The smell of strong morning coffee fills the cozy kitchen. You want to be here all the time, inhaling the aromas of freshly prepared food - fried meat, mushroom soup, sweet freshly baked muffins.

Here you want to meet in the evening, have leisurely conversations after a working day, spend the weekend doing pre-dinner chores for the family, or just sit, when your family has already fallen asleep, with a cup of herbal tea. Yes, right here, behind this kitchen wooden countertop - warm, cozy, welcoming... and, it seems, eternal.

When choosing a kitchen set, the consumer is faced with the question of selecting a surface for the work area, i.e. countertops. This surface experiences enormous loads and strength tests every day. However, there is no way to do without it.

A large number of people give their preference to wood. Natural, warm, durable and textured material will not leave anyone indifferent. However, there are a number of nuances due to certain operating rules that you must know and remember when purchasing.

Wooden countertops are very popular due to their positive properties.

Features of a wooden table top

Wood is an excellent material from which furniture is made. Inexperienced and little-informed people in this matter worry about the possibility of fungus, mold, and cracked varnish. Professionals think differently. In their opinion, a wooden countertop is no worse than its analogues made of artificial stone, for example.

Using the necessary and proper care, the tree will please the eye for a very long time. There are practically no materials used in the kitchen that are weakly subject to wear and tear. The peculiarity of wood is that it can age gracefully. In order to save money, you can make only the surface of the working area from a natural component, which will combine well with individual decorative elements.

How to cover the tabletop

Having decided on the material, you need to understand that the optimal surface for the table will only be natural wood. In no case is veneer, MDF or chipboard used. Particular attention is paid to the age of the tree, its place of growth, and storage conditions.

It is important to know that a laminated wood surface will be more elastic and flexible than the same surface made from solid wood. The type of raw material is also important. Care methods must necessarily include treatment with special protective agents. What is the table covered with? It can be varnish, wax or oil. There are three options for covering the table surface: varnish, wax and oil.

Practicality or durability

In order not to make a mistake in your choice, you should keep in mind some features of tree species. Harder ones, such as oak or beech, will last longer. However, their cost is much higher.

Among the democratic ones, pine, birch, ash or larch are perfect. Speaking about the latter, we should note a number of advantages. Its surface is quite dense and resistant to various types of damage. The presence of gum in the composition prevents the growth of fungi and mold, as well as rot, which is very important considering where it will be used. Larch is also capable of absorbing or releasing excess moisture.

Oil, wax or varnish

Avoiding the harmful effects of water, temperature, acid and alkali will help extend the life of a wooden tabletop. Here the question immediately arises of how to cover a wooden tabletop so that it lasts a long time.

Among those available, processing using the following means is suitable:

- oil;

- wax;

- varnish

Surface treatment with oil, or rather its impregnation, is the optimal way to protect wooden products. It provides a kind of barrier that repels water from the surface. Oil absorbed into the top layer of wood will prevent it from getting wet when in contact with water. Oil compositions are not washed off, but require frequent use. At the moment, you can choose different compositions that match the color. Oil protects wood from moisture.

Wax is a natural and environmentally friendly material. The effect of its use is similar to oil. But in addition to protecting against water, the wax coating also protects against minor mechanical impacts (scuffs and scratches). However, there are also disadvantages. A wax coating wears out quickly and requires updating and polishing more often than an oil coating. Before this, the old layer is cleaned off.

Using varnish on a wooden tabletop is a radical method. It protects wood from water, minor mechanical damage, and exposure to ultraviolet radiation, while the structure of the tree itself does not change. The color of the surface remains the same, and a natural exchange of moisture also occurs, preventing the appearance of fungi and mold.

This coating also protects against temperature influences without flaking or cracking. To remove the varnish coating, the tabletop will have to be scraped.

The nuances of choosing a wooden countertop

So that all of the above problems arise as rarely as possible, and no repair work is required. When choosing a wooden work surface for the kitchen, you need to take into account a number of nuances.

Material. If we talk about wood, the best options are oak, teak, walnut and beech and others. These breeds are strong and durable. But they are also the most expensive. If you choose other options, pine is the best. It contains resins that protect the wood from rotting.

Manufacturing method. Solid countertops (solid), which were mentioned above, are not affordable for everyone. Therefore, in the selection process, people often give options to glued models. The latter, especially if they consist of different types of wood, can combine strength, visual appeal and positive features of all types of wood that compose them. Veneer is a very thin covering of natural wood. In the case of the tabletop, he covers it with a slab of MDF or inexpensive types of wood. Finally, laminated options based on chipboard or MDF are very popular. They have a wide variety of appearances.

Coating process

Proper treatment of a wooden surface is the key to its long service life. This rule especially applies to kitchen countertops. In addition to the fact that you need to choose the right treatment product, it is also important to properly prepare the surface, apply protection and dry. The following describes the process of how to coat surfaces using oil compositions as an example.

