Thanks to its remarkable decorative and performance characteristics, finishing the façade of a house with stone and plaster is still the most attractive choice. This is a rather complex and time-consuming process associated with the selection of the most optimal materials in terms of quality and price, as well as compliance with cladding technology. Mistakes made during work are difficult to eliminate later and will reduce the expected effect many times over.

Advantages and disadvantages of finishing a building with stone and plaster

This type of home design has several serious advantages:

- First of all, it protects the walls from adverse external influences. The plaster is applied in a fairly thick layer and protects the facade from precipitation, wind, frost and the influence of ultraviolet radiation.

- The plaster-stone cladding provides little sound insulation, but it still exists. Compare the silence in old stucco village houses and in modern high-rise buildings, of course, everything speaks in favor of plastered surfaces. If stone predominates in the cladding, then the protection of the house will be much higher than cladding with other materials.

- Stone decoration is not only beautiful. Cladding with artificial or natural stone is an excellent shockproof remedy against mechanical damage to walls, especially the base.

- The service life of properly executed finishing is quite long, and therefore you will not have to think about repairing the facade for a long time.

- In the end, it's just very beautiful. Houses covered with plaster and stone look stylish and neat.

Plastered facades with stone finishing are a stylish classic.

The disadvantages of such finishing are, first of all, its considerable cost. If you want to make a budget option for facade design, then it is better to pay attention to siding or vinyl tiles. Another disadvantage is the difficulty of finishing, especially on some surfaces. It is possible to cover a wooden house with a decorative plaster mixture, but for this it is necessary to carry out complex preparatory work: make lathing, reinforcement, etc. The same applies to facing work.

Lathing for plastering work on wood

Wooden cladding materials

Any wood materials used for cladding require additional treatment with products that protect against insects, pests, moisture and flame.

Among the most popular wood cladding materials:

- Eurolining is a thin profiled board made from softwood (pine, spruce). Eurolining is thoroughly dried during the manufacturing process (no more than 15% humidity). It is important that it does not have knots or other defects that could cause premature destruction of the material over time.

- Shingles – often called “wood shingles.” These are small-sized (40x2 cm) plates, which after installation look very elegant.

- Siding (board) - can be planed or unplaned, laid horizontally, vertically end-to-end or overlapping. Often used for Scandinavian style exteriors.

- Planken (a type of eurolining) - the main difference between this material is the absence of a tongue-and-groove connection. Each element is mounted separately. Because of this, the finish does not look like a single whole canvas; the joints are visible. But if repairs are necessary, replacing a separate plank is easier than dismantling a row of lining.

- Block house is a finishing material that has a convex face on the front side. This makes the cladding of the house look like a wall made of wooden logs.

The advantages of wooden cladding materials are naturalness, ease of installation and presentable appearance. Disadvantages include a short service life and the need for regular treatment with fire retardant, antiseptic and hydrophobic compounds.

Types of facade plasters

All plaster mixtures can be divided into several types, depending on the composition:

- Cement or mineral plaster mixture is made on the basis of high-quality cement and mineral additives. It has a low cost. Working with cement mortar is easy, since it does not dry too quickly and you can correct your shortcomings. Unfortunately, the colors of these plaster compositions are not very diverse, but they have good wear resistance, impact resistance and weather resistance. Therefore, they are used mainly in the form of starting solutions.

- Silicate plaster compositions. The basis of this mixture is silicate glass, an alloy of potassium and sodium. It is rich in mineral additives and pigment. Silicate plaster can be classified as mineral due to its composition. It is perfect for mineral bases - concrete, tuff blocks, brick. Its ability to transmit moisture is used for application to coarse concrete, where it is better not to apply acrylic and silicone compounds.

- Acrylic plaster mixtures are very easy to work with. Any beginner can handle them. Decorative acrylic compositions do not allow water to pass through and this must be taken into account. But they are self-cleaning, UV-resistant and impact-resistant. They are sold ready-made and cost slightly higher than previous plasters. Their colors are the most saturated and varied.

