Plinth finishing became widespread throughout the world in the 20th century. And if previously plinth panels performed an exclusively protective function - protecting the plinth and foundation from the adverse effects of the external environment - today the aesthetic component of the building becomes important. First of all, attention is focused on the base: it brings a characteristic charm to the appearance of the entire building and gives an idea of the inhabitants of the house and their taste preferences.

Finishing materials that combine style and high protective characteristics are in high demand. To choose a truly high-quality material that can simultaneously decorate the base and protect it, you should study in detail the types of cladding siding, its advantages and disadvantages.

- What is brick basement siding?

- What types does it come in?

- Which is better?

- How much does it cost to cover a plinth with brick panels: prices for material and cost of work

- How to install basement siding under a brick with your own hands: installation procedure

- Why do you need a base belt / flashing?

- Basement brick siding: reviews from real people

- Where to buy from the manufacturer?

What is brick basement siding?

Basement (foundation) brick siding is a cladding panel that protects the base of the house from the aggressive influence of the outside world: from weather conditions (rain, wind, sunlight, sudden temperature changes), corrosion, termites, mechanical damage. In addition, plinth panels are an excellent decoration option: various colors and relief surfaces will give the appearance of the building completeness and expressiveness.

Dimensions

The dimensions of basement brick siding depend on the material of the product. The most common panel dimensions are:

- vinyl and acrylic – 800x590x21, 1127x461x19, 1130x468x17 mm;

- metal – 1000x420, 3000x330x0.5 mm;

- concrete – 690x280x30, 580x375x35, 750x280x40 mm.

The average length of siding ranges from 1-3 meters or more.

It is advisable to select the dimensions of the concrete panels according to the height of the stone so that it is a multiple of the height of the base. For example, the height of the plinth is 900 mm. To reduce undercutting, select tiles 300 mm wide (for example, Big Sandstone 600x300 mm).

When facing complex surfaces with height differences, it is best to use panels of small dimensions. To calculate the number of products, it is necessary to measure the length and height of the base and, in accordance with this, select the tile of the required size. For example, with a plinth height of 0.9 m and a length of 6 m, a Big Sandstone panel with dimensions of 600x300 mm is suitable. Siding installation is carried out in 3 rows. One row will require 10 pieces. tiles We multiply the resulting number by the number of rows: 10*3=30 pcs. (5.4 sq.m.) – required number of concrete panels per side. The total volume of the tiles is calculated for all 4 sides of the house: 5.4 * 4 = 21.6 sq.m.

Photos of clad houses

Using the example of several photographs, we will consider options for facing with brick siding.

Application

Covering a house with brick imitation siding is done outside in most situations, but it is also possible to use such elements inside the building. Material application options:

- Cladding the general surface of the sides, the basement, and columns of the veranda during the construction of a large house. The most preferred colors are brown and white. They can be combined with plastered and painted walls.

- Covering a barbecue or fireplace in the house. Then fiber cement panels are used, since there is direct fire.

- For finishing gazebos, pavilions, and outbuildings.

For decorative purposes, you can use panels of different colors. The base is made in dark colors, and the rest is in light colors.

What types does it come in?

There are many types of materials for creating brick plinth panels: concrete, metal, polymers (vinyl, acrylic), stone chips, etc. In addition, the external texture of each material is divided into a large number of variations. Let's look at the most common examples of plinth panels.

Acrylic

Acrylic siding is a polymer material. Its main advantage over other types of plastic cladding is the wide variety of colors that are resistant to the negative effects of ultraviolet radiation. In addition, acrylic panels protect the base and foundation from the penetration of moisture, rot and chemicals. A significant drawback is the cost of base acrylic panels - they are much more expensive than all other materials. In addition, acrylic has low impact resistance and high fragility.

Vinyl

Vinyl siding is made from a mixture of PVC and acrylic plastic. It perfectly protects the basement of the house from adverse environmental influences: high humidity, ultraviolet rays. PVC panels are inexpensive, but have several significant disadvantages. These include the material's tendency to become brittle and its increased response to temperature changes. With the first drawback, the service life of PVC panels is short-lived, since any mechanical impact on the base will cause its covering to become covered with scratches or even cracks. With the second deficiency (in the event of a fire), the vinyl siding will begin to melt and release toxic substances that are dangerous to human and animal life.

