For a person far from construction, the very idea of making a roof out of plastic sounds like an April Fool's joke. Besides, it's not very successful. After all, the plastic we encounter in everyday life is often a fragile, easily broken material. This means that the plastic roof should quickly collapse under the slightest load. And who needs such a short-lived roof?

Such ideas are far from reality. Modern roofing plastic materials are very different from ordinary household plastic in properties. So much so that some of their types outperform conventional roofing coverings in terms of strength and load-bearing capacity. And this does not take into account other advantages.

What is plastic roofing

In appearance, plastic roof covering has much in common with slate made from asbestos cement. The material is also durable and most often has a wave-like shape. Plastic roofing sheets have a glossy surface that shines from the sun's rays. Their light transmittance reaches 90-92%. Thanks to this feature, they can be transparent and compete with glass.

When producing plastic slate, special pigments are added to the polymers used, giving the product a specific color design. When choosing such a roofing covering, there is no need to limit your imagination and thus you can realize any design ideas. The color of the sheets can be varied and with varying degrees of transparency.

Let's sum it up

A plastic roof is practical, holds a distributed load well, is not subject to corrosion and can be 90% transparent. At the same time, most plastic panels for roofs do not have very high resistance to point loads and a short service life, although there are materials that stand out in terms of these characteristics compared to other polymers.

Here's what the roof plastic is called:

- Polycarbonate. This is a whole family of materials, which includes:

- especially durable, even bulletproof, monolithic polycarbonate;

- lightweight and cheap cellular phone that effectively prevents heat loss;

- thin, but profiled to hold up to 350 kg/m2 load.

- Profiled PVC . Less durable than profiled polycarbonate, but with biaxial orientation it is more elastic and better able to withstand impact loads.

- Composite plastic . Specialized multicomponent materials, difficult to produce and therefore expensive. They are used for constructing roofs in aggressive conditions and for vandal-proof structures.

The roofs of gazebos, verandas, greenhouses, winter gardens, greenhouses, galleries, and canopies are usually made of plastic. Monolithic polycarbonate is used for glazing the atriums of commercial and public buildings, and sometimes for partially covering the roofs of private houses.

Using corrugated plastic materials

The main advantage of polymer slate is its low weight and high light transmission.

They cover the roofs of many buildings, including:

- public transport stops;

- greenhouses, greenhouses;

- industrial buildings - workshops, warehouses, hangars, loading and unloading points;

- open summer areas of restaurants and cafes;

- shopping pavilions;

- terraces, balconies and verandas, courtyards;

- telephone booths;

- hanging shelters for swimming pools, sports fields, parking lots, etc.

When arranging residential premises, plastic slate is used extremely rarely due to poor thermal insulation characteristics. Sometimes it is used in the construction of summer holiday houses.

Scope of application

The main advantage of the plastic analogue is its low weight . This allows it to be used in areas where a regular one would not be as convenient.

Most often it is used for:

- greenhouses;

- summer cafes;

- stops;

- greenhouses;

- canopies for swimming pools;

- covered parking lots;

- production hangars, workshops;

- shopping pavilions;

- verandas;

- balconies.

NOTE!

Due to the fact that the material has poor thermal insulation, it is not used for full installation in residential buildings , but it is well suited for updating an old roof without dismantling.

Range and selection of polymer roofing materials

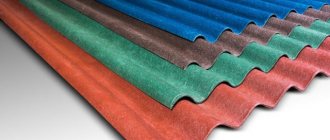

If you decide to use plastic slate for your roof, the first thing you should pay attention to is its color design.

It could be:

- transparent;

- white;

- colored.

Manufacturers produce products that have not only colors without impurities, but also mixed ones, for example, turquoise, bronze and others.

According to the degree of light transmission, plastic roof materials are:

- transparent;

- unclear (matte);

- translucent (smoky).

Transparent slate has a maximum degree of transparency, reaching 92%. This type of product is used to cover rooms that require increased lighting.

The translucent material looks as if covered with haze, and its degree of light transmission ranges from 50 to 75%. Through such plastic, you can distinguish the outlines of objects, but you will not be able to examine them. Matte slate has the lowest light transmission, almost impervious to light due to its intense coloring.

A roof equipped with plastic roofing looks different due to differences in the cross-section of the materials, which can be:

- straightforward;

- wavy;

- trapezoidal.

Roofing corrugated plastic and trapezoidal roofing are characterized by greater strength, durability and flexibility compared to straight products. It is more resistant to mechanical stress, such as the impact of falling hail.

