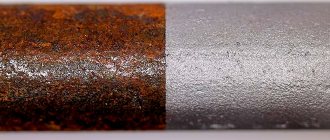

Treating rust before painting the metal is a necessary component of repair work.

The purpose of this effect is not only to restore the metal product’s attractive appearance, but also to maintain functionality and extend its service life.

We’ll talk about how to treat metal from rust before painting it in this article.

Effective ways to remove rust from metal before painting

Treating rust before painting the metal is a necessary component of repair work.

The purpose of this effect is not only to restore the metal product’s attractive appearance, but also to maintain functionality and extend its service life.

We’ll talk about how to treat metal from rust before painting it in this article.

On your own or with a service?

The owner of a new car will most likely request service, even if it is expensive. A native of the “garage community” of bygone times will prefer independent tinkering: neither stripping nor priming will scare him. But the average consumer, who has neither extra money nor “garage” skills, should look at modern auto chemical products. An example is the so-called Movil - once the name “Movil” was formed from the names of two capitals, Moscow and Vilnius. But today the term has become a household word: there are quite a lot of Movils on sale.

Types of processing of rusty metal surfaces

The choice of rust treatment method depends on the degree of corrosion and the type of item itself.

It is also necessary to consider what metal care products are available and available for use. The most common processing methods include:

- Chemical.

- Mechanical.

- Thermal. It is carried out using a torch.

Rust cannot be removed by washing with plain water. For this purpose, targeted, comprehensive processing is required.

You will find all the most useful and important information about rust removal methods and techniques in this section.

Thermal

The thermal method is rarely used . The use of an oxygen-acetylene torch makes it possible to remove mill scale well, but does not completely remove rust.

Mechanical

Physical impact on rust is designed to remove the top layer of material that has become loose. This can be done in several ways:

- manually (using a brush with metal bristles and scrapers);

- using a grinding machine or a special machine.

In addition to those products that are available at home, industrial enterprises also use serious devices using special equipment to treat rust:

- shot blasting;

- water sandblasting;

- sandblasting

The best result is obtained by a combination of abrasive and chemical effects.

Chemical

Chemical treatment is carried out using homemade products and purchased, ready-to-use preparations. In addition, large metal surfaces are also subjected to special influences that help preserve and protect the material:

- connection with organic additives, providing bluing;

- cementation - a chemical reaction with carbon;

- nitriding, etc.

Treatments carried out at home include:

- preparation of material;

- exposure to a chemical;

- wash.

The type of chemical exposure must take into account the degree of damage to the metal.

For removal from plastic

Due to the physical properties of this material, the use of mechanical or thermal options for removing paint is sharply limited. If you use a mechanical method to remove paint from plastic window frames or from the plastic surface of a window sill, you can ruin the appearance of the apartment so much that you will want to replace the entire window opening. With the thermal method, plastic products may warp.

The exception is heating water-based paint to low values: 60–70°C. It is better to do this with a construction hairdryer with temperature control. As a result, the water emulsion swells and is easily removed from the plastic surface. In other cases, to remove paint of a different composition from plastic, it is better to use a chemical method. Any other kind is removed from plastic using special removers, the main disadvantage of which is their toxicity.

A product for removing paint from plastic (photo source - Yandex.Images)

In addition to them, the following chemical compositions are used:

- 20% solution of caustic potassium or caustic sodium (50% solution of caustic soda is allowed), with exposure for 4–5 hours;

- solvents used in the preparation of paint (white spirit, solvent and others);

- “Mole” brake fluid – a gel for clearing blockages in pipes;

- methanol

When using methanol, it is important to remember its strong toxicity and rinse the surface well after treatment.

There is an effective option that does not contain toxic substances at all. This is a method based on the use of silicone sealant or liquid glass.

A plastic product (can be effectively used for voluminous, complexly shaped surfaces) is covered with a layer of sealant. The mixture is kept until completely dry. Next, an incision is made carefully with a sharp object, and the entire film is completely removed from the surface of the plastic.

For removal from glass

When painting work is carried out, no matter how carefully it is done, traces of paint remain, disturbing the appearance of glass window openings. An effective way to remove fresh stains from a window is to use universal special products designed for removing paint from glass. For dried traces, you can use already known methods: mechanical, chemical or thermal. A softened paint stain, given the hardness and smoothness of the glass surface, can be easily removed manually with pointed objects.

