When is garage repair required?

The first sign that a garage is unsuitable for further use in most cases is the appearance of moisture in the room itself after rain or melting snow. Even a minor leak can cause damage to the car, the appearance of dampness, and fungal growths. Any deformed area of the roof needs timely repair.

The reason for garage roof repair may be:

- adverse effects of weather conditions;

- bad ecology;

- non-compliance with the stages of roofing work;

- improper preparation of the premises;

- poor quality of materials used;

- lack of timely repair of minor roof defects;

- violation of waterproofing due to destruction of the bitumen layer;

- Wetting of the insulation, which leads to swelling of the under-roof covering;

- negative impact of ice formed due to melting snow covers.

Only a well-built garage can guarantee the safety of your car.

Briefly about the main thing

The main causes of leakage are poor quality materials and unskilled workers. In both cases, it should be remembered that if you save too much, the roof may begin to leak immediately after installation, and this will lead to additional expenses.

The most common materials for sealing cracks in garage roofs are bitumen and roofing felt. They have good adhesive and water-repellent properties.

You should carefully consider what type of work is needed to fix the leak, since completely replacing the entire coating will cost a lot of money. This can be avoided by spot repairs if there are few problem areas: they can be repaired with patches or simply filled with resin.

Ratings 0

Types of repair work

Repairing a garage roof is not as difficult as it seems, which is ensured by the height of the room acceptable for installation work and the small size of the roof itself.

It all starts with determining the scale of the upcoming repair and the necessary materials. Depending on the degree of damage to the old roof, the repair can be partial, when individual deformed parts are replaced, or major, when the structure must be completely dismantled. The roof can be covered with different materials - metal tiles, slate, corrugated sheets, which have different performance properties and costs.

Depending on the condition of the roof, major or local repairs may be required

Overhaul of a heavily damaged roof structure

It is recommended to plan major repairs during a warm period with minimal precipitation, but in this case there are exceptions. If the situation does not tolerate delays and requires immediate elimination of defects, then repairs are allowed in any weather, but then it is necessary to stretch an awning over the roof, protecting it from rain and snow. Due to the small size of the garage, repairs are usually completed in one day. If installation is delayed, then at least waterproofing should be installed within the first 24 hours.

Most often, the garage roof begins to leak

During major renovations, it is important to pay attention to removing the old coating. If the old roofing felt is in good condition and laid in 2-3 layers, then it can be left as waterproofing. In case of significant damage, the coating is carefully removed from the structure. If there is a reinforced concrete base, it is more convenient and faster to remove the material with an ax; from a wooden frame, you will have to remove the layer with a knife and a grabber.

Work with the roof is carried out only if the temperature indicated on the packaging is observed. If roof repairs are carried out in winter, then the material should first be kept in a warm room (15–20 degrees) for about 4 hours and only then installation should be carried out.

Depending on the area of the roof, the complexity of the work, and the selected materials, an estimate is calculated, which includes the following costs:

- for transportation of materials;

- surface preparation;

- coating deposition;

- repair of junctions and pipes.

The average cost of 1 m2 of reliable roofing coverings is 100 rubles; choosing a cheaper option does not guarantee long-term operation of the structure.

A properly repaired roof will last for years.

Current repairs - an opportunity to inexpensively restore the functionality of the roof

Soft roofing is often subject to defects in the form of punctures, tears, leakage of seams and adjacent elements, it swells and even gradually slides. However, the presence of any of the listed flaws does not mean the formation of leaks, but requires elimination.

Current repairs, unlike major repairs, involve work to restore the original functions of the coating to no more than 10% of the total area.

Content

The roof of buildings of any type, size and purpose tends to wear out, to the great regret of the owners. Its strength is regularly tested by gusty gusts of wind, hail, heavy rains, birds, abandoned stones and suddenly fallen trees. Similar factors with equal consistency attack the roofs of garages, which sometimes do not cause as much concern among owners as a leaking ceiling in an apartment. Due to absolutely unjustified frivolity, the beloved “iron horse” or “swallow” suffers in a manner not childish, slowly rusting from excess moisture.

