A metal staircase is one of the varieties of such structures, which is distinguished by its strength, reliability and durability. Such structures are installed both outside buildings and inside a residential building, providing comfortable access to the second floor, attic or attic. Stairs on a metal frame today are available in various configurations, because thanks to modern technologies, any, even the most complex, shape can be made from metal.

However, without finishing, such structures cannot be considered complete. A bare frame is not yet a full-fledged staircase. The modern market offers a large selection of finishing materials. Wood has gained the most popularity. It is this natural material that perfectly harmonizes with cold metal, opening up the widest scope for designers to bring their ideas to life.

Variety of finishing materials

Staircase covering can be complete or partial. It largely depends on the style of decoration of the room.

Wood

A wooden staircase retains heat well, so there is no need to cover it with a path

Natural wood is one of the most popular materials. With its help, steps and fencing are finished. In this case, the structure looks monolithic. Oak, beech, and exotic wood species are used for cladding. The budget option involves the use of coniferous materials. These can be boards or lining.

The finish can be additionally decorated with tinting compounds. The advantages of wood cladding are environmental friendliness, luxurious appearance, ease of installation and repair, and durability. If it is not possible to sheathe the structure with natural material, you can use MDF panels.

A natural stone

Natural stone finishing requires a solid base

The steps of concrete stairs are often finished with natural stone: marble, granite, sandstone, basalt tiles. This material is durable and decorative. The finish looks expensive. It can be used not only indoors. It is best used on wide structures that are installed in large rooms.

The advantage of the stone is fire resistance, a wide selection of shades and textures. The disadvantages of cladding include poor sound insulation (steps cause loud noise) and high cost. Often it is necessary to involve specialists to carry out work.

Steps with this finish remain cold.

Carpet

The carpet does not slip, it can be washed without removing it

Carpet is used if there are children or elderly people in the house. This material makes the steps less slippery and noisy. You can install the trim right away. For fixation, use wooden or plastic plinths or brass rods. To increase the service life of the material, felt is laid underneath it.

The carpet is durable, resistant to moisture and abrasion. You can do the cladding of the stairs yourself. The advantage of carpet is that it will be pleasant to walk on the steps even barefoot, since the product is soft and warm. It is suitable for wooden and concrete stairs.

Laminate

For finishing stairs, buy laminate with increased strength

The choice of laminate as a finishing material depends on the design features of the structure. This cladding is best suited for wooden stairs. They take on a very neat and beautiful appearance. Since the structure is subjected to mechanical stress every day, it is necessary to choose a high-strength laminate with an anti-slip coating. Before laying the lamellas, the base requires leveling and waterproofing.

The advantage of the material is the variety of shades, the ability to select the required size of elements, and ease of installation. You can do it yourself. Laminate is able to imitate other natural facing materials.

Dye

Metal or concrete stairs can be finished with paint. If the structure leads to a cellar, basement or domestic premises, it is better to use a composition with water-repellent properties. The advantage of the paint is its good decorative ability and a wide selection of shades.

Requirements for structures

Everyone should feel safe in stairwells - these requirements are dictated by concern for the safety of people and are contained in regulatory documents. Any structure must have the necessary strength to withstand a certain load. In general, the characteristics that a glass staircase, a reinforced concrete floor slab or a steel form should have are as follows:

- Reliability.

- Rigidity.

- Safety for humans.

There are a number of requirements for these stairs

, and these rules must be applied everywhere. For structures used in the interior of a house - stairs, furniture, and other household items - the aesthetic side of the issue should, if possible, be present. Beautiful designs are doubly pleasant to use; this is true for both home and office. It is very difficult for designers to take into account literally all the requirements; I would like to create a spiral staircase made of glass, but, unfortunately, this is difficult to implement in practice due to the extreme fragility of the material. That is why combination with other materials – wood, metal, cable-stayed structures – is more often practiced.

Stair steps

No less important is the issue of ensuring strength and resistance to destruction of steps - an element that often comes into contact with a person, more precisely, with his shoes, and is subject to abrasion. It is doubly desirable to make a wooden staircase with a glass railing, and equipped so that it can be used in winter and summer, and in rain and snow. For this, elements made of polyurethane or a special notch are used - the main thing is to create a solution with a surface that effectively resists slipping. Do not forget about the standard requirements: width, height, thickness of the step, regulated by national and interregional standards, as well as other standards - GOST and SNiP.

In this video you will learn how to install a glass staircase:

Glass railings for stairs

There is another way to break and change the established image of a flight of stairs as something boring, utilitarian: sheets of triplex, special tempered glass, are fixed on racks, making the entire structure look airier and lighter.

Combination with wood, metal and stone is not only not forbidden, but also encouraged - more powerful, solid materials emphasize the fragility of glass fencing, which, in turn, is in perfect harmony with forged elements and granite slabs. Of course, for this you will need not ordinary window glass, but exceptionally strong glass, which is not afraid of loads and deformations.

