In most cases, the heat-insulating properties of house walls are insufficient, and to maintain optimal temperature conditions in the premises installation of a separate layer of thermal insulation is required.

Good thermal insulation not only eliminates temperature changes (and, accordingly, reduces heating costs), but also minimizes the formation of internal condensation , which contributes to the growth of mold and the destruction of roofing and wall materials.

Polyurethane is a polymer material used in many areas of production. It has also found its application in construction as a good wall insulation material. Polyurethane is expensive and difficult to install , but these disadvantages are compensated by the high reliability of the material.

Based on the high cost of the material, many choose insulation from cheaper materials, such as:

- mineral wool;

- Styrofoam;

- penoizol;

- extruded polystyrene foam;

- penoplex;

- penofol.

You can find the most effective choice here.

Internal and external insulation

The thermal insulation layer can be installed both outside and inside the wall. external thermal insulation is preferable .

This is due to the fact that it allows the dew point (the area where condensation forms) to be moved away from the wall, preventing the destruction of its components. When using this method, the usable area of the premises is not reduced.

But it also has disadvantages: the appearance of the facade changes, and installation work can only be carried out in dry weather.

Internal thermal insulation does not affect the appearance of the facade, and you do not need to wait for good weather to install it. But the shift of the dew point into the inner space of the wall and the reduction in the usable area of the premises do not allow making a clear choice in favor of this method.

IMPORTANT!

When installing internal thermal insulation, you need to bring out sockets and other internal communications without walling them up.

The effectiveness of a particular method also depends on the selected material . Polyurethane is laid in a relatively thick layer, and its installation on the inside of the wall significantly reduces the amount of free space in the premises. Although the material is moisture resistant, the formation of condensation cannot be ruled out when the dew point is shifted inside the wall.

Dew point

These factors make it preferable to choose external thermal insulation when using polyurethane.

Insulation with polyurethane from the inside is also possible, but it requires additional costs for installing a separate vapor barrier layer, and when planning rooms, you need to take into account the reduction in their area.

Since ancient times, people have paid sufficient attention to insulating their baths.

After all, the quality of insulation of a bathhouse or sauna structure is directly related to the quality of the parka.

For quite a long time, mineral wool was used to insulate baths, which lost its importance and lost its competitiveness with the advent of polyurethane foam on the building materials market.

As you know, this material works on the principle of a thermos, retaining heat inside. This principle is achieved by spraying the building material, which eliminates any gaps and air penetration.

Also, it should be noted that a rather important fact is that polyurethane foam has a G2 fire certificate. This guarantees the preservation of the premises even with a high risk of fire.

The main feature that is characteristic only of polyurethane foam is the environmentally friendly materials that are used to create the insulation. And since a bathhouse or sauna requires a high percentage of humidity, as well as high temperature, this quality is extremely necessary.

Material characteristics

Polyurethane is a two-component material that is formed by combining a polyol and an isocyanate.

It has high wear resistance and good insulating properties, making it widely applicable in industry.

It is used to make sealants, elastic forms (including shoe soles), implants and other products.

Polyurethane comes in both liquid and solid forms. In private construction, a liquid material is used, which is applied to the walls by spraying and immediately turns into foam due to contact with air.

The material can be sprayed not only on vertical, but also on horizontal surfaces, which will allow it to be used for insulating ceilings, floors, and basements.

NOTE!

The service life of the material declared by manufacturers is 40-50 years.

Polyurethane in its original state is vulnerable to moisture, but the foam it forms is resistant not only to water, but also to gasoline, ethers, alcohols and most other aggressive liquids.

Polyurethane foam (PPU) is available in two main varieties: with open cells (“soft foam”) and with a closed structure (“hard foam”) . A material with a closed structure has better vapor barrier properties, but its price is higher than that of “soft foam”.

Types of polyurethane foam

The average thermal conductivity coefficient of polyurethane foam is 0.025 W/(M*K).

Advantages:

- High adhesion. Polyurethane adheres well to any surface, even rough and uneven, and fills all recesses, providing complete and continuous coverage of the wall over its entire area.

- Quick application and hardening (1 hour).

- Resistant to rot and mold.

- Lightness: polyurethane does not weigh down the structure.

- Non-flammability.

Flaws:

- Relatively high price.

- Self-installation of polyurethane foam is difficult.

- Contact with fire does not cause the material to ignite, but it does begin to emit smoke containing toxic substances.