- Silicone compounds are also sold in finished form and are based on a polymer, due to which they have the highest plasticity of all types. The properties of silicone compounds for facade work are irreplaceable. They have the longest service life, are wear-resistant, impact-resistant, do not form cracks, do not allow moisture to pass through and are not subject to temperature changes. Silicone plasters are the most expensive material of all, but their cost is justified.

Applying a leveling layer with a mineral solution.

Facade plaster mixtures for combined design can be:

- starting ones, which are used to apply a leveling, rough layer;

- finishing or decorative.

Decorative facade plasters

Starting compositions have a coarser and stronger structure. Typically these are mineral mixtures based on high-quality cement and additives. Finishing plasters are thinner and more flexible. If it is a textured solution, then it contains marble chips. It reproduces on the surface a pattern corresponding to the name: lamb, bark beetle, etc.

How the bark beetle structure is made

This plaster looks original only on facade walls; it is not recommended to use it when decorating the interior of premises. The first operations of applying plaster are standard; the “bark beetle” is obtained at the finishing stage. For work, you can use metal or rubber grout. The second one is better - pebbles don’t slide on it, it’s easier to make grooves, the direction of the grooves changes without problems.

Rubber spatula for grouting

“Bark beetle” can be done using both vertical and circular grouting movements. Do not press it hard, the main thing is that during movement the pebbles do not slip, but roll. Rolling creates grooves. Don’t forget to periodically rinse the grout, otherwise the grooves will be sealed with milk and the process will have to be repeated many times.

Up and down movements

Spiral structure of the "Bark beetle"

Important. Various textural changes can only be made on surfaces pre-treated with two layers of white primer. In the grooves, the thickness of the plaster is only a few tenths of a millimeter; the base will be visible through. In this case, the primer not only increases the adhesion of materials, but also makes the base uniform, which is very important for bark beetle plaster.

Recommendations for decorating a house with plaster

Plaster work on the facade, especially in the case of subsequent partial cladding, must be carried out with special care. Any height difference or unevenness on the surface will spoil the whole picture. Almost all decorative coatings need ideally smooth walls, with a few exceptions - lamb and fur coat are more tolerant of the ideal. The discrepancies can be no more than 2 cm. How to achieve this? We will try to give clear recommendations.

- Prepare the wall by removing all old cladding, paint, and plaster. If the plaster holds up well, then you can repair it and level the top layer.

- Examine the wall. If the unevenness is 3 cm or more, we recommend using beacons for the first rough leveling layer:

- The surface is primed.

- If the insulation is not applied, then you can proceed to the next stage.

- Metal or wooden slats are attached at equal intervals. A cord is stretched between them.

- The solution should have the thickness of a good jelly, but not too thick.

- The plaster is thrown onto the wall with a trowel and smoothed with a trowel. All this is done between the beacons in accordance with the cord that indicates the plane.

- The first layer must dry, after which primer and mesh adhesive are applied. You can do it differently: the mesh is immersed on the first layer of plaster that has not yet dried, but the first option is preferable.

- Next, a leveling layer of finishing plaster is applied. If this is a decorative textured mixture, then it is leveled with a grater or roller according to the provided technology, which is described on our website in separate articles.

Layered plaster “pie” with insulation

Types of facade stone

Facing stone is presented in the construction and finishing market in two main categories: natural and artificial.

Natural

Among this group, sandstone, quartzite, dolomite, marble, limestone, granite, and basalt are especially valued. Cladding with these materials gives the house luxury and reliability, since the service life of most types of natural stones is unlimited. There are known buildings that are hundreds and thousands of years old, covered with ordinary granite or limestone:

- The softest material is slate. It is often used for interior work, although facade cladding also deserves attention. It has a budget price compared to other types. It is porous and non-hydrophobic.

- The strongest are granite and basalt.

- Marble has a variety of textures and is easy to install. It is used for cladding external and internal premises.