Leaks are a clear indicator of a violation of the integrity of the roof or flaws in the construction of the roofing pie. However, you should not wait for smudges to appear on the walls and ceiling. In order not to encounter serious facts that require expensive repairs, it is necessary to carry out preventive inspections of the upper floor of the garage from the outside regularly 4 times a year and monitor the condition of the ceiling daily.

Garage roofs, like the buildings they cover, are a term that combines a wide range of structural varieties. They are erected above standard free-standing boxes, and above garage boxes lined up in a row, and above household structures of vast private estates. They can be single- and double-sloped, hipped, attic, etc. They can be equipped with any of the existing types of roofing materials, the choice of which depends on the status and financial capabilities of the owners.

What manufacturers of building materials offer for roofing repair work

In addition to the materials traditionally used for garage roof construction, there are many options that are not inferior in quality and ease of installation.

Flexible roofing from Technonikol for garage renovation

TechnoNIKOL is a supplier of various types of building materials, among which there is a finishing coating for the roof. This roof has a unique structure - it is made of a layer of fiberglass or polyester, coated on all sides with a bitumen composition. To enhance resistance to mechanical, atmospheric and other factors, the coating is covered with basalt chips on top. The Technonikol sheets have a self-adhesive surface on the bottom, which is protected by film.

The ability to choose any color adds a bonus in favor of choosing a product from this manufacturer. A garage decorated with such material will not only be well protected from precipitation, but will also attract attention.

TechnoNIKOL has many advantages

You can use any TechnoNIKOL roofing to install the roof:

- soft tiles;

- rolls of overlay coating.

Despite the small range of roofing products, Technonikol is becoming popular among car owners quite quickly. It not only replicates the properties of traditional materials used for roof repairs, but also improves them many times over. This finishing coating is suitable for both partial replacement of deformed areas and major dismantling.

Why do people choose TechnoNIKOL, leaving behind years-proven installation methods? Its main advantages:

- Ability to withstand high and low temperatures. The roof can withstand exposure to both +50 degrees and -60 degrees.

- The impeccability of the waterproofing layer - even the longest rainfalls or abundant melting of the snow cover will not break the tightness of the structure.

- No corrosion processes. The composition does not rot, rust, or oxidize, regardless of the level of humidity.

- High resistance to wind and mechanical loads. Such a roof will last through a strong hurricane, large hail, and falling trees and branches.

- Easy to use and installation. To repair a garage, all you need is the desire and a minimum set of tools; no additional equipment or special skills are needed.

- Focused pricing policy on people with any budget. For those who want to save money without sacrificing quality and for those who like to get something more than just a roofing covering by paying a little extra for it, a suitable brand will be selected.

Roofing from TechnoNIKOL has waterproofing properties.

Like any material, TechnoNIKOL is not without its drawbacks. In this case, there is only one - laying the roofing layer is allowed only on top of a solid base. To fulfill this requirement, you will have to spend a little money - assemble a pitched roof and purchase plywood for its entire area.

Laying process

Installation of the finishing layer is carried out depending on what material will be used. It can be laid by fusing the coating or attaching it to fasteners. In the first case, the work is carried out on a flat roof, when the rolls are rolled out over the entire surface of the garage, heated with a burner and glued due to the melted structure. If we are talking about inclined structures, then a suitable method would be to fasten the material with self-tapping screws, nails, and even staples from a construction stapler.

Any type of installation requires careful preparation of the base. So, the surface must be smooth, clean and dry.

The manufacturer warns that any repair work using Technonikol is allowed only in dry weather. If there is rain or fog outside, the material will soon begin to bubble. Favorable temperatures range from +7 to +26 degrees, that is, installation is best done in spring or early autumn.

As a rule, there are no difficulties when laying the TechnoNIKOL soft covering, but all work requires a clear sequence and the use of only recommended additional elements.

