After installing plastic windows, the window opening does not look the best: foam, pieces of plaster stick out, and the wall material is visible in places. All this “beauty” is closed in various ways, the most practical, fast and inexpensive of which is plastic slopes. It is better to make them from sandwich panels (two layers of plastic with polypropylene foam between them). They are dense, durable, made of good material.

There are two main methods for installing plastic slopes: with and without a starting profile. Both come with step-by-step instructions and photos. Decide for yourself how to attach slopes to plastic windows. Both methods give good results.

What are they needed for

The installation of plastic finishing is the most common way to improve the space of a window opening. PVC slopes have a pleasant glossy surface and are combined with the window profile material. Plastic panels help protect the assembly seam from exposure to sunlight and moisture .

Finishing the slopes after installing the window is done using plastic

The mounting foam, with which the window system is fixed in the opening, is a water-repellent material. But if it is not protected from direct sunlight, it will begin to deteriorate and moisture will freely begin to penetrate into its pores, destroying it from the inside. Therefore, slopes for plastic windows must be installed as soon as possible after installing the window. How to make slopes on plastic windows will be discussed in this article.

Pros and cons of doing the work yourself

The advantages of installing products yourself are:

- savings on work costs;

- gaining experience and gaining new knowledge;

- with strict adherence to technology, confidence in the quality of work.

If you do all the steps yourself, you can know exactly the nuances of each operation. This will help you quickly fix problems as soon as they appear.

Minuses:

- poor-quality installation in the absence of knowledge and experience;

- illiterate selection of material;

- incorrect measurements.

All these shortcomings reduce the performance characteristics of windows.

Properties of plastic slopes

Slopes for plastic windows can be made of two types of material - these can be window slopes made of PVC panels or sandwich panels.

The slope serves to protect the polyurethane foam from destruction

Both types of plastic panels have common positive qualities:

- long service life;

- plastic slopes for windows have a decorative appearance and are combined with the material from which the window system is made;

- finishing the window slopes inside with plastic allows you to reliably protect the mounting foam from environmental influences;

- installation of plastic slopes is possible for finishing arched openings, since flexible PVC casing can be used;

- you can install PVC panels with your own hands, without professional skills and special expensive equipment;

- plastic panels for slopes can be cut with a hacksaw for metal, but this must be done carefully, without exerting force, so that the PVC panel does not crack;

- Do-it-yourself installation of plastic windows occurs quickly and without the formation of serious pollution and construction waste;

- PVC panels are easy to care for - just wipe them occasionally with a cloth soaked in a soapy solution;

- they have low thermal conductivity;

- the plastic window element is highly moisture resistant;

- Finishing the slopes of plastic windows will reliably protect them from freezing.

Products made from PVC panels

Before installing plastic slopes with your own hands, you need to familiarize yourself with the qualities of the material used to make them. One of them could be a PVC panel.

Description of material

Another name for this material is ceiling panels. They are made from polyvinyl chloride.

They consist of two plastic plates with stiffening ribs inside. Some models are provided with locking connections at the ends.

The panels may have different sizes, but during installation they will still have to be cut to the required dimensions. Despite the fact that the panels can have a length of 3 and 6 meters, you should purchase 6-meter products . The thickness of the panels varies from 0.5 to 1.2 cm. The type of products can also be different: panels, slats or PVC sheets.

They also purchase components for plastic panels. The kit should include fasteners and plastic elements. Their description is presented in the figure below.

Accessories for plastic panels

One of the advantages of any plastic panels is their wide range of colors. Colored PVC slopes can be matched to any interior.

The color of the finishing plastic can be matched to any interior

The interior decoration will look original when covering the window openings with plastic panels with an image or imitation of any natural or artificial material. When the windows are colored or brown, painted products can be used. It is important that in this case the window fittings are combined with them.

(function(w, d, n, s, t) { w[n] = w[n] || []; w[n].push(function() { Ya.Context.AdvManager.render({ blockId: "RA-510923-1", renderTo: "yandex_rtb_R-A-510923-1", async: true }); }); t = d.getElementsByTagName("script")[0]; s = d.createElement(" script"); s.type = "text/javascript"; s.src = "//an.yandex.ru/system/context.js"; s.async = true; t.parentNode.insertBefore(s, t) ; })(this, this.document, "yandexContextAsyncCallbacks");

PVC panels can imitate a wooden surface

The panels can be plain, laminated, varnished, or have a printed pattern or image applied using thermal printing on their surface. Installing plastic slopes will give the windows a neat, decorative appearance. How to make plastic slopes will be described below.