This is interesting: the features of glass railings.

With transparent fencing in the interior of your home, you can completely transform it, create your own style, completely different from the usual and standard ones. From a design point of view, the use of the decorative properties of glass opens up broad prospects for creative people who are not afraid of experiments. Sometimes they manage to realize different ideas and get them into the finished product in one fell swoop.

https://youtube.com/watch?v=0xS4j3Q6I3U

“Staircase to the house” - professional production of wooden stairs with any design

If you are not confident that you can do it yourself, you should not risk the safety of your household - order a professionally made staircase from specialized specialists. They will design the structure, observing current GOSTs, make calculations, and help you choose a convenient and beautiful option for wooden cladding.

offers a large selection of mid-flight, screw designs at an affordable price. Buyers have access to ready-made options from the catalog (more than 400 models), as well as products for individual projects. Certified materials and high-quality compounds from Votteler, Loba, AkzoNobel are used in production. By collaborating directly with manufacturers, the company optimizes the cost of products and increases the efficiency of solving all technical problems. "Stairway to Home" offers:

- a wide selection of models made of wood, on a metal frame (with straight steps, winder steps, with platforms, etc.), a variety of finishing options;

- assembly and installation services of structures at sites in Moscow and the Moscow region - we install stairs in private houses, apartments, commercial spaces;

- delivery of manufactured structures to all regions of Russia using proven transport services;

- professional assistance in choosing designs, shapes, finishes and so on.

To place an order, ask a question, or find out about the terms of cooperation, contact the company’s managers by phone or write to us in an online chat.

Combined stairs by design type

The term “combined” implies the use of structural elements of various types. The variety of combination options is great, but the most popular types include the following types:

The march design is made with support from the stringer and bowstring. In this case, one side of the steps is attached to the stringer, and the other is fixed with a bowstring.

- Bolts are used to fasten one side of the march, and the other is secured to the opposite wall.

- Fastening with bolts and support on one side of the march, and the other on the stringer.

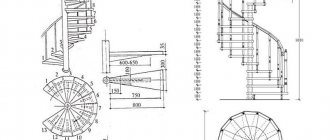

Combination of a screw structure with a support pillar and winder steps, supported by a bowstring.

Stringers for arranging combined flights are made of wood, metal or concrete. Steps can be glass, wood, metal or natural stone. Metal, wood and plastic are used for fencing.

Finishing work

The work will be done using the following tools:

- screwdriver and self-tapping screws;

- a hammer with a rubber head, designed for possible fixation;

- wood carving tools;

- cleaver;

- building level;

- rulers and pencils for wood;

Preparing parts

- The first stage is measuring all elements of the staircase structure that are planned to be sheathed. This must be done carefully, eliminating the possibility of cracks forming or fastening too tightly. This can lead to deformations and cracks.

- After this, the measurements taken are transferred to the wood.

- According to the completed markings, the parts are cut.

- If the steps have different shapes, then it is worth numbering them so as not to get confused during the assembly process.

- When processing parts, it is worth slightly rounding the corners located on the front side. This will ensure more comfortable operation, reducing the risk of possible damage to the wood and increasing safety.

- After preparing the steps, they move on to processing the railings and balusters, if the design involves covering them. When cutting out the railing, first determine the length, then adjust the width and shape.

Professionals recommend measuring each step for cladding. Even if they seem the same. This will eliminate errors and subsequent incorrect installation.

Stages of work

Fastening the steps

First you need to decide on the design of the staircase and the option that will be used to cover the frame. According to the requirements, it is necessary to select the type of wood for cladding. Afterwards, the cladding parts are prepared. The solid wood is adjusted to the size of the frame. If the work is simple and does not have any special decorative flourishes, then you can get by with a hand saw for wood and a large file. The treads should be fixed in such a way that they have a small protrusion in front of up to one centimeter. This will not only give a nice look, but will also allow you to make the most secure fastening. Fasten them from top to bottom

After installation, it is necessary to check each one for strength, as well as how smoothly they are secured with a building level. When installing risers, it is important to comply with the following requirement: they must rest as tightly as possible against the metal frame. They are fastened in the same way, starting from the top, and after fastening they are checked for strength and evenness. Provided that the frame is completely covered, the next step will be the selection of the balustrade

They not only perform a protective and supporting function, but are also an important decorative element of the staircase structure. Balustrades are installed in increments of 15-20 centimeters. If there are children in the house, this step should be reduced to 9-10 centimeters. Next, we fasten the prepared wood parts. This is done using self-tapping screws. It is necessary to drill holes in the frame in those places where the sheathing will be attached. Using self-tapping screws, the wood cladding is attached to the metal frame. It is necessary to screw the self-tapping screw into the wood with a 5 mm deepening of the head. The balusters are fastened to the treads using self-tapping screws. Next, railings are laid on them.