- Limestone, sandstone and shell rock are of a budget nature. These materials bring warmth into the house in winter and coolness in summer. Due to their excellent properties and low cost, they are widely used.

- Dagestan stone has become popular in our country; it is a practical and beautiful heat insulator

Natural cladding material for facade work

Natural materials enjoy well-deserved love among designers and finishers around the world.

Artificial

In terms of its properties, artificial facing material is no worse than natural one. Density, wear resistance, hydrophobicity and the ability to withstand atmospheric influences are usually higher in artificial stones.

For example, artificial marble is not subject to color changes like natural marble, and decorative slate will have a presentable appearance for much longer, since it is stronger than natural one. Mold does not form on the surface of decorative stone cladding, and its wear resistance is higher than many types of natural stone. There are two more undeniable advantages of artificial materials - lower cost and ease of installation.

Decorative facing material

Siding

Siding is made from polyvinyl chloride. Thanks to this, even with a sheet thickness of 1.5 mm, it is very durable. The sheet can also be based on metal, which is covered on top with PVC, which is resistant to sunlight, moisture and damage.

Other benefits of siding include:

- vinyl siding is not susceptible to rotting and is not attractive to pests and rodents;

- polyvinyl chloride does not lose its color even with prolonged exposure to sunlight;

- metal siding is fire resistant;

- the material is not afraid of temperature changes, operating conditions are from +100 to -50 degrees.

Siding types:

- Vinyl - pressed from polyvinyl chloride by forming it in an extruder. A subtype of vinyl material is foam siding, which is thicker and stronger.

- Made of metal - made of aluminum or steel. The first option is cheaper, so it is more often used for public buildings. Steel siding is more common in the private sector.

- Fiber cement - made from a mixture of cellulose fibers, quartz sand and cement diluted with water. May contain additional mineral components that improve the strength of the material and its resistance to negative temperatures. The disadvantage of this siding is its high cost. But it is available in a variety of textures and colors, for example, with imitation wood or stone.

DIY stone cladding

Let's look at a brief instruction on façade cladding:

- Calculate the amount of material needed. As a rule, it is indicated in m2, and you only need to calculate the coverage area. Do not forget that there is also jointing, crowbar, fighting and random errors in calculations. Joining reduces the quantity, but calculating its area for stone material is very difficult. Therefore, purchase 10% more than the required quantity.

- The walls must be leveled using plaster, as described in the previous section. The differences should not exceed 2 cm. The condition of the wall is important for laying natural stone. It should not be wet and frozen. Start working only at temperatures from +5 to +25 degrees. In the rain, you should also not bother with cladding.

- It is better to apply the laying mixture to the back surface of the material itself, and not to the wall. If laying occurs in the heat, wet the surface.

- Press the stone against the wall and carefully clean off any excess mortar.

- Do the jointing with a special mixture from a jointing tool or a regular plastic bag adapted for this procedure.

In the video you can study in more detail the technology of cladding with stone material.

Cladding of facade walls with natural stone

Installation work

| Name | Price |

| Construction of a subsystem for a parapet cover | 500 rub/m. |

| — galvanized with polymer coating | 320 rub/m. |

| - aluminum | 480 rub/m. |

| - made of stainless steel | 640 rub/m. |

| Installation of additional elements (parapet cover, slopes, ebbs) | 350 rub/m. |

| - metal | 277 rub/m. |

| - aluminum-composite | 288 rub/m. |

| - aluminum | 550 rub/m. |

Design work, m2

| Name of works | Price |

| Testing the load-bearing capacity of walls | For free |

| Geodetic survey of the structure | 20 rub/m2 |

| Development of working documentation for façade installation | 70 rub/m2 |

| Development of a design project for the facade of a building | 30,000 rub. |

| Obtaining a building color passport | RUB 155,000 |

| Creating a work production project | 30,000 rub. |

| Obtaining an OATI warrant to carry out work when ordering facade repairs | 40,000 rub. |

| Development and approval of TML | 30,000 rub. |

Combined facades: photo ideas

There are many options for combined facades and there is no special recipe. Everyone can come up with their own design and make their home unique. Of course, there are classic ways to design the façade. For example, when the lining of the corners and the base is made of stone, and the rest of the surface is made of plaster mixture. Here, too, you can use your imagination and make the classics unusual, as in the photo below.