Positive qualities of the material

High-quality finishing of slopes with plastic with your own hands is obtained thanks to the properties of the ceiling panels.

- the material is non-toxic;

- have high moisture resistance;

- they are easy to install and maintain;

- have little weight, so they do not create a load on the base;

- plastic is a non-flammable material, but when melted it emits toxic, acrid smoke; products are resistant to temperature changes;

- have frost resistance;

- create an ideal, flat, rigidly fixed surface;

- have a modern look and are suitable for any interior;

- the honeycomb structure provides reliable noise insulation;

- do not accumulate static electricity on their surface;

- panels are resistant to household chemicals.

Installation

How to install plastic slopes on windows with your own hands step by step is shown below. Before you start finishing the slopes with panels, you need to take measurements. The inner sides are measured twice - at the window and at the wall .

- The installation of plastic slopes on windows begins with removing the mounting foam that has gone beyond the seam along the perimeter of the window frame. To do this you need to use a sharp construction knife;

Before installing the slopes, remove excess foam - It will be necessary to attach a wooden block along the perimeter of the window frame. When making a bar, you need to make a slope on one of its faces. This is done so that the block can be firmly fixed near the window frame;

To secure the slope, a wooden block with a slope is made - the finished bars should be installed around the perimeter of the window frame in such a way as to overlap it slightly. Fastening can be done using self-tapping screws or dowels;

The block is secured with self-tapping screws around the perimeter of the frame - a plastic strip, called a starting profile, is purchased at a hardware store. Using a construction stapler or self-tapping screws, attach it around the perimeter of the window to a wooden block;

A starting profile is mounted to a wooden block - We manufacture the necessary elements using the previously obtained dimensions. We cut the plastic carefully so as not to damage it;

Cutting the PVC panel must be done without strong pressure - The panels must first be installed on the side walls of the window opening. Panels must be placed in the starting profile;

The panel is inserted into the starting profile - the part must be separated from the wall and the space covered with foam. Then put it in place and press down a little so that the foam sets;

The PVC panel is fixed using polyurethane foam - in this way it is necessary to finish the entire window opening;

- To properly make plastic slopes, decorative corners are attached to the finished fragments. The finished product is fixed with masking tape until it sets completely.

Use masking tape to secure the slopes until the foam dries completely.

When installing slopes on plastic windows, you can attach platbands to their corners. How to make slopes with platbands is shown in the step-by-step instructions below.

Scheme for installing a slope with a platband

Installation of a slope with platband

Sealing joints

Even with the most precise cutting of the finishing elements of the slope, gaps still form at the joints. They must be sealed to prevent moisture, cold air and noise from entering the room and the window structure.

In order for this work to be done professionally, you will need to choose the right sealant and strictly follow the seam sealing technology .

What to seal it with?

There are many types of sealants on the market for all types of work, which differ in their characteristics. The most popular types of work for this type of work are silicone, polyurethane and hybrid MS-polymer. Silicone sealants are considered the most universal of them, this is due to their special protective capabilities.

Within the class, they are divided into acidic and neutral varieties, each of which has its own characteristics. For PVC windows, a neutral silicone sealant is better suited, since an acidic one can corrode metal parts and concrete due to the presence of acetic acid in its composition.

The advantages of such sealants when sealing slope joints are:

Temperature range from -30 to +60 C. There are special heat-resistant modifications that can operate at temperatures up to 400 C.- The sealant creates a monolithic seam with excellent elasticity and wear resistance.

- Prevents moisture from penetrating into the window unit.

- It has high noise and soundproof characteristics.

- Biologically safe because it contains a fungicidal additive that counteracts the formation of fungi and mold.

- Large selection of sealant colors.

- Reasonable price.

- Long term use over 10 years.

The disadvantages of such protection include the impossibility of painting it, since paint destroys its structure; in addition, it is almost impossible to apply a new layer of sealant to an already applied layer of sealant, since they will crack and the protection will need to be carried out again from the very beginning.

Quite a lot of users choose polyurethane-based compounds for sealing. They come in one-component and two-component types, the latter being more difficult to use because they need to be mixed before application. One-component is available in the form of a paste-like substance of polyurethane fluoropolymer. Its hardening occurs due to the moisture contained in the air.