Covering a metal staircase

You can also sheathe a metal frame. This is done using drywall, screws and wood panels. Work begins by covering the side surface with wooden panels. Their sizes are selected in advance. Fastening is done with a screwdriver using self-tapping screws to the balusters. The lower flight of the stairs is sheathed with plasterboard. Fix it on the side and bottom parts of the steps.

It is not at all necessary to finish the metal frame if it has an attractive appearance. But this finishing option can hide existing shortcomings.

Coating wooden finishing elements with varnish or paint is the final stage. You can also paint over metal parts that are left in sight.

Recommendations

A compact and cozy spiral staircase is not at all an advertisement from the cover of a magazine or the fantasy of an expensive designer. Experts keep several effective secrets that help bring all this to life with minimal material costs. The only thing that is required to the maximum extent is desire, diligence and scrupulous adherence to instructions. To make it easier to cope with this task yourself, re-read the main recommendations for this process.

The length of one turn of the staircase must be at least two meters so that it is comfortable for a person of any height to move along it. When finalizing wooden structures, pay special attention to the painting process. If you are more than satisfied with the natural pattern of the material, then you can get by with a two- or three-layer coating of yacht or parquet varnish.

Before you start painting or varnishing the surface, be sure to clean it of construction debris, dust and other types of contamination.

Then you will get a durable, high-quality coating. Pay attention to the angle of the steps. Ideally, they should be parallel to the floor so that there is no risk of feet slipping and injury. Materials for the manufacture of stairs must be of high quality, strong and durable

When selecting, take a close look at all the components and components.

- Fire safety is paramount. All materials must have heat-resistant impregnation and treatment.

- Moisture is also a bad companion for spiral staircases of various materials. Therefore, you should immediately clarify the question at the selection stage whether the structure is treated with a special moisture-resistant coating.

- All fastening tools must be in place and securely screwed in, driven in, and fixed. The plane of the steps should be perfectly smooth without any unpleasant protruding additions.

- In the process of marking and creating drawings of the future structure, be sure to take all measurements several times and double-check yourself. Incorrectly specified dimensions can lead to uncomfortable operation: misalignment, creaking, and rapid wear of components.

- If there is a need to replace a step, fastener, railing, baluster, etc., do so immediately. Otherwise, both the entire structure as a whole and the person climbing or descending it may suffer.

- Constantly take care of your spiral staircase: clean it on time, paint it, repair it if necessary.

How to veneer a concrete staircase with wood

Concrete stairs are monumental, reliable, safe and durable. However, the material is cold, and the surface of the steps is difficult to level until smooth. The solution is to cover the marches with wooden panels. It will hide roughness, help level the height of the steps, and make them pleasant to the touch.

The concrete surface must be prepared before finishing.

It is important to pour the screed correctly, evenly, and arrange the frame with an evenly distributed mass so that when using the stairs, the wooden steps do not deform or crack. If the structure is frameless, differences can be eliminated using a substrate

It is usually made from moisture-resistant plywood. In addition to a flat surface, it has another important advantage - it protects the wood from moisture changes inherent in concrete. With plywood, the structure will be more durable; cracks and deformations will not appear on the steps.

Finishing the steps

Before finishing, the treads are cut out of wood to the size of the concrete steps. The concrete base is cleaned of plaster, “notches”, growths, the surface is blown off or dust is collected with a vacuum cleaner. It is advisable to treat the concrete base with an antiseptic to protect the wooden parts of the stairs from mold and biological hazards. After that:

- Elements are cut out of plywood to fit the size of the wooden sheathing;

- adhesive mastic is applied to the concrete steps of the stairs and the plywood parts are pressed, then the level is adjusted;

- plywood is nailed to the base using dowel nails;

- install the side cladding elements, imitating stringers, using adhesive-sealant and self-tapping screws;

- Use self-tapping screws and glue to fix the wooden steps, checking the level, and then screw in the risers - first fix the lower elements, then move up the flight of stairs, leaving small gaps;

- pass along the joints with sealant (you can pour polyurethane foam into the cracks);

- mask gaps in the finishing with decorative putty.

Installation of stair railing

The fencing on the stairs can be metal (in which case it is enough to cover the railings) or completely wooden. In the second case, it is necessary to calculate, cut and process the surface of handrails, balusters and posts in advance. These elements complete the cladding of the concrete structure, increasing its safety and creating a warmer appearance.

Before work, you need to prepare handrails for cladding, balusters, anchor bolts and studs for securing parts. A hole is drilled in the concrete where the plug is installed. An anchor bolt is screwed into it, onto which a support post is placed, and it is fixed with a coupling.