As a vapor barrier layer responsible for maintaining the temperature balance and humidity level in the room, it is recommended to use a special TechnoNIKOL film with a three-layer structure. The ease of use of this high-strength fabric also lies in the fact that it fits perfectly on any base, including untreated surfaces. It is advisable to cover pitched structures with a membrane, and flat roofs with perforated or non-perforated film.

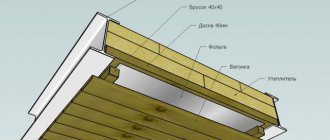

Soft roofing consists of several layers

Since tiles from different packages may have slight color differences, it is better to mix the sheets together in advance to ensure uniformity of the palette. The protective film on the bottom of the covering must remain intact until the element is laid.

The stages of roof installation are as follows:

- The main frame is covered with a lining carpet. The outlets of ventilation systems and key elements of the roof need additional strengthening.

- In areas of ventilation vents, sheathing is carried out with special devices and a thorough application of bitumen composition.

- The edges of the slopes are decorated with cornice strips and pediments, followed by the installation of ridge-cornice elements. In the absence of special tiles, the use of ordinary sheet petals is allowed. The tiles are fastened to the substrate with nails at a distance of 2–3 cm from the edge.

The edges of the slopes and corners must be processed - At the next stage, the tiles are installed in rows so that each upper row slightly overlaps the lower one. Along the edges, the tiles should lie flush over the entire area.

- Mastic is applied over the vertical gable row.

- To cover the ridge, a Technonikol aerator and ridge tiles are used.

You need to finish the job with a ridge aerator

Following the advice of professionals, you can lay rows from the middle of the pitched structure.

Depending on how inclined the flat roof is, the number of layers of material to be laid is determined. For significant slopes, a two-layer application is sufficient; small corners require more reinforcement.

There are several ways to install roll coverings

Installation is carried out in stages:

- A bitumen primer is applied to a clean, level base, after which you need to wait for it to dry completely.

- The roll is rolled out from the eaves upward, gradually heating with a burner.

Laying TechnoNIKOL occurs under the influence of fire - As soon as the coating strip completely lies on the frame, you should go over it with a roller again, paying special attention to the edges. The swollen areas are heated again and pressed to the surface.

- The next layer is overlapped by 8 cm on the side and 15 cm on the end.

- If there are funnels, you need to cut and glue a double square measuring 70x70 cm.

- Next to the parapets, the material is placed with an allowance, while for the top layer 5 cm is enough, and the bottom one should be raised by 25–30 cm. The junction points are insulated with a special tape.

The material must be protected from exposure to high temperatures, since the process of melting the protective film may begin, and it is almost impossible to peel it off from the material.

Video: laying the TechnoNIKOL roof

Impeccable waterproofing of the garage roof using Bikrost

Thanks to a unique composition based on fiberglass and binders with adhesive bitumen, Bikrost flawlessly copes with the waterproofing of roofing structures.

The material is laid according to the following scheme:

- The roof is cleared of leaves, branches and other debris and primed well.

- The rolled sheet is gradually rolled out and heated by a burner. Vulnerable areas such as corners and edges should be thoroughly heated. The canvas should be immediately pressed tightly to the base.

- For a high-quality connection, the material is overlapped by 7–10 cm.

You need to install Bikrost carefully but quickly, since its bitumen base can set in a few minutes. In general, the process is similar to laying roofing felt, but there is no need to waste time heating the resin and rubbing it on the roof.

Bikrost is a popular roofing material

When using Bikrost as the main roofing material, it is important to consider a number of factors:

- It does an excellent job of protecting the roof if the structure has a slight slope. If the angle of inclination is 15 degrees or less, then it is recommended to roll out the sheets perpendicular to the slope; if the roof slope is greater than the indicated parameters, then parallel installation would be advisable.

- When covering a roof for the first time, a two-layer application is required, with the first layer being a material with a double-sided polymer film coating, for example, the KhPP brand, and the second is a roll treated with large grains of topping (KhKP brand) on top.

- The ideal option would be to fuse the material using a torch, but if this tool is not available, you can use bitumen mastic.

