The basement of a house is a kind of connecting link between the foundation and the walls. To protect it from external negative influences (precipitation, temperature changes, ultraviolet radiation, mechanical damage), it is necessary to use an appropriate facing material. Concrete panels that imitate stone can not only keep the base in good condition, but also perform a decorative function, giving the exterior of the building a complete look.

- Stone-look façade plinth panels: what is it?

- What types are they?

- Which option should I choose?

- How much does it cost to finish the plinth with stone-look facade panels: price of material and cost of work

- Features of finishing the base with stone panels with your own hands: step-by-step instructions

- Where to buy from the manufacturer?

What is a plinth

The part of the foundation protruding above the ground is called the plinth. Sometimes the base is a separate structure that is mounted between the foundation and the walls. The main function of the plinth is to protect the building from moisture and cold. In order for the base to cope with this task, it must be insulated and waterproofed.

The visible part of the foundation is called the plinth Source mauro-gianvanni.ru

There are three types of bases:

- protruding when the base protrudes beyond the walls;

- in the same plane, when the walls and base are in the same plane;

- sinking when the wall extends beyond the base.

Types of base according to location relative to the wall Source dom-steny.ru

The third option is most common; in this case, water flowing from the walls of the building does not fall on the foundation and the waterproofing layer separating the walls and base does not require additional protection.

A plinth flush with the wall is rarely used. Technically, it does not have certain advantages and disadvantages, but with such a mutual arrangement of the foundation and walls, there is practically no tangible boundary between them. To make the house look beautiful, the distinction is made artificially, using different panels for the facade and plinth.

The use of a protruding plinth most often indicates that the house has a basement. When finishing this type of base, additional drip eliminators (drippers) are installed on top of it, protecting the waterproofing layer between the wall and the foundation from destruction. The drip edge is an angular metal strip that is installed on the protruding part of the base, fitting tightly to the wall.

An example of finishing a protruding foundation Source 90zavod.ru

In turn, the base itself also needs protection from the negative effects of the environment. To perform this function, the foundation is finished with plastic panels and other materials.

Foundation plaster with imitation masonry

Foundation plaster

It is possible to create an imitation of masonry on the basement section of a building, as well as protect the foundation from external environmental influences, not only by using facing materials. An interesting design solution could be plastering the surface. A construction knife or screwdriver will help give the plastic plaster mixture the appearance of stone, and subsequent coating with acrylic dyes will add a realistic resemblance. If necessary, a heat-insulating layer is mounted on the base of the foundation, on top of which a plaster mesh is attached, and then a sand-cement mixture is added. For better adhesion of the mortar to the surface, long nails or fragments of wire are inserted into it. After allowing the mortar to dry slightly, they begin to manually “shape” the masonry. Using a construction knife, screwdriver or any other tool, lines are drawn to imitate seams. Then the drawn lines are deepened by several centimeters.

Important. All work on plastering the foundation must be done with gloves. Cement can damage the integrity of the skin even with short-term contact.

natural textures

The resulting stones are smoothed by hand, giving them a rounded shape. To create a natural texture, you can use special overlays that leave characteristic imprints. Several types of such overlays with different reliefs will allow you to achieve realistic execution. The paint for the stone is chosen based on your own taste and desire and the general exterior. A combination of 3 or 4 shades will add depth of color, relief and volume to the created surface.

Basement siding: advantages and disadvantages

To finish the foundation, there is basement siding; it consists of panels for cladding the basement. The name is conditional, since these same panels can also be used for finishing facades.

Among the advantages should be highlighted:

- a wide range of;

- possibility of finishing facades;

- efficiency;

- quick installation.

There are practically no disadvantages to basement siding. Installation requires high precision and professionalism. Poor siding installation can, over time, lead to panels bending and gaps appearing between them. The integrity of the finish will be compromised and, as a result, the protective function will also be compromised. Therefore, it is better to entrust the installation of panels to experienced craftsmen so that you do not have to spend money on finishing materials again.

Treatment

In order for the base to be beautiful and reliable for many years, it is not enough to simply plaster it. In addition to introducing various additives into the solution, after the base has dried, etching and waterproofing are carried out. Disinfection of the outer layer is achieved by treatment with an acid suspension. They work with a paint roller, sprayer, with the obligatory use of skin and respiratory protection.

We recommend watching a video on how to properly treat a basement floor with a specialized protective solution.

After drying, the solution is washed off with water, the effluent of which must be drained away from the house into prepared depressions in the ground.

Types of plinth finishing

The foundation cladding can be made of natural stone or clinker tiles, vinyl siding, sandwich panels, and corrugated sheets. Almost all types of facade finishing can be transferred to the base.

Stone

One of the expensive materials is stone. The high cost of such finishing is justified by the naturalness of the material, the labor intensity of preparatory (construction of an additional foundation) and main work, and the need to hire highly qualified workers.

If at the design stage of the house the finishing of the base with natural stone is taken into account, then the foundation will be built with the necessary margin of safety and will easily withstand additional masonry. If the project is not designed for additional loads (the finishing of the base is carried out during a major overhaul), then it is necessary to build an additional foundation adjacent to the main one.

In addition, it will take time to select a “stone” design so that the latter turns out beautiful and unique. Well, thanks to this finishing the base will be reliably protected.

Finishing the base with natural stone Source roomester.ru

Clinker tiles

For lovers of brickwork, there is an option to finish the base with clinker tiles. Beauty, combined with the thermal insulation characteristics of the material, gives a first-class look to the base and perfectly insulates the base of the building.

The material, like stone, is very heavy, so when facing the base, it may be necessary to build an additional foundation. Installation also has its own nuances, sometimes unknown to the average installer.

Finishing the foundation with clinker tiles Source remlandia.ru

Corrugated sheet

Profiled sheets (abbreviated as corrugated sheets or corrugated sheets) are widely used in construction as roofing and cladding materials, and are also used as external fencing.

The advantages of the material include low cost, quick installation, convenient sheet size, the ability to choose wave height, and a wide range of colors. Finishing the base with corrugated sheets does not weigh down the building; the material itself has excellent tightness, so it is well suited for cladding the base of country houses and outbuildings.

Lining the foundation with corrugated sheets vertically Source sargorstroy.ru

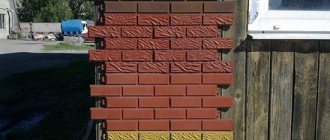

All of the listed types of cladding can be replaced with plinth panels, which, in essence, are the same materials, only previously fixed on a prepared base. This allows you to significantly simplify installation and increase the speed of work.

Plinth panels: types and characteristics

Plinth panels for exterior home decoration are used most often, as they combine the beauty and characteristics of natural materials, but at the same time are much lighter in weight and labor costs during installation. There are four types of panels:

Fiber cement panels

90% consist of cement, the remaining 10% are plastic, cellulose and mineral additives. The front side of the panel is an imitation of wood, stone or brick - it can be covered with stone chips or painted.

Manufacturing companies

The modern market for facing materials is represented by various manufacturing companies. The most famous are:

- "AltaProfile". In terms of quality characteristics, the basement siding of this brand meets all existing standards, and its cost is much lower than its foreign analogues.

- Dock. The company is a leader among manufacturers of basement siding. The brand's products can be found in more than 260 cities around the world. It is distinguished by high quality, practicality and reasonable price.

- "Dolomite". The company uses natural dolomite stone as the basis for its production, hence the company name. All basement siding comes in a wide range of colors. The raw materials for siding production are supplied by a leading European company, which is a guarantee of the quality of the manufactured product.

- "Technical equipment". The company is engaged in the production of plastic products. The brand also specializes in creating basement siding. The brand's work is distinguished by the combination of excellent quality of facade panels and reasonable cost. The emphasis is on the production of siding that imitates stone.

- Nailite. American brand. The main assortment consists of brick and classic panels with imitation stone, which are in greatest demand. The cost is significantly higher than that of competitors.

- The Russian organization "Aelit" is engaged in the production of vinyl basement siding - a high-quality and reliable material that is used for cladding buildings with a stone/brick look.

- Fineber, the largest Russian company, has a large assortment of panels that occupy the average price niche. The brand's products have the best price-quality ratio for consumers.

- Nordside is the largest domestic manufacturer of facade materials. To create siding panels, we use high-quality polymer mixtures from renowned European suppliers. Nordside products are resistant to temperature changes, negative atmospheric conditions and ultraviolet radiation.

Video description

It’s clear about fiber cement panels in the video:

The manufacturer guarantees the preservation of the original characteristics of the panels (high strength, frost resistance, resistance to sudden temperature changes) for at least 20 years. The only disadvantages that can be highlighted are a high level of moisture absorption and low resistance to mechanical stress. The advantages are all of the above characteristics and a wide range, from colors to different surface textures.

Etapi robot on plaster foundation

- all over the entire area of the concrete plinth (nothing is needed at all) using a sharp metal object (a screwdriver) to make notches;

- the surface is verified and primed;

- cracks (seams of masonry) and grooves are wetted with water and filled with cement-stained soil;

- with the help of dowels and staples, the chain-link mesh with a split edge is “adjusted”;

- Beacons are installed. For which steps are placed in the skin foundation and 1.5-2 m between them:

Scheme of different forms of the base.

- For additional hydraulic levels, find out and climb along the ground along the walls and along the smudge. You must walk right up to the foundation, immediately checking it, but not closer than 2-3 cm to the most protruding part.

- At the point of the webbing of the corner (wall) and the smudge, a pin is installed vertically, equal to the height of the plinth.

- The space (gap) between the joint and the foundation is “filled” with a split so that there is a vertical mound, before which heavy rhubarb is applied for its alignment. The vertical suddenly vibrates. There must be a handful of such lighthouses.

- At the pin of the heel beacons, 3 pins are hammered in, between which the lace is stretched. This will serve as a reference point for plastering. There may be 3 lines of laces: at the bottom of the base, at the top and in the middle. Between the cords and beacons there is a gap of 1 mm.

- After the cement hump-beacons dry out, the foundation is sprayed. Wet the surface of the surface with water, then sprinkle creamy cement grit on it with a ladle, trowel, or brush with long bristles. Thickness of the ball - 5-9 mm;

- primer is applied to the dry (not dry) “brush”. Vin is of the same cement grade, but more rare;

- After “flashing” the primer, proceed to the next stage of plaster and apply a paintball. The wine turns out to be thicker and more plastic. Hydroisolating ingredients are added to this warehouse;

- The final steps are to rub the surface to achieve optimal evenness and smoothness. For this purpose, vikorist graters with a fine mesh inserted into them, special concrete graters with a relief surface, and standard polystyrene foam are used. It is important to choose the right moment for grinding: you are guilty of “shopitis”, but the surface is guilty of buty sche dosit voloyu.

can be carved: embroider it “under the whole or stone”, make the surface embossed (decorative), make it smooth. Behind the concrete surface you can lay tiles or porcelain tiles. All these technologies are carefully chosen and selected in accordance with the aesthetic appearance of the façade. They can also be used to add individuality and beautify your home.

How to prepare and install

When choosing the type of finishing, it is necessary to take into account the following preparatory work, for example, when finishing with natural stone, an additional foundation is laid under it. All other panels do not require installation of a foundation under them, and are mounted on a prepared sheathing.

The lathing can be of two types - wooden and metal. It is advisable to use a metal profile for finishing with fiber cement panels, since they are heavier than plastic panels for the base of a house, which are most often attached to wooden sheathing.

The sheathing pitch is calculated depending on the insulation used, or the lack thereof. If the installation is carried out without the use of lathing (when the material of the base allows the use of frameless fastening), the surface of the base is leveled, in particular, the protrusions that interfere with installation are cut off.

An example of a metal frame for finishing the base with stone-look panels Source sargorstroy.ru

When using insulation, you should take into account the distance of the sheathing to the walls, taking into account the gap for ventilation of condensate collection. The pitch of the sheathing must correspond to the panel installation diagram so that the panel is attached correctly. Therefore, it is better to entrust the work to a specialist so as not to rack your brains over calculations or carrying out double work when the calculations turn out to be incorrect. After all, then you will have to purchase new material to replace the damaged one, and re-clad the base.

Tips for installing facade panels under stone

- When calculating the number of panels, add 10 - 15% to the resulting number. This must be done, since the blocks have to be trimmed during installation.

- Before installing the sheathing, you should first make markings in increments of 30 - 40 cm. After the position of the beams has been accurately determined, they are installed on the wall. The correct installation of the planks is checked using a horizontal and vertical level.

- The screws are screwed into the center of the holes.

- After installing the starting panel, pull the thread from the panel to the opposite corner. The correct tension is checked with a level. All lower blocks are installed according to this guideline.

- The installation of basement blocks is completed by installing a drainage system. It is placed on the upper horizontal surface of the base. Metal elements are used for this.

Installation diagram of plinth panelsSource bauenhaus.ua

What determines the cost of materials and work?

The cost of the work depends directly on the amount of labor, the type of finishing of the base, and the professionalism of the installers. For example, finishing a foundation with natural stone is a more labor-intensive process than finishing it with plastic panels. And professional workers know their worth, and they charge accordingly more for the quality of work performed.

The cost of the material depends on the following indicators:

- Country and manufacturer. The more famous the company, the higher the cost and the likelihood of overpaying for the brand. But at the same time, large companies periodically announce promotions and discounts, most often in order to introduce new types of materials to the market. If you manage to “catch” such a promotion, then you can buy the material at a fairly “tasty” price.

- The material used, the composition of the polymer coating, modifiers, plasticizers, and so on.

- The sophistication of models with intricate textures and multi-colored tinting - they will cost more than panels that have one color and a simpler, more uniform texture.

- Characteristics of foundation panels (strength, frost resistance, resistance to mechanical damage, impact resistance, and so on). The better the characteristics, the higher the cost.

Performing priming

All surfaces that need to be protected from plaster, such as window frames, must be covered with masking tape.

A durable and high-quality plaster coating can be obtained only with the correct use of a deeply penetrating primer in two layers. If the base part is to be painted, then only a façade primer with maximum drooping properties is used for processing. Only the use of high-quality materials and compliance with technological requirements for the preliminary preparation of the base for applying plaster can significantly increase the service life and improve the appearance.

Silicone quartz primer ST 15 Ceresit

If you plan to further perform decorative finishing work, then it is advisable to give preference to a façade adhesive or acrylic-based primer.

Type of primer composition

Features and Specifications