A spray gun is a device designed to cover various surfaces with paint and other substances converted into a fine air mixture under high pressure. Sprayers are mechanical, pneumatic and electric. The most important difference between electric spray guns and pneumatic ones is that the tools have built-in compressors. Different types of spray guns are actively used when performing finishing work during renovation of a home, office or industrial premises. But this is not the only possible option for using them. Sprayers are also actively used in other areas of activity, for example, in the production of furniture and in the process of performing body work in car repair shops.

Advantages and purpose of spray guns

In addition to speeding up finishing work significantly compared to manual execution, spray guns also have such an important advantage as the ability to spray a wide variety of liquids. They can be used to apply paint, primer, putty and varnish. In addition, painting with spray guns is guaranteed to provide high quality work, which is hardly achievable if you work with a brush or roller. Spray guns are mobile, they can be freely moved to another work area, they allow you to paint large areas of the surface.

Paint sprayers can be used both for professional purposes and for DIY home repairs. They can quickly repaint a house outside or inside, or perform spectacular airbrushing on a car body. Manufacturers are constantly working to improve the design of spray guns, thanks to which modernized devices provide higher quality paint application. In addition to painting, a spray gun at home allows you to perform a wide range of work, which includes:

- spraying protective compounds when you have to work with a significant amount of various impregnations, glue, stains, etc.;

- spraying garden trees, bushes, flowers cultivated in personal plots with special means for various purposes: fertilizers, pest control, lime used for whitewashing the bases of trunks;

- disinfection of various objects by spraying antiseptics.

Spray guns can be used to work with all liquid substances that are broken into small fractions that easily pass through the nozzle opening. In this case, their viscosity must correspond to the technical characteristics of the gun used. Now let's talk in more detail about the different types of sprayers.

Pneumatic

It was this type of sprayer that was first invented and began to be used to automate painting work. Pneumatic spray guns are still widely used today as a professional tool for performing certain types of painting work, ensuring excellent quality.

A pneumatic sprayer operates on the principle of delivering sprayed substances from a container into which they are previously poured into a nozzle. Once inside, paint or other sprayed material is crushed into tiny droplets by a powerful jet of air. The resulting finely dispersed mixture is picked up by it and carried out by a torch. Here it is sprayed in a cone and covers the surface to be treated in an even layer.

Pneumatic sprayers are available in two versions - with an upper or lower placement of a container for paint or other substance applied to the working surface. Manufacturers supply the market with different types of pneumatic spray guns, but differ in such parameters as maximum pressure and volume of air consumed. The performance of the device depends on the value of these parameters.

Electrical

An ordinary electric paint sprayer is a universal device, usually of a household grade. But certain design advantages of such units allow them to be successfully used at a professional level. All electric type sprayers are divided into:

- Airless - in them, paint is supplied to the nozzle using a piston pump, which can pump high pressure levels. The design of the nozzle is responsible for the quality of atomization of the compositions used. Drops of paint in this way are broken into fairly small particles, but their size is larger than that of particles of fine mixtures of pneumatic sprayers. The method of painting surfaces with airless electric spray guns is universal; it allows you to spray paint and varnish compositions of high viscosity. For industrial purposes, this method, which is characterized by a high consumption of the sprayed substance, is used when applying, for example, primer compositions, when priority is given to speed of work rather than an absolutely ideal level of quality.

- Air - in them, the dye is fed into a nozzle and crushed into dispersed dust by an air flow generated by solenoid or turbine electric motors. The presence of these engines that force air flow is the main difference from airless ones. Electric motors are either mounted in the sprayer housing or used in a free-standing version. Spray guns with an independent electric motor are suspended on the operator’s shoulder or rolled behind him like a vacuum cleaner. Air spray guns have a wide range of uses. Based on performance indicators, you can select modifications for both domestic and professional use.

Spray gun HAMMER PRZ500B 500W + garden multitool TESLA MT-06 4in1

Inlet pressure adjustment

The spray gun is powered by compressed air. The higher the pressure, the better the painting effect. For each tool model, the manufacturer indicates the corresponding standardized pressure values. It is at this pressure that it is recommended to paint with a pneumatic spray gun. To set the pressure, many people use a pressure gauge, which is located on the compressor. This is incorrect because this pressure gauge gives the air output pressure value. Air comes to the instrument at a different, lower pressure. Losses are observed in the high-pressure hose, and the longer its length, the greater the difference at the outlet of the compressor and the inlet to the spray gun.