Cleaning glass from paint (photo source - Yandex.Images)

How to remove plaque using folk remedies?

The effectiveness of the exposure method is increased by a combination of chemical treatment and mechanical action . Homemade recipes are based on the use of easily available products that may already be in the household. Their main advantage is low cost and availability.

As a rule, the choice in favor of folk recipes is made with minor corrosion. Most often it is not difficult to deal with it.

Coca-Cola

Using Coca-Cola in the household allows you to clean various surfaces.

One popular recipe is to use the drink to remove rust. In order for the orthophosphoric acid in the drink to take effect, you can use a rag soaked in Cola . A rag is soaked generously in the drink and applied to the surface that needs to be cleaned from corrosion.

This recipe is suitable when the rust has not penetrated deep into the metal, since the concentration of phosphoric acid in Coca-Cola is low. The exposure time should be at least several hours, preferably a day.

But if the metal is seriously damaged, this method is ineffective . At the end of exposure, the cola is washed off with water and the surface is wiped dry. When using Cola, it is enough to use only rubber gloves as a means of protection. Read more about using Coca-Cola against rust here.

Acids

Various acids have proven themselves in the fight against rust:

Lemon

One of the easiest recipes to deal with rust is to use citric acid.

The product can be used in two ways:

- apply generously with a sponge to the affected areas of the metal;

- soak a rag in the solution and apply to the rusted areas.

The last of the presented options is more effective, but even this method will not eliminate serious corrosion.

The duration of action of the composition is at least an hour . After this, the metal should be cleaned with a stiff brush, and the residue should be washed off. Read more about the use of citric acid in the fight against rust here.

Vinegar

Vinegar also allows you to remove rust during mild corrosion processes.

For exposure, undiluted vinegar is used. If the rusted items are small in size, they can be placed in a container and simply poured . For large metal objects, ensure that the cleaned surface comes into contact with vinegar.

After exposure to acetic acid, the surface is refined by mechanical rubbing and washing off the remaining vinegar.

Before painting directly, the metal must be primed. You can learn more about using vinegar to combat metal corrosion in this article.

Sorrel

Oxalic acid is a drug that is available in powder form . This remedy gives good results, but requires very careful use, as it is poisonous. Use may only be carried out in compliance with all necessary protective measures.

How to use:

- Apply the solution generously with a brush.

- Leave for 30-40 minutes.

- Remove loose rust.

- Rinse off any remaining product with water.

Oxalic acid is suitable for advanced cases and large area surface treatment.

Orthophosphoric

Phosphoric acid is a commonly used component of ready-made rust converters.

This substance is highly effective and can be used even in advanced cases.

To prepare metal for painting, an acid concentration of 15-20% is required. Exposure to orthophosphoric acid should not be long - just 5 minutes is enough. After this, you can walk over the surface with a brush.

Video description

How to remove rust using Silit, watch this video.

Some home craftsmen use Coca-Cola or Pepsi to get rid of corrosion. These drinks contain phosphoric acid, which easily removes small rust stains. Wipe metal surfaces with liquids or immerse parts in them. Then rinse under running water.

Pepsi can easily cope with rust in small areas Source yandex.net

A mixture based on paraffin and kerosene is also popular. Take these products in equal proportions and mix. Apply to the surface to be treated in several thin layers with a sponge or brush. Leave it for at least a day. After the specified time, remove the mixture along with the rust with a rag, rinse with water and remove moisture with a rag or sponge. It is best to use this method for tools. Do not forget about a mask, gloves and safety glasses when processing with a kerosene-paraffin mixture.

How to clean with special compounds?

Purchased anti-corrosion treatment products have a rich composition containing active substances in high concentrations . These drugs will help in cases where there is advanced corrosion with serious damage to the metal, covering a significant area or the surface of serious equipment, for example, a car, is damaged.

Before using the converter, the surface must be prepared:

- eliminate contamination;

- clean off loose layers of rust;

- degrease the surface.

Hi-Gear Rust Treatment

Hi-Gear is a rust converter that can cope with even advanced corrosion, as it penetrates even into the deep layers of the material. The drug is applied by spraying. As a result of a chemical reaction, rust is eliminated, and a polymer protective composition is formed on the surface.