Preparing the wooden surface

The first step will be to clean the countertop from all kinds of dirt and greasy marks. Next it is dried.

On a note! The wood moisture content should be no more than 12% according to DIN EN 13183-2.

To ensure that the oil adheres well and is absorbed, the wood is sanded, starting with coarser abrasives, gradually moving to finer ones. Also, after each abrasive, the coating is cleaned. You may need to putty it to remove deeper scratches. A special restoration kit based on wax is ideal.

Preparation of the product

The main thing you need to pay attention to when choosing a coating is its quality. A good protective agent will protect the wooden surface from mechanical damage and moisture and give it a shiny, renewed look. The coating must be of high quality to provide the furniture with protection and a well-groomed appearance.

The product must also be prepared. Before treating a wooden countertop in the kitchen, the composition must be thoroughly mixed for 5 minutes. The product must be mixed well.

Application

The composition is applied with a brush or cloth, and the latter should not leave lint on the surface. It will take about 12 hours for the first layer to dry. Then you can apply the next one, and so on. The number of layers will directly depend on how the product is applied. Using a brush, two treatments are enough; a fabric coating will require up to 4 layers.

Use a brush or cloth for application.

When the product is well absorbed, the entire treated area is thoroughly wiped with a soft and clean cloth.

After the product has been absorbed, wipe the surface with a cloth.

Drying

Drying time varies from several hours to several days. Naturally based oils or mixtures containing acrylic require a longer drying period. They can also increase strength gradually. It is important not to use a freshly treated countertop for a while.

After applying the coating, it is important to let the furniture dry.

Varnishing the table top

The varnish can be applied in different sequences. The stain can be used both before the surface is covered with a primer mixture and on top of it.

What is the best way to proceed depends on the wishes of the one who carries out the coating, since there is no difference in the final result.

Since the varnish is applied in several approaches, after the first layer has completely dried, the tabletop must be sanded well.

It is imperative that a primer and stain be used first.

Among other things, their use significantly saves the consumption of varnish, the pricing policy of which is by no means cheap.

When choosing a stain, you need to take into account the composition of the varnish that will be used to cover the wooden table. Alcohol, aqueous and self-diluted solvents are used.

Work order

- To begin, apply a small amount of stain to the countertop. It is necessary to ensure that there are no smudges, droplets or humps on the surface. After application, the surface must be allowed to dry. Depending on the composition, varnish and stain require different times. Since painting is carried out in stages, you need to ensure that each previous layer dries well before applying the next one. This can be determined by touching the base with your fingertip. If it is not sticky, you can continue working. Upon completion, the table should be left to dry thoroughly (24 hours is sufficient). The exception is compositions made on the basis of water or polyurethane.

- If the countertop needs to be shaded, it is recommended to cover it with several layers of stain. With each subsequent layer the surface will become darker.

- To give the tabletop a smooth finish, it must be sanded during operation using sandpaper. This method eliminates unevenness in the surface fibers. But the first sanding is carried out only after the first layer of varnish has been applied and completely dried.

- In general, in order for the coating to be truly durable and to extend the life of the table, it is recommended to cover it with three layers of the product.

The coating can be done on your own, saving some of your finances.

It’s just important not to rush and carry it out according to all the rules.

Pros and cons of wooden surfaces

Wood can be called the best material for making kitchen furniture. But, as with everything and everywhere, there are advantages and disadvantages. The first include:

- environmental friendliness;

- good thermal insulation;

- natural appearance;

- variety of forms;

- variety of colors, shades;

- ease of restoration work.

Wooden flooring in the kitchen has many advantages.

To the second:

- rapid contamination;

- possible fire;

- susceptibility to mechanical stress;

- quite high cost.

Among the disadvantages are the possibility of fire and the high cost of the material.

There is absolutely no need to be afraid of using wood in the kitchen. This is a good solution for modern headsets.

Tabletop care

Proper care will extend the life of your wooden countertop. However, during the preparation of a culinary masterpiece, and more than one, the surface can be subject to all sorts of influences, from scratches with a knife, hot dishes to spilled water or a fallen frying pan.

In order for the countertop to last a long time, it is necessary to properly care for it.

Following these rules will help you save money and nerves:

- using cutting boards rather than table surfaces;

- it is better to use special stands for hot dishes on the work surface;

- no prolonged exposure to water;

- cleaning the countertop with soft brushes and sponges to avoid damage;

- removing various stains using a soft cloth and a neutral product without abrasives;

- timely sanding of small scratches and stubborn stains with fine abrasive sandpaper;

- using a special wood polish;

- Caring for a wooden countertop should be daily and regular.

It is important to use cutting boards while working.

By following the rules of caring for wooden surfaces, you can enjoy the beauty, warmth and comfort of your kitchen for a long time.