- Polyurethane quickly deteriorates when exposed to direct sunlight - ultraviolet protection is required.

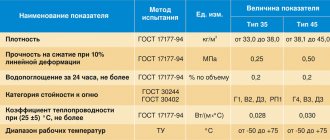

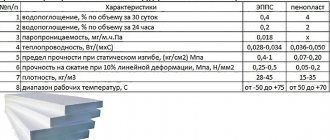

Comparison of thermal insulation characteristics of materials

During the construction of any facility

...it is necessary to take into account not only the insulation of residential premises, but also the insulation of roofs. Today, there is a huge variety of building materials that can be used to insulate roofs and roofs, such as glass wool, polystyrene foam, mineral wool, etc.

As for polyurethane foam, it differs significantly from the materials already listed. Thanks to the material application technology unique to polyurethane foam, it has a significant advantage, since the solution applied to the surfaces being treated neutralizes any penetration of foreign air. Also, polyurethane foam acts as protection for structures from wear. This material is not only environmentally friendly, but also moisture resistant. Thus, polyurethane foam does not imply allergic reactions, as well as the release of toxic substances, which absolutely does not harm people inside the room.

It should be noted that polyurethane foam has another significant advantage over other building materials - it is light weight, which in no way burdens the building structure.

Also, a huge advantage of using polyurethane foam is that there is no need for all kinds of additional fasteners.

Preparing for self-application

Polyurethane foam is considered one of the most difficult thermal insulation materials to install. It is much easier for the owner of the house to call specialists who know the installation technology and have the necessary equipment.

But independent installation is also possible, although it requires thorough preparation.

Kit for self-insulation

To insulate walls with your own hands you will need:

- 2 cylinders with polyol and isocyanate.

- Spray gun.

- A compressor that creates the pressure necessary to atomize the material.

- Heads (nozzles) on the gun that allow you to regulate the volume of foam flow and its pressure.

- Personal protective equipment: respirator, gloves, suit.

- Heating block (optional; required for operation at low temperatures);

CAREFULLY!

Working without protective equipment is strictly not recommended. Polyurethane foam loses its toxic properties only after complete hardening; until this point, inhaling its vapors can be harmful to health.

Sputtering process

If you have entered into an agreement with a company, a minibus arrives at the appointed time. It contains spraying equipment. To operate a high-pressure apparatus, a voltage of 380 V is required. If you only have 220 V, you usually start a generator that produces the required voltage. A low-pressure apparatus can operate from a 220 V network, but, as discussed below, the quality of thermal insulation will be significantly worse.

Typically, only hoses are pulled into or around the house to supply the foam components to the gun. It's comfortable. Workers who spray thermal insulation are dressed in protective suits, wearing a respirator, gloves and goggles. A respirator is necessary, since before hardening the components of the foam are toxic, and everything else is to protect the skin from ingress of polyurethane foam, which then cannot be removed.

The foam is applied from bottom to top, in small portions. Fill everything in without skipping, trying to prevent the formation of shells. As the foam expands, make sure that the layer thickness is no less than the required one. After the foam hardens, the excess can be cut off, but the deficiency cannot be made up for.

Calculation of the thickness of the polyurethane foam layer

Heat transfer resistance is a standardized characteristic that is set separately for each region.

The thickness of the polyurethane foam layer must be calculated in accordance with this parameter.

The standards indicate the values of the total heat transfer resistance related to the entire wall structure.

For this reason, the calculations take into account not only insulation materials, but also the parameters of the insulated structure.

Self-calculation formulas are complex and cumbersome, but there are a large number of online calculators that find the required insulation thickness based on user-entered data (region, wall material, its thickness, insulation materials and additional finishing).

The average thickness of the polyurethane foam layer is 10-30 centimeters.

Negative aspects of using foamed polymer

Most brands of foam have flame retardant additives. But this does not mean that the polymer is absolutely safe in fires. Like any organic substance, at high temperatures foam releases large amounts of toxic gases, which are most often caused by fires.

The second negative side is the intense destruction of the polymer under the influence of solar radiation. Often, to lose the properties of polyurethane foam, it is enough to expose the material to the open sun for a couple of weeks. Therefore, the insulation layer must be covered with sheet plastic or fiberboard.

