During hot seasons, everyone dreams of having their own swimming pool where they can relax at any time. The installation of such a building is quite complicated, but doable. In addition to creating a sealed concrete bowl, you need to consider a filtration and water supply system, as well as much more.

When all the dirty work is completed, the question of finishing the pool bowl arises. Today there are many options for creating an unusual and stylish artificial pond. You can use PVC film, stone, tiles, mosaics and other materials. Each of them has its own characteristics. Therefore, it would be logical to first understand what requirements apply to materials for finishing concrete pools.

What material is suitable for finishing the pool?

First of all, you need to take into account that various preparations are used to purify water, which can be aggressive to surfaces. Since we are talking about a humid environment, the requirements are appropriate:

- Moisture resistance. When choosing a material, you need to pay attention to its water absorption rate. It should not exceed 1%. If you give preference to porous finishes or loose building materials, you can soon expect leaks. Water will accumulate under the finishing layer and destroy the concrete.

- Chemical resistance. Disinfection and maintaining the required pH balance is an important condition for the operation of swimming pools. Therefore, the facing material should not enter into chemical reactions with such products.

- Resistant to mold and bacterial activity. Pool water is usually warm enough to provide an excellent breeding ground for various microorganisms. If the facing material is porous and has a loose structure, then fungal and algae spores will easily begin to penetrate into it. It is impossible to clean them, so you will have to completely replace the lining.

- Long service life. It should be taken into account that water has a much higher density than air. One cubic meter of water weighs 1000 kg. Therefore, the material must be resistant to such constant loads.

Of course, you cannot choose toxic materials or those that are easily damaged. Based on this, there are several options for finishing the pool.

Our works

| Novorizhskoe highway | 1st Uspenskoye Highway | village "KREKSHINO" |

| Swimming pool on the territory of a private country house, village. New items, Novorizhskoe highway | Swimming pool on the territory of a private country house, 1st Uspenskoe Highway. | Swimming pool on the territory of a private country house, cat. village "KREKSHINO". |

| Kaluga highway | Rublevo-Uspenskoe highway | Novorizhskoe highway |

| Overflow pool, Kaluga highway. | Swimming pool in a private house, Rublevo-Uspenskoe highway. | Overflow pool, village. New items, Novorizhskoe highway. |

| View all works | ||

PVC film

This is the cheapest, most accessible and easiest to install option. PVC film is resistant to temperature changes and direct sunlight. But not every film is suitable for finishing a concrete pool. As a rule, material with a thickness of at least 1 mm is used for these purposes. The film must consist of four layers. One of them is a high-strength synthetic material (Kevlar or polyester will do). If we talk about the best types, then it is recommended to choose film:

- Polyvinyl chloride. The basis of the material is plasticized polyvinyl chloride. This film contains all the necessary additives that will reliably protect the surface from various bacteria and mold. This film is recommended for use in indoor pools.

- Butyl rubber. This is a more durable and strong material. The film does not change its characteristics even in severe frosts. Despite this, the material is excellently cut with scissors and glues together without problems during installation. This is the best option for an outdoor pool.

If we talk about the procedure for laying PVC film, it is done quite quickly. First, the material is overlapped and then secured by heating. The resulting seams are sealed with hot polyvinyl chloride. At the next stage, a special fastening strip is installed and the previously prepared PVC sheet is welded to it. All that remains is to weld the film in the corners of the bowl.

Pros and cons of finishing

If we consider the advantages of PVC film, we can highlight:

- Low cost.

- Easy to install. The film stretches quickly, and one person can do it. But with mosaics or tiles you will have to suffer.

- High efficiency of sealing the bowl.

- Nice appearance.

But there are also several disadvantages. For example, PVC film looks much “simpler” than tiles or mosaics. There is one more drawback that is usually noticed after installation of the film - the steps are too slippery. However, this nuance can be easily eliminated if you purchase an additional piece of material (especially for steps), which has a ribbed surface.

Concrete container

It is durable and suitable for any hydraulic conditions. The pool can be made in any configuration and you can choose whatever finish you want. A variety of equipment is produced for them, allowing them to create various effects.

Spacious concrete pool Source pinterest.com

Tile

This option looks more interesting and allows you to choose from numerous color options. The tiles are laid using a specialized adhesive (usually epoxy with high adhesion rates). Laying the material usually starts from the bottom, moving to the walls. But, if the drain is located on one side, then it is better to install the tiles in rows. The material is laid on the walls, just like in any other room (for example, a bathroom). There is only one minor difference - thicker seams are made for the pool, which must be treated with grout that has high frost and moisture resistance.

If we talk about the advantages of tiles, they are obvious:

- The material is more reliable and durable.

- Looks much better than PVC film.

- High level of sealing.

- Due to the fact that special rough tiles are used for pools, it will be very difficult to slip on them.

- If one tile is damaged, it is not difficult to replace it.

The downside is the higher cost. It will also be difficult to lay the tiles evenly on your own if you do not have any experience working with such material. It will take more time. Also, when choosing tiles, you need to take into account important points.

Choosing the right tiles

As already mentioned, the tiles should be rough. In addition, it is worth:

- Purchase tiles with the highest possible water-repellent properties (for imported tiles the optimal value is 0.14%, and for domestic tiles 1%).

- Buy products with increased adhesive properties. The back of the tile should have grooves rather than a flat surface.

- Use only high-quality waterproof adhesive.

Healthy! It is better to purchase titanium grout. Such compositions are not susceptible to the formation of fungus and mold.

- Give preference to Italian, Portuguese and domestic products. These tiles are of higher quality.