Summarizing the above, we can highlight the following: a wooden countertop is an excellent solution for a work area in the kitchen; the correct choice of wood, careful handling, proper care and timely treatment with protective agents, and, if necessary, restoration, will help preserve the natural beauty and durability of the tree.

Types of wood coatings

Wooden countertops suffer damage more often than other parts of furniture. Scratches, detergents, moisture, ultraviolet radiation, mold, mildew, insects - everything affects its appearance. Compounds with protective and decorative characteristics will help extend the life of a wooden tabletop.

There are two groups of coatings for wooden countertops:

- For external treatment, the compositions must protect against moisture, mold, insects and ultraviolet radiation.

- For the interior, in addition to its protective properties, the coating must be safe for health.

The choice of composition depends on the material and purpose of the countertop. For the kitchen, bathroom, bathhouse you need good protection from moisture and temperature. Garden furniture is treated to protect it from the sun, precipitation and parasites.

The bathroom needs good protection from moisture

Wooden countertops for living rooms do not need protection from moisture as much, but decorativeness is important for them. Coffee, dressing, writing, coffee, dining tables and tables are treated with oil, wax, glaze or varnish. Covering the structure of natural wood with paint should be done as a last resort - if necessary, hide severe damage or create a color accent in the interior.

The coating can change the shade of the wood

How to treat a wooden tabletop?

The surface of the table in the kitchen is an essential part of kitchen furniture; it is subject to constant mechanical stress and is damaged over time. Therefore, owners of kitchen furniture ask themselves an important question: - How to cover the countertop so that it does not lose its presentation for many years?

In the kitchen, the top of the table or the area located on top of the floor cabinets is used as a work area for cutting food and preparing food, as well as a place to place household appliances and kitchen utensils. Such a working area must be resistant to shock and various mechanical damage, to the effects of temperature, ultraviolet radiation and water.

Features of wood countertops

Kitchen sets are made using various raw materials, such as wood. It can be either natural, that is, without a special composition applied on top, or coated with varnish or paint.

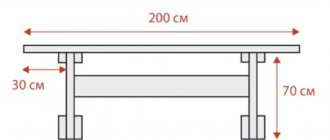

The table provides data on wooden tables.

Characteristic Description

| Design |

|

| Material | The wood material can be anything, but the most commonly used are cherry, walnut, oak, and maple. Exotic woods are used less frequently (teak, rosewood). |

| Shape of the finished piece of furniture | Ready-made pieces of furniture for the kitchen can be of various shapes: rectangle, oval, circle, corner shape. |

The advantages of countertops made of wood are:

- a large number of different forms;

- attractive appearance;

- ease of carrying out restoration work;

- This material is environmentally friendly and warm.

The disadvantages of countertops made from wood raw materials are:

- ease of fire;

- ease of contamination;

- can be scratched easily;

- is quite expensive.

Ways to protect your kitchen work surface

The working area of the room in which food is prepared is exposed to various liquids, so in order for it to serve for many years, it must be protected from water.

There are several ways to do this:

- Use oil to treat objects made of wood, which is absorbed into the material and prevents the fibers from swelling when wet. The following industrial products can be used for wooden surfaces: OSMO TopOil, Belinka, Adler Legno or many others. To treat the work area together with this substance or even instead of it, use a special wax. But it is necessary to remember that such a product will have to be renewed over time, that is, applied again.

- Treat it several times with a special varnish for wood surfaces. If desired, a little pigment is added to it so that the deep fibers of the wood become darker, and the cooking surface itself acquires expressiveness.

Oil coating for kitchen units

Oil protects furniture from not only moisture, but also from chemical, natural and household influences. This industrial product is largely colorless and can be plant-based, mineral-based or synthetic.

These coatings differ from each other in the drying method:

- It dries completely, hardens after drying, it cannot be washed off with water and the original appearance of the treated furniture is preserved for quite a long time.

- It does not dry at all or dries only half and saturates the wood quite deeply. It is made using natural ingredients. It is removed using mechanical force.

Before applying such a product, the surface to be treated is thoroughly cleaned of all contaminants and dried. If necessary, old paint or varnish will have to be removed. And if there are defects, they must be leveled with a special putty and then sanded with sandpaper.

The oil is applied using a brush or cloth that does not leave lint, it is applied along the entire length of the fibers. The very first layer should dry for twelve hours, then a new layer is applied. Their total quantity in this composition depends on the method in which the product itself will be applied. If a brush is used, two treatments will be done. And when using a rag, you need to do three or four layers. After the composition is completely absorbed, the entire treated area should be wiped well with a soft and clean cloth.

The presented coating has a number of positive properties:

- Does not change the color of the surface for working with food, emphasizes its “pattern”.

- It leaves the original natural exchange of moisture in the surface and prevents the appearance of fungi, so the original appearance of the treated area does not change for a long time.