Metal

Metal cladding panels are made of aluminum. They are not as common as other cladding materials due to their high cost. Among the advantages: metal siding looks impressive on the base. In addition to its characteristic shine, it perfectly copes with protective functions: it protects the foundation from the destructive effects of moisture, snow, and frost. In addition, it is not subject to physical damage and retains its strength characteristics for many years. But the rationality of its widespread use is questionable: it is difficult to install. If installed incorrectly, metal siding creates thunderous noise in strong winds and rain. In addition, metal siding has a limited series of textures. Basically, these are options that imitate boards rather than brick.

Concrete

Concrete is considered a universal material for the manufacture of basement siding. With their high performance characteristics and relatively inexpensive cost, brick-like facing concrete panels are in demand on the sales market.

The main advantages of concrete panels:

- high strength characteristics;

- corrosion resistance;

- resistance to mechanical stress and abrasion;

- moisture resistance;

- resistance to chemically aggressive substances, mold and insects;

- fire resistance;

- frost resistance;

- low cost;

- resistance to ultraviolet rays;

- environmental friendliness.

Brick-like concrete siding panels are distinguished by high-quality protection of the foundation from the aggressive influence of the external environment. In addition, they are distinguished by an enviable variety of shapes, textures and colors. Colorful brick panels such as “shagreen”, “besser” or other textured products that imitate stone will give the house a characteristic charm and charm in style.

Fiber-reinforced concrete siding is often reinforced to increase its resistance to mechanical damage. The service life of concrete is at least 50 years, and its components do not harm the environment.

You can watch a video about the types of concrete plinth panels from the YouTube channel of the LOBAS company here.

How is the fastening done?

- Siding is fastened from bottom to top. The lower part of the panel has a lock - a longitudinal profile designed to attach and secure the lower edge either to the starting strip or to the bottom row panel.

- The upper edge is equipped with a nail strip - a flat strip with a row of oblong holes into which self-tapping screws are screwed. The sides of the panels correspond to each other or to special corner additional elements, also designed in the form of brickwork.

- In the set, the entire surface completely replicates the appearance of a brick wall; joints and joints are completely invisible. If you need to use panels of several colors, no problems arise, since the material is completely interchangeable and allows you to combine several color options for greater expressiveness.

Which is better?

In order to decide on the choice of material, it is necessary to carefully study the advantages and disadvantages of the product, evaluate the number of textures and the range of colors presented. Facing siding must be resistant to physical wear, moisture, sudden temperature changes and ultraviolet radiation. The list of desired qualities should also include mechanical abrasion, fire resistance, and immunity to chemically aggressive components, rot, and insects. Only some of the listed plinth cladding materials have all these characteristics, and concrete is considered the most advantageous of them. Fiber-reinforced concrete panels have all the declared quality characteristics. In addition, they are easy to manufacture and install and are distinguished by an enviable variety of shapes and textures. A wide color spectrum allows you to color the desired product to suit your taste, and the coloring pigment (due to its addition during the manufacturing process of the panel) maintains color fastness for many years.

Concrete siding is not as expensive as acrylic, and its obvious advantages are highly valued in the construction industry. The service life of basement concrete panels, while maintaining their original technological characteristics, will easily exceed 50 years of service.

Tips for decorative facade finishing

In order not to overpay for extra slabs, and not to buy missing ones, you should correctly calculate the required number of sheets. When purchasing blocks, ask the seller for a certificate - you cannot trust dubious companies.

Decorating a house is an expensive task and involves long-term use of materials. It is important that it is of good quality.

On a note! Any type of siding can be installed not only on the entire wall, but also on individual fragments: areas under the roof, corners, windows, and along the perimeter. It is possible to combine several types of panels.

A combination of the same type of panels, but in different colors, looks good - this will preserve heat and sound insulation and give the house an elegant look. Such a house will not only become more comfortable to live in, but will also acquire a new, original design.

A combination of several types of finishes (expensive and cheap siding) will help save money.