- Choose not ceramic, but porcelain tiles for cladding the walls of a concrete pool. This option tolerates temperature changes much better. In addition, porcelain tiles have higher frost resistance and low water absorption. It gets dirty less and does not absorb dirt at all.

Mosaic

This material is often used in sanatoriums, hotels and other places aimed at high traffic levels of visitors. The mosaic looks the most interesting. Thanks to this material, you can create entire paintings.

The installation of this material is in many ways similar to tiles, except that the facing elements are much smaller. Their installation will take many times longer, especially if you plan to create an image. This is a labor-intensive process that you can’t always do yourself. On the other hand, mosaic (especially glass) does not absorb moisture at all and has the longest service life. It is easy to clean and does not form mold. If you skillfully combine this finishing with other decorative elements, you will get a luxurious pool.

But you will have to pay a lot for such beauty. Mosaic is more expensive than the materials described above. Most often, you also have to pay for the services of a craftsman who will lay out the panel according to your sketch. To reduce the cost of such a project, you can also use ceramic mosaic or even combine it with tiles.

Overflow type

The water is level with the edges of the bowl and the floor of the room. Excess liquid goes through the grates into overflow trays and then enters the filtration system. The construction of an overflow type pool is 1.5-2 times more expensive than the construction of a skimmer type pool.

Ideal surface Source de.dreamstime.com

Stone

Sandstone and rubble can be used to finish the pool, but more often preference is given to:

- Granite. Such a stone will not fade and will easily tolerate temperature changes. In addition, it is very difficult to damage. Granite is waterproof and completely resistant to pool cleaning chemicals.

Healthy! Granite is considered the most durable stone on Earth.

- Marble. A completely environmentally friendly material that has antiseptic properties. Fungus and mold do not form on marble. It is easy to polish (marble is made up of grains of dolomite and calcite), so even if you manage to scratch it, it is an easy mistake to fix. In addition, it is believed that marble has healing properties and is an excellent stress reliever, so it will come in handy in the pool. But chemistry gradually destroys marble. Over time, too aggressive agents (for example, chlorine) may begin to turn into chalk. However, the problem can be solved with specialized means.

Healthy! When wet, marble becomes slippery, so it is best not to use it on the bottom of the pool, the area around it, or for stairs.

Laying the stone is done in the same way as in the case of tiles, using epoxy glue.

But natural stone also has disadvantages. For example,:

- High price. For example, to decorate a pool with marble, you need to be prepared for the fact that one slab (slab) can cost from 4,000 to 32,000 rubles. Granite will be cheaper, but will also hit your wallet hard.

- Difficulty in installation. The stone weighs quite a lot.

- It's easy to run into a fake. If they sell you only imitation marble instead of natural stone, it will be very difficult to recognize the forgery. Only a specialist can handle this. Granite is counterfeited less often.

Types of waterproofing

Types of waterproofing There are at least two types of waterproofing that you can do yourself:

- External;

- Internal.

The external waterproofing system is aimed at protecting the pool from the penetration of groundwater into it. The main factor influencing the method of finishing a waterproofing system is the level of water in the ground. Knowing it, you can already determine the direction of building this system with your own hands. Consumables that may be required for the manufacture of external waterproofing:

- Special coatings that protect the pool from external moisture;

- Mixtures applied to the inner layer;

- Protective films.

Other materials for pool lining

Today, few people can afford marble cladding, so it’s worth considering more down-to-earth options. They are not used so often, but also deserve attention.

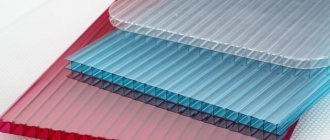

Polypropylene

This is one of the cheapest options. In this case, polypropylene sheets of 5 mm or more are used. The installation principle is the same as in the case of PVC film, but you must immediately be prepared for the fact that the joints of the sheets will be visible to the naked eye.

The advantages include:

- Resistant to sunlight, fungi, mold, chemicals and temperature changes.

- Light weight, so sheets can be laid quickly and easily.

- Non-toxic. More precisely, the material complies with SanPin standards.

- Resistance to deformation and high strength.

- Elasticity. This allows you to easily lay polypropylene even in bowls of complex shapes.

But despite all the advantages, polypropylene is not recommended for open artificial reservoirs. Also, do not leave the bowl without water. In this case, polypropylene can easily become deformed. At very low temperatures it becomes very brittle and bursts.

Dye

This is also a fairly budget option. But paint cannot simply be applied to a concrete surface. Additional activities will be required. For example, you need not only to clean the surface, but also to saturate it with an acidic composition, which is then washed off with water. After this, the bowl is coated with a special sodium phosphate compound and washed again. After the surface has dried, it is degreased and covered with putty to eliminate any microcracks. Next, a primer is applied and only after that you can start painting.

The paint has good adhesion. This is a hydrophobic coating that does not slip even when wet. In addition, such cladding does not deform and can withstand heavy loads. But if you are considering paint for an outdoor pool, then it is better to refuse this option. The fact is that you will have to update the coating every few years. Also, such compositions do not always tolerate treatment with chemical compounds and the appearance of such a pool will not look so attractive.

However, if you use rubber paint rather than ordinary paint, there will be much more advantages. This is an elastic and more durable material that has excellent waterproofing properties. The rubber does not peel off and does not require updating. It does not crack under the influence of low temperatures, and when heated it also remains safe for humans.

Tools and accessories

The work will require tools:

- trowel;

- Master OK;

- a set of spatulas of different sizes and shapes;

- grater;

- brushes;

- ladle;

- rule;

- building level;

- rollers;

- yardstick;

- plumb line;

- construction mixer;

- beacons and planks;

- rags;

- containers.

When working on plastering, protective equipment against construction dust is required (special glasses, respirator, gloves).