Balusters are also installed - they are screwed onto the short end of the pin, and the long end is fixed in concrete through the treads. For convenience, when tightening anchor bolts, use an electric drill. Additionally, for strength, the balusters are placed on glue. It is convenient to tighten the handrails to the posts through gearboxes, securing them with zip bolts. After fixing the railings to the supports, the cladding is completed - you can tell yourself and your hands that they have coped well with a difficult task.

Installation step by step

At the very beginning of the cladding, we determine whether additional fastening of the structure is required. Fasteners may be needed, for example, in a staircase with turning steps.

Installation can be done in 2 ways:

- Laying steps on top of corners. And then we fasten it so that the corners of the stairs are hidden by board steps.

- Fastening to corners welded to channels. Steps are laid into the resulting frames.

Examples of finished works

Metal structure cladding technology

When you have decided on the wood and purchased lumber for cladding in the required quantity, you can begin installation. But before this, it is necessary to make accurate calculations and prepare tools, without which it is impossible to finish the staircase.

Necessary tool

To sheathe a metal staircase with wood with your own hands, you will need the following list of tools:

- hammer drill and screwdriver;

- jigsaw for cutting material;

- plane, file, sandpaper;

- hammer, rubber mallet, pliers;

- tape measure, building level;

- set of wrenches, self-tapping screws.

Preparatory work

To sheathe a metal staircase, it is not enough just to acquire the necessary tools. How reliable, durable and easy to use the structure will depend on correctly completed preparatory work.

So what needs to be done:

1. Using a tape measure, measure each step of the iron staircase, as well as its side parts and the length of the flight.

2. Write down the received data on a piece of paper and mark the necessary parts on the lumber.

3. Cut out all the necessary blanks of suitable sizes, process rough edges with a file, and sharp corners with emery.

4. Number the elements for covering the steps, taking into account that you will carry out the finishing process from bottom to top. It is better to do this in places that will not be visible after installation.

5. Using sandpaper, sand the surfaces to perfect smoothness. You can use a sander, so the work will go faster.

6. Finally, it is enough to treat all wooden elements with an antiseptic and wait until they dry completely.

Metal frame cladding

When all the parts are carefully processed and ready for installation, we proceed to cladding the frame. The whole process looks like this:

1. We begin work by finishing the steps from bottom to top. To do this, we lay wooden treads and fix them with self-tapping screws. The caps of the fasteners should be deepened into the boards by half a centimeter.

2. Install risers. They must fit tightly to the frame; to fasten them we also use self-tapping screws with a metal drill.

3. We begin assembling the fencing elements. The balusters are installed on the steps along the edges; we screw in the screws on the back side of the steps. It is advisable to place the supporting elements at intervals of 15-20 cm. Next, we attach the handrail to the installed balusters.

Rear mounting

The peculiarity of this cladding method is that the wooden parts are laid on top of the frame, and the screws are screwed in from the back side. First you need to drill holes in the metal itself in the right places for fastenings. Just prepare a container with cold water in advance to cool the drill - often the metal in such frames has a thickness of 5-7 mm.

Next we move on to the installation of each step. Everything is very simple here. First you need to make a backing from plywood and fix it to the frame using mounting adhesive with a filling effect. Just don’t use polyurethane foam instead of glue - it dries out over time, which will lead to unpleasant squeaks.

We lay treads on top of the substrate and tighten them from the reverse side with self-tapping screws through pre-drilled holes in the metal. As for risers, the technology for their installation is no different from the process described above.

Exterior decoration of the stairs

At the final stage, all that remains is to sheathe the back side and trim the side part of the staircase structure. This can be done using chipboard sheets, plasterboard or lining. First, we prepare the parts of the required size and sheathe the side edge like a bowstring; for this it is better to use wooden panels. We cover the lower part of the flight of stairs with plasterboard. Fastening is carried out using self-tapping screws.

After covering a metal staircase with wood, do not forget about the finishing touch, on which the final result will depend. Additionally, we coat the tiled parts of the staircase with wood paint or open them with varnish, tinted or transparent - whatever you like.

Sheathing a metal frame and installing balusters (3 videos)

Additional skin protection

When the staircase is already lined with wood, you can tint the elements in almost any color scheme. But before that, we impregnate it with an antiseptic; it prevents the materials from rotting from mold and moisture.

Another way to cover the cladding is relief. We use a hand-held grinding machine (attachment – steel brush). Methodically “comb” the fibers of the cladding. As a result: soft ones are removed, and hard ones create excellent relief patterns. Then, using varnish, we give the steps the necessary tones. And finally: we again sand the surfaces of the steps. This will cause the varnish to remain only in the depressions of the relief.

What to cover the metal frame with?

The frame made of corrosion-resistant materials (stainless steel, aluminum) can be left open, and it is better to sheathe the iron staircase on all sides

.