A plastered house with siding located in the basement of the same shade looks beautiful.

Designers do not recommend combining brick finishes with wooden materials. Such a building will have an unsightly appearance.

The use of slabs imitating brick is not limited only to residential buildings. They can be installed on gazebos, outbuildings, and finish the foundation of permanent fences.

When choosing the type of sheets, you should take into account the operating conditions: humidity, the possibility of mechanical damage, temperature changes.

How much does it cost to cover a plinth with brick-like panels: prices for material and cost of work?

The cost of lining the basement with brick siding depends on several factors:

- difficulties in installing panels;

- material of manufacture;

- transportation distance;

- complexity of the front surface ornament.

The cheapest material is PVC plastic. In Moscow, its cost varies from 700 to 1000 rubles. per sq.m., since it is easy to install, but has a small set of required performance characteristics. The most expensive material is acrylic. Its price range in Moscow varies from 1000 to 1500 rubles per sq.m. It has all the necessary characteristics in terms of strength and durability, but the manufacturing process is quite labor-intensive.

In Nizhny Novgorod, prices for plinth panels are not much different from Moscow. PVC plastic is also considered the cheapest here: it is purchased at a price of 880 rubles/sq.m. due to the practicality and simplicity of the device. The most expensive is basement siding, made of polypropylene foam. Its price is about 1,300 rubles/sq.m., since the manufacturing and installation technology is quite complex.

Prices for cladding panels in Moscow do not differ significantly from the cost of the same panels in Nizhny Novgorod, but the Moscow price tag is designed for large wholesale orders. The price per unit of the product will be much more expensive than originally stated. In addition, the final cost of the order usually does not include delivery, which also increases the customer’s costs.

In Nizhny Novgorod, the cost of delivery to other regions will be significantly lower than in Moscow. In addition, self-pickup of finished products to the construction site is always possible.

The products of the Nizhny Novgorod company LOBAS are in steady demand not only in the region, but also beyond its borders. Concrete plinth panels are made of high-strength reinforced concrete. They are relatively inexpensive, and the quality of the product and the variety of its textures and coloring options will pleasantly surprise you. There you can also purchase materials for cladding the entire facade.

Preparing the sheathing

To install the panels, a support system is required, since the material cannot be attached directly to the wall. Firstly, it is necessary to provide a ventilation gap, and secondly, the presence of insulation on the walls will not allow installing siding directly on their surface.

Wooden or metal strips are used to create a supporting system that provides ventilation and can hold the material.

Requirements for them:

- Straight, without curvature, lines;

- The thickness of the planks must correspond to the thickness of the insulation (this especially applies to wooden parts);

- The pitch of the planks (the distance between the rows) should ensure the strength and reliability of the installation of the panels.

When choosing a material, you should take into account all the features and properties of wood and metal.

Experts recommend using metal guides for gypsum boards; they have a straight surface, are securely attached to the walls and can be reconfigured many times (if errors are detected), which is much more difficult for wooden planks.

At the same time, the thermal conductivity of the metal should be taken into account and it should be insulated so as not to form cold bridges with the inevitable appearance of condensation.

Installation of the load-bearing sheathing is carried out in the direction perpendicular to the location of the panels. If a double layer is used - the main one and the counter-lattice, then the first is installed in the direction of installation of the panels, then the counter-lattice is installed in a perpendicular orientation.

How to install basement siding under a brick with your own hands: installation procedure

Do-it-yourself installation of siding panels under the plinth occurs in stages:

- preparing the base surface;

- installation of facade siding using glue or lathing;

- final processing of mounted cladding slabs (grouting of joints).

We will consider the process of preparatory and installation work in more detail.

How to attach facade panels to a plinth?

Before installation work, you must prepare the following materials and tools:

- wooden beam or metal profile, if the method of installation on the lathing is chosen;

- starting and finishing strips for more precise installation of panels;

- corner elements for hiding the joining seams of siding panels;

- fastening elements (screws, dowel-nails, etc.) for connecting the siding to the base frame;

- grinder for cutting concrete panels to the required dimensions;

- perforator;

- building level;

- roulette;

- primer solution;

- primer brush;

- putty knife;

- adhesive solution or adhesive foam when installing on a reinforcing mesh.

Preparatory work:

- inspect the surface of the base for cracks and chips; If possible, eliminate unevenness with plaster or putty;

- after a while, cover the plastered surface with several layers of primer for better adhesion to the facing panels;

- if desired, the base is additionally sheathed with insulation;

- calculate the number of panels (multiply the length of the plinth by the height, and divide the resulting value by the area of the slab).

Next, the base panels are installed. It is carried out in two ways: with glue and with lathing.

On glue

Thermal panels are best suited for lining the base with adhesive foam. Before starting installation, it is recommended to clean the surface from dirt and dust with a brush.

The production technology is as follows.

- The first thing you need to do is select the glue. It is selected of a certain brand, depending on the cladding material and climatic conditions of the area, in order to subsequently avoid distortion or warping of the panels due to sudden temperature changes.

- Apply foam adhesive with a spatula to the inside of the plinth panel and glue it to the prepared surface of the plinth. The thickness of the glue should be approximately 2 cm. If necessary, glue a reinforcing mesh to the surface of the base for greater stability of the frame.

- It is best to install siding starting with the corner elements. To avoid sliding of the plate when attaching it to the base using a drill and self-tapping screws, it is necessary to pre-drill holes in the panel. Then the tile will not slip during installation.

- The gaps between the panels should be foamed. After hardening, excess adhesive foam must be removed with a hacksaw.

- It is not allowed to apply foam adhesive to the entire surface of the siding tiles to avoid deformation of the structure.

- The joints between the panels are grouted with a spatula.

On the sheathing

Let's consider the option of installing facing siding on the sheathing.

- On the cleaned surface of the base, a metal or wooden profile with a pitch of 500-600 mm and a starting strip are mounted using self-tapping screws. The level determines the accuracy of the frame position.

- The siding is cut with a grinder to the required size. Next, the base panels and the finishing strip are installed one by one on the finished frame using dowels. Siding is installed from left to right and from bottom to top.

It is necessary to ensure that the joints of the panels match and the seams create the correct pattern.

How to arrange the corners?

When using plastic materials (acrylic, vinyl, polystyrene foam, etc.), the corners of the base are formed first. The corner elements of the siding are attached to them using self-tapping screws. They are often made in a different color and texture from the main type of panels.

Finishing corners with concrete siding is done end-to-end or overlapping. In the first option, the sheathing of the corner panels should be flush with the main plinth panels. In the second option, the corner panels are mounted 20-30 mm higher than the base panels and overlap them.

It is important to install corner elements, directing the cut edge towards the wall, not the corner. This way the cladding will look more neat and will more reliably protect the edge of the base from the negative influence of precipitation, mechanical damage and corrosion.

Finishing the base with brick siding: video

The technology and process of cladding the basement of a house with concrete siding are shown in the following videos.

Summing up

The market for construction and finishing materials provides many varieties of siding to suit every taste in a wide range of prices. Budget type products have a rather low aesthetic value. They are recommended to be used exclusively as protection for thermal insulation materials of technical structures. To decorate the facades of residential buildings, it is more advisable to use premium-class siding, which will not only protect building structures and insulation from the negative influence of external factors, but will also become a real decoration of the house.

Save time: selected articles delivered to your inbox every week

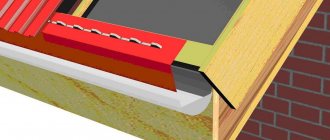

Why do you need a base belt/drip?

The low tide acts as a protective barrier for the building: it creates an additional barrier that prevents rain and snow from falling on the base. Metal, plastic, brick and concrete are used as materials for the manufacture of ebb, depending on what style must be followed to maintain the aesthetic appearance of the structure.

The plinth belts are mounted with a slight slope towards the street - this allows rainwater to drain without touching the plinth.

Advantages and disadvantages of use

Each type of panel imitating brick has its pros and cons. The significant advantages of siding compared to brick are:

- low weight - polymers and metal are several times lighter than ordinary brick, this significantly reduces the load on the walls;

- accessibility - sheets made from synthetic raw materials are much cheaper;

- ease of installation - siding is mounted using special locks;

- easy repair - if the plate is damaged, it can be easily replaced with a new one.

Basement brick siding: reviews from real people

LOBAS brick plinth panels are in demand not only in Nizhny Novgorod, but also in other cities and regions of Russia. We are responsible for product quality and guarantee timely installation.

Below are reviews from our clients:

Ivanov Sergey, Chkalovsk

“I decided to renovate a country house in my village and decided to try concrete tiles as cladding for the basement. I contacted the Lobas company and was pleased with my choice. The “12 bricks” facade siding suited the style of the dacha perfectly. The consultants helped with the choice of tiles and their colors. I am very pleased and will contact you again"

Kurnikov Victor, Nizhny Novgorod

“I would like to express my deep gratitude to the LOBAS company for purchasing brick-like plinth panels for cladding the house. During construction, I thought about what kind of siding would be best to cover the base: plastic or concrete. I read reviews on the Internet and decided to try concrete panels. The LOBAS company not only helped me choose the siding I liked, but also helped me find installers to speed up the work. Now all the neighbors are asking what kind of siding this is and where to buy it. Thank you very much, you have the best products!”

Salnikov Nikolay, Kstovo

“I used shagreen concrete tiles on the advice of a friend. I was pleased with the quality of the products: they really protect the base from rain and snow, are easy to clean, and do not fade in the sun. The price is also reasonable. The managers advised me on all issues competently and suggested which tiles to use in my case (I have a private house). Now I recommend you to everyone"

Production technology

Base siding is produced from polyvinyl chloride, which is diluted with special biochemical reagents and stabilizers. Additives ensure the resistance of the finishing surface to ultraviolet radiation. The composition of the siding ensures its fire safety and resistance to precipitation.

Siding is produced on automatic equipment that has molds. The latter are manufactured using special technology. To create a mold, a base is used - a brick-lined wall. This ensures an accurate imitation of brickwork siding, repeating all chips and unevenness of the stone.

Where to buy from the manufacturer?

The LOBAS company has been manufacturing, supplying and installing concrete products since 2005. Our products are manufactured in accordance with regulatory documents and undergo annual quality checks in independent laboratories.

Concrete has the necessary technological characteristics: it is high-strength, does not undergo abrasion and corrosion, is fire-resistant, can withstand at least 200 freezing and thawing cycles, is waterproof and at the same time environmentally friendly.

Advantages of our concrete tiles:

- has high strength thanks to the reinforcing fiber fiber VSM-12, which is part of the concrete;

- withstands sudden temperature changes;

- does not lose its original properties from the adverse effects of the environment: rain, precipitation, ultraviolet rays;

- It is resistant to fire and chemicals.

Concrete brick plinth panels are made in standard or custom sizes (to order). You can provide sketches from which slabs will be made to your taste, or you can choose a suitable option from the collection presented on the website.

All of our plinth panels are distinguished by a wide variety of shapes and textures: from siding imitating smooth brick to panels imitating artificial stone. The variety of colors and shades of products is just as diverse: from yellow, red, brown to amber or lilac.

If you want to order concrete plinth panels for brick, call 8 (800) 333-16-86. Our managers will be happy to answer all your questions and help you decide on the choice of products. We are ready to advise you at all stages of production: from ordering drawings to shipping finished products. Choose LOBAS products!

From all of the above, it is clear that concrete is the most profitable material for the manufacture of plinth panels, since its performance characteristics are not inferior to either polymer or metal, and its low cost allows you to purchase products in large volumes.

Specifications

The products can be characterized as follows:

- they are not able to change even when used in high-low temperature conditions;

- the material is environmentally friendly and is not subject to the formation and spread of mold;

- can be used in combination with various types of other finishing materials;

- has high levels of protective properties that do not allow the building to collapse from exposure to rain, snow and various negative natural phenomena;

- Products are characterized by color fastness throughout the entire period of operation;

- has a high level of reliability and does not crack or delaminate, regardless of operating conditions.

NOTE!

The standard panel dimensions are 1 x 0.5 m.