When carrying out facing work, many nuances need to be taken into account. To ensure good adhesion of the tiles to the surface, the correct amount of tile adhesive should be applied. The layer of mortar is determined based on the dimensions and type of facing material. The thickness of the tile adhesive depends on other factors. When facing, it is worth considering the presence of defects at the base. To fill potholes, tile adhesive will have to be applied in a thicker layer.

| Product | |

| Surface area m2 | |

| Layer thickness, mm. | |

Types of glue and its features

First you need to understand the features of adhesive mixtures. Although the material itself that is planned to be laid plays a major role, at the same time the type of glue is no less important.

In total, only three types of adhesive mixtures can be distinguished, namely:

- Cement mortar. This mixture is used in most cases. It contains cement, sand and additional modifying compounds. This glue is simple and easy to use, which is why it is most common.

- The second one is a two-component adhesive. Most of these include epoxy compounds, which involve a mixture of epoxy resin and catalyst. This mixture can provide fairly effective adhesion of the tile to the surface.

- And the last one is dispersive. This glue is sold as a ready-to-use mixture. It is mainly based on resin components, in some cases polymeric substances are also used. The most popular composition of this type is latex glue.

It can already be noted that the thickness of the tiles when using cement adhesive will be greater than in other cases.

Ingredients of two-component formulations

It is easy to find two-component mixtures in construction and hardware supermarkets and specialized online stores.

They include

- Catalyst;

- Resinous filler;

- Quartz component;

- Functional additives.

This kind of mixture is good because it practically does not settle when it dries. Thus, the master can find out exactly what the height of the adhesive layer will be even when applying the adhesive liquid. Most often, this type of composition is applied in layers ranging from two to five millimeters thick.

Dependence of glue thickness on various factors

Now let’s look at what determines the thickness of tile adhesive when laying tiles. It should be noted that when laying, it may vary, but there are some restrictions. In this case, in order to obtain a reliable and durable coating, it is necessary to adhere to certain standards, or rather limits, both minimum and maximum.

In particular, speaking about the minimum value, we can note a layer of 2 millimeters, which is used when laying small products. At the same time, for larger tiles the minimum threshold is a layer of 4-5 mm. In the same way, the thickness of the adhesive when laying tiles on the floor can be up to 12 mm.

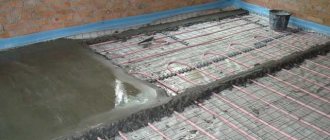

The maximum threshold, depending on what kind of tiles are laid and how, can reach sizes of several centimeters. If we consider it in total, we can see that the increase in the amount of mixture is caused by the need to level the coating. But still, if you can’t do this with a layer of glue of 10 millimeters for ordinary tiles, and 2 centimeters for porcelain tiles, then you will need to carry out a screed or other type of surface leveling.

Therefore, we note that the size of the layer may vary. Even the most qualified specialists cannot say with accuracy what thickness is needed, since they themselves are always adjusting to the base and level in their work. Therefore, it is necessary to take into account the minimum and maximum values in greater complexity.

Now let's take a closer look at the factors that affect the thickness of the tiles on the floor or wall. And let's begin.

Practical tips for choosing the thickness of porcelain tiles

You should not immediately buy thick porcelain stoneware slabs; the strength of the floor depends not only on this indicator, but also on compliance with masonry technology. If the master does not use a special comb to apply an even and uniform layer of glue, but “sculpts” it with a staple only in a few places on the tile, then even thick material in the gaps can crack from relatively small efforts.

Working with adhesive for porcelain tiles

It is recommended to check the integrity of the performers. This can be done in two ways: watch their work or check the already installed tiles. The first option is not always possible, but it’s never too late to check the floor. The tiled floor needs to be tapped, the sound over the entire surface of the tiles should be the same and dull. If there are places with a loud knock, then the work was done by an unscrupulous or unskilled performer; between the tiles and the base there are large air chambers not filled with glue.

Diagram of the stages of laying porcelain stoneware

When purchasing material, be sure to pay attention to the linear dimensions. The thicker the tile, the more complex the annealing technology, the higher the risk of getting defective. Take two tiles from different packages and place them facing each other. Wobbling or gaps between them are strictly unacceptable; the edges must be smooth and match perfectly. Porcelain tiles are much more difficult to level than ordinary ceramic tiles; because of this, the requirements for linearity and flatness are more stringent.

The thickness of the tile has a significant impact on the price, with all other indicators being the same. Practitioners know that properly laid porcelain tiles 7 mm thick can withstand the same forces as tiles 12 mm thick, but made with defects. And in price these materials differ significantly. Conclusion - a professional tiler can save significant money, and the strength of the flooring will meet the required parameters.

Dependence on tile size

The first thing that determines the adhesive layer when laying tiles is the size of the material. Thus, depending on the dimensions of the tile, its weight depends, at the same time, the thickness of the adhesive is calculated on the load on the surface. Thus, specialists have already calculated the required thickness based on many years of experience (in some cases, of course, minor adjustments are made). When using synthetic glue, the layer will be 1-2 millimeters smaller, and with a cement mixture, correspondingly larger.

- For tile dimensions from 5 to 10 centimeters - 2-3 mm.

- With a size of 10-15 centimeters, the glue layer will be 3-4 mm.

- 15-20 cm – 4-5 mm.

- 20-25 cm – 5-6 mm.

- 25-30 cm – 6-7 mm.

- From 40 centimeters or more - from 7 to 10 millimeters.

Additional dependencies

It is also worth considering other factors, since the size of the tile itself is not the only one among them. For example, when laying porcelain stoneware, the layer will be larger than when using tiles. In addition, it is important to consider where the tiles are laid, on the floor or on the wall. Thus, the thickness of the adhesive layer when laying tiles on the floor will be several millimeters greater than when working with wall cladding.