Plastic slate can be sheet or roll. Plastic roof sheets can have different sizes and are therefore selected taking into account the roof parameters. The most common products are 2x0.9; 2x1.086 and 20x1.14 meters. Each sheet has from 7 to 12 corrugations in the form of waves, trapezoids, which differ not only in size, but also in depth.

When installing sheet material, it often has to be cut into separate pieces of the required size. To do this, use a jigsaw, a regular hacksaw or scissors. Roofing material in a roll has a length of 10 to 30 or more meters and a width of 1.5–3 meters. It is first spread on the roof and then cut into sheets.

Installation of plastic slate in a roll along the entire length of the canopy or slope eliminates the presence of a large number of joints. As a result, the process of laying roof coverings is simplified and accelerated.

Features of DIY installation - practical tips

Small architectural forms using transparent roofing are quite easy to install even by amateurs. The most important thing is to take into account some features of light-transmitting materials:

- To arrange the frame, it is necessary to choose the appropriate type of profiles: for large spans - a steel profile; in medium-sized spans - aluminum; on small spans - PVC profile.

- Much attention should be paid to proper sealing: synthetic rubber is most often used to seal the frame, and silicone waterproofing mastic or sealant is used for joints and edges of the roof.

- We must take into account the slope of the roof: the steeper it is, the less the load on the sheet.

- If additional thermal insulation is required, it is better to give preference to cellular polycarbonate or plexiglass.

- To avoid the accumulation of excessive condensation, it is necessary to ensure sufficient ventilation of the entire room and especially the under-roof space.

- During installation, it is necessary to minimize physical impact on the roof - do not step on it.

- The protective coating (film) can be removed after installation is complete.

A transparent roof, built according to all the rules, will last from 15 to 50 years (depending on the chosen material). It is not picky in maintenance - dome structures are washed naturally during rain; to clean other types of roofing, a soft sponge and soap and water are sufficient.

Light-transmitting roofing materials provide a huge scope for design imagination, offering an endless variety of ideas and nuances. The most important thing is to take into account all the design features, load-bearing load and functional purpose of the future roof or fence.

© rmnt.ru, Igor Maksimov

Slate made from PVC

On the building materials market, the most common plastic roofing covering made of polyvinyl chloride is found. It is inexpensive and has many advantages: high impact resistance, durability, resistance to corrosion processes, low weight, ease of operation.

When choosing a PVC roofing sheet, you should pay attention to the country where it was produced. The fact is that cheap Chinese products quickly become unusable, fade under the sun's rays and are pierced by hailstones. After 2-3 years, such slate requires replacement. Manufacturers provide a guarantee for high-quality plastic PVC roofing for 10-15 years, but with proper care it will last about 25-30 years.

The technical characteristics of polyvinyl chloride slate are as follows:

- Thickness from 0.8 to 3 millimeters.

- Operating temperature – 40 + 65 degrees. Thermal deformation occurs at a temperature of + 67 degrees. At sub-zero temperatures of 40 degrees, polyvinyl chloride becomes brittle, it breaks easily, and cracks form on it.

- Translucency is no more than 83% for transparent materials, and no higher than 74% for matte and translucent materials.

- The warranty period is about 10-15 years.

Customer Reviews

I spent a long time selecting material to make a roof in the winter garden. I didn’t want to cover it with regular roofing material, since the lighting would be significantly reduced. That is why I took the risk of using transparent plastic slate. I heard a lot about it, but I didn’t dare to use it. The result was very pleasing, light, spacious and reliable. In addition, the material is very easy to work with.

Alexander 36, Barnaul

I made a small greenhouse for my mother, used plastic slate not only to cover the roof, but also sheathed the walls with it, the design turned out excellent. The main thing is to make the frame correctly, and covering it with slate was not difficult. It looks great, what the plants need, the light penetrates completely inside. The finished structure turned out to be quite durable. After the rain, to clean the side walls, we use ordinary water from a hose and the greenhouse is like new again.

Vladimir 28, Verkhnerusskoe

I didn’t immediately muster up the courage to buy; the material caused obvious mistrust. Plastic has always been associated with something very fragile. But based on the recommendation, I still bought it in order to complete the gazebo, I can say that I was mistaken about the plastic slate. An excellent option for small buildings, I was very pleased with the color range, we easily found the right color. You can do the installation yourself.

Anatoly 45 years old, Kaluga region

Video about PVC slate.

What else to read on the topic?

Author of the article:

Sergey Novozhilov is an expert on roofing materials with 9 years of practical experience in the field of engineering solutions in construction.

