Distinctive qualities of floor tiles

The main distinguishing feature of floor tiles from wall tiles is their thickness. This is because floor tiles experience heavy loads, and therefore the requirements for them are more stringent.

However, the thickness of the floor tiles only plays a role if the base on which they are laid is not strong enough. If the tiles are laid on a concrete base or on top of old tiles, then it is possible to lay thin porcelain tiles, with a thickness of 3 mm or more.

In places where ultra-high wear resistance is needed, a type of tile is laid - clinker, which is fired at 1200-1300 °C, while simple tiles are fired at 800-1000 °C.

Through stronger sintering of clay particles, clinker acquires special strength, and at the same time its water-repellent properties are enhanced. Thanks to this, it copes better with severe frosts, because water cannot penetrate into the pores, and, therefore, the clinker is not destroyed due to the expansion of water in them.

There is no difference between floor and wall tiles and they can be used with equal success on any surface.

General material concept

When studying how thick the tiles used in construction should be, you should first of all pay attention to the general characteristics of the material.

- This can be a profile element for the floor made of tiles, ceramics or wood.

- Looks like a wreck. It, for example, can consist of different types of wood.

- This coating differs from parquet in the significant size of its individual elements.

If you want to fill your home with the beauty and subtle natural aroma of wood, you need to give priority to this type of flooring, which has undeniable advantages.

Dimensions

Most often on the market you can find tiles in the shape of a square, the side of which can vary from 10 to 60 cm.

However, it is not possible to provide a complete list of tile sizes due to the following reasons:

- there are no specific standards for choosing sizes (for more details: “What sizes of floor tiles are there”);

- floor tiles are not always square in shape, they can be of any shape, there are diamond shaped tiles on the market, hexagonal tiles and so on.

Caring for tile joints

Cleaning tiles should be done with acid-free products. Can be washed with plain water or water with soap or powder. Typically, tile manufacturers indicate the cleaning agent that is acceptable for cleaning.

If mold has already appeared, immediate removal is required to prevent further spread. It is cleaned off along with a small layer of putty (depending on the depth of penetration of the fungus). Remove dust. To prevent the reappearance of fungus, an antifungal agent is applied to the space between the tiles. If a small layer is cleaned off, leave it in this form; if you had to remove all the putty, fill the cracks with new one.

Thickness

The minimum thickness of commercially available ceramic floor tiles is 3 mm. However, tiles with this thickness are quite rare; most often on the market you can find tiles from 5 mm.

The maximum thickness of tiles present on the market is up to 25 mm. But these are special tiles, and most often there are tiles with a maximum thickness of 12 mm.

It is worth noting that the thicker the tile, the more expensive it is. This is due to the fact that the production of one square meter requires large expenditures of raw materials and the cost of firing them. In addition, its transportation also becomes more expensive.

Composition of adhesive

The thickness of the adhesive layer is determined by the composition of the glue itself and the presence of various additives in it. There are three basic types of cladding products:

- cement mortar - produced in the form of a dry mixture based on Portland cement, sand and plasticizers. The solutions firmly hold the tiles on the surface, but are characterized by high consumption;

- two-component products - made on the basis of epoxy resin and catalysts. This is a viscous adhesive with increased fixation properties and minimal consumption;

- dispersion agents - their composition includes resin and polymer components. They are used sparingly, but the maximum and minimum layer thickness is calculated individually for each surface and type of ceramic tile.

Strength

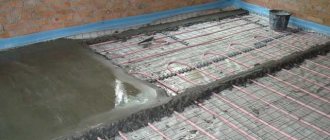

Quite often, the tiles are laid on a wooden plywood floor or on a dry gypsum fiber screed. Naturally, excessive impact or load on a small area can either crack the tile or cause it to fall away from the base.

There are two solutions to this problem:

- Increased strength by choosing thicker tiles. On unstable bases lay tiles or porcelain tiles 9-10 mm thick. Porcelain tiles with a thickness of 12 mm and above are usually used in production, in places where people and equipment exert load on the floor. In this case, the thickness of the adhesive when laying tiles on the floor should not exceed 20-22 mm. It is important to understand the difference between porcelain tiles and floor tiles in order to make the right choice.

- Another option is to use smaller tiles. If you choose a tile with dimensions of 10-15 cm2, then during a deforming load the coating will simply bend for a moment, and the tile will remain undamaged, even with a small thickness of 6-7 mm. In this case, the thickness of the floor tile adhesive should be no more than 15 mm.

It should be taken into account that laying tiles on an unstable base must be accompanied by the use of elastic types of grout. Otherwise, their rapid destruction is inevitable. It is also worth knowing how long it takes for floor tiles to dry after installation, so that you can continue repair work.

When laying tiles on a hard floor, be it a screed or a concrete floor, if all installation rules are followed, there are no requirements for the strength of the coating, because the load will be completely absorbed by the rigid base.

Calculation of the amount of adhesive

When purchasing facing material, it is recommended to immediately purchase the required amount of ready-made adhesive or dry mixture.

What affects the thickness of the adhesive layer?

First of all, the area of the tile element is taken into account:

- 50*50 mm – 3 mm glue;

- 10*10 cm – 4 mm glue;

- 150*150 mm, 100*200 mm – 6 mm;

- 20*25 cm – 8 mm;

- 30*30 cm – 10 mm of adhesive mixture.

The quality of the coating on which the tiles are mounted is of no small importance. To fix tiles on smooth walls or on a floor without defects and a large number of pores, you will need less glue than for uneven porous surfaces.

