Some say that after using the converter everything is bad for them. And others say that everything is fine with them.

The trick is that everyone is right. :))

Let's figure out what these people did.

Some applied the converter and waited for it to work. We cleaned off the accumulated deposits with a hard scourer or simply wiped them with a rag, then degreased the part (what matters here!) and primed it.

Others applied the converter and waited for it to work. We washed it off with water (with or without baking soda, it doesn’t matter), degreased it (what matters!) and primed it.

For both the former and the latter, the result can be either positive or negative. :)))

Magic?! NO! Magic doesn't exist.

Phosphoric acid (namely, it is the main element in the rust converter) dissolves in water, ethanol and other solvents. For those who don’t know, ethanol is banal alcohol.

From here the following follows. Any rust converter based on this acid can be neutralized either with water or any other solvent. Alcohol is also a solvent if so :))

Further, following common logic, everyone knows that if bare metal is poured with water, it will accelerate the formation of rust almost instantly (and it will not necessarily be visible to the naked eye)

This leads to the following: Wash off the rust breaker from bare body metal with water, idiotic!

And this is where we start to get to the magic.

Why is it that some people washed off the part with water and primed it and everything is fine for them, while others who seem to have done the same thing are doing poorly?

And at the same time, for some who did not wash it off, everything can either be good or bad.

And the magic lies in the pre-priming stage. Namely, degreasing the surface.

———- thinner solvent degreaser——

Before painting, as everyone knows, the surface must be degreased.

And here the dancing with the tambourine begins. Which then can become one of the reasons that will lead to misunderstandings with the rust converter.

The fact is that there are DEGREASERS and there are SOLVENTS. Both are designed to clean the surface.

BUT! SOLVENT AND DEGREASER ARE DIFFERENT PRODUCTS. When painting a car, it is a degreaser and not a solvent that is used to clean the surface before painting.

DEGREASER (SO CALLED ANTISILICONE) ACTS DIFFERENTLY THAN SOLVENT.

The difference between them is the same as between a solvent and a thinner. Car paint cannot be diluted with a solvent; for this purpose, a thinner must be used.

———- thinner solvent degreaser

——

*Thinner and degreaser*

THINNER AND DEGREASER

much

less aggressive

than

solvents

and in addition to this, both THINNER AND DEGREASER, unlike

solvents

, DO NOT LEAVE AN OILY RESTRAINT on the surface after they evaporate. There are nuances in the composition itself, but that doesn’t matter anymore.

the solvent leaves an oil residue, but removes water well;

the solvent does not accelerate the formation of rust; on the contrary, it slows it down

+++++++++++++++++++++++++++++++ +

the degreaser does not remove all the water the degreaser does not completely neutralize the converter

Option 1 (degreaser is bad, solvent is good):

Treated with a converter. Next, rinse with water and degrease

and primed.

If degreased with a degreaser

then it will not completely remove the water that remains in the micropores of the metal and which, unnoticed by the naked eye, has generated rust.

As a result, after applying the primer and paint, problems may arise in the form of undermining the paintwork and the sin will fall on the converter.

But if they DEGREASED WITH SOLVENTS.

then there will be no water.

because SOLVENTS DRY SURFACES VERY WELL.

and there will be NO RUST.

The solvent does not accelerate the formation of rust; on the contrary, it slows it down

AS IT DEHYDRATES. and with this option, everything can end well. ————- Option 2:

Apply converter. I cleaned off the accumulated deposits with a stiff brush or simply wiped them with a rag, degreased the part and primed it.

If you degrease it with a degreaser, it will not completely neutralize the converter.

And in the end, already under the ground, the converter refines its own and then everything can be bad.

If degreased with solvent. Then he neutralized the converter well and everything is fine. ———————————

What to do and how to work with a rust converter?

I will tell you how I see the treatment of a rusty surface (using a rust converter)

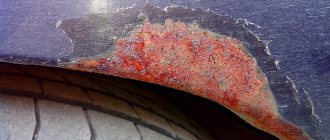

1 First, rust must be removed mechanically

. As carefully as possible.

