average snow cover; line 2 levels of waterproofing from roofing felt - at a height of 0.2 m and 0.5 m from the blind area; the first row is laid along a stretched string, so that the bricks do not touch it, subsequent layers are checked with a level - this is especially important for the facing row; every 5 rows there is a layer of reinforcement; if the wall is supposed to be plastered, the seams are not completely clogged with mortar - this technique is called “laying empty space”; the facing row is filled with the mortar mixture flush with the wall - “undercut”, sometimes a decorative (convex or concave) seam is made; so that the corners are even, construction begins with them, using the order - a corner with marks for bricks.

Finishing technology

Procedure:

- Fix the starting and corner profiles. Then they set the finishing bar. The screws are not tightened approximately 1 turn to compensate for the expansion of the material.

- The vertical H-profile is fixed using the marks in increments of 30-40 cm.

- Sheathing begins from the bottom. The panel is inserted into the starting strip and secured to the profile with self-tapping screws. There is a gap of 5 mm between the cap and the material.

- The next lamella is inserted into the groove of the previous one, snapped into place, and also secured with self-tapping screws.

- The last element is inserted into the finishing strip until it clicks.

Wood sheathing is not installed on a brick wall.

Vapor permeability

In any residential premises, the walls must vent accumulated steam towards the street. High humidity appears:

As a result of residents' breathing, laundry, dishwashing, showering and bathing.

If the windows are closed (and this is common during the heating season), all the moisture remains in the rooms and settles on the walls. Even a good ventilation system cannot completely cope with such a problem. As a result of temperature changes. When room air is heated, it can hold more moisture than when it cools.

When the air comes into contact with colder walls, it releases water in the form of condensation. This process is clearly visible in the windows that “cry” in cold weather. In winter, excess dampness also appears in the corners of the living space in the form of mold or wet walls.

This gives rise to a general rule: the better the wall allows steam to pass through, the faster the humidity level in the house normalizes. “Breathing” building materials filter condensation through pores (capillaries) and remove it outside.

If the wall is impermeable to moisture, water vapor, when encountering an insurmountable obstacle, begins to accumulate in the thickness of the structure, which leads to the gradual destruction of the building.

General rules and recommendations

It is worth choosing finishing materials taking into account the advice of professionals:

- If the weight of the finish is important, they prefer the lightest materials: vinyl and wood siding, plaster.

- If durability is not important, use plastic panels and concrete tiles. plaster. If it is important to protect the walls of the building for a long time, they make cladding from clinker, brick, or natural stone.

- If the structure of the wall pie is complex, it is important to select the finish so that its vapor permeability exceeds the vapor permeability of the brick wall. Fiber cement siding and plaster compounds are suitable for this, but artificial stone, clinker or vinyl siding are not suitable.

The finishing of a brick building is made with many different materials. The main criteria here are moisture resistance and decorativeness.

Why is it not recommended to insulate walls from the inside?

Many people approach the insulation of their apartments “carelessly” and do not take into account the real needs and problems. It’s very tempting to quickly and at minimal cost insulate a wall from the inside and not have to worry about it. But, unfortunately, this method has many disadvantages that people forget about or simply don’t want to hear about.

1.

It is important to understand that after insulation the temperature distribution in the wall changes. Under normal conditions, warm air warms the wall from the inside

But the insulation does not allow heat to pass through and prevents the wall from warming up.

Let's consider the position of the dew point in the absence of wall insulation, insulation from the inside and outside:

As a result (let me remind you, we are considering insulation from the inside):

- the dew point shifts to the inner surface of the wall, which promises the formation of condensation behind the insulation, dampness in the room, fungus, musty smell and all that follows; due to freezing of the wall and sharp temperature fluctuations, the service life of the walls is reduced; under normal conditions, after ventilation, fresh air does not heat up only by heating radiators, but also due to the heat accumulated by the walls. Having insulated the walls from the inside, when opening the window it can become colder by 6-8 degrees, and for the temperature to return to normal, it takes from several hours to one or two days.

2.

Many people think that it is much cheaper to insulate from the inside, since there is no need to call climbers. And they don’t even consider the option of insulating the walls of the apartment from the outside. It is a myth.