- If the outer part of the object for such treatment is exposed to elevated temperatures, then the product does not delaminate and does not flow.

- Furniture oil is environmentally friendly, so contact of food ingredients with a surface containing the described composition will not harm human health.

- Oil hides small scratches, worn areas and stains left by cookware.

- If there is a need to renew contaminated areas, you can remove only part of this coating, and then reapply it to the desired areas.

- The oil is well suited even for aged wood containing pores, as it is deeply absorbed, gives it elasticity and prevents it from drying out.

What types of furniture varnishes are there?

Furniture varnish coatings can be classified not only by composition or color, but also by degree of gloss, method of application and purpose.

If we talk about the effect after coating, then the products are divided into glossy, matte, colored and craquelure varnishes. If you use varnish with a glossy effect, the furniture will reflect light as much as possible, making it the main asset of the room. Using a matte or semi-matte product you can achieve naturalness; such furniture looks good with chrome fittings. The matte option can be used for both home and office furniture. In addition, there will be no hand marks left on furniture coated with matte varnish, and this will help hide minor defects in the product. Using colored varnish, you can choose the desired shade that will fit into the interior. Such products help turn inexpensive wood into an exquisite species. And craquelure varnish will create the effect of cracks on the surface, with its help you can turn a new product into an antique.

Now let's look at the composition of varnishes. Products based on natural oil are classified as oil varnishes. Typically, linseed oil is used here. But now many manufacturers, in order to reduce the price of the product, use synthetic rather than natural ingredients. White Spirit is used as a solvent here. After coating with such a product, the product receives a durable film that will protect against many environmental factors. Oil products can be used for both home and garden furniture. When the solvent evaporates, the layer dries completely, which is one of the main advantages of this varnish.

The next option is nitrocellulose varnish. It can be used for garden and home furniture. To make such a product, resin, colloxylin and organic components are used. It will take about one hour for one thin layer to dry. The result will be a hard and smooth film. It is also worth noting that the nitrocellulose version is very popular due to its lack of odor.

A water-based varnish is considered environmentally friendly. This option is odorless, does not contain toxins and is fireproof. Thanks to these properties, this product can be used for processing furniture in children's rooms. The varnish dries quite quickly and creates a durable and elastic film. Water-based varnishes can be classified into several options according to the type of binder. One such binder is acrylic resin. This option has a milky color, but when it dries there will be a transparent film that will have high strength. This varnish should be used in rooms with low humidity, otherwise the product simply will not dry. There are also varnishes that use polyurethane. The main feature of this varnish is protection against mechanical stress and abrasion.

Varnishes based on alkyd resins protect wood well from moisture. Moreover, such products are easy to apply and tolerate temperature changes well. Alkyd varnish can be used for both indoor and outdoor furniture. But this option requires a long drying time, which is a minor drawback.

If we classify products by purpose, then manufacturers add special components that enhance a certain effect. For example, to use varnish on garden furniture, you will need a water-repellent component. There are also varnishes that are resistant to temperature changes, impact-resistant or weather-resistant.

According to the method of application, products can be divided into traditional varnishes, which are applied with a brush, and aerosol ones. The aerosol version is economical and easy to use. This way you can easily cover hard-to-reach places; when applied, you will get an even layer that dries quickly. Most often, the aerosol version is used when restoring old furniture so as not to damage its surface.

Operating rules

Regardless of which varnish coating option is chosen for the job, certain rules should be followed. Failure to comply with them can lead to poor results, which will subsequently affect the quality of the coating.

First of all, the room where work is carried out must be well ventilated. This condition is important even if the varnish is odorless. In addition, for your own safety, it is better to wear a protective suit and have personal protective equipment. This way, the skin, eyes and respiratory tract will be reliably protected. There should be no sources of fire nearby as the product can easily ignite.

Now you can get to work. But before this, you should remove the old varnish coating from the surface, if any. There should not be even a small uncleaned area left, otherwise the result will not be an even coating. If the product that will be varnished has cracks or small “pits”, then they must be eliminated using putty. Now you can coat the furniture with a layer of primer, after which you can apply the paint product. The layers of varnish should be thin; each new layer can be applied only after the previous one has dried.

If the product will be used in the form of an aerosol, then if you do not have the skills to do so, it is better to practice on an unnecessary board or plywood. Before use, shake the can well. It should be approximately 30 centimeters from the surface where the product will be applied. Movements must be in a horizontal direction. If you hold the can too close to the surface, smudges will appear. After the first layer has dried, you need to sand the surface. And remove all dust using a dry cloth or cloth. Then apply the next layer. If desired, after complete drying, a third layer can be applied.

Updating the tree workspace

No matter how carefully the work area in the food preparation room is used, over time it still loses its original appearance. After which you can either buy a new headset or try to update it. Painting is the easiest way to update.