2 Next, the surface must be wiped with solvent.

. In order to thoroughly remove all contaminants.

3 Then treat with a rust converter.

Moreover, it is necessary to process it more than once, but at least 2 times, and apply the converter by rubbing it into the surface with a stiff brush or sponge. So that it penetrates as deep into the pores as possible.

What does Tsinkar promise to do for your car?

A good rust converter fights the initial stages of corrosion, removes deep-seated damage to the body and preserves the metal that has not yet been affected by this unpleasant process. If you managed to notice the damage in time and also use a rust converter correctly, there is a real chance to significantly reduce damage and the risk of complete failure of body parts. On the manufacturer's packaging there are several promises and descriptions of the operating principle of Tsinkar:

- at its low price (about 100-150 rubles per 1 liter), the product received excellent reviews from specialists in many automotive services;

- the chemical acts exclusively on corrosion spots on the car body, there are no unpleasant effects;

- the instructions for use are quite simple, below we will explain how to use the product for good results;

- it is possible to reanimate old metal surfaces without replacing them with further partial welding;

- Tsinkar eats away damage from the deepest craters on the metal; with proper processing, not even traces of corrosion remain.

If the car can really be restored, then the reviews for this product should be enormous. But in reality there are also many negative opinions. Not everyone uses such a product correctly, and this can become a problem. And the cost of one bottle of the product turns out to be quite high. When working with such products, special attention should be paid to personal safety.

How to protect yourself from the influence of rust converter?

If you decide to treat your car with Zinkar, buy special rubber gloves with high protection and a guarantee of a weak chemical reaction. Chemical protection ensures that the rust converter will not corrode your skin. The activity of the product is very high, so it is better not to forget about personal protective equipment.

In addition, it is important to use goggles and a mask or an effective respirator to protect your respiratory system and vision. Otherwise, if the product gets into the eyes, the mucous membrane may be damaged. Inhaling the product is also not recommended; this can cause severe irritation of the respiratory tract and an unpredictable reaction of the body.

Do I need to wash off Tsinkar after application?

Before we begin to describe the use of rust converter on a car body, let's say that efficiency can only be high when washed off. To do this, use a soda solution with a high content of active ingredient. Otherwise, the metal under the resulting layer will rot even more readily.

The car must be treated correctly with Zinkar, otherwise the whole purpose of using this product will be destroyed. Never apply primer until the entire surface has been washed and dried. Otherwise, the rust converter will do the opposite and cause obvious trouble.

What happens if the product is not washed off?

Removing most of the converter is a necessary process. The active components of the product that remain on the metal can themselves serve as a source of surface destruction - corrosion.

If the previously applied product has not been washed off, then the subsequent paint coating will not be durable, and corrosion processes may continue right underneath it.

Acid-containing converters, for example, those based on orthophosphoric acid, may partially remain on the surface without completely reacting with corrosion products.

If they do not react, they will continue to have a caustic effect . As a result, rusting will return and may even become more intense.

Many rust removers are not primers and do not provide reliable adhesion.

Instructions for working with Zinkar - how to use a rust converter?

The use of such products must strictly comply with the manufacturer's requirements. If the instructions for use are unnecessary material for you, it is very difficult to get a good result. Even experienced bodybuilders who have never encountered Tsinkar carefully study the manufacturer’s requirements before using a rust converter. There are several requirements for working with a car:

- The area you are going to treat is simply cleaned by all means possible. Open holes and rot are removed mechanically.

- Next, the car body is cleaned using a metal brush and a grinder or drill. This will help achieve greater efficiency. But you shouldn’t be overzealous with this process.

- Only then is the required amount of rust converter applied to the surface. Judging by the reviews, the amount recommended by the manufacturer is optimal.

- You should also use a soda solution for rinsing when the product has already completed its task. After this, the body is dried, protection must be performed immediately.

- The protective layer is applied after welding, if necessary. Priming is carried out using various types and acidic primer compositions.