To eliminate the possibility of using a spray gun with approximate pressure, you should use a special gearbox with a pressure gauge. Next, let's look at how to correctly set the pressure on a spray gun with different types of pressure gauges:

- The removable pressure gauge-regulator is a gearbox that connects to our paint gun. To adjust the inlet pressure, you will need to unscrew the air and torch size adjustment screws to the maximum. After this, press the trigger and look at the pressure gauge needle. If the value is more or less than the norm, then use the adjusting screw on the pressure gauge to achieve the desired value. For most standard pneumatic spray guns the standard setting is 2 atmospheres

- Built-in pressure gauge - the principle of adjusting the inlet pressure is that you need to fully open the torch size regulator and pull the trigger. Using the air supply screw on the gun, the required pressure is set, controlled by the tool’s digital pressure gauge

- The pressure gauge does not have a regulator. To do this, you need to fully open the air supply and torch size regulators. Next, you need to pull the trigger and adjust the pressure using the pressure gauge connected to the spray gun

- When the pressure gauge is not connected to the spray gun, most often the operator uses the spray gun without using an additional pressure gauge. How to set the optimal pressure for painting in this case? A pressure gauge on the compressor is used for this. The pressure setting for it is set as follows - unscrew the adjusting screws for air and torch size. We pull the trigger and rotate the regulator on the compressor, setting the appropriate pressure. It is important to remember that the pressure drop in the hose is up to 1 atmosphere

If the inlet pressure is not adjusted, the efficiency of paint application will be reduced, which will certainly affect the quality of application of the paint and varnish material. Air is the basis of the painting process, so if you do not pay special attention to pressure, the entire process will be carried out with serious violations.

Spray gun device

It is similar for different types of spray guns. The body is made mainly in the form of a pistol or a rod (rod). Mounted on it:

- a handle that allows you to hold the device and direct the flow of spray solution to the work area;

- a reservoir for filling a liquid spray substance;

- trigger - it allows you to control the locking needle by pressing with different pressure levels;

- nozzle or nozzle - an opening in the front of the gun, which is part of the spray head, some types of which are equipped with additional holes for supplying air flow;

- pressure regulator - usually installed in the back of the gun, above the handle, designed to adjust the pressure force with which air is supplied (for pneumatic sprayers).

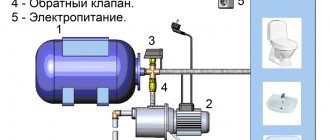

The sprayed substance comes from the tank after the operator presses the trigger of the device. The spray contour of the composition poured into the tank (torch) is set by the air nozzles around the nozzle. Additionally, the shape of the torch is adjusted using the screw provided by the design of the unit. For the spray gun to function normally, a power supply system is required. It can be integrated into the design or connected separately.

Electric spray guns also differ in the type of power supply. Sprayers powered by electricity are the most widely used. If there are no central communications at the site where work is being carried out, networked spray guns can be powered from a diesel or gasoline electric generator. Battery units are also in demand. Moreover, they are used not only at sites located far from central electrical communications, but also where there is network electricity - in order to achieve greater mobility, for example, when working on towers. Cordless spray guns are much more expensive than their mains counterparts. It is worth buying them for household purposes only if the devices will be used intensively.

Battery spray gun REDVERG RD-PS18V 18V, 0.6 l, 0.4 l/min, without battery

Airless spray guns

Similar to pneumatic paint sprayers, there are manual and automatic airless paint sprayers. Externally, pneumatic and airless paint spray guns are similar to each other. In both cases, their components are a handle, a trigger, and a nozzle is responsible for crushing paintwork materials. But the principle of this division is different. In an airless spray gun, this occurs due to the high speed of flow of paint material from the nozzle hole caused by high pressure (this hole usually has the shape of an ellipse). The nozzle, together with the body and accelerator throttle, is one of the three most important components of the spray head of an airless paint sprayer.

When choosing a nozzle, the determining factors are the equivalent diameter and spray angle. The larger this diameter, the more viscous compounds can be used and the greater the thickness of the resulting film. The size of the nozzle diameter and the pump performance are interrelated quantities. That is, each diameter value corresponds to a liquid flow rate at which the pressure will be sufficient for high-quality spraying of paint, anti-corrosion, impregnating and other compounds.

The paint supply pressure is regulated by an air valve (for pumps with a pneumatic drive) or a special pressure regulator (in the case of electric or gasoline-powered pumps).

After use, the device must be washed. The intake hose is lowered into a container with washing liquid, and it is driven through the entire system, including the paint sprayer, until it is completely clean. Thorough washing helps to eliminate operational problems such as filter clogging, nozzle clogging, etc.