The worst sin in carrying out work on applying a layer of foamed polyurethane foam is violating the proportions of the components used. If the mixing chamber and flow rate are set incorrectly, for example with too much isocyanate, the foam will be very weak and hard. If it is deficient, we will get the opposite effect - the foamed polymer will not harden, will be soft, and will gradually lose its bubble structure.

Pie wall

The main condition for applying polyurethane is the construction of a lathing made of wood or a metal profile on the wall surface. The insulation will be applied to the space between the sheathing guides . The lathing not only creates “cells” for applying polyurethane foam, but also performs a leveling function.

Separate vapor and waterproofing is not needed if polyurethane foam with a closed structure is used, since its moisture-proof properties are very high. Open cell material requires the installation of a vapor barrier layer.

wall pie

For external insulation, it is installed between the thermal insulation and the wall structure. The most popular vapor barrier material is polyethylene , which is laid with an overlap under the sheathing over its entire area.

Waterproofing and windproofing is always installed between the polyurethane foam layer and the external finish of the wall.

Scope of application

Polyurethane foam is applied to surfaces only by spraying. Liquid insulation is easy to apply and dries instantly. Its peculiarity is that it is evenly distributed along a given path and does not leave gaps or joints after complete hardening. With it, all operations are performed many times faster than with any other insulating substance.

The material is applied to any surface, be it wood, iron, concrete, metal structures or mixed types of walls and ceilings. Polyurethane foam is applied to residential buildings, houses, structures, industrial warehouses, collectors, and is used in large-scale applications. This is an ideal insulation for any structures and elements.

Algorithm for wall insulation with polyurethane foam

Before installing the sheathing, the wall surface must be made smooth. The cracks are sealed according to the following algorithm:

- All debris is removed from the gap.

- Cement mortar (if the wall is brick), plaster mixture or fiberglass mixture (if the wall is covered with plaster), putty (if the wall is covered with plasterboard) is poured into the empty space.

The wall must be cleaned of dirt and cement deposits.

The most common lathing material is wood . It should have a humidity of no more than 11-13%, the optimal cross-section of the beam is 40-60 mm, before installation the sheathing elements are treated with an antiseptic.

The distance between the edge guides and the corners of the building must be at least 10 centimeters.

Insulation scheme

After preparing the wall and installing the sheathing, you can begin applying polyurethane.

Mixing of polyol and isocyanate occurs directly during the work. These materials are supplied in two cylinders, which are connected to each other and to the sprayer using a hose.

Before connecting the cylinders to the sprayer, you need to put on protective clothing (respirator, suit and gloves).

The connection of these components is tightened using a special key, which is included with most kits.

By default, the spray gun does not come with a nozzle. It should be put on only after a test run of the insulating components (they can be poured into a plastic bag), which allows you to make sure that they are supplied evenly from both cylinders.

Thermal insulation of walls outside

Moving cylinders is permissible only by those elements that are specified in the instructions (in most cases, separate handles are provided for this).

Spraying of polyurethane occurs in the direction from the bottom of the wall to its top. The optimal distance between the spray gun and the wall is 500-600 mm. It is most convenient to start spraying from hard-to-reach areas, subsequently moving on to filling the rest of the surface with insulation.

NOTE!

Before applying the next layer of foam, you need to wait until the previous one has dried , since otherwise you may exceed the required thickness of the thermal insulation.

Thermal insulation of walls from the inside

At the end of the work, you need to remove the nozzle from the gun, close the taps on the tanks and remove the hoses.

Installation of wall coverings should be carried out as early as possible so that the insulation is not exposed to the destructive effects of sunlight.

Thermal insulation of frame houses

For frame houses, it is important to use high-quality insulation, which will be able to protect the room from temperature changes and excess moisture. PPU copes with these tasks, and can also well reduce the level of noise penetration, which is also important to consider when using it.

In frame foundations, it is important to insulate every joint, including verandas, attics, and balconies.

Insulation of a frame house: how important is an integrated approach to the matter?

The insulation does not form gaps, adheres tightly to the base, therefore it is used in both horizontal and vertical positions. It is applied to the ceiling, insulating the floor and walls. At the same time, the application technology is followed using special equipment. It is best to entrust this process to professionals who clearly know how much to mix the mixture and how to properly apply it to the surface.

How to insulate a floor in a frame house: technology features

The following conditions are met:

- for the subfloor you need to choose good boards that need to be pressed tightly together;

- to ventilate the underground, you need to use a wind barrier, onto which OSB is additionally screwed on top;

- insulation is laid between the joists;

- a vapor barrier is applied on top of the insulation, which is pulled to the joists with a stapler;

- Finishing plank flooring is made using tongue-and-groove boards.

