When building a house or renovating, every owner must understand that the staircase that leads to the second floor must not only fulfill its functions, but also fit favorably into the overall interior of the room. You should also not forget that finishing the staircase, for example, with wood, will protect the structure and save a person from constant minor breakdowns of this structure.

Covering a metal staircase with wood will solve several more problems. Thus, it will take on a more attractive appearance and be more wear-resistant. Here it is worth paying attention to the quality of materials. If possible, it is better to spend money on expensive wood once, since in any case, sooner or later, the cheap material will have to be replaced.

Wood cladding of stairs

A staircase in a house is not only a way to move between floors, but also a kind of “highlight” or interior decoration. When the staircase is initially made of wood, then it does not need cladding. The tree will look great. It is necessary to veneer staircases built of concrete or metal, for example. Concrete and metal stairs are more durable than wood. But the appearance of such stairs leaves much to be desired.

Stairs are lined with ceramic tiles or wood. While ceramic tiles are more suitable for outdoor staircases, wood cladding is excellent for indoor staircases.

A few simple tips

To cover a concrete staircase with wood, you do not need to have any special skills, knowledge or tools. But in order to avoid mistakes, it is worth taking into account the nuances and features indicated by experienced craftsmen.

Regardless of what materials and design methods you choose, you need to remember some nuances:

- Hard wood species (ash, beech, oak) are more difficult to process (they are especially difficult to sand).

- The wood for cladding must have the same humidity as the climate of the room. To do this, let the board rest for several days where the finishing will be done.

- Do not store boards in a vertical position - in some cases this can lead to bending of the material.

- If you want to arrange a wooden panel along the march on the wall, first make a vertical finish, then lay the treads.

- For cladding risers, you can choose cheaper and softer wood.

- It is better to use decking boards for cladding external stairs.

- If you want to save on installation and skip some steps, operation can be not only inconvenient, but also dangerous - cheap glue causes the linings to shift, narrow steps cause falls, cheap boards crack, etc.

Cladding a concrete staircase with wood is an opportunity to create an aesthetic, durable and safe structure that will delight you for a long time with its ease of use and noble appearance.

What wood to use for staircase cladding

As you know, wood exists on the modern market in various forms and “manifestations”. For cladding the stairs, use solid wood or laminated boards. As a rule, plywood is used as a substrate.

The thickness of the facing material should be about 30-40 mm if there is an overhang of the tread. Or, if there is no overhang of the tread, then the thickness of the facing material should be 20 mm.

You can sheathe the stairs with wood of many species. It is important to take into account the basic requirements for the facing material. Namely, strength, durability, wear resistance and durability.

The most suitable wood for the listed characteristics is oak, beech, ash and maple. It is these listed wood species that have high strength and hardness. They perfectly resist wear and mechanical stress. These types of wood are durable. In addition, they have a beautiful texture and color.

In addition to the listed wood species, sometimes pine and larch are used for cladding stairs. Such lumber is more affordable in price. But their strength is very low. With a limited budget, both pine and larch are not a bad solution. But if you have the opportunity to pay extra, it is better to still opt for hardwood. In addition to all that has been said, larch wood, for example, will be difficult to work with due to the large amount of resins it contains.

Another option to slightly reduce the cost of staircase cladding is to use wood for the treads, which is more expensive in cost. And for the risers - cheaper wood.

Chemical anchors

A chemical anchor refers to a one- or two-component composition that helps fill all holes in the concrete after cleaning the base. This material can be used for bricks and gas silicate blocks. When the channel is filled, it is necessary to install fasteners or studs.

A corresponding reaction occurs in the liquid anchor, which helps the material expand and harden faster. All channels and voids that are nearby must be filled in the same way. The end result is a reliable fixation.

Wood is the most popular material as it is easy to process and can also optimally enhance the decor of a concrete structure. In addition, cladding the stairs with your own hands is quite possible for a person with minimal experience in construction. If it is not there, then professional help will not hurt.

Stages of cladding a concrete staircase with wood with your own hands

The first step is to level the surface of the concrete steps. To do this, measure the height of each of them. We use the highest one as a guide. And adjust the size of the rest using a self-leveling screed. After the screed has dried, the surface should be cleaned of dirt and dust.

The next step is applying the primer. This is not a completely mandatory step. But the primer significantly affects the durability of the steps. And provides high-quality adhesion between wood and concrete.

Next comes the installation of the substrate. Most often, plywood is used as a substrate for cladding. This is not a requirement. But this way, the facing boards will not be properly protected from moisture. Plywood is attached with liquid nails to concrete steps. Additionally reinforced with dowels. It is important to control using a level to ensure that the surface remains level.

The final stage is the installation of the facing board. Three bolts with a diameter of at least 6 millimeters are driven into the riser. The caps are cut off from the bolts themselves. You need to drill holes in the facing board for these bolts, after leaving marks.

The facing board is placed on bolts and further strengthened with liquid nails. The tread is secured to the plywood with liquid nails and inserted into a groove made on the top riser.

Subscribe to our Yandex.Zen channel

Metal structure cladding technology

Each staircase on a metal frame with wooden steps is not only a well-prepared, highly artistic project, but also a complex design from an architectural point of view, so during its manufacture you will have to take into account quite a lot of technological features. In most cases, people solve this problem by turning to highly qualified specialists.

If we are talking about using soft wood for this purpose that lends itself well to finishing, the whole process will not be extremely difficult and will require compliance with the following stages of work:

- First, the master needs to decide on the design of the future staircase structure and the method of covering the metal frame. At this stage, it is assumed that only the steps or steps with risers need to be finished.

- Once the specific type of wood has been determined, it is necessary to begin preparing the parts for the cladding, as well as its elements. To do this, the array is adjusted to the size of the structure, eliminating the possibility of cracks.

- After the measurements, you can begin to cut out the details of the steps, which are best numbered.

- Fences on steps, in addition to performing a protective function, are also effective decorative elements of the structure as a whole, so their selection is no less important.

- Installation of wooden elements is mainly done using a screwdriver. First you need to fix the step at the top. Next, you can begin to strengthen the risers into the frame, holding them as tightly as possible to the element of the metal staircase. The same actions are performed on the rest of the structure.

- Next, the frame is completely covered with a wooden panel, which was previously cut to the shape of the steps. At the same time, do not forget about the side of the stairs.

- When this work has been completed, you can begin decorating the rear part. Typically, plasterboard sheets are used for such purposes.

- At the last stage, each wooden element is coated with varnish or paint.

Methods for installing step cladding

The following can be used to cover a metal staircase with wooden steps:

- screws and self-tapping screws. To perform such work, you will have to make holes on the reverse metal side to tighten the screw;

- in some cases, the steps are placed on high-quality glue, but the surface must be perfectly flat;

- if it is necessary to level the surface, an additional wooden frame can be used for cladding.

Required Tools

To finish a concrete staircase with wood, you will need tools.

For preparatory work:

- putty knife;

- roulette;

- pencil;

- plumb line

Tools for working with wood.

You may need a carpentry machine. For installation work:

- a hacksaw with a fine tooth for wood;

- hammer;

- electric jigsaw;

- perforator;

- electric drill;

- a circular saw;

- Sander;

- milling machine;

- screwdriver

For the job you will also need a primer, concrete putty, dowels, liquid nails, glue, acrylic sealant and wood varnish.

Arrangement of a flight of stairs

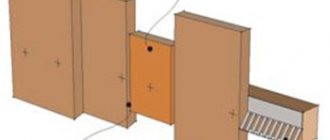

Any staircase consists of the following main elements:

- A flight of stairs, consisting of one or more flights, formed by a number of sequential steps that begin and end with a landing.

- Steps. For ease of lifting, the height between them is kept within 16-18 cm, the depth - 27 cm. The working width of the tread - the horizontal part - is selected depending on the technical conditions.

- Railing (baluster). Usually low, about a meter in height, fences running along the edge of the flight of stairs and landings, made up of posts connected to each other by handrails.

- Handrail. The upper element of the railing, which serves as support during ascent and descent. Another row can be mounted directly on the wall.

During the cladding process, additional parts are used - risers, wooden vertical elements located relative to the tread at an angle of 900. Their presence allows, by increasing the load-bearing load, to withstand the given height of the step. To make work easier and increase the reliability of the finished structure, mounting grooves for dowels are prepared on the tread blanks with risers.

And one more element - the filing, installed on the reverse side of the flight of stairs. Since it is not subject to physical stress, it can be made from any finishing materials - drywall, plywood, decorative panels.

Depending on the design, stairs are made open (without risers) or closed. In the latter case, the cladding is done from the back side, fixing it on the tread and riser .