In addition, the base itself also affects the thickness of the tile adhesive. If the base is made according to the level, without any defects, then the thickness will remain unchanged. If they have any bulges, pits or other defects, then the thickness in some cases will need to be reduced, and in some places increased. Although, if there are defects, high-quality masonry is out of the question, so it would be advisable to perform leveling in order to save effort, time and financial costs, since the cost of glue is somewhat more expensive than mixtures for leveling.

The surface of the material also becomes an important factor. In some cases, porcelain tiles may have distortions, i.e. convexity or convexity in its surface. In such a situation, it is necessary to provide the same layer (no more than 10 mm) at the extreme points, and adjust the central one to the edges.

Common challenges you may encounter

Didn't have time to finish the cladding

Sometimes some façade work cannot be completed during the warm period. Postponing them to spring is impossible for various reasons. Completion of begun facade work during the onset of frost requires the installation of a thermal circuit or heating with heat guns. The cost of work per square meter increases significantly.

The cladding is peeling off

When the weather gets warmer, the cladding, glued in the cold using conventional cement adhesives, peels off and comes off due to temperature changes.

Using the wrong materials in the cold

If you add salt to regular tile adhesive to protect against freezing, then at the end of the work, irremovable efflorescence will appear on the facade. Conventional mixtures in the cold have little plasticity, are difficult to apply and cannot be adjusted. Mixtures without frost-resistant additives in the cold have to be applied in a thicker layer than at normal temperatures. Therefore, glue consumption increases in the cold.

Moisture absorption and humidity

And here are a few more factors that need to be taken into account when answering the question of what layer of tile adhesive is needed. In particular, we are talking about the humidity of the solution, along with the ability of the base to absorb moisture. Taking these factors into account, we can say that when laying ceramics, the use of semi-dry mortar is strictly prohibited, and at the same time, the base must be primed. In this case, it is necessary to make such a number of layers that will minimize moisture absorption.

In this case, if there is a high level of moisture absorption at the base, it becomes necessary to increase the layer in order to avoid the tiles peeling off after drying. And we note that additional moistening of the base will not help much, especially when it comes to plaster.

The main mistake of many is over-hydration. Because people pour a lot of water to avoid such drying out and subsequent peeling of the tiles. And this entails a decrease in the durability of the coating, since in the presence of excess moisture, adhesive mixtures lose their performance characteristics.

Laying tiles on walls

Before installation, the base must be leveled. Then you should wait until the surface dries. The location of the tiles is planned on paper and marked vertically and horizontally on the wall. First, the lowest point of the wall is selected. Then the height of one element is noted.

Draw a horizontal line, which will become a guide for the masonry. There should be no sections in the visible part of the wall. The elements are laid out whole.

Using a Notched Spatula

In order to properly distribute the glue, you must use special devices (tools). In this case, we are talking about a special notched trowel, using which you can make your work much easier.

Here, the thickness of the tile with glue will depend directly on the size of the teeth. There is one factor to consider when choosing a tool. The thickness of the applied layer is approximately half the height of the teeth. Thus, choosing a spatula with 8 mm teeth, a 4 mm layer of adhesive is applied to the tile.

In addition, it is necessary to take into account the fact that on the back side of the tile there is a corrugated pattern, into which the mortar also goes.

Also, the size of the spatula teeth will depend on the type of glue. Thus, for example, to apply synthetic glue based on resins or latex, a tool with teeth of 2-4 mm will be used. At the same time, for cement adhesive this value will be 8 mm and higher, depending on the thickness.

In addition, an important factor is that the adhesive mixture must cover at least 80% of the base of the tile. That is why the composition is applied to both the tile and the base. In this case, the application must be perpendicular, i.e. If the mortar is applied horizontally on the tiles, then it must be applied vertically on the base.

Rules for applying the solution

Most often, purchased powder adhesives are used in repairs. In order for them to acquire their properties, the mixture must be diluted with water according to the instructions before use. In this case, you should not immediately add the entire volume of liquid; it is recommended to knead a thicker mixture first, and then dilute it as necessary. After this, you should leave the solution to infuse for about 10-15 minutes so that all components bond well with each other and form a high-quality adhesive mass.

To distribute the adhesive mixture over the surface as efficiently as possible, use a notched trowel. The number of the tool indicates the size of its teeth; the larger the tile, the larger they should be. It is recommended to apply the adhesive directly to the walls or floor. If you need to remove unevenness, then you can additionally lubricate the tile itself. A small spatula is used as an auxiliary tool.

To ensure even distribution of tile adhesive, it is recommended to apply it using a notched trowel.

In order for the glue to better adhere to the tiles and surface, it is recommended to wet them with water and dry them in advance. Please note that porcelain tiles practically do not absorb water.

How to calculate the amount of glue?

And the last question that we will further examine will be the calculation of the amount of the required adhesive mixture. The calculation itself is performed in several steps, which we will consider:

- The first step will be to determine the dimensions of the material and select the required thickness of the adhesive mixture based on the data presented above. The quality of the foundation also needs to be taken into account.

- Based on the instructions provided on the glue packaging, you can find out its consumption per square meter with a layer of 1 millimeter.

- Thus, it is necessary to multiply the thickness of the selected layer by the consumption indicated on the packaging. Thus we get an intermediate result.

- Next, you should calculate the area of the cladding. And after calculations, we multiply it by the result obtained at the previous stage.

- This way we get a number that shows us the consumption of the adhesive mixture for the entire room. But, at the same time, also take into account possible force majeure circumstances that often arise during installation. For them, a glue reserve of 10-15 percent should be provided. Accordingly, we multiply the previous number by 1.1 or even 1.2.

It is easier to calculate tile adhesive using an online calculator.