Insulating the walls of a frame house: materials and technologies

The components that make up polyurethane foam are quite toxic, so they should be supplied only with respirators. After hardening, this material is absolutely harmless and has high thermal insulation properties. The technology of mixing the components occurs in a gun under pressure. The components are heated to 45 degrees. In the form of fine dust under pressure, they are mixed and sprayed onto the surface.

On the surface the composition foams and then hardens. This is the essence of PPU insulation. For work, a material with a closed cellular structure and closed is used. All components must be in the equipment in equal proportions. Exceeding one of them leads to a decrease in the quality of insulation.

Foam for waterproofing

Foam is often used to protect against moisture. Under the influence of water, it begins to increase in volume and harden within 24 hours. Such products are sold in cans. The peculiarity of such foam is its fixing and waterproofing features. Used for work outside and inside.

We can say that foam as insulation is an excellent solution. It has a lot of advantages and is a universal solution. Sometimes other insulation materials other than foam cannot be used. Therefore, if funds allow, you can hire professionals who will quickly and efficiently do all the work for you.

Manufacturers of heat insulators for pipes

In construction stores, insulation materials for pipes are mainly from domestic manufacturers, but it should be noted that Russian products have a very decent high quality and a more affordable price than imported products, so there is no particular point in chasing after some brands.

Thus, the most popular manufacturers of these materials were Termocom.

The first company produces insulation materials that contain waterproofing additives, while the second company pays more attention to ensuring the safety of pipes. Energoflex products differ from other heat insulators in that freon is used in their production, while other manufacturers produce polyethylene foam using a propane-butane mixture

Due to freon, the material acquires higher resistance to water vapor.

The cost of polyethylene foam insulation varies depending on its density, thickness and diameter, as well as on the method of its manufacture. It is clear that the range of prices, based on what has been said, is very large - from 10 to 200 rubles per linear meter.

In conclusion, it must be added that insulation for pipes made of foamed polyethylene will be an ideal solution if it is used under operating conditions acceptable to it, that is, not requiring increased fire safety measures. In the other cases listed above, the material will last for many years, without deformation or reduction in thermal insulation qualities.

Is it possible to increase sound insulation in this way?

The foam has sound insulation properties. This is affected by:

- The thickness of the applied insulation layer reflects the incoming noise.

- Elasticity absorbs vibration from sounds.

- The tightness of seams and cracks prevents noise from penetrating into the room.

But the foam in the cylinders does not have the same characteristics as the material sprayed through the equipment.

The only type of foam in cylinders that has good performance is MAXFORTE SoundFLEX.

Today, foam is widely used to insulate walls indoors and outdoors. It is used in attics and basements, attics and loggias. Insulation of pipelines and chimneys is carried out.

The material has many positive aspects and has good sound insulation properties. When using insulation, you should familiarize yourself with the application method and also think about the cladding.

Is penoizol harmful to health?

After testing, Russian manufacturers were convinced of the safety of using penoizol. There are certificates confirming this. But polystyrene foam is prohibited in Canada and is not used in the USA as insulation. In the UK, safety guidelines are followed regarding the use of urea foam as a toxic substance. The problem lies in the concentration of formaldehyde, which is released during polymerization. At high concentrations in the air it causes allergies and tumors in the future

Therefore, it is very important to use high-quality materials and adherence to pouring technology. In high-quality products and in the hands of craftsmen, the minimum content of formaldehyde is safe

High-quality insulation in cylinders: features of polyurethane

PPU is one of the most popular types of thermal insulation materials produced in cans. What else do you need to know about him?

Features and properties of polyurethane foam:

- The qualities of this insulation directly depend on its composition and the additives it contains;

- Using polyurethane, you can quickly and without much difficulty insulate a structure of any configuration;

- This material is not afraid of the chemical effects of alkali or acid, and is able to withstand dampness and is too tough for insects and rodents.

True, as an option you can use “Ekopen” - one of the varieties of polyurethane foam. With its help, you can safely insulate walls and roofs, and with increased vapor permeability. Eco-foam will perform well when insulating ceilings, attic or interfloor ceilings.

But it should be borne in mind that the use of Ecopen is not intended for external insulation of a building without a protective coating, since it is a rather sensitive material to the effects of precipitation and mechanical loads.