Restoration of soft roof

After the rain stops, go upstairs and continue your search. Places of suspected leaks should be marked by placing, for example, a brick on them. Now we need to wait for sunny weather and start repairs. At the ready you need to have several scraps of glassine and roofing felt, a tape measure, a knife, a brush and, finally, several cans of bitumen mastic. Minor repair technology:

- Cut the coating crosswise with a knife at the leakage site. Please specify the size depending on the situation.

- Bend the corners and coat the inside of the cut with mastic.

- Cut a square patch from glassine paper, place it under the edges of the cutout and, by smoothing it, glue it to the base. The patch should be measured a few centimeters larger than the cutout to ensure the required overlap.

- Coat the bent petals and glue them like an envelope to the applied patch.

- Glue an additional roofing felt patch on top so as to cover the cutout by at least 10 cm on one side.

Is it possible to repair a garage roof in winter and how to do it correctly

In winter, due to weather changes, extreme conditions are created for any external work, therefore repair of old roofing is carried out only in exceptional cases. Heated bitumen compositions, suitable for the warm period, are replaced with cold mastic, more suitable for severe frosts. It is offered in liquid form in containers of various sizes, does not require any preparatory manipulations and is immediately ready for use. To some extent, cold weather simplifies the process, since there is no need to heat the bitumen or resin mass over a fire.

In winter, repair work is carried out only as a last resort.

The master’s primary task is to make the maximum amount of effort to secure the new coating over the old one. So, in places of damage, you should thoroughly clean the dirt, remove debris, and dry the surface with a hairdryer. All swelling, folds and other defects are cut crosswise with a knife. The old mastic should be removed from under the layer of material and everything should be dried. The treated elements are lubricated with fresh mass and pressed against the roof with force. A patch of a material of a similar composition with a preliminary coating of mastic is applied over the slot.

In this way, all imperfect areas of the roof surface are repaired. In places where the roof is torn, mastic is poured over the entire damaged part, followed by a new piece of roofing layer.

The formation of roof leaks some time after rain indicates the absence of specific damage, this means that the roof is completely covered with cracks, which gradually allow moisture to pass through. Then patching equipment will not help; a major replacement of the roof is necessary.

A detailed description of garage roof repairs will make the work much easier, but if serious difficulties arise, you should not experiment, but rather contact a specialist, which will help you avoid unnecessary costs in case of poor quality coating.

Content

A convincing signal indicating the need for roof repair is usually trivial leaks. They appear for various reasons, which include:

- Design violations. These include errors in the arrangement of layers of the roofing pie, incorrectly calculated insulation thickness, incorrectly selected coating, etc.

- Installation errors. This is non-compliance with technology: incorrectly installed fasteners, insufficient application of adhesive and similar mistakes.

- Household damage. Their list most often includes punctures and breaks in the coating resulting from careless movement on the roof, the fall of heavy objects with sharp edges, heavy winds, and cleaning with a metal shovel.

To correct defects resulting from design violations, a major overhaul is needed. Not every home master will be able to cope with it without professional assistance. But the damage indicated in the second and third paragraphs is eliminated during routine repairs. It does not require global dismantling, a large amount of work or highly complex operations. Almost all damages included in the current repair scope are accessible to an inexperienced contractor. Let's consider them.

Determining the location of damage

Traces of damage to the integrity of the coating do not always appear during periods of active snow melting and rainfall. Although the ceiling, the cladding of the attic, and damp rafters that are wet due to liquid precipitation are reasonably considered to be one hundred percent indicators. It happens that atmospheric moisture that has penetrated under the coating first “cruises” along the waterproofing for some time, and then seeps into a crack that finally meets on its way. According to popular wisdom, water will always find a “hole” for itself, and is even capable of “sharpening a stone.” How can a wooden rafter system, lathing and mineral wool insulation be used to combat its impact?

For the sake of long-term service of the roof, inspections must be carried out regularly 4 times a year. They are needed for the timely identification of existing and emerging breakthroughs, which sooner or later will definitely make themselves felt. To ensure that the consequences of small punctures, cracks, and potentially dangerous swellings do not take on an emergency nature, the roof is inspected each time in two stages, these are:

- Studying the condition of the roofing structure from the attic with a thorough check of wet spots and the degree of damage to system parts.