Not only is it not cheaper, but sometimes even more expensive. We don't know why. Just check.

3. Reducing the usable area of the apartment: For example, for an ordinary two-room apartment, the loss of space can reach from 0.5 (non-corner) to 1 square.

m. (corner). Cost of 1 sq.

m of housing in Nizhny Novgorod - about 55,000 rubles. A decent amount, isn't it?

4. In addition to all this, if you decide to insulate the walls from the inside, you will have to completely destroy the interior, which is very unpleasant, especially if you have just recently made expensive repairs.

The only advantage of insulating walls from the inside is that such work can be done independently and at any time of the year.

Budget Remodeling Ideas

Repaint the paneling

Lining is a typical finish for old Soviet dachas. In order not to waste your budget on interior cladding, you can repaint it. Here are some tips if you decide to take the plunge:

- choose covering paints rather than glazing paints;

- give up the idea of leaving the natural texture of the wood - this will not improve the old lining;

- choose light shades of paint and do not make the rooms multi-colored.

If you like the color of natural wood, it is better to use it in furniture. In old houses, the lining was covered with matte varnish, which looks completely unesthetic. And over time, her appearance will definitely not improve.

Restore or buy new furniture

Old vintage furniture should be preserved, it is very fashionable now. I restore it in my projects. If the furniture is not valuable, you can repaint it using the same covering paint. And furniture from a domestic manufacturer is inexpensive - for example, in one of my projects I chose furniture from a Belarusian manufacturer in the natural color of wood and repainted it a beautiful gray-green color with patina.

Paint your kitchen cabinets

A completely budget option is to paint the facades of the old pine kitchen and make a new countertop. Choose a light or bright color - at the dacha it is always the center of life. If possible, make a wooden bar counter, perhaps from larch and pine panels, cover it with oil for the countertops, guests always gather around it.

Preparation

Before updating the outside of a brick house, you need to purchase tools and finishing materials, then prepare the wall surfaces. This process includes:

- cleaning walls from previously applied cladding, dirt, climbing plants;

- sealing cracks;

- drying the facade at high humidity;

- destruction of fungal plaque and treatment with an antiseptic;

- impregnation with a primer with increased moisture absorption;

- adjusting the thickness of heat-insulating raw materials;

- completion of plastering work;

- coating application.

Return to contents

Responses from the past

When we talk about the reconstruction and restoration of old brick houses, we most often mean buildings from the beginning - mid-last century. And there they used slightly different construction technologies and other building materials. Accordingly, you need to be prepared to learn about waterproofing the foundation with birch bark, bracing corners with metal pins, combining masonry mortar, etc. All this has served for decades with virtually no complaints, but in combination with modern materials and taking into account increased loads it can behave unpredictably.

Converting an old building into a residential building

To turn an old building into a living space, the following basic conditions are required:

- Regular water supply;

- efficient heating system;

- uninterrupted power supply;

- modern sewer system.

Not all old buildings have such benefits of civilization. What does it take to provide your home with everything you need?

If there is no water supply, you need to find out about the nearest water mains. You will need permission to connect to them. If there are no such nearby, you will have to solve the issue differently. Houses left over from old times sometimes have wells. But most often they are not suitable for regular water supply. Therefore, the best solution would be to dig a well and install a deep-well pump.

The type of heating system you choose depends largely on the fuel source. There are old stone houses or brick buildings equipped with a wood stove. If there is no gas supply to the area in which the facility is located, stove heating can be installed. If you don’t want dirt and dust in your house, use electricity. But keep in mind that you will then have to regularly shell out large sums for energy use.

Functions of facing bricks

The brickwork of the facades performs several functions at once:

- Decorative;

- Protecting the building from moisture;

- Insulation;

- Protection of load-bearing walls of a building from external factors;

The walls of houses are now most often made from cheaper materials, such as foam concrete, aerated concrete or cheap brick; only the facade is made from more expensive brick.

Siding installation instructions

To ensure that the cladding of the walls of a house with brick siding is reliable and durable, you should select good quality materials and ensure the availability of appropriate components and accessories for installation.