To paint the work area, do the following:

- clean the tabletop with sandpaper or a sanding machine;

- cover up all defects with special putty;

- walk over the surface to be treated with paint containing alkyd resin; the very first application of this paint will serve as a primer;

- if you wish, you can decorate the surface for kitchen work (draw something yourself or using stencils).

You can decorate the working part of the kitchen furniture using the decoupage technique. This technique consists of gluing decorative napkins onto the item being renewed, and then varnishing them several times.

Another way to update is to use a film of self-adhesive material, which allows you to give the updated item the appearance of a wood surface, stone, marble, leather or metal. Before gluing, the part of the furniture to be treated will have to be washed thoroughly, wiped dry and be sure to degrease.

Before using self-adhesive film, determine the dimensions of the area that needs to be updated in order to cut the film correctly. Pieces of this film should be cut slightly larger than the table itself. After gluing, do not leave any bumps or folds on the film. Smoothing the film is done with a plastic scraper.

Preparing the surface for painting

The countertop that you plan to paint must be clean, intact and dry. Fill all chips and cracks with putty, after drying, clean these places, or better yet, the entire surface as a whole. This will not only get rid of differences and unevenness, but also give the surface roughness, which will improve paint adhesion.

If the tabletop is very old, with multiple damages, and you doubt that you will be able to repair them perfectly, it is better to make an overlay - for example, from an MDF sheet or moisture-resistant plywood. By screwing such an overlay to the surface, you will get a smooth surface ready for painting. Only the edges need to be sealed with putty.

To improve paint adhesion, use a primer that matches the material of the countertop (primer for wood, primer for mineral surfaces, etc.). Or use a universal primer. Allow the primed countertop to dry before you begin painting. Not only the top layer, but the entire countertop as a whole should be dry. Some materials (wood, unglazed ceramics) absorb the primer especially actively, so it is better to continue the work the next day.

Caring for your cutting board

No matter what material the kitchen countertop is covered with, it is better to cut food not on it itself, but on the surface of the cutting board. The raw materials for creating a cutting board can vary. Kitchen boards can be made using plastic, special glass or wood (most often chosen because it is a natural antiseptic).

A new cutting board needs to be soaked, for which oil is suitable. This impregnation will protect it from liquid, food and bacteria getting inside it.

The oil layer of the board should be harmless to health and resistant to various damages. If you use sunflower or olive-based oil to cover the cutting surface, it may deteriorate after some time, and the board will need to be thrown away. Products based on coconuts or flax are expensive, but will not allow the cutting surface to become unusable.

Mineral-based oil is a good option for coating a cutting board. To do this, wipe the cutting board with it, wait until the composition is absorbed, and wipe it with a dry cloth. The procedure must be repeated once every thirty days.

Beeswax can be added to this cutting board coating to add density to the coating. Wax will increase resistance to moisture and prevent aging of the cutting board. After applying the oil and wax, you will have to let the product dry and then polish the outside of the board until it shines.

You should also remember to disinfect the board for cutting ingredients for preparing dishes. You can disinfect cutting boards using these methods:

- hot water and detergent containing surfactants;

- vinegar;

- hydrogen peroxide;

- chlorine-containing bath cleaning products.

Restoring a wood countertop

Under the negative influence of liquid and high temperature, the top of the table may become higher, become loose or delaminate, after which the wooden surface must be restored.

Restoration is carried out as follows:

- all damaged areas must be removed;

- dry and sand the outer part of the table to be restored;

- make a mixture containing sawdust and polyvinyl acetate glue;

- fill all the empty spaces in the table that appeared after sanding with the resulting mixture; wood putty is also suitable for these purposes;

- leave the restored item under pressure until it dries for about one day;

- As soon as the table is completely dry, it must be protected with a product containing silicone, oiled or varnished over the entire area of the object.

To remove small scratches, you can wipe the problem area with strong brewed black tea, a walnut kernel, a mixture of vinegar and olive extract, and you can also use machine oil.

If there are scratches on a wooden surface that are deep, then sandpaper is used to sand it, and then sanding. And to give the effects of glossiness and shine, you will have to use felt.

As a result of all of the above, we can conclude that to keep a wood kitchen countertop in good condition, it is best to coat it with an oil-based compound with the addition of wax. And to preserve the board for cutting food, it would also be good for her to do this application. Then these items will serve for a long time, provided that their protective coating is updated in a timely manner.

Practicality and durability

There are two main requirements for a wooden tabletop: it must be practical and durable.

Advantages of wood:

- Eco-friendly, safe to use and dispose of.

- Natural color enhances any interior.

- Pleasant tactile sensations from warm natural material.

- Ease of making different shapes.

- Never goes out of style.

- Natural wood fits into almost any kitchen style.

Flaws:

- Requires careful care.

- Easily damaged.

- Fire hazardous.

- Expensive.

- Heavy in weight.

The durability of a wooden tabletop depends on the source material and manufacturing method.