- Inspection of the roof covering from the outside with a detailed inspection of defects and inspection of areas of possible water penetration.

It should be taken into account that wet spots identified from the attic do not always coincide with existing holes found on the outside of the roof. The causes and consequences of leaks are practically combined or are closest to each other on flat roofs. This is not typical for pitched structures: in reality, water penetrates higher than it leaves its destructive traces. The researcher of his own stingrays must certainly remember this circumstance.

Tip #2. What to do with bitumen shingles?

If the leak is small, you just need to replace the part with which problems arose. For this:

- Take a nail puller and remove all damaged sheets of asphalt shingles. The device must be operated carefully so as not to damage entire elements.

- Checking the lining. If there are signs of leaks in it, obvious peeling or divergence of seams, then we apply bitumen-polymer mastic to these places.

- We attach a new element that matches the color and shape.

- We carefully process the joints.

In extreme cases, the roof is completely replaced. Typically, drastic measures are needed when working with very old or poor-quality coatings. If a leak is discovered in just such a case, then replacing individual sections may be too tedious and time-consuming. Therefore, carefully assess the scale of work and the practicality of the chosen solution to the issue.

Features of care and operation

Your roof should be cleaned and thoroughly inspected annually. Constant monitoring will allow you to notice the threat in time and prevent subsequent destruction.

A roof made of corrugated sheets is functional and lasts a very long time thanks to a reliable polymer layer - it protects the roof covering from corrosion. Constant exposure to moisture and low temperature, UV radiation, and various contaminants cause the destruction of the polymer coating. For this reason, cleaning roofs is a necessary job to increase their lifespan. It is convenient to clean with a stream of water, directing it along the slope from top to bottom.

Snow does not often collect on the polymer coating, and the matte surface does not allow it to slide down. Roof cleaning is carried out using tools that cannot damage the material. A wooden scraper with a soft rubber pad is suitable for this.

Soft roofing is subject to the same impacts as other coverings. Timely preventive inspections will allow you to detect defects in the roofing carpet in time and quickly eliminate the shortcomings.

A roof covered with natural tiles requires almost no maintenance. Cleaning the covering from fallen snow is done with scrapers, a shovel and a soft broom, which will not damage or move the tiles. Seasonal inspection includes monitoring the strength of hooks and detecting leaks. Work is performed in soft shoes every 4 years.

The construction of a gable roof on a garage requires compliance with safety requirements, like any work at height, and it is necessary to adhere to electrical and fire safety rules. This is the only way the roof will serve you for a long time and without extra costs.

Preparatory stage

The roof can easily be considered one of the most vulnerable parts of the garage box. The fact is that the garage is affected by precipitation. A soft coating can be quite stable, but a lot depends on the characteristics of the material. Modern coatings, if they are laid on the garage roof strictly in accordance with the manufacturer's instructions, have a long service life.

You need to pay close attention to the installation of a garage roof roof. Before starting restoration work, carefully inspect the roof of the garage box

Assess the condition of the roofing material and determine the degree of wear. Local repair is only possible if you see minor damage located locally. Then you can replace individual sections of the decking.

In case of serious damage, it is easier to immediately repair the roof or lay a new layer. For this, mastic, roofing felt, and soft rolled material can be used. If the roof slopes, leave the repaired layer. It will act as a waterproofing coating. Make a sheathing on it, put a soft roof on it. Instead, it is possible to lay sheet material.

Repair depends on what material was used. Before starting work, thoroughly clean the roof covering from dust. Remove debris, dirt and dried mastic.

If you find through holes to repair the roof, make a cross-shaped cut in the material. By bending the edges, remove moisture trapped under the roof and get rid of debris. If you see that the soft roofing is very worn, cut it out. Be sure to dry the coating of the garage box; only then can you carry out local repairs. Take a gas burner. Using it, you will dry the garage roof. If you don’t have a burner, you can take a hair dryer.