How can you replace “Tsinkar”

There are many products similar to this rust converter that are sold. If the oxide layer is small, try making the following composition at home:

- mix water and citric acid in equal proportions;

- add a tablespoon of alkali, that is, ordinary baking soda, to the solution;

- wait 30-40 minutes;

- treat the surface with the resulting composition, dry and rinse it;

- coat the metal with primer and paint well.

Now you know how to use the Tsinkar product correctly. If the instructions are strictly followed, even novice craftsmen should not have any problems. You just need to strictly follow precautions and protect the skin and mucous membranes from burns.

–> –> –> –> –> Content

:

Priming and protecting the body after using the converter

To reduce the cost of future body repairs, good protection should be used. Immediately after treatment with this product and drying of the body parts, welding work can be carried out. It is important to treat all exposed areas so that they do not rust or deteriorate over time. During the processing process, fairly simple and effective solutions are used. After treatment with Zinkar, protection is performed as follows:

- a primer should be applied to all treated surfaces of the car, choosing a good protective material;

- when applying, it is important to remember the need to apply additional protective materials on top;

- if we are talking about external external parts, priming and subsequent painting must be done in a chamber;

- if the body is not properly dried before priming, it will not be possible to properly treat and protect the surface;

- The quality of the primer must be very high, since already damaged parts easily rust at the first opportunity.

Of course, a rust converter is not a panacea. Rather, this is one of the possible emergency methods of solving the problem. In most situations, service technicians prefer to carry out welding work. This ensures higher quality and good reliability of repairs. However, welding areas should also be treated to protect against corrosion. In any case, repair areas have a high risk of damage in the near future.

How to avoid possible failures

It happens that after using the product, rust appears again. Most often, the fault is non-compliance with the technology, which is described in detail in the instructions. For example, a spray from a can may flow unevenly if you hold it at a distance of less than or more than 15-20 cm from the surface. Some people forget to shake the solution before use, which can cause it to separate. When applying, the brush must be pressed firmly against the base so that the treatment is more thorough and there are no unpainted areas left.

Let's sum it up

The question of how to restore car body parts after corrosion damage is quite complicated. You can use various options for means, techniques and protection options. However, there are a number of difficulties in using professional methods - it is impossible to apply them in your own garage and do everything correctly. Rust converters help remove corrosion, but do not guarantee that the body will last a long time without problems. These materials are designed today and now to remove already damaged elements.

Next, you will have to treat the body to protect the exposed areas from further corrosion damage. Tsinkar is also not a panacea for all types of body diseases. It only removes rust well and copes well with large damages. Otherwise, it is a fairly simple product with high chemical activity. If used incorrectly, negative consequences are quite possible.

Today, most car owners, faced with a problem such as corrosion, decide to use the Tsinkar rust converter to clean rusted parts. The use of this product, according to the manufacturer, will not only protect the machine from the need to replace individual parts, but will also create a special protective layer on it, which will prevent the formation of corrosion on metal elements for a long time.

The most famous remedies

Tsinkar

This rust converter is most often used when working with a specific metal and works best with steel. A special chemical composition: salt, zinc and manganese, affects the affected area from several sides at once. It not only destroys corrosion, but also forms a protective film on the metal.

In order to work with this product, you must act very carefully and be sure to follow safety regulations.

The highly toxic drug is not flammable, but the room in which the work is planned must have adequate ventilation.

Chainmail

This coating will help protect ferrous metal from the adverse effects of external factors. The name speaks for itself - it can be used both for damaged metal and for absolutely clean metal. The manufacturer allows its use before painting as a primer.

Sonax

To ensure perfect removal of rust marks and the formation of a protective layer before painting, use this converter. It can be applied to the surface either with a special tool or with a regular brush. At least two layers should be used, each of which should dry completely after at least 12 hours.

Movil with converter

If you are faced with minor signs of corrosion, this composition will cope with them perfectly. It will help remove the existing source of destruction and protect the surface from moisture and prevent new rust from appearing.