Classic finishes in bright southern colors

You can use one of the materials in a minimal amount. In the photo below, the facade is made of plaster, similar to a whitewashed Mediterranean house. The stone is represented by a small applique.

Plastered house with small stone appliqué

Or you can do the opposite - make the cladding the main accent, and carry out plastering work on a minimal area.

Finishing with minimal use of plaster

An excellent solution is to use decorative finishing material for corners, plinths and window slopes. The soft combination of colors and geometry of shapes gives the effect of aristocracy.

Geometry and soft color transitions to create an imitation of the facades of noble houses of the 19th century

A great way to highlight individual architectural forms using stone. Cladding an imitation pipe and partially finishing the walls will give the effect of a rich country house from the beginning of the last century.

Partial finishing of architectural forms with stone material

Here is another example of a combination of plaster and stone facade design. The porch and attic space are made of cladding material, while the rest of the space is a plaster facade.

Partial stone finishing of the porch

Non-standard forms of stone facing material can be ordered for non-classical window openings. Mosaic yellow plaster will add chic to the entire surface of the house.

Non-standard window “stone” openings and mosaic plaster

Notice how unusual the design of the house in the photo is. The building itself is located on a slope, and therefore requires non-standard design. The base is lined and protected from ground and atmospheric waters. The walls of the house are covered with plaster compounds of different colors, which emphasizes the position of the house.

Decorating a house on a slope

The unusual architecture of the house should be emphasized by the decoration. In the photo you see a fairy-tale house, decorated with plaster and natural materials in a non-classical version.

Finishing emphasizes architectural forms

Another option is to use stone and plaster finishes to create an unusual facade design.

The use of stone cladding, plaster and wooden decor for wall decoration

If you use different types of bandages, you can create patterns from the facing stone directly on the surface of the plaster. In the photo below you see the facade decor created by the “Bark Beetle” plaster mass and the pattern of the cladding.

Drawings from stone sling

Look up close at how impressive and reliable the natural sandstone on the base of the building and the “Bark Beetle” plaster walls look.

Sandstone and bark beetle finishing

Finishing the facade of the house with plaster and stone gives a classic combination of materials. Despite the minor difficulties, you are convinced that every owner can do this kind of decoration of external walls with his own hands.

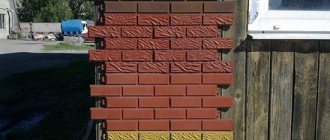

Facing brick

Can be used for house facades, plinths and foundations. Thanks to the wide variety of colors and textures, facing brick allows you to implement any finishing options, regardless of the chosen architectural style.

Among the advantages of brick:

- long service life;

- brick resistance to wear and mechanical damage;

- presentable appearance and a large selection of brick shades.

There are several types of facing bricks:

- Ceramic - made from clay that is resistant to temperature fluctuations. Coloring pigments are added to it, after which the mixture is pressed into molds and fired in a kiln. For exterior finishing, hollow bricks are used, which have less weight and low thermal conductivity.

- Silicate is the most budget-friendly type of facing brick. Its basis is sand and cement. The downside of such bricks is their reduced resistance to moisture.

- Clinker brick is one of the subtypes of clinker brick, but superior to it in terms of performance characteristics. This is achieved by using the highest quality raw materials and firing at higher temperatures. Unfortunately, this negatively affects the cost; clinker brick is more expensive than standard ceramic brick.

- Hyper-pressed - the components of the brick include shell rock, cement and coloring pigment. In its production, no firing procedure is used; instead, the brick is pressed under very high pressure. As a result, the brick is resistant to sub-zero temperatures and ultraviolet radiation, and does not crack or fade in the sun. The only disadvantage of the material is its large weight, which after cladding puts additional load on the supporting structures.