The most common combination for a private home is metal and wood. For cladding, hard and soft wood is used (oak, beech, larch, pine, walnut). Advantages of wood for cladding:

- ease of processing;

- low thermal conductivity;

- high frost resistance;

- You can make the cladding yourself.

The shortcomings of wooden cladding can be corrected with protective impregnations

When choosing, we recommend paying attention to the individual properties of each type of wood; treads should be finished with hard oak, beech, larch; risers should be finished with cheaper soft pine, spruce, fir

Metal frames made of stainless steel or metal with galvanic treatment (chrome plating, brass plating) go well with glass. This is one of the home staircase options that looks natural in modern and traditional interior design styles. Steps, balusters, and railings are made of glass. To protect against falls, anti-slip pads are installed on the steps or sandblasted. Finishing a staircase with your own hands is very difficult - you need specialists who have experience, tools and equipment for working with glass.

WPC (wood-polymer composite board) is similar in texture, thermal conductivity, and color to wood, but without its disadvantages. High moisture resistance allows the material to be used for finishing street structures, flights for baths, saunas, and attics. Sheathing is not difficult to do yourself, without the involvement of installers, using an electric saw or a hacksaw to cut the boards and following the step-by-step technology for working with WPC. If you decorate a staircase with decking, it will last up to 50 years, will not fade in the sun, will not crack from impacts, and will not be worn out by constant walking. The surface is well washed from dirt.

The ends of inexpensive iron frames are covered with budget plasterboard. It is easy to cut and its surface can be processed.

Fencing

The fence plays not only a protective function, but can also be an interior item.

Decorative design

The main requirements for any type of fencing are:

- Safety;

- Strength;

- Decorative.

The absence of a fence reduces safety, but sometimes this option is required by the designer.

Without fencing

Suitable fencing made from:

- Metal;

- Glass;

- Plastic;

- Combined.

A combination of different materials is often used in fencing designs.

Combined type

Structurally, the fencing system consists of:

- Railing;

- Baluster;

- Decorative elements.

Railings and handrails serve to support a person when moving. They can be attached through a system of balusters to the steps, or mounted on the wall.

Handrail

Balusters transfer the load from the railing to the steps or floor. In addition, they serve as decorative filling for the fence.

Support posts

Decorative elements of the fence are grilles and protective screens.

Fencing

The height of the fence can vary from 90 cm to 150 cm.

Metal fence

Metal types are made from:

- Regular steel;

- Of stainless steel;

- Chromed steel;

- Aluminum;

- Forged metal;

- Cast iron.

Conventional profiled steel is used, as a rule, for fairly simple fences. The most common option is fencing made of stainless steel.

Made of stainless steel

They are easy to manufacture and install. The main advantage of such fences is their durability and high strength.

Stainless steel

Thanks to these qualities, stainless steel fencing is widely used in public buildings with heavy loads on staircase systems.

Railing

Chromed steel has an excellent appearance and is well protected from corrosion. Aluminum fencing is lightweight. They can be finished with colored metal coatings and polymer materials.

Interesting combination

Forged elements of metal fencing are distinguished by their sophistication and unique style.

Forged

Such designs are most often made to order. The cost of the product depends on the complexity of the execution. Cast iron casting is not common.

Glass fencing

Glass fencing is made mainly from:

- Tempered glass;

- Multilayer;

- Molded;

- Frost-resistant;

- Bulletproof.

Tempered glass, subjected to special heat treatment, acquires greater strength. The most common type of fencing is laminated glass screens. If triplex glass is used, the stairs become truly safe to use.

Original design

Glass bending technology makes it possible to obtain curved parts. Like tempered glass, it is heat treated to strengthen it.

Bent material

Frost-resistant glass for fencing is used in the case of external staircase structures. Bulletproof glass in stair railings is used extremely rarely, only for certain objects.

Appearance

A wide variety of glass finishing options allows you to choose it for any interior design solution.

It could be:

- Transparent;

- Matte;

- Tinted;

- Engraved;

- With beveled edge;

- With photo printing;

- With color film or film with a pattern.

The most important thing is that the material is durable and safe.

Colored

Quite often, various lighting is used for glass fencing.

Backlight

It emphasizes the airiness of the entire system and can add a variety of colors to it.

Colored material

By placing lamps anywhere in the structure, it is possible to constantly change the appearance of the entire interior.

Combined fencing

Typically, combined fencing is also made of glass and metal. It is possible to add wooden elements, such as handrails.

Combined option

Quite often, a metal fence is supplemented with a solid glass screen in order to increase its safety.

Preparing for work

First, assemble the tool. To cover a metal staircase you will need:

- Drill with drill bits for metal and wood.

- A screwdriver and a set of bits for it.

- Roulette.

- Hacksaw.

- Construction pencil.

- A set of bolts, nuts and screws for wood and metal.

