The manufacturer of the original ondulin is the French company Onduline SA, founded on the outskirts of Paris in 1944 specifically for the production of this material by Gaston Gromier. He was 29 years old, but his youth did not prevent the French entrepreneur from showing foresight and choosing the perfect moment for this project.

The end of the Second World War was approaching, the scale of reconstruction work in Europe was to be unprecedented. And the success of the manufacturer of inexpensive, reliable and beautiful roofing was a foregone conclusion.

Now the company occupies 75% of the European market and has factories throughout Europe, in the USA, Malaysia, and Turkey. And for Russian consumers, a factory was built in Nizhny Novgorod, with a capacity of 15,000,000 sheets per year. The manufacturer assures that this volume completely covers the needs of domestic consumers.

What is ondulin made from?

Probably many in childhood had the opportunity to make crafts from papier-mâché (translated from French as “chewed paper”).

It is not surprising that the French also came up with ondulin - because it is the same thing! The technological process begins with the processing and cleaning of waste paper, which is then crushed and mixed with water.

The result is a pulp from which wavy sheets of a familiar shape are formed. The sheets are then painted and impregnated with bitumen at high temperature and pressure.

What is andulin

It is often called Euro slate, because in appearance it resembles ordinary asbestos slate. That is, it is a profiled sheet, the profiles of which are waves. But andulin is made from completely different materials:

- base – cellulose fibers;

- impregnation – distilled bitumen;

- additives: pigments , resin, minerals .

The technological process is based on the formation of a finished mixture from a tape by pressing and drying euroslate sheets. They come in standard sizes. Namely:

- length – 2 m;

- width – 0.95 m;

- profile height – 36 mm;

- sheet thickness – 3 mm;

- weight of one panel – 6 kg.

Standardization of sizes allows you to accurately calculate the required amount of roofing material to cover a certain area of the roof slope. That is, the calculation can be carried out so accurately as to guarantee the minimization of waste when adjusting the installation of andulin.

Dimensions of andulin panel Source homius.ru

Please note the light weight of the product. This makes it possible not to build a powerful rafter system. And this is another reason to save a little. And other technical characteristics of the andulin roof:

- one hundred percent moisture resistance ;

- operating temperature : from -25C to +75C;

- does not fade under the influence of sunlight ;

- neutrality to various chemically active substances ;

- biological resistance is not the highest, that is, mosses and mold may appear on the andulin roof , but this problem is easy to deal with;

- good soundproofing qualities of the material , under such a roof in the rooms you can’t hear rain or hail drumming on the roof;

- andulin does not rust or rot ;

- the manufacturer provides a 15-year guarantee , although experts assure that this period can double if installation is carried out correctly;

- it is an environmentally friendly material consisting of almost organic compounds;

- the color variety leaves much to be desired, because today the manufacturer offers only six types of shades ;

Multi-colored Euro slate – andulin Source id.aviarydecor.com

- at sub-zero temperatures, andulin becomes brittle , so it is not recommended to walk on this type of roof in winter to avoid unpleasant circumstances;

- unfortunately, andulin is a material that supports combustion , and this is probably the biggest disadvantage;

- reasonable price , which is in optimal proportion to the quality of the material.

Features of ondulin

Any material has advantages and disadvantages. The advantages of ondulin are as follows:

- Durability - only the manufacturer's warranty period is 15 years. And the approximate lifespan of actual operation is about 50 years.

- The price of an ondulin roof is significantly lower than other materials of similar durability.

- Light weight.

- No harmful substances in the composition.

- Flexibility.

- Ease of machining.

- Soundproofing properties.

- Aesthetics. Ondulin is available in several colors, and its wavy surface looks very attractive. You can easily verify this by finding a photo of an ondulin roof on the Internet.

However, there are also disadvantages:

- Flammability. With prolonged exposure to fire (fire), ondulin supports combustion.

- Low strength. Although ondulin can withstand a distributed load of more than 900 kilograms per square meter, it will not withstand strong local impact (for example, a blow with a hammer).

- Gradual fading of the decorative layer. True, the manufacturer promises that this will happen no earlier than in 10 years.