Hardwood trees are used. A tabletop made of oak or beech will last a long time. Surfaces made of ash, walnut, birch, and pine are more affordable. Many manufacturers prefer larch - an expensive but durable material.

Its features:

- dense wood;

- resistant to mechanical damage and stress;

- the composition contains gum - a natural antiseptic that protects against mold, mildew, and prevents the process of rotting;

- When temperature changes, it releases and absorbs moisture.

Solid surfaces are subject to curvature. Glued wood, that is, assembled from several plates, is as flexible and elastic as possible.

Practicality is due to resistance to moisture, temperature changes, and strength.

Table of characteristics of compositions for processing wooden countertops

| Name | pros | Minuses |

| Oil |

|

|

| Oil-wax (for interior and exterior work, transparent and colored) |

|

|

| Paint (enamel) |

|

|

| Varnish |

|

|

| Azure (composition with the properties of varnish and impregnation at the same time) |

|

|

For wood with a pronounced structure, a transparent coating is suitable

Oil, wax or varnish

In order for a wooden tabletop to serve for a long time while maintaining an attractive appearance, it is covered with a protective layer. It saves it from moisture, aggressive detergents, extends its service life, and saturates the natural color.

Interesting! A popular color is Venetian oak.

Manufacturers of kitchen sets and woodworkers know how to process a wooden countertop in the kitchen. Three options are recommended: varnish, oil, wax.

Varnish

Advantages of varnish coating:

- The wood pattern and rich color are better visible;

- several layers prevent surface destruction;

- protection from moisture;

- durability.

The varnish treatment is suitable for both the kitchen table and the countertop. Experts recommend polyurethane and acrylic varnishes.

When using them, table and tabletop:

- will retain its appearance for a long time;

- will withstand cold and hot dishes on its surface;

- will be reliably protected from contamination.

Oil

Special wood oil creates a water-repellent film on the surface. Oil products are made from plant, mineral and synthetic raw materials.

Depending on the drying process, they are divided into:

- Partially dry. Deeply impregnate the wood. The top layer is removed mechanically.

- Completely dry. A hard layer forms on the surface. It does not wash off with water.

Benefits of oil coating:

- highlights the natural color of wood;

- does not exfoliate;

- completely absorbed and does not flow at high temperatures;

- prevents the formation of fungus;

- does not cause harm to health when in contact with food;

- hides abrasions and minor scratches.

Wax

Wax is a good option for coating a wooden surface:

- makes the surface waterproof;

- prevents the appearance of mold and mildew;

- Withstands common kitchen detergents.

How to treat a wooden tabletop

- It is safer and more reliable to cover a solid wood tabletop with bio-impregnation - a mixture of vegetable oils and beeswax. The high-quality impregnation composition can withstand high humidity, temperature and mechanical stress, as well as ordinary, not too aggressive detergents.

- You can choose pure oil, without adding wax, but the coating will have to be renewed frequently and grease stains will leave marks on it. If you need a glossy surface for a wooden tabletop, it is better to use glaze.

- Varnish and paint are suitable for garden furniture, but not for kitchens.

- Film is a saving option for a table made of wood-based materials, but sticking it on a tabletop made of natural wood is a crime.

On a note! Oil and wax are produced for different types of wood. This needs to be taken into account when purchasing.

Oil and wax mixture

Sometimes this coating is called wax, without mentioning oil. In addition to environmental friendliness and moisture-proof properties, the plastic mixture has other advantages:

- the consistency resembles a viscous varnish;

- easily distributed over the surface;

- does not create a glossy film;

- resists fire well.

Most often, refractory carnauba or light beeswax is used for countertops. The first gives the tree reliable protection, but is difficult to apply. The second one is easy to rub and gives the wood a soft shine, but the protection against damage is not so reliable; at high temperatures the wax begins to melt.

Coating can be applied with a brush or lint-free cloth

Waxes are:

- colorless, they make the tabletop a little whitish;

- compositions of natural color give a slight effect of wet wood;

- decorative ones are suitable for dark wood or to darken a countertop.

The coating is safe and decorative, but it is not very easy to apply. First you need to prepare the surface of the wooden countertop:

- remove the old coating, if any;

- sand the wood with sandpaper, starting with coarse grain and ending with fine grain number 240, 320.

The wax-oil layer dries for several days, then it is sanded and the coating is applied again. The work is repeated 3-4 times. If you finish with hard wax and rub it well, the surface will receive a noble, muted shine.

On a note! Liquid coating is great for new wood or countertops with minor scratches. Severe damage or cracks should first be filled with hard wax, and then the entire countertop should be covered with impregnation.

Oils for coating wooden countertops

Pure vegetable oil is the safest way to treat a wooden countertop:

- tung protects against mold, rot, insects, penetrates deeply into the wood;

- tar - a natural antiseptic;

- linen is suitable for all types of work, penetrates deeply into wood, and repels moisture well;

- teak – universal protection for any wooden surfaces.