The use of Hi-Gear requires caution , since the composition is capable of reacting not only with corrosion products, but also with the paintwork. After exposure to the converter, it must be washed off using alcohol-based solvents.

Despite the high price for the bottle, the purchase can be considered profitable, since the consumption of the product is very economical. The price of the package is about 700 rubles.

Phenom

Hairdryer is a rust converter that is often chosen by car enthusiasts. The product is well distributed on the surface and creates a dense polymer layer. The drug is a reliable means of preventing relapse of corrosion at the treatment site for many years.

The hairdryer comes in a compact black package and is a white liquid . Due to the small volume of the product in one bottle, several bottles may be needed to treat a large area of metal.

Pros of use:

- efficiency;

- affordable price for 1 bottle;

- a protective layer is created;

- quick and easy application - brush application;

- high-quality metal processing through complex influence.

The price of a small bottle is about 150 rubles.

Kudo KV-70005

Kudo is a structural modifier that effectively combats rust due to the presence of acids. The drug can be used to eliminate small areas of corrosion. The product is packaged in small bottles and is conveniently applied with the included brush.

Price for 15 ml - 120 rubles.

Corrosion Removal Methods

Corrosion can be eliminated in the following ways:

- Mechanical – used for severe corrosion, it involves removing rust by stripping down to metal, followed by priming, puttying and painting the area of the body being repaired;

Advantages of the method: elimination of large and deep stains, damage under swelling paint, as well as low cost and availability of the necessary materials.

Disadvantages: length of the process.

- Chemical - involves using rust removers. Such reagents are widely represented on the modern market.

Advantages of the method: elimination of corrosion in hard-to-reach places, higher process speed.

Disadvantages: inability to use on heavily damaged areas.

Let's consider the process of eliminating corrosion using each of the methods presented above in more detail.

Recommendations

To ensure that rust treatment on metal is as productive as possible, you must adhere to the following recommendations:

- The corrosion process begins from the most vulnerable areas. Its spread can be prevented by cleaning and creating a protective coating.

- When carrying out rust removal work, personal protective equipment must be used.

- When working with purchased products, rust converters, you must first study the instructions for the selected product and strictly follow them.

- Even expensive rust converters are not able to restore metal if it has very significant damage, for example, through corrosion.

- Preventing rust will help keep your metal products in good condition.

- The most reliable protection of metal is its galvanization. The use of products containing zinc helps prevent corrosion.

Video: how to get rid of rust on a car body using the Zinkor-Auto kit

#1 OFFLINE Rean

- My car: Opel Insignia 2.0T

- My name is Aleksey

- From: Rostov-on-Don

Just recently I became the owner of a white insignia and today I encountered the same problem. On the roof above the rear window I found several small spots of rust (rust is on the paint, if you scratch the rust with something, intact paint appears under it), I suspect that during transportation, rusty water dripped from the car transporter and left such traces.

Actually the question is - tell me how you can remove these spots with minimal harm to the paintwork?

#2 OFFLINE Nightmail

- Gender: Man

- Moscow city

- My car: Opel Insignia HB 2.0t 4×4 MT 2011

- I'm Ilya

- From: Moscow

I would still go to a decent car wash - firstly, there should be tested chemicals there, and secondly, if something happens, who will be the one to ask.

What is rust?

The corrosion process itself is the spontaneous destruction of metal elements under the influence of oxygen. At the chemical level, we obtain the reduction of oxygen, which is why a layer of rust appears on the metals.

There is a fairly broad classification of corrosion according to the conditions of occurrence, nature and a number of additional effects, but in rolled metal we are interested in only some of them.

Please note: not only metal products undergo the aging process. The term “aging/fatigue” is also inherent in plastics, rubber, concrete + other types of materials that are used in industry and everyday life.

The reasons for such processes are quite natural - a decrease in operational characteristics due to the physics + chemistry of the environment. Non-ferrous metals are less susceptible to corrosion, however, “aging” cannot be completely eliminated. An oxide film can slow down the formation of rust, but it is extremely difficult for widely used building materials to completely avoid the process.