Please note that covering a garage with a soft roof can only be done in warm and dry weather.

Rafter frame

The basis of each gable roof is a rafter frame, a set of elements that ensure the stability and stability of the roof structure. The garage roof is built on the basis of rafters made of coniferous wood impregnated with antiseptic and fire-resistant substances. Depending on the layout of the building, the weight and coverage area of the roofing material, 2 different types of rafter systems are used:

- Hanging. A characteristic feature of this type of rafters, which distinguishes them from layered ones, is that they have only two support points. The upper part of the rafters rests on the ridge girder, and the lower part is attached to the mauerlat. This option is used to cover garages for one car space, where there are no load-bearing walls inside that can be used as an additional point of support. Hanging rafters do not experience expansion loads, they only work on deflection, so there are fewer elements in such a system. To stabilize the frame, tie rods, crossbars, headstocks and struts are installed. Using hanging rafters, you can cover a garage up to 14 m wide with your own hands.

- Layered. The difference between layered buildings and hanging ones is that they have an additional point of support - a rack, which is installed on the internal load-bearing wall, redistributing the load and directing it to the foundation of the garage. Because of this, the frame is subject to not only a bending load, but also an expansion load. To balance the rafter system, tie-rods, ridge purlins, racks, crossbars, beams and struts are used. If you have one internal load-bearing wall, you can cover a garage up to 28 m wide, however, this method of organizing the frame is more difficult to design and install yourself.

Criteria for choosing a waterproof roof covering

To prevent rust from appearing on the metal parts of your car, you need to take care to protect your garage from moisture. Water penetrates into the room from the outside due to precipitation and from the inside due to vapor condensation. Waterproofing the garage roof is designed to ensure the safety of the property contained in the box from the negative effects of dampness.

Manufacturers fill the market with a wide selection of materials that can protect the roof from water penetration. The most effective roofing moisture-proof coating must meet the following requirements:

- Maximum moisture resistance. Waterproofing must have the ability to retain vapors and keep the room free of water.

- The elasticity of the material is of great importance. It allows you to resist elastic deformations that cause the destruction of the roofing.

- Resistance to external loads is determined by strength. It also resists deformation.

- The thermal impermeability of the material allows you to retain heat in the garage.

This characteristic helps maintain the required temperature in the room. Source sideg.konybihus.ru.net

When starting to build a garage, it is necessary to purchase waterproofing that best matches the above characteristics. This will ensure adequate protection of the room from dampness, preserving the car from rust for a long time.

Asbestos-cement slate and euro slate

In fact, these are completely different materials, but they have a similar appearance (sheets with a wavy surface) and installation technology. The material can only be used on pitched roofs with a slope of at least 10 degrees; it is not suitable for flat ones.

Asbestos-cement slate, banned in Europe, is still recognized in our country.

There are quite a few reasons for this:

- cheap material;

- relative durability of operation (up to 15-20 years);

- ease of installation;

- high maintainability;

- non-flammability;

- chemical resistance.

The disadvantages include the following:

quite large weight of slate sheet; fragility of the material; in a fire it does not burn, but bursts; unpainted slate becomes overgrown with moss over time; low mechanical strength - it is better not to walk on the roof, and care must be taken during transportation and loading and unloading operations.

Euro slate (including ondulin) are sheets formed from cellulose impregnated with a polymer-bitumen composition.

The material is immediately colored and looks very attractive. Installation is similar to that of conventional slate. The cost of Euro slate is significantly higher than that of regular slate.

But it also has enough advantages:

- low level of water absorption;

- ease of processing - easy to cut with a hacksaw;

- has flexibility and elasticity;

- not affected by fungus and mold;

- If the installation technology is followed, it can withstand loads of up to 300 kg/sq.m. m;

- retains its original color for a long time;

- practically not deformed;

- resistant to aggressive environments;

- The service life can be up to 50 years (with a guarantee of 15 years).

Therefore, if you want to avoid problems with your garage roof for many years, then you should consider the option of using Euro slate.