Tools

Some manufacturers offer the necessary tools for attaching siding with the panels, but they can also be found at home. To work you will need equipment for:

- markings: level, cord, tape measure, marker;

- cutting: hacksaw, grinder;

- hole preparation: drill;

- fixing the sheathing and panels: screwdriver, screwdriver, hammer.

It is also necessary to correctly calculate the required number of fasteners to avoid excessive waste.

Calculation of materials and components

Calculation of the amount of materials and components takes into account the surface area, as well as the type of finish.

Calculation of materials and components

For frame

For the lathing you will need wooden beams or a metal profile. The area of the surface to be coated should be calculated.

Next, it is important to decide what cell size is needed

Based on the selected size, the quantity of the required profile is determined.

For insulation

Calculations of thermal insulation material also directly depend on the surface area, as well as on the type of insulation and the number of layers.

This is important, since the heat insulator will be adjusted, which will lead to overspending. Also, for insulation, a second row of sheathing will be required to provide ventilation.

This also needs to be taken into account when calculating materials.

For siding

Next, you will need to divide this figure by the area of one panel to find out the required amount of material. Here you will also need to add 10%, since trimming is an integral process when facing.

Marking and installation of the frame

Installation of any brick siding begins with the arrangement of the frame. To do this, you will need to mark using a tape measure and a level.

Frame installation

Insulation

Thermal insulation materials begin to be mounted from below and move upward

It is important to ensure that the insulation fits tightly to the frame, and it should also be additionally secured with dowels or self-tapping screws

Thermal insulation of the building from the outside

To increase the water-repellent properties of the material, it is necessary to place a waterproofing membrane on top of it. Next, you will need to install a second layer of sheathing, providing a gap for ventilation.

Setting the corners and starting bar

Manufacturers offer special corner parts. It is with their installation, as well as the starting strip, that the process of laying siding under brick begins. The starting strip is attached 4 cm above the bottom edge of the future first panel. When fixing this element, you should check its evenness, since it is on this that further cladding will be oriented.

Installation of corners

An important requirement is strictly vertical fixation.

How to finish slopes and junctions with window and door openings

To cover window and door openings you will need to use a special profile. It must be fastened around the perimeter of the window or door, while ensuring a tight fit of the elements. This profile will become the basis for attaching the siding.

Installation of brick siding

Installation of the panels is very simple, since each panel has a locking connection. The siding must be attached to the profile using self-tapping screws or dowel nails.

Panel installation

The fastening begins from the starting bar, and is fixed at the top with the finishing element

It is important not to completely tighten the fasteners, which will prevent deformation from thermal expansion.

Brick siding for exterior finishing: a worthy alternative to masonry

Is your desire to have a good-quality brick house not realized? Don't rush to give up your dream. Modern finishing materials can create a real miracle. Using brick siding for exterior decoration, even a dilapidated wooden structure can be turned into a modern architectural structure.

Brick-like facade panels: a good way to decorate a house without putting unnecessary stress on the walls (read more)

You just need to choose the right panels that will protect the house from winds and dampness, and also make its design presentable.

Thermal panels

Thermal panels are a material that performs two functions at once - cladding and external insulation of houses. A layer of decorative coating is applied to the thermal insulation layer at the factory. It looks like marble or natural stone, does not burn, and has low water absorption characteristics.

You can clad and insulate a house with one material at the same time using thermal panels

This finishing material is made from polystyrene foam, mineral wool or extruded polystyrene foam. Depending on the type of insulation, the installation method is selected: polystyrene foam and polystyrene foam are glued to the appropriate composition. The joints are closed with a special aluminum strip or rubbed with paste.

Panels for façade cladding based on mineral wool are mounted only on a special system of profiles, and the joints are also sealed.

A very attractive idea is to immediately insulate the house and cladding it. Excellent appearance, and the characteristics of this cladding are impressive. It’s just a pity that there is little operating experience and no reviews yet: it appeared only recently.

There are also clinker thermal panels. Clinker tiles are glued to the insulation. The material is not cheap, but the characteristics are impressive, as is the variety of finishes.

Another option for thermal panels is with clinker tiles

The choice of materials that can be used to cover a house at any time - winter or summer - is considerable. There are expensive options, and there are cheaper ones. In any case, in addition to cost, be sure to consider vapor permeability. Then you won’t have to deal with mold and dampness.