Natural oils protect wood from damage, parasites and natural influences; there are vegetable, mineral and combined ones. To enhance the properties, solid particles in the form of crumbs or solvents can be added.

Azure – double protection for wood

There are several types of azure:

- oil;

- water soluble;

- with an aggressive solvent.

Based on the thickness of the layer, they are distinguished:

- Thin-layer glaze - has a liquid consistency, does not form a film, and is suitable for furniture prone to deformation.

- Thick-layer - the hard composition hardens into a film, suitable for interior decoration.

- Medium layer - an intermediate coating option. Azure is well absorbed into wood and forms a thin, breathable film.

Water-soluble compounds are safe for health. They can be used in a children's room and other living spaces, in a bathhouse or sauna.

Attention! Azures with aggressive components can cause allergies. They can only be used outdoors.

The glaze gives the tabletop a slight shine

How to protect your kitchen work surface

The tabletop is one of the main workplaces of the housewife. The surface tolerates mechanical, thermal, and chemical influences.

To make kitchen surfaces, manufacturers use the following materials:

- Chipboard, MDF;

- solid wood;

- acrylic stone;

- glass;

- agglomerate - artificial stone;

- stainless steel;

- ceramic tiles;

- granite, marble - natural stones.

To protect your kitchen surface, follow these rules:

- Use cutting boards on countertops made of any material.

- Wipe down chipboard surfaces. They swell from drops of water and food debris. Forks and knives left on the table scratch the surface.

- Countertops coated with varnish or paint should not be cleaned with abrasive detergents. The use of metal brushes and hard sponges is prohibited.

- It is not recommended to place hot dishes on any surface.

It is difficult to protect kitchen countertops from minor damage. Splashes of water, grease, sharp cutlery, hot and cold dishes cause stains, chips, and bloating.

Wooden tables and countertops in the kitchen are more vulnerable to various types of damage than surfaces made of other materials.

There are several ways to hide the resulting flaws:

- Small scratches are wiped with a cotton swab soaked in strongly brewed black tea and machine oil.

- Deep cuts are treated first with coarse sandpaper, then with fine-grained sandpaper and polished with felt.

- Minor abrasions are revealed by the pale color. They are soaked in black tea. Deep ones that have passed through all the protective layers of the coating require cleaning and applying a new layer of oil or varnish.

- The darkened countertop is treated with a weak solution of hydrogen peroxide.

- Lemon juice removes stubborn stains.

To protect your kitchen table and wood countertop:

- use self-adhesive film;

- when installing the headset, a silicone layer is laid between the tabletop and the wall, which protects against moisture;

- use stands made of plastic and wood.

Self-adhesive films are especially popular for protecting kitchen furniture. They are:

- Transparent. Then the natural color of the wood remains visible.

- With designs imitating ceramic tiles, mosaics, depicting animals, plants, fruits, etc.

They are glued to areas near the sink, cabinets, aprons, and dining tables are updated. Self-adhesive film for kitchen countertops is impractical. Moisture and detergents quickly deteriorate.

Care instructions

In order for a wooden tabletop to retain its appearance longer, it is necessary to properly care for it:

- The wood is wiped with mineral oil. It adds shine and prevents the growth of harmful microbes.

- Every day, remove any remaining water and food, first with a damp sponge, then wipe dry. To clean the countertop and wash dishes, use different sponges and rags.

- Hot dishes, iron containers with sharp edges at the bottom, heavy kitchen appliances are placed on stands.

Practicality or durability?

How to make a countertop practical and durable? Both of these qualities are laid down initially, at the stage of choosing a wooden surface.

What to look for when choosing a wooden kitchen surface?

- You cannot use veneer, MDF, chipboard, only natural wood.

- Has the meaning:

- age of wood;

- place of felling;

- storage conditions.

- Products made from laminated wood are more flexible and resilient than their analogues from solid wood.

- A properly selected coating will protect the wood in harsh operating conditions in the kitchen. Before covering a wooden tabletop with oil or other suitable composition, it is worth studying the available range of coatings, their properties, and features. Even better is to test the chosen product on a small piece of wood.

- It is necessary to clearly define the methods of surface care and the possibility of restoration in case of damage.

A wooden tabletop must be smooth, durable, resistant to moisture, temperature, and cuts. A product made from harder wood will last longer. Classic options for kitchen countertops are oak or beech. Tabletops made of ash, pine, walnut, and birch are more affordable.

Larch works well. Its dense wood is resistant to mechanical destruction and deformation. Gum in larch wood prevents the growth of fungi and rotting, such properties are ideal for difficult kitchen conditions. Larch has the important property of giving up or absorbing moisture when humidity conditions change.