To paint small surfaces, wired and cordless portable airless paint sprayers are used. For example, with a lithium-ion battery. The pump is installed directly in the body of the spray gun. The regulator allows you to change the pressure over a wide range.

Types of spray systems

Based on this feature, the following categories of spray guns are distinguished:

- HP are high-pressure electric models, which are distinguished by uniformity of the torch and fast flow rate of fine suspension.

- MR - average pressure devices.

- LVMP - models for painting with a small amount of paint and under medium air pressure.

- HVLP - in sprayers of this category, the torch is formed under low air pressure and at a moderate paint flow rate, which allows it to be distributed in an even layer.

- LVLP - electric spray guns of this category paint surfaces at low pressure and minimum paint supply speed. The result is a homogeneous torch, which means that high quality coating is guaranteed.

- NTE - such spray guns provide maximum paint supply.

- RP - this category of sprayers is characterized by low pressure.

Changing painting methods depending on gun type

The general principle of spray painting requires holding the spray gun perpendicular to the surface being painted. This is quite difficult to do, especially in hard-to-reach places and when working from the bottom up (for example, in wheel arches). In practice, an experienced master does not think about the position of the spray gun in his hand, focusing on the shape of the torch. Flaws in amateur painting using an inclined spray gun appear in the form of stripes and “clouds” (on metallic paints) or ripples (on regular car enamels).

Correct position of the spray gun relative to the surface to be painted.

The distance to the body metal depends on the type of spray gun. A conventional high-pressure spray gun produces a conical spray that is effective at a distance of 25–30 centimeters. At shorter distances, paint particles hit and bounce off the metal, resulting in paint haze, dusting, and streaking.

For low-pressure guns (HVLP, RP, LVLP) with a cup-shaped torch, the optimal distance is from 10 to 20 cm. When moving the spray gun, you should try to keep it parallel to the surface of the body, avoid arc-shaped and circular movements. Try to cover the enamel strips by two-thirds, maintain a constant speed of movement of the gun (40–50 centimeters per second). When painting dismantled parts (fenders, hoods, doors), special rotary stands are used, which allow you to first paint the internal surfaces, corners, and ends of the body element. After this, the front surface is painted.

Experienced craftsmen use a method of continuous painting of a part, while the spray gun moves in a wave-like manner. When doing amateur painting, in the first stages it is better to use horizontal passes, in which the gun is moved in and out with the trigger partially pressed. This way you avoid a “dry” edge.

The “splatter” spraying method, in which paint is applied pointwise with short trigger presses, is used only for hard-to-reach areas of internal surfaces. With this spraying method, insufficient coverage or sagging is inevitable. It is used to avoid overuse of paint. For cylindrical, lattice parts, the size of the torch is adjusted to the width (diameter) of the element, and it is painted in 3-4 vertical or horizontal passes.

The best option for large-scale tasks

When large areas are to be painted or otherwise processed, it is recommended to use a painting station for such purposes. The design of such a device allows you to supply spray compositions directly from the bucket or container in which the manufacturers supply it. The spray gun is separated from the pump that delivers the sprayed material. During the work, the master holds only a compact paint gun in his hand. Paint is pumped into the nozzle using a pump installed on a special platform together with an electric motor. Such stations have wide customization options. They are usually purchased for professional use.

Spray gun WAGNER W590 Flexio, 630 W, 1.3 l, 0.5 l/min

Manual sprayers of mechanical type

In a situation where it is necessary to work with a spray gun on an object that, due to various circumstances, is not connected to a centralized power grid, a battery-powered spray gun will also not help; its charge will be enough to work without interruption for about an hour. Hand spray guns can help out. These devices consist of a metal or plastic cylinder housing in which a mechanical plunger-type pump, similar to a car pump, is placed. Two hoses are removed from the body: one is intended for pumping the sprayed substance into the internal tank, the second goes directly to the sprayer. There are simpler mechanical units, which are ideal for household use. In such spray guns, the paint or other solution that needs to be sprayed is poured directly into the body, then it is sealed, after which air is pumped inside by a pump.

The pump operates in two modes; they are switched using ball valves. First, the sprayed composition is pumped from the outer tank into the cylinder, after which pressure is built up in the inner tank. When operating values are reached, you can begin spraying the injected composition. To make it convenient for the operator to work with such a device and to be able to treat a large surface without moving, such sprayers are equipped with long rod handles (up to 2 meters).