In general, the algorithm for calculating the amount of glue looks like this:

- Take the dimensions of the purchased tiles and select the optimal layer of mortar indicated on the package.

- Find on the packaging indicators of glue consumption per 1 m2 with a layer of 1 mm.

- Multiply the layer indicator (from point No. 1) and the flow rate (from point No. 2). You will get an intermediate version of the adhesive consumption per 1 m2 of decor area.

- Calculate the total area of the facing surface.

- Multiply the resulting number of square meters with the glue consumption per 1 m2. This is the total cost of the solution.

- The final result must be multiplied by 1.1 - this is a 10% margin, which in most cases will be needed due to calculation errors and changes in surface quality.

Humidity and moisture absorption

When solving the problem of calculating glue consumption, you should take into account 2 more indicators:

- moisture absorption of the facing surface;

- humidity of the solution.

When laying tiles on the wall, it is prohibited to use semi-dry mixtures, otherwise a strong adhesion will not be obtained. If the wall is too porous and rough, it is recommended to prime it in several layers until the increased moisture absorption of the area stops.

When arranging the floor, it is allowed to prepare a drier solution, but only if the floor base does not have increased moisture absorption. Nevertheless, the solution must be sufficiently plastic and easily distributed over the surface.

Design

Often, to increase the visual volume of a room, tiles with dimensions of at least 40 cm2 are used. The effect is explained by the exceptional features of human perception, when the dimensions of the room are determined by the areas of 2 planes - the ceiling and the floor. It turns out that the larger the outlines of individual parts of the floor covering look, the larger the entire plane appears.

However, this approach does not always work. A similar method will be justified for a kitchen with an area of 5-6 m2. But in a small bathroom, tiles measuring 50x50 cm will simply look ugly.

Another option is to use tiles of different sizes in one room. For example, in the center of the room you can lay 60x60 mm tiles, and the outer part of the room can be bordered with 30x20 mm tiles. This combination using different colors will give the floor a special originality.

Glue layer

When planning the tiling, it is important to determine the total thickness of the application along with the tile. The amount of solution depends on both the material and the dimensions

The larger the tile, the thicker the glue is applied. You should not put too much mortar, because instead of the declared strength it will begin to flake. In addition, it slows down the drying time. 4-8 mm is enough for standard tile cladding.

The choice of adhesive and application thickness is important

To hold massive tiles on the surface of walls or floors, select an adhesive with a suitable composition. There are special mixtures that allow you to use a minimum amount of mass for reliable results.

Taking into account these features, the optimal finishing is selected; it will last for many years. You should not install overly strong and oversized tiles, because they place additional load on the base being tiled.

Some tips

In conclusion, we should share a number of useful and interesting facts about the sizes of ceramic tiles:

- If you plan to tile any one room, it is better if the tiles are from the same batch. This is important because each individual batch with the same specified dimensions will always have a slight deviation from the original dimensions. In some cases they can reach as much as 4-5 mm. This is due to the fact that clay, being the basis of ceramic tiles, is heterogeneous in its structure, which means that in each individual case the shrinkage will be different, even taking into account the fact that the firing parameters remain unchanged. In addition, the shade of the tiles may vary slightly.

- The thickness may also differ from the declared one, however, this parameter is not critical, because the thickness of floor tiles with glue can always be adjusted to the desired height of the base.

- The optimal joint thickness for 30 cm tiles will be 2-3 mm, and for 50x50 cm tiles – 4-5 mm. The larger the tile size, the greater the deviations in size. This difference is easily compensated for by slight variations in the width of the seams.

Finally

We hope that the article has given you the opportunity to better understand issues related to the size of the tiles, their thickness and the correctness of their application. Visual information can be gleaned from the video attached below.

How to use the solution correctly?

To apply the product you will need two types of spatulas:

- regular smooth for mixing and scooping up adhesive;

- toothed to distribute the composition over the surface.

The key point is proper preparation of the solution. Experienced craftsmen advise mixing a thicker mixture, and then bringing it with water to the desired plastic consistency.

Use a smooth spatula to scoop out a small amount of glue. Part is applied to the surface of the cladding, part is applied to the back side of the tile. Then, using a notched trowel, “smooth” the layer on the tile, distributing the glue over the entire area of the element and achieving the adjusted thickness. Excess composition is removed from the edges and sent to a common container with the solution.

Characteristics of porcelain stoneware

Initially, porcelain stoneware was produced as a particularly durable tile for technical use in public and industrial buildings.

Surprisingly, in Europe such material is considered an ordinary tile, only in the CIS countries it was given a separate name. It is produced by semi-dry pressing under a pressure of 400-500 kg/cm2 and then fired at a temperature of 1200-1300 degrees.

Press powder is made from slip - a homogenized mixture of white-burning clay, kaolin, quartz sand, feldspars, pegmatites and water. Coloring oxides are often added to the composition, which allow the material to be given the desired shade.

Table of technical characteristics of floor coverings

Technical characteristics of porcelain stoneware floor tiles:

- Water absorption: 0.05-0.01%.

- The bending strength of imported collections is 500-600 kg/cm2, while domestic analogues have indicators of 470-550 kg/cm2.

- Hardness on the Mohs scale: 6-8 (domestic analogues 5-8).

- Degree of wear resistance: 3-5 (for ceramic tiles this indicator is 1-5).

- The number of frost resistance cycles is 3-4 times higher than that of conventional tiles: from 100 to 300 cycles at temperatures from -5 to +5 degrees.