One-component polyurethane sealants are characterized by exceptional adhesion in practice to various building materials:

- brick,

- blocks,

- concrete,

- tree,

- glass,

- PVC and metal.

It can be applied to a previously laid layer of polyurethane sealant.

Sealants of this type have many advantages, including:

- High elasticity often reaching 100%.

- Highest adhesion.

- Long term use over 10 years.

- Resistance to mechanical stress; when stretched, it returns to its original state.

- High operating temperature range.

- Can be painted.

- Resistant to weathering and does not corrode treated surfaces.

- The disadvantages include its high cost.

Hybrid MS-polymer sealants are innovative materials in the field of elastomeric building materials; they incorporate the best characteristics of silicone and polyurethane, due to which they surpass all existing sealants in their properties.

The main advantages of MS-polymer materials when working with slopes of PVC windows:

High resistance to atmospheric influences, including UV rays.- There is no smell.

- Easy to apply to treated surfaces, fast hardening speed.

- Environmentally safe.

- The treated surface can be painted.

- Good adhesion to any materials.

- Able to withstand high temperature differences - 40 to 120 C.

- It is not susceptible to and does not create corrosive and oxidative processes.

The disadvantages include a very high price, which limits its use.

Sealant application technology

Once the type of sealant has been selected, prepare the surfaces of the slope for its application - they must be clean and dry.

Instructions for applying sealant to the seams of slopes for PVC windows step by step:

- It is necessary to glue protective masking tape to the window frame and that section of the slope that does not need to be sealed, so as not to cover the surfaces of the slope and the window with sealant and paint.

- Fill the cracks with the selected sealant so as not to leave voids.

- Using a narrow brush, smooth the sealant over the surface to be treated.

- Wait until the sealant hardens completely and remove the protective tapes.

For those sealants that can be painted and can be recoated, after the first coat has dried, apply additional sealant, wait until it dries and paint it the desired color. After the paint has dried, remove the protective tapes.

Sandwich panel products

Do-it-yourself installation of plastic slopes can be done using multilayer material coated on both sides with decorative plastic. By installing plastic slopes with your own hands using sandwich panels, you don’t have to provide additional thermal insulation .

Sandwich panels have high thermal insulation properties

Installation of PVC slopes when using this material occurs quickly and with a minimum amount of debris. The use of slopes made of PVC panels of this type provides protection for windows from freezing.

Sandwich panels have the following characteristics:

- PVC provides reliable heat and sound insulation;

- finishing window slopes with this material increases the energy efficiency of the window system as a whole;

- if you correctly make slopes from panels with your own hands, then the window opening will acquire a neat appearance;

- finishing windows with plastic with your own hands is done quickly and efficiently;

- Even an untrained person can make slopes from plastic with insulation.

Installation

The sandwich panel can be attached in the same way as a PVC panel. How to properly make such a finish yourself is shown below.

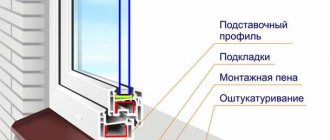

Construction of a slope using sandwich panels

How to finish window slopes with plastic without a starting profile is shown step by step below.

- this installation method is relevant when the distance from the frame to the opening is small, when there is simply nowhere to mount the starting profile;

- excess foam is carefully removed. A thin strip is attached to all sides of the opening; in this case, the panel is installed in foam by 1 cm, so the latter is trimmed accordingly along the entire perimeter;

Sandwich panels are installed in a groove in the mounting foam. - First, the upper part is inserted into the resulting groove. It bends a little, and the resulting space is covered with a small amount of foam; the panel is fastened with self-tapping screws to the rail;

The sandwich panel is secured with self-tapping screws - The side fragments are mounted in the same way.

What tools do you need to prepare?

The internal and external elements of the slopes must be very precisely cut and fitted to each other with minimal gaps. To do this, you need to choose precise cutting tools.

What to cut: hand and electric saws and jigsaws or a grinder with an appropriate attachment stand out; you can use an electric mini-circular saw with a laser for cutting wood and PVC, which has a 45-degree cut function.

In addition, to perform slopes the contractor will need:

- screwdriver;

- guns for glue and polyurethane foam;

- construction knife;

- measuring instruments: corner, ruler, tape measure, level and pencil;

- sponge roller and brush;

- spatula 5-10 cm wide;

- stapler;

- liquid Nails.