Rate this article:

Loading…

Plastic roofing made from polycarbonate

Externally, polycarbonate slate looks the same as PVC products. Their difference lies in the higher price of polycarbonate and better performance. In addition, such slate retains its strength and light resistance for a long time, does not turn yellow or become cloudy. Large hailstones and hammer blows leave dents on the sheet of material, but cracks and holes will not appear on it.

The technical characteristics of this type of plastic slate are as follows:

- The thickness of the material is from 0.8 to 6 millimeters.

- Transparency does not exceed 90-92%.

- The operating temperature ranges from -50 to +100 degrees. The material can withstand short-term temperatures up to +120 degrees.

- Manufacturers provide 10-15 years of guaranteed operation, but in fact this period reaches 30 years.

Price

If you decide to purchase a plastic roof, you can expect a price of approximately 250 rubles per sheet. The final cost will depend on the chosen manufacturer, thickness and type of coating.

It is important to note that in winter (due to low sales during this period of time) many manufacturers provide significant discounts. There is an opportunity to save significantly and purchase material in advance that can be safely installed after warming.

In Russia, the most famous manufacturer of plastic roofing materials is domestic. And also users have good opinions about French products.

From the video you can learn how to use polycarbonate for a canopy:

Fiberglass slate

To produce plastic roofing, a polymer such as fiberglass is also used. This material is combined. It consists of a heat-treated polymer (polyester resin) that is reinforced with woven glass fibers that act as reinforcement.

Reinforced slate is highly durable, resistant to ultraviolet radiation, and does not turn yellow or fade. Its leaf weighs little: with a size of 3x1 meter it is about 3.5 kilograms.

Technical characteristics of fiberglass roofing:

- Product thickness is from 0.8 to 2 millimeters.

- Light transmission does not exceed 92%.

- Retains its qualities at temperatures from - 40 to + 120 degrees.

- Service life is approximately 25 - 30 years.

Light transmission degree

Today, plastic flooring is available in three varieties:

- transparent;

- translucent;

- matte.

Regardless of the degree of light transmission of the material, all canvases have a perfectly smooth surface and a very wide range of colors.

Thanks to these properties, operating and installation costs are reduced:

- special technology ensures high durability. Even after a long period of use, the original appearance is preserved;

- In case of any contamination, the roof is cleaned by rain. using>

Advantages and disadvantages of plastic roofing

Different types of polymer slate have common advantages, including:

- High light transmittance . Fiberglass and polycarbonate have the highest transparency, reaching 92%. This figure for PVC plastic roofing is no more than 83%. Limit values of light transmission are observed for transparent products that do not have coloring components. Average values refer to translucent slate, while the lowest values refer to matte materials. The presence of a good level of transparency allows the use of plastic roofing when arranging rooms that require additional daylight. Buildings such as greenhouses, greenhouses, balconies and terraces really need sunlight. You can cover not only the entire roof with plastic slate, but also partially, thereby creating skylights.

- Immunity to mechanical loads . The inherent strength of polymer materials allows them to resist increased bending and impact forces.

- Light product weight . It is 2 - 3 times smaller than glass, provided that they have the same thickness. A roof made of such slate is quite light, which makes it possible to erect a building on a lightweight foundation with a reduction in the thickness of the walls.

- Simple installation technology . To build a roof using polymer materials, you do not need any special knowledge or experience in carrying out such installation. This work is done without much labor. An important role in this is played by the light weight of plastic roof sheets - each worker can lift them onto the roof independently.

- The widest selection of colors and shades . Pigments added to the composition of polymer raw materials make it possible to arrange the roof of any desired color. You can also choose colorless sheets - transparent.

- Flexibility . The plastic covering can be bent when it is cold, making it possible to construct roofs of complex configurations - in the form of domes, arches, etc.

- Resistance to different weather conditions - strong wind loads, temperature changes, sunlight, hail, rain and snow. Plastic roofing is waterproof; it does not get wet or swell from moisture.

- Resistance to corrosive processes and chemical compounds . The condition of polymer slate is not affected by corrosion or exposure to aggressive environments, and it is not subject to rotting. Its performance characteristics do not depend on acid rain, emissions from industrial enterprises, or pollution from vehicles. Due to this property of plastic roofing, it is used in the construction of roofs in workshops, warehouse facilities, industrial workshops, etc.

- Fire safety . At extremely high temperatures, the material begins to melt, but it does not ignite. As a result, the fire does not spread to flammable objects and things.

- Easy to care for . The surface of plastic sheets is smooth and therefore, when the roof slope is no more than 10 degrees, dust does not accumulate on it. Even if dirt appears, it can be washed off with water from a hose. Plastic slate has a solid structure, so dust does not penetrate inside such a sheet, and over time it does not lose its inherent light-transmitting qualities.

- Environmental friendliness . Asbestos-cement slate contains asbestos, a substance that poses an environmental hazard. As for polymer materials for roofs, they are absolutely clean from an environmental point of view. They do not contain components harmful to people and the environment.

There are much fewer disadvantages of polymer roofing materials:

- A person cannot move on a roof constructed using plastic panels. This circumstance complicates installation work and therefore it is impossible to do without arranging bridges.

- Expansion due to heating. As a result, the plastic increases slightly in size, and after cooling it returns to its original state. To prevent this from leading to the formation of cracks, the holes for fastening should be made 2-3 millimeters larger than the diameter of the products for fixing the slate.

- The need for the construction of frequent sheathing. The sheets of plastic are thin and flexible, so if the pitch of the slats is long, they will begin to hang down.

- Low thermal insulation rates. For this reason, plastic slate is not used when arranging residential premises.

Taking into account the advantages and disadvantages of plastic roofing, it should be noted that this material has unique characteristics.

Installation rules

Laying plastic corrugated sheets on the roof is not a difficult task, and you can easily do it yourself. Just follow the rules:

- Perform installation only at outdoor temperatures not lower than +5 °C and not higher than +25 °C.

- Lay the sheets perpendicular to the sheathing in rows from bottom to top. Begin installation on the side of the roof that is opposite to the prevailing wind. This means that if at the construction site the wind most often blows from the south, then you need to start laying rows of sheets from the north.

- Choose the overlap correctly: longitudinal - one wave, in windy places - two waves; transverse - at least 150 mm, with heavy snow and wind loads, as well as on roofs with a slope of less than 10% - at least 200 mm.

- Do not step on the sheets directly as this may cause them to become deformed. Use a backing to distribute the weight evenly: a board, plywood, a sheet of chipboard at least three meters long.

- Fastening of corrugated plastic sheeting on the roof is carried out at the top of the wave with the obligatory backing, on a wall or fence - at the bottom of the wave.

- Before screwing in the self-tapping screws, to compensate for thermal expansion, you need to drill a hole at the attachment point with a diameter of 4-5 mm.

- To fasten corrugated plastic sheets, use only special screws with a rubber gasket.

- The minimum overhang is 40 mm, the maximum is 200 mm.

- If the plastic is protected from ultraviolet rays not by additives, but by spraying, the sheets are laid with the protective coating facing up. Inscriptions and the brand logo of any sheet are made on the side that should be facing the sky.

Try to enlist the help of at least one person - this will greatly speed up the work, especially lifting the material onto the roof, and also make it safer.

Specifications

Due to the narrower scope of application, the variety of plastic corrugated sheets is not as great as that of metal ones. In particular, in Russia you can freely buy transparent corrugated sheeting of only a few brands, similar in shape and wave height to wall profiles S-8, S-20, MP-20 and S-21, as well as with wave heights of 11 and 16 mm. Other types of plastic corrugated sheet are usually only available to order and in large quantities.

The table below shows the technical characteristics of the most common polycarbonate and PVC profiled sheet with 8 mm wave.

These are approximate values, since the transparent profile sheet is produced not according to GOST, like steel corrugated sheets, but according to the manufacturer’s technical specifications. Therefore, check the exact dimensions and other characteristics with the specific manufacturer or dealer from whom you will purchase the material. Technical characteristics of plastic corrugated sheet

| Options | PVC corrugated sheeting | Polycarbonate corrugated sheeting |

| Thickness, mm | 0,7–1,5 | 0,8–3 |

| Width, mm | 660–1060 | 1200 |

| Length, m | 1,2–3,6 | 1-6 |

| Weight 1 m², kg | from 1.15 | from 1.17 |

| Light transmittance,% | up to 83% | up to 90% |

| Thermal conductivity, W/m °C | 0,14 | 0,21 |

Note

On request, the manufacturer can produce sheets of arbitrary length up to 12 meters. But this will cost more than a standard size profile and only makes sense for large quantities.

Price

The cost of a polycarbonate roof will be floating, as it depends on the type of material chosen and its thickness. For example:

- A transparent sheet of profiled material measuring 2000x1150x0.8 mm will cost 1,000 rubles, while the same sheet, but turquoise in color, will cost 100 rubles more.

- A sheet of transparent honeycomb material with dimensions of 2100x6000 mm and a thickness of 4 mm will cost 4,750 rubles, and a blue sheet is 200 rubles more expensive.

- Honeycomb material with a thickness of 6 mm will cost 1000 rubles more.