- Level.

- Plumb.

- Set of carpentry tools.

Selection of material

- Next, let's look at the material. First of all, of course, the wood itself.

- For the upper linings of stair steps it is better to use hardwood - oak, hornbeam, ash, cherry or beech. It’s not worth saving on the main pads, because they will bear the heaviest load.

- For vertical gaps between steps, ideally it is better to use the same material, but if you cover the stairs with carpet or are simply short on money, you can get by with inexpensive coniferous wood. The same applies to the side pads.

- Choose a balustrade. It is better to buy ready-made balusters and railings, preferably of the same type of wood as the overlays, so that your staircase does not look like a traffic light. It is not recommended to make them yourself, since you probably won’t be able to do it beautifully, you will spend a lot of time, and the price will not differ much from the factory price.

- Be sure to take care of the substrate. No matter how well the ladder is welded, there will still be minor distortions. To smooth them, a backing is used, usually ordinary plywood.

An important point: to prevent your wooden structures from collapsing later, pay attention to the moisture content of the wood. Freshly cut timber cannot be used

Its humidity ranges from 35 to 100%. Optimum humidity 12%.

Iron barn construction technologies

There are permanent metal sheds, and there are prefabricated ones. A solid iron barn may have a concrete floor, which is poured onto a prepared base, or it may have a wooden floor. If a plank floor is planned, the upper frame on which it will rest is made of a thick-walled profile pipe with a cross-section of 60*60 mm or 60*40 mm or a corner with a wall thickness of 4-5 mm or more. The floor joists are attached to the frame. They can also be metal, or they can be wooden.

In a small metal shed you can make a floor without joists. To do this, the binding can be made from a corner with a thickness of about 4-6 mm and a side of at least 10 cm. The shelf of the corner can be used as a support for the boards. Only the board must be at least 40 mm thick. For large spans, additional support may be needed. It can be made from a profile pipe of the appropriate section.

Metal shed with wood floor

A prefabricated/collapsible metal shed consists of separately welded wall frames that are bolted together. The sheathing is most often corrugated sheets, which can be quickly installed and removed. The roof is made of the same material. You can install such a structure at your dacha in a couple of hours, just as you can dismantle it. They are placed in unguarded dachas for the season, and then either hidden under lock and key or taken away to winter quarters.

There is another option for a prefabricated shed (they are also called a “house block”) - for those who do not want to bother with manufacturing. The industry produces ready-made kits that are assembled like a construction kit. There are Chinese-made options, and there are domestic ones. The price difference is not catastrophic 20-30%. And choose what you trust more. The assembly of one of the Russian collapsible iron sheds is shown in the video.

2300 rub. /stage

Two straight stringers

2800 rub. /stage

Ridge stringer

2400 rub. /stage

Two ridge stringers

3150 rub. /stage

Sheet metal stringers

2800 rub. /stage

For pouring concrete

3150 rub. /stage

Fire escape stairs

3500 rub. /stage

Work execution algorithm

- First, decide on the appearance of your metal and wood staircase.

Will you sheathe only the steps or completely all the elements, including risers and side parts.

Then the instructions and algorithm of actions are somewhat different.

- Drill through the trim and backing to a hole in the metal.

- Next, use a wood drill the size of a screw head and then widen the finished hole in order to recess the screw head. Subsequently, this recess is closed with special wooden furniture plugs and sanded. Self-tapping screws, when fastening from above, are taken on metal.

- The next step is to attach the trim to the vertical opening between the steps. We attach it by analogy with the main overlay, the only thing is that we do not install a backing.

- Next, we begin work with the balustrade. A staircase made of metal and wood without railings not only loses in design, but is also dangerous. Since railings come in different sizes, initially choose one that is comfortable for you.

The method described above is convenient, reliable, but not always practical. It is well suited for wide flights of stairs, but if the stairs are already narrow, and even the railings eat up to 100-150 mm, it will be extremely uncomfortable to walk.

In this case, with narrow stairs, the fence is attached to the side, at the end of the stairs, with anchors. The posts are fastened with two anchors, and a holder is attached under the balusters with one anchor, and the baluster is mounted into it.

- The main work is done, all that remains is to sew up the side of the stairs. When you have done all of the above with your own hands, it will not be difficult for you to secure the side panel, since everything is similar here.

- A metal staircase covered with wood will be unfinished if you do not cover the back side. No matter how carefully you try to do it, an uncovered back side will ruin the look. There are several methods; you can cover it with plasterboard or chipboard; some people like lining. If possible, you can simply install a built-in wardrobe under the stairs.

Rear side lining.

I would also like to say something about wood processing. The fact is that it is better to round off all sharp corners on wooden parts, and the main rounding work should be carried out even before installing the parts. After installation, you will slightly correct it with sandpaper and the staircase will take on a finished look.