I will explain the types of rust in the household aspect with a separate table.

| Type | Description |

| Yellow | Divalent ferum oxide. It manifests itself in environments with high humidity and lack of oxygen. This type of rust is often found in water. |

| Brown | Occurs without water. It is extremely rare in everyday life and industry, so I will not focus on it. |

| Black | A special type of rust that occurs in an environment with little access to oxygen and completely without moisture. A ferromagnetic oxide having a stable structure and a slow rate of propagation over the metal surface. |

| Red | The most common type of rust that forms in an environment with oxygen and medium to high humidity. The danger of red rust is iron hydroxide, which causes the metal to peel off until it completely decomposes. |

In addition to classification by type, there is a distribution of corrosion depending on the degree of distribution - uniform, local and intercrystalline. The latter poses the greatest danger to metal structures.

Several types of rust can easily coexist on one piece of metal. In our country, iron is considered the most vulnerable to corrosion, and given the widespread use of alloys based on this chemical element, we can encounter rust everywhere.

Corrosion protection

Follow the simple tips below to protect your car from corrosion:

- wash your car regularly;

- install mudguards (if you don’t have them);

- treat the car with polishing agents (such as “liquid glass”);

- carry out anti-corrosion treatment on the underbody of the car.

Regularly inspect your clean car for problem areas. Remove any small stains that appear in a timely manner. Remember: severe advanced corrosion will lead to expensive body repairs.

Take good care of your car, and then the methods described above will not be useful to you!

How to remove rust from metal: visual instructions + useful tips

The question of how to remove rust from metal can be solved by two methods - mechanical and chemical. Let's take a closer look at each of them.

1) Mechanical cleaning

The cleaning method involves the use of manual or automated tools that will remove a layer of rust due to mechanical action. Before using this cleaning option, I advise you to assess the degree of corrosion of the metal surface in advance.

In half of the cases, mechanical action will not be able to clean the surface even 90%. In return, we will get a bunch of new microcracks, through which rust will begin to spread at an even greater speed. Now directly about the removal methods.

A) Use a metal brush

The most popular option when treating small areas with a shallow degree of corrosion penetration. The tool itself is a regular base with a handle on which bristles made of small metal fibers are located.

I’ll tell you about the classification of hand brushes in a separate table.

| Classifier | Elements | Description |

| Handle material | Plastic | The products are lightweight, which allows a person to use the tool for a longer time. The base is impact-resistant plastic, which is easy to clean and wipe off. Among the disadvantages, I would highlight fragility and inconvenience of use when the palm gets wet. |

| Tree | The price tag is 40%-80% more expensive than plastic analogues. Due to the increased safety margin, they have better resistance to mechanical stress. The disadvantages are the price and the tendency for the wood to rot. | |

| Handle type | Standard | A current option for household use and small-scale production. |

| Extended | Used for surfaces that are difficult to reach with a standard handle. | |

| Curved | A specialized handle that allows you to strip at a certain angle. |

Scheme for cleaning rust from metal:

- Fixing an element when its size is small.

- Surface treatment using circular movements clockwise and counterclockwise.

- Periodic cleaning of rust from the stripping area.

The last 2 steps are repeated until the employee achieves the desired result. From time to time, the part is removed from the fixing element and installed in a more convenient position.

Please note: it is not rational to clean large areas with damage using this method.

The amount of effort expended cannot compensate for the result obtained. In addition, manual cleaning will take tens of times longer than using a semi-automatic tool.

B) How to remove rust from metal using special attachments?

I consider it the best method to solve the corrosion problem. Tools such as a grinder or a screwdriver are now available in any household. To fully use the functionality of a semi-automatic unit in the fight against rust, it is enough to buy a couple of special grinding attachments.

Important: Do not use flap wheels to remove rust. Due to the special structure of the abrasive and the arrangement of the elements, the plane of the nozzle very quickly becomes clogged with rust particles, which is why its efficiency is reduced to zero.

New wheels not only clog quickly, but also damage the geometry of the metal being processed. The only reasonable solution for using a flap attachment is descaling.