Advantages of wooden surfaces over other types:

- environmental friendliness;

- beautiful texture;

- variety of colors, shades;

- ease of processing, unlimited possibilities in creating different shapes, neat edges with the possibility of various milling;

- ease of updating and repair.

Don't forget about the disadvantages:

- requires more careful care than other types of surfaces

- periodic restoration is required;

- high cost of the material, expensive processing work.

In a situation with wood, you need to remember that all the difficulties in selecting, caring for, and repairing it will more than pay off in coziness, beauty and extraordinary feelings of comfort in the kitchen.

Preparing the tabletop for varnishing

Before covering a wooden table with the selected composition, it is necessary to carry out a number of measures to clean the wood from the previous coating. The old varnish must be completely removed from the surface of the countertop. To do this, you can use coarse sandpaper or an electric sander.

There are modern chemicals that allow you to quickly remove old varnish. They contain a solvent that effectively removes old coating. It is important to strictly follow the manufacturer's instructions, otherwise there is a risk of damaging the wood. The softened varnish is removed using a spatula or any convenient tool at hand.

The old varnish must be completely removed Source mastermario.ru

Oil, wax or varnish?

A high-quality coating with good compounds will give a wooden tabletop a beautiful look and protect it from moisture and aggressive detergents.

How to cover a wooden tabletop so that it lasts as long as possible and at the same time remains beautiful?

- Oil, wax.

- Alkyd coatings.

- Water-dispersed compositions.

Ideally impregnated with oil, oil-wax. Oil, nourishing the wood structure, gives it water-repellent properties. When properly treated with good oil and wax, the countertop becomes resistant to household chemicals and detergents, which are often used for washing kitchen utensils.

A special oil designed to impregnate wood that comes into contact with food will ensure environmentally friendly processing.

You can apply colored glaze, stain, and other water-dispersed coatings followed by application of varnish. The properties of the varnish used, its resistance to moisture, and multi-layer coating are important.

A high-quality coating is carried out in several layers - two or three - regardless of the paint composition. Do not mix alkyd and acrylic coatings. Before covering the countertop with the base compound, it is important to select the appropriate primer.

Advice!

For maximum durability, the coating should be renewed one year after application. It takes time for the product to “get used” to the surface at different temperatures. When exposed to external conditions, microcracks appear on the surface of the coatings, which are visually indistinguishable. Therefore, it will be useful to lightly sand the top layer and apply a new layer with the same composition.

The quality of the coating can be tested in the following way: apply a few drops of water to the countertop and observe how quickly they are absorbed. A good coating has excellent water-repellent properties.

It is important to consider the drying time of the compositions; it can vary from several hours to several days. Natural oils and acrylic mixtures have a long drying period or accumulate strength gradually over time, so it is important to limit the use of the countertop during the drying period.

It is impossible to protect wood from scratches and mechanical influences with paints and oils, so there is only one way out - treat wooden countertops with the utmost care.

How to cover a wooden countertop in the kitchen? Manufacturers and experts recommend varnish, oil and wax.

The ideal solution is a combination of oil and wax. The composition is used as a coating for a wooden kitchen table and work surface. With daily careful care, they will delight you with comfort and warmth for a long time.

We recommend:

- How to cover a roof with corrugated sheets with your own hands: everything...

- Summer kitchen in the country: 150 successful projects (+ photos)…

- Do-it-yourself wooden kitchen countertop:…

- Storing pans in the kitchen: in a drawer, on a shelf, in…

- How to remove scratches, chips, cuts from kitchen...

- Tables made of profile pipe and wood: how to make…

How to restore a wooden table

Before you varnish your dining table or kitchen worktop, you should evaluate the condition very carefully.

The surface may already be painted, mechanically processed, glossy, or varnished. Regardless of what varnish the surface will be coated with, it is necessary to carry out preparatory work. In the video: how to cover a table with stain.

Preparation

The first step is to remove all the old coating. This is done so that the texture of the wood is clearly visible, using an electric tool. When the table is as smooth as possible, the surface does not have any defects, then you can move on to the next stage.

Removing old coating

The chemical remover is applied to the table surface and then wiped off after 10 minutes. To apply and remove a layer of paint or varnish, use a rag.

You can also remove the old coating by sanding. Doing this by hand takes a very long time, so it is better to use a power tool. The work is performed at low speeds so as not to damage the wood.

Varnish application technology

To apply varnish, it is better to use brushes or rollers. Using a colorless varnish for a wooden table in one layer, it is very difficult to obtain the desired shade - this is only possible if you cover the surface in several layers.

After the stains and primers have dried, they can be varnished. The varnish is applied in a thin, even layer, trying to avoid drips. After the first layer has dried, it is recommended to sand the surface. For a high-quality result, varnish in three layers of varnish.

In a day, the old table will turn into a new one and no one will ever be able to say that it is very old. Knowing how to cover a table, you can restore other wooden furniture in this way.