Upon completion of all installation work, it should be stained to improve the appearance of the wood texture and opened with several layers of varnish.

How to avoid mistakes?

To avoid miscalculations, when designing a structure, you need to exercise maximum care. If possible, it is better to entrust such work to experienced professionals.

It is necessary to pay special attention to several points

- It is recommended to avoid skimping on the main elements of the staircase, otherwise it may not be as durable as you expected.

- Using glass stairs for wooden houses is an option that is not suitable in all cases. You need to focus on a specific situation, the overall design of the room. Such designs are better suited for buildings made of brick and concrete.

- The strength of a glass staircase will directly depend on how many holes there are in the structural elements. There should be as few of them as possible. You can reduce the number of holes using glue.

Covering the staircase metal frame with wood

Metal stairs are strong, durable, and the frame is produced quickly enough. Wooden finishing gives the structure an aesthetic appearance, making it more pleasant and safer to move around. The cladding can be done in different ways - by attaching tread dies to metal steps or completely covering the metal frame with elements, simulating bowstrings, installing pillars and fences. In the second case, the staircase will become more impressive and more pleasant to look at. The cladding can be done using DIY tools.

Installation of steps

Having chosen the tree and calculated the layout of the steps, you need to think in advance about what the finish will be. The treads can be treated with mastic to make them non-slip, covered with varnish or wax, but it is not recommended to use oil paints. After this, the elements need to be adjusted to the size of the frame, cut out and numbered. To prevent chips from appearing at the corners of the treads, they can be rounded.

Risers can be made from inexpensive pine or other softwood. For treads it is recommended to use hard wood - beech, hornbeam, oak, non-slip teak. Next, the steps are secured with a screwdriver, the risers are firmly pressed into the frame, fixing them.

Installation of fences

Before installing the fence, it is necessary to make its design and calculation. The height, pitch of the balusters, width of the railings, as well as the appearance of the elements are determined in advance. Having selected a suitable stair railing design, you must:

- calculate the location of the staircase balusters (the gap between them is usually 9-22 cm) and the cross-section/width of the railings that is comfortable for the owners;

- install each of the balusters along the edge of the step and check whether it is placed vertically;

- fix the balusters on the studs;

- Place the railings on top of the balusters and secure them.

Finishing the back of the stairs and lining the frame

After installing the stair railings, you can cover the rear part of the structure, close the side parts and completely cover the frame. First, wooden panels are cut out according to the shape of the steps and fixed to the side. After covering the risers and treads, the back part of the staircases is decorated (you can also cover them with plasterboard). After finishing the work, you can cover the wood with a finishing material (varnish, paint, wax) and be sure to let it dry.

Existing standards

A rich assortment today allows us to implement any, even the most daring projects, but in the pursuit of beauty we must not forget that railings must first of all ensure safety and reduce the risk of injury. Compliance with norms and standards helps achieve this.

In order to make it comfortable to go up and down the stairs, you need to choose the optimal height of the railings. This can be done experimentally: an adult should, going down the stairs, extend his arm in front of him. His assistant, armed with a tape measure, must measure the distance from his hand to the step located under it.

The optimal height of the stair railing is 90 cmSource devynoh.sadunibo.ru.net

When manufacturing standard structures, handrails are installed at a height of 90 cm from the flight span. If there are small children in the house, you can install two handrails: one for adults with a height of 90 to 110 cm, the other for children with a height of 50 cm.

The distance between the balusters in any type of design should not exceed 50 cm. And if there is a small child in the house, then for safety reasons the distance between the balusters should be 15 cm. This will eliminate the risk of the baby falling out of the flight of stairs.

Double handrails: for adults and for childrenSource vseolestnicah.ru

The number of balusters is adjusted by the weight of the handrail. There should be exactly as many of them as needed to eliminate the sagging of the supporting element. In the classic design, one baluster is attached to each step. There are unusual railings with several balusters attached to each step. It always looks impressive, but such a technique is justified only when with its help the execution of a specific stylistic concept is formed. If the width of the stairs is more than a meter, you need to install fences on both sides.

Fencing on both sides of the staircaseSource huxatem.mebocap.ru.net

Frame features

Full covering of a metal staircase with wood

Covering a metal staircase with wood is one of the most common options for improving the appearance. The design of the product without additional decorative elements looks sloppy and is also unsafe to use. A frame covered with natural material will bring coziness to your home. It looks stylish and attractive.

There are two ways to make cladding:

- partially - the decor is applied to the structure only in individual elements; most often, the material is used to cover those fragments that are subjected to increased loads on a daily basis;

- completely - this method allows you to visually create the impression that the staircase is made of wood.