What circles should be taken into service in the fight against rust.

| Title + photo | Description |

| Gtool CD | The basis of such circles is made of non-woven material. The shape is a web made of nylon in a volumetric flow. Abrasive grains are applied to the surface of the threads with special glue. The high productivity of the circle is due to the large pores between the threads. Recommendations for operation: no more than 4,5000 rpm. |

| CIBO | Similar to the circle discussed above, only with a focus on a more subtle scope of work. The abrasive threads are thinner + the base itself has a high supply of elasticity, due to which the worker can process uneven surfaces. The nozzle does not heat the metal and, due to the fine grain of the abrasive, can be used for processing non-ferrous metals. For ease of work, I advise you to take an angle grinder with speed control. |

| Cibo FAG 5 | Circles with high levels of flexibility and softness. Ideal for treating uneven surfaces with low to medium rust levels. Due to the large surface of contact between the abrasive and the surface, the nozzle generates quite a lot of heat during operation, and this fact must be taken into account in advance. For comfortable work, it is better to take an angle grinder with speed control. |

Depending on the type of surface being processed, the fixation of parts is done at the discretion of the worker. To avoid work-related injuries, I advise you to always use a vice for processing small elements.

B) Cleaning with foil

A popular method for cleaning chrome surfaces. Due to the specifics of the process, the applicability of foil is limited to the stripping area. For large volumes of work, it is more rational to resort to attachments to angle grinders.

Algorithm for stripping with foil using an example:

- We are putting together a starter kit to get started. In addition to foil, you will need a container of water, paper napkins and a bottle of WD-40, which is used by car owners to treat car terminals.

- Fill a container with warm water. Crimp a small piece of foil into a medium-density ball.

- Dip a wad of foil into the water and begin to scrub off the rust. The liquid in the foil will help wash off the flakes + reduce the number of abrasions during surface treatment.

- After removing the main layer of rust with foil, you need to wipe the element with a dry cloth. Next, apply a little WD-40 to the paper and rub it into the metal with smooth movements for 30-60 seconds.

- Then we go over it again with a dry cloth and check the result.

Using WD-40 is not a rule, but a wish. If a person is processing a regular part, and not a chrome-plated one as in the example above, foil and warm water will be enough for him. For greater effect, water can be replaced with 3% vinegar. It will be much easier to erase rust with foil while using acid.

D) Sandblasting

The method has found wide application in industry and in the processing of car bodies. Thanks to automatic feeding and fast results, the rust removal option is ideal for large volumes of work.

Advantages of sandblasting:

- cheapness;

- high processing speed. 10-15 times faster than a grinder with an attachment;

- high-quality removal of rust from hard-to-reach places;

- increased adhesion.

The difficulty of using this method lies in the high cost of the equipment itself, if we consider purchasing it exclusively for home use. Normal units start at 60,000 rubles.

If you order metal stripping from rust from professionals, then for one square meter they require from 250 rubles. For a one-time promotion, such an expense can be called justified, but for large volumes of work it is better to fork out for used equipment.

2) Household chemical cleaning

A) Vinegar

The type of vinegar is not important. Rice, apple, wine - any will do. In addition to the natural substance, synthetic vinegar, which is obtained from petroleum products, also works well. It is sold in powder form, similar to dry ice.

Important: synthetic vinegar is an aggressive acidic environment, and therefore when working with it you should carefully consider safety precautions when working with chemicals. Gloves and glasses are required attributes.

When using natural vinegar, there is no need to dilute the liquid. When working with synthetic, you need to make a concentrate from 7% to 75%. Vary the amount of water in the powder depending on the degree of neglect of the rust cleaning object.

How cleaning occurs:

- Fill the container with vinegar.

- We immerse the part that needs to be cleaned of rust into it.

- We are waiting 24 hours.

- We rinse under water and evaluate the result.

If there is too much rust, the algorithm can be repeated 1-2 more times, or simply leave the part to soak in a vinegar bath for a couple of days at once. I note that the cleaned surface quickly oxidizes, so after drying, the part should be coated with lubricant or paint as soon as possible.

B) Limonka

Another common remedy that any housewife has in her kitchen. If necessary, you can buy lemon juice at your nearest grocery store. The advantage of treatment with citric acid is the formation of an oxide film. The layer will be able to protect the metal surface after removing the rust for a couple of days, which is enough to apply an anti-corrosion substance or lubricant.

How to remove rust from metal with lemon:

- Degreasing the surface.

- Filling the container with warm water.

- Dissolving lemongrass in water at a ratio of 1 to 1.

- Placing a part in a liquid.

- Waiting 4-24 hours.

- Flushing.

The rust will peel off from the metal on its own. The remaining solution is non-toxic, so flushing it down the sink is a prudent solution for the sewer system.

Popular methods for removing rust from metal at home: