Omsa socks set

349 ₽ More details

Omsa socks set

349 ₽ More details

Three-pole circuit breakers

The roof ladder should provide easy ascent for carrying out various types of preventive and repair roofing work. This is the main functional task of all types and types of stairs.

Reliability and strength of the structure, safety in operation, compliance with the architectural appearance of the building are important components in the design and manufacture of stairs of any kind and type.

Why do you need a ladder on the roof?

Sometimes the developer approaches the issue of installing a staircase structure as an optional additional expense.

The roof ladder has a number of useful functions

The reasoning in such cases is serious:

- the roof is made of high quality, the roofing materials are expensive and durable;

- joints and matings are made correctly and with a large margin of reliability;

- additional elements for fastening the stairs may damage the roofing.

But, at first glance, a completely logical justification for the uselessness or extremely rare demand for a staircase on the roof of a house is refuted in practice.

Saving on the installation of auxiliary roofing structures leads to significant losses over time.

In this video you will learn how to make a ladder for the roof:

Superstructure

For maximum protection of the exit, as well as to increase its functionality, the hatch can be supplemented with a special small add-on. In this case, a person climbs the ladder through the hatch into the superstructure, while remaining inside the building. Then the door to the roof opens. This option is especially convenient on roofs that are in use, since it allows you not to close the manhole cover every time.

In some projects, the superstructure is conceived as another mini-floor. They go up into it via an ordinary staircase, like, for example, into an attic, and from there through an ordinary front door they go out to the roof. This design solution complicates the structure of the building, but makes access to the roof very convenient and absolutely safe. If the house is built without a mini-floor, it is very difficult to complete it, as this will require a complete reconstruction of the roof.

Exit to the roof through the superstructureSource houzz.com

Carrying out regular preventive examinations

It is carried out with the aim of visually identifying and preventing emerging prerequisites for roof leaks, such as:

- corrosion of fastenings;

- partial separation or peeling of roof coverings as a result of exposure to the elements;

- the appearance of dirt and accumulation of fallen leaves in places where the structure breaks;

- the formation of ice that does not melt for a long time, changing the direction of water flow;

- clogging of the drainage system;

- loosening of fastenings of skate elements;

- violation of draft in the exhaust devices of stoves, fireplaces and other thermal equipment

To ensure the normal functioning of all systems of the house, a roofing ladder is necessary.

Carrying out repairs and additional work

Even with a perfectly executed roof, an emergency situation may arise when leaks need to be sealed or individual roofing elements need to be replaced. Often this situation requires a quick response. A timely made staircase for the roof or a correctly installed staircase structure of the house in emergency situations will avoid significant costs and troubles.

Often, to improve the comfort and safety of a home, it becomes necessary to install, replace or repair additional structures and devices located on the roof. These include

- antennas and similar devices;

- security cameras and control devices;

- lightning rods;

- lightning protection devices;

- chimneys and pipe elements;

- devices such as a weather vane or flagpole.

To perform work with such elements, sometimes a high portable stepladder (for climbing) and a ridge ladder (for work on the roof surface) are sufficient.

Types of staircase structures

Stair lifting structures can be:

- Wall, wall: necessary for ascent and descent.

- Pitched – used for roofing work.

- Emergency ones have a purpose corresponding to their name; they are required for structures with windows located above 3.5 m.

The main requirements for products: low weight and high strength parameters.

They are produced by industry in a wide range, a wide variety of models and various combinations of materials used for production.

An inexpensive solution for many roofing systems can be a self-made or purchased wooden structure.

For metal roofing

Wood products do not harmonize with metal roofing.

Light and durable aluminum marches are most often installed on such roofs. For reliability, they are fastened to the roof at the bottom of the metal wave. Companies that sell metal tiles offer ready-made staircases with identical colors.

It is necessary to purchase roofing ladders for metal tiles that are sized or longer. The excess part is cut off with a hacksaw.

It is not allowed to cut a painted structure with a grinder due to damage to the paint layer and subsequent corrosion.

For each type of roof, you can choose the appropriate staircase

Installing auxiliary options

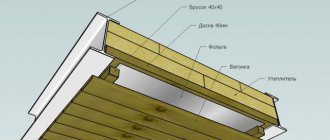

Before asking the question “how to lay metal tiles on a roof,” you need to pay attention to what is under it or in symbiosis. First of all, this concerns the installation of hydro- and vapor barriers, as well as the installation of sheathing under the roof.

The waterproofing system is placed between the rafters and the counter-lattice. Its main purpose is to prevent moisture from the outside from entering the inner roofing part.

The vapor barrier system is placed under the rafters (at the very bottom of the roofing part). Its main purpose is to prevent moisture that may form inside the room from entering the inner layers of the roof.

The sheathing is located directly under the metal shingles. Its task is to create a rigid frame that will support the roof. The sheathing is made from wooden beams and edged boards.

Security

Any roof ladder, whether manufactured in a factory or independently, must comply with safety regulations and standards. For example, GOST determines that roofing ladders must be manufactured on the basis of the following standards that guarantee the safe operation of the products:

- the location of the bottom step of the stairs cannot be higher than 1 m from the ground level;

- the highest point of the march must be fixed using special reinforced fastening elements;

- the distance from the wall should be no more than 130 cm and no less than 20 cm;

- the flight of stairs should be located near the window in accessible proximity.