About the stages of finishing the stairs

If you decide to finish the staircase yourself, remember that non-standard home layout, poorly prepared surfaces for work and even minimal errors in calculations can cost you stress and extra expenses. Finishing staircase structures with wood can hide many errors, align the steps in size, and give it an attractive appearance. Trust the professionals at Lesenka! We work on a turnkey basis because we have qualified craftsmen and designers, modern equipment, and high-quality materials. Processing an order includes several stages:

- Customer choice of design, color, configuration of finishing materials and decorative elements;

- Taking measurements, drawing up a project and a contract;

- Production of templates, blanks for steps, fences and decorative elements;

- Cleaning and priming the surface of the structure;

- Installation of facing materials.

- Installation of fencing: support posts, balusters, handrails

Features of combining the product

In the process of creating a wooden finish on a metal structure, a person will have to use not only his skills and knowledge, but also show highly artistic taste. It is this method of solving the problem that is considered the best option for ensuring that the staircase fits into the interior of the room. This is due to the fact that this particular material, in addition to strength, has another advantage, namely flexibility during processing.

Thus, the master will have the opportunity to give the structure almost any desired shape. Also, do not forget that by finishing a metal staircase with wood, the problem associated with an increased risk of injury will be solved.

The covering itself can be either partial or complete. Depending on the decision made by the master, the base for the steps will be fixed either to crocuses or to bowstrings. Regarding the features that characterize the differences of this design, they will be as follows:

- Prices for combined models will be higher when compared with products made exclusively from wood.

- Strength. Usually achieved not only through the use of a metal frame, but also through the correct use of wood. To do this, the structure is finished with thin boards in order to reduce pressure on the main part.

- Each wooden element can be easily replaced with a new one. If another owner moves into the house and does not like this design, he will be able to change its appearance using a different type of wood.

- To get rid of the creaking of boards when a person moves, they must be positioned in such a way that there is no contact between the products. And each board must be placed on a rigid support.

- Installation quality. As for the metal frame, it is better to approve it during the main repair process. And in the future it is better to carry out finishing after all the rough work has been completed. In this case, the master will have the opportunity to manage each process much more flexibly, changing and correcting even the most minor errors.

In this video you will learn more about finishing the stairs:

Advantages of combined structures

- Stairs with a metal frame have excellent performance.

- They are distinguished by an increased service life, compared to all-wood structures.

- The weight of structures, thanks to wood cladding, is significantly less than that of purely metal or concrete stairs.

- Iron or steel gives structures an increased level of strength and wear resistance. Wooden steps – comfort and safety of movement.

- The base material used is strong but lightweight metal grades that have increased corrosion resistance.

Stairs on a metal frame: theory and practice

- Based on the project and your preferences, covering the frame with wood can be partial or complete.

Advantages and disadvantages of drywall

Finishing craftsmen most often use plasterboard sheets. This is explained by the fact that drywall is easy to use and has a number of advantages over other finishing materials:

- Strength

- Easy to process

- Environmentally friendly material

- The ability to create the most unusual designs

- Length of service life

- Ease of surface treatment - painting, stucco molding, wallpapering, applying decorative plaster

Also a significant advantage is the cost, which is lower than that of wood.

The disadvantage is the fact that without a plywood or metal frame, drywall will soon become deformed, bend, cracks and dents will appear.

Assembling the frame is not difficult, but requires attention. To install the frame structure you need:

How to sheathe a metal frame step by step

To decorate an installed frame with wood yourself, you need tools and consumables:

- screwdriver;

- level, ruler, square;

- saw for cutting lumber;

- chisel or feather drill for marking and cutting grooves;

- glue, primer;

- screws, dowels, bolts;

- finishing coating.

What we do step by step

:

- We prepare the parts with which we will cover the frame - we take measurements, markings, cutting steps, railings, balusters.

- Let's prepare the base. We clean the steel from dust and dirt, and the iron surface from rust, treat the metal with leveling mastics and protective coatings. We are waiting for it to dry completely. We drill holes in the frame for fastening the elements and side trim.

- Wood paneling of the stairs. We lay the steps, securing them with self-tapping screws (if there are risers, it is better to start facing them and then install the treads). We mark the places for the balusters, align the posts so that the upper edge forms a line parallel to the flight, and fasten them to the steps. We lay the handrail on top, attach it with glue and fasteners. If the iron frame needs to be closed, start sheathing it from the sides. Measure the board according to the height of the stringer, cutting out the grooves for the steps. Secure it to the frame with screws at least 60 mm long, every 30 cm. Then lay the steps, starting from the top, leveling them.

- We cover the surface of the paintwork at least 2 times, applying each layer in stages, after the previous one has dried.

To prevent the steps from creaking, attach them to the frame on a plywood backing.

The greater the weight of the wooden cladding, the less noise the staircase makes.

Screw self-tapping screws with a 5 mm recess into the wooden surface. Seal the holes with mastic to match the color of the wood.