EVA-0112

The composition of this converter is quite simple. It contains orthophosphoric acid 85% and a base. Before use, it should be mixed in a certain proportion: 3 parts of the first substance to 100 parts of the second. The shelf life of the prepared solution is one day. In intact packaging, the composition can be stored for about six months at above-zero temperatures. It can be used as a primer. It is especially effective when interacting with paint based on epoxy resin. You can improve the rust converter by adding barium carbonate or benzidine to its composition. The approximate amount of the substance is 0.05 to 0.5%.

Sources used:

- https://avtozhidkost.ru/kak-polzovatsya-tsinkaryom-pered-pokraskoj-avtomobilya/

- https://kraskaok.ru/preobrazovatel-rzhavchiny-tsinkar-dostoinstva-sostava-i-sposoby-naneseniya/

- https://autokuz.ru/pokraska/kuzov-bamper/chem-smyt-preobrazovatel-rzhavchiny.html

Basic data

Metal parts of a car constantly suffer from corrosion that forms on them under the influence of excessive humidity. Over time, the rust that appears corrodes the parts so much that holes begin to form on them. As a result, the car performs worse and worse or stops starting altogether (if the power unit’s spare parts are damaged), forcing the owner to carry out expensive replacement of individual components. That is why protecting metal elements from corrosion is an extremely important task.

All currently existing methods of protecting metal from corrosion can be divided into two groups:

- Electrochemical protection. The metal is processed using galvanic steam and corresponding electrical impulses. Not used in its pure form. Requires mandatory additional conservation of the metal surface.

- Conservation methods of protection. A dense protective layer is created on the metal surface. For example, after using a paint coating.

Result of application

Automotive chemicals "Tsinkar" is a rust converter, which is one of the most effective means used to combat corrosion. When applied to a metal surface, the process of rust destruction begins, during which the oxide forms of iron are transformed into phosphates. This process is accompanied by additional reactions of zinc and manganese, during which a fairly strong and at the same time “active” complex-element protective layer is formed on the metal surface.

At the same time, zinc suppresses emerging corrosion, and manganese creates an alloying effect, strengthening the already reliable protective layer. It is noteworthy that such an effect is not observed after using monophosphate compounds.

Advantages and disadvantages

To make an informed choice of a suitable rust converter, you need to know in advance all its pros and cons.

The advantages of the product include:

Efficiency.- Creation of a protective coating.

- Convenient application.

- Possibility to select the volume of purchased product.

- Absence of flammable components.

- Democratic price.

- Recognizable packaging.

- Economical consumption.

The disadvantages include:

- Toxicity of the product.

- The need to use protective equipment during work.

- The need to re-coat with Zinkar, and in case of deep rust - multiple times.

- The chemical activity of the drug is not only in relation to rust, but also to varnishes and paints.

Benefits of use

The main advantage of Tsinkar auto chemical products is the price. On average, the cost of one bottle varies between 200–250 rubles. In addition, the product is easily distributed even over hard-to-reach surfaces, which, in turn, allows you to save quite a lot of time on dismantling parts that need to be cleaned of rust.

Starting in 2006, when a series of tests was completed, the Tsinkar converter received a new bottle with a spray. Despite the fact that the color scheme of the bottle has not changed, remaining yellow-orange, its shape, according to consumers, has become more comfortable to hold in the hand.

How does it affect rust?

Automotive chemicals "Tsinkar" is a rust converter that is used as the main protection when processing metal products. Thanks to its composition, it actively acts on existing rust, removing it from the metal elements of the car.

In order to prevent the formation of corrosion on the car for as long as possible, all metal (steel) parts should be treated with a converter before painting them or applying any other protection.

The consumption of the product when treating the surface of a car is on average 110–340 g/m2 - the exact consumption of the product directly depends on the method of application.

Terms of use

Re-processing of the metal surface is allowed only after the first layer has completely dried. This is evidenced by the formation of a whitish or grayish coating. Go over it with a stiff hair brush. This allows you to get rid of unreacted elements of the composition and prepare the coating for the next cycle.

Each new layer enhances the physical and chemical qualities of the anti-corrosion coating, guaranteeing reliable protection against external factors that lead to rust. The number of applications carried out has no restrictions.

You should refrain from the desire to save the converter. It is not recommended to limit yourself to one layer, especially when the product is used in critical areas and structures.

The best option is to carry out two treatments. If the product is needed only to get rid of rust, but not to extend the life of a metal product, one coating will be enough.

Mode of application

How should you use “Tsinkar”? The rust converter (instructions and composition are indicated on the back of the bottle) is made on the basis of zinc, which, settling on the surface, prevents the recurrence of corrosion. To achieve maximum results, the rust-damaged area should be cleaned down to bare metal. To do this, you can use a wire brush or sandpaper.

After the visible layer of rust has been removed, you should wipe the surface with a cotton pad soaked in the converter, or spray the latter onto the surface. If you did everything correctly, a gray coating will form on the cleaned area. After the appearance of rust, the rust residues are removed and the treatment is repeated several more times. Often 3-4 procedures are enough before painting.

Automotive chemicals "Tsinkar" is a rust converter that carefully and effectively cleans the surface. The only drawback of this tool is the painstaking work, because the entire process is done manually. As a result, it takes much more time to treat one area with Zinkar than to treat it with a salt converter. However, you must take into account that such painstaking work has its advantages, because after treatment with the product we are considering, even a very problematic area becomes completely unaffected by rust.

When using the product, work only in a well-ventilated area and keep your eyes and skin protected from contact with it. It is noteworthy that the Tsinkar rust converter is not flammable, but it still should not be sprayed near fire sources.

Safety requirements

If safety recommendations are followed, Tsinkar will not cause problems during application and storage. It contains orthophosphoric acid - a combustible, flammable substance, so you should work away from sources of heat and fire. In order not to harm your health, you need to ensure high-quality ventilation in the room, and carry out all manipulations in a respirator, gloves, and protective clothing. If the composition gets on the skin, wash it with soap and water; if redness and pain appear, consult a doctor immediately.

Other recommendations for using the product:

- do not allow heating above +55 degrees;

- store in a dark place out of reach of children;

- strictly avoid contact with eyes and mucous membranes.

User reviews

The first thing you need to pay attention to if you decide to purchase a Tsinkar rust converter is user reviews, which for the most part boil down to the fact that this is one of the most effective ways to combat corrosion. In addition, it can be used not only for treating automotive surfaces, but also in everyday life, because thanks to its chemical composition, the product quickly copes with rust on any metal structures and parts. As a result, a dense protective layer is formed on the treated metal (steel) surface.

What else do consumers like? The main advantages of using the Tsinkar rust converter are listed below:

- Price. The cost of one bottle is approximately 200 rubles.

- Economical in use. If you believe the reviews, one bottle of the product is enough to treat the body of a car.

- Ease of use. The shape of the bottle is made as easy as possible to grip, so that the container does not slip out of your hands.

- Uniform distribution. The bottle is equipped with a spray nozzle, thanks to which the product applies as evenly as possible and can be used even in hard-to-reach places.

Do I need to wash off the rust converter after treatment?

Most buyers, after anti-corrosion treatment of a car, are interested in: how to wash off the Tsinkar rust converter and is it necessary to do it? The thing is that a dense protective anti-corrosion layer of gray or gray-white color is formed on the surface of metal elements. If the treated parts will not be painted in the future, it is better to wipe off the coating from the converter using the hard side of a slightly damp sponge, which should be moistened with water or an alcohol solution. It is better to leave particles of the composition that will not be erased during the process on the surface. They represent a conversion (crystalline) layer that prevents the formation of corrosion.

If the Zinkar treatment was carried out before the actual painting of the car, after the last layer of the product has dried, you can apply the paint without removing the coating.

Compound

Zinkar's composition includes the following components:

- phosphoric acid;

- complexing agent;

- manganese and zinc compounds;

- water.

Phosphoric acid is the main active ingredient responsible for the transformation of rust. The complexing agent maintains the consistency of the drug and is a binding component.

Phosphates form a reliable protective coating on the surface:

- zinc protects against electrochemical corrosion;

- manganese is responsible for surface alloying.