Ladder structures are classified as products of increased danger during operation, therefore each line of regulations determines their maximum safe use.

It is especially worth highlighting the special fire standards:

- withstand load for steps – 180 kg;

- structures must be coated with anti-corrosion compounds;

- the use of toxic chemical materials in coatings is prohibited;

- the steps should not retain snow and water;

- If the height of the product is 6 m or more, the march fencing is required.

Necessary calculations

Today, hardware stores offer a wide selection of roofing ladders.

In most cases, these are modules with the necessary set of accessories for assembly and subsequent fastening. You can purchase a ready-made design or make it yourself.

In both cases, careful calculations are required.

- First of all, you should identify those objects to which you will need to provide access via stairs.

- You need to measure the length of the slope from the overhang to the highest access point. After this, calculate the number of modules required for further installation of the stairs. If the dimensions of the modules are not suitable, you can trim them.

- It is also necessary to calculate the number of brackets required for fastening. With a module length of 1.8 meters, 4 pieces are required. If the length is 3 meters, you need to stock up on 6 brackets.

- To determine the number of stair steps required, you need to calculate the anti-slip coatings: that is how many steps will need to be installed.

When calculating for a façade type of staircase, a slightly different algorithm is used.

- First of all, you should measure the distance from the roof eaves to the ground surface. After this, the required length of the ladder is calculated, taking into account that it should be installed at a distance of one meter from the ground.

- Then they calculate how many brackets and modules will be needed.

Self-fabrication of a prefabricated structure

Working on a roof without a mobile ladder is not only difficult, but also dangerous: a flight of stairs can damage the roofing material when performing repair work.

The solution to the question of how to properly make a reliable roof ladder is based only on indicators of their convenience and safety:

- the crossbars are made of timber - it is much more comfortable to stand on them than on boards;

- An excessively frequent arrangement of steps interferes with work and adds additional weight to the march;

- the steps should be fastened with nails, bending them and recessing them on the other side - this is much more reliable than using screws;

- An increase in the hook in the structure helps to increase the reliability of fixing the march, and therefore safety for the performer of the work.

As a size guide, you can use any similar factory-made product.

How to make a simple ladder for safe work on the roof

It’s easy to make a flight of stairs for working on the roof yourself if you follow the listed descriptions and recommendations:

- the design consists of two strings and rungs;

- for bowstrings, timber measuring 50×70 mm is used;

- for the crossbars on the bowstrings mounted on the edge, cuts are made for the steps along their width;

- steps are also made of timber 30-50 mm thick;

- the distance between two parallel strings is chosen arbitrarily, convenient for the user;

- it must be a multiple of the wave in cases where the roofing is made of corrugated material;

- steps in the required quantity are cut into pieces equal to the distance between the outer edges of the bowstrings;

- the steps are launched into the prepared cuts flush with the outside of the bowstrings and nailed to them;

- three nails should be driven in from each edge of the step;

- It is not recommended to use screws, since they break under the stress of breaking and do not bend like nails;

- to hook the march to the ridge of the roof, a hook is made from thick boards, which are sewn with nails 150-200 mm long to the march at the angle of the roof;

- the hook must be at least 30 cm long;

- the angle must first be measured using a protractor;

- to facilitate the work of fastening the hook and the march, you can make a corner template from scraps of boards;

- if the hook is not enough to securely fasten the march on the ridge, then a counterweight board is attached to it on the back side of the ramp.

There are many recommendations for ladders on the roof.

A ladder for performing various repairs after they have been completed can remain at the top if it does not worsen the appearance of the structure.

Otherwise, it can be removed, and the best place to store it may be the end wall of the building. A hook is placed in a convenient place on the wall, and the product is hung until it is used again.

About materials

If you have skills in handling metal elements, it makes sense to think about a ladder made from them. This design has many advantages, since it has

- strength;

- elegant appearance;

- durability;

- ease of maintenance.

But at the same time, the construction of the structure will require rather complex tools and certain work experience. Therefore, we recommend turning your attention to wooden stairs. They are easy to install, allow you to perform almost any task related to roofing work, are easy to carry (which is important) and are quite durable if the wooden elements are made from softwood, and even impregnated with antiseptics.

Materials you will need:

- a wooden beam with a cross-section of 4x4 cm, taken in the required quantity and treated with fire retardant and antiseptics;

- boards 25 mm thick and 60 mm wide. The length and number of elements are calculated depending on the size of the slope;

- nails, preferably stainless steel, 100 mm long.

The tools are limited to a saw (for cutting material into blanks), a tape measure and a hammer.

Satellite dishes are now not uncommon, and they are installed on the roof of private houses. A staircase built on the roof not only protects you and your loved ones from accidents, but also serves as a convenience and protects the roof of the house from damage. Walking on the top of the house and improperly handling tools can cause the ceiling to cave in. After all, a rotten or damaged roof causes leaks during rainy periods and melting snow.