Installation of andulin roofing

There are also differences in the installation of ondulin and standard slate due to the properties of the materials. Due to bitumen impregnation, the European standard is less resistant to heat. Paris sheets can withstand up to 60-70 degrees. However, ondulin from most third-party manufacturers softens already at 35-40.

Accordingly, a do-it-yourself andulin roof , if it has a chimney, is made complex. Fire-resistant boxes and spark arresters are made around fire-hazardous objects. If you place ondulin close to the chimney, you expose the house to the risk of fire.

Otherwise, installation of an ondulin roof is simple. It can be placed either on a new roof frame or on an old roof. The euro slate is attached to the sheathing with self-tapping screws. Manufacturers offer special nails in the kit.

A standard sheet 2 meters long and 95 centimeters wide requires 20 fasteners. They are distributed evenly. The smaller size of the andulin sheet allows you to use fewer nails. However, there is no need to skimp on fasteners. The weak fastening of Euro slate makes it vulnerable to storm winds

Lathing for ondulin is required in any case, even when laying it on an old roof. The frame is made up of beams with a cross-section of 4 by 6 centimeters. The pitch between the boards is 45 centimeters with a roof slope of 10-15 degrees. On steep slopes, beams are attached every 60 centimeters.

There should be no more than 4 overlaps in one corner of the ondulin. Otherwise, the fixed edge of the slate may become deformed. This is also caused by workers walking on sunken areas of the panels. Therefore, installers move only along the humps of ondulin. This rule also works with regular slate.

The flexibility and pliability of ondulin encourage inexperienced installers to slightly stretch the sheets. Fixed in this state, they begin to crack over time. Initially, the roof looks good.

This is a misleading impression. It’s not worth stretching the andulin for the sake of 7-10 percent savings. A linear connection and 3-5 cm overlap of panels are required. By the way, unlike ordinary slate, they are also mounted on facades.

They are ventilated and the cheapest. A counter-lattice is placed on the same frame of bars filled with insulation. The Ondutis membrane is attached to it.

It should sag slightly. The membrane is followed by a horizontal lathing and euro slate on it. The option works, but manufacturers recommend ondulin specifically for roofs.

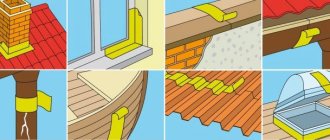

Additional elements for laying ondulin

A number of elements are produced that are necessary for laying ondulin on roofs of various profiles and ensuring the output of stove and ventilation pipes:

- Ridge - covers the external bends of the roof.

- Endova - covers the internal bends of the roof or the junction of the roof to the wall.

- Gable - Used to cover the corners of roof gables.

- Onduflesh is a tape for sealing joints between roofing and other elements, such as chimneys and roof windows.

- Covering apron - can be used on part of the joints of the roof with other elements, where the roof goes down.

- Nails with lockable or solid plastic heads.

- Ventilation pipe on the base, repeating the ribs of ondulin.

- Eaves filler is a soft wave-shaped profile for filling the space between the end of the ondulin and the base of the roof.

Basic material parameters

A French company recently proposed andulin instead of more familiar materials, which has an acceptable price-quality ratio with higher reliability. Of course, the appearance of the material cannot be called a determining factor, but many note both the aesthetics and presentability of andulin roofs, which really stand out against the background of the same roofing covering.

The most important features of the material include:

- Preservation of appearance and properties even when exposed to high and low temperatures.

- Possibility of high protection for standard gable roofs.

- Resistant to fungal growths and any other damage.

- Protection from ultraviolet rays.

- Good resistance to fuels, lubricants and chemicals (alkalis and acids).

Thanks to these properties, andulin is ideal for roofing in regions where climatic conditions are unstable. At the same time, the installation of andulin tiles is carried out by both professional craftsmen and novice craftsmen.

A unique roof has many advantages that tempt you to choose it. These include:

- Long service life of the material (from fifteen years and above) with preservation of technical characteristics throughout the entire service life.

- A high level of strength is achieved through production technology.

- A profitable investment, as the durable material has a low cost.

- Suitable for multi-disciplinary construction: for the construction of roofs of private houses and non-residential buildings.

When purchasing such a roofing covering, you can be sure of its high-quality components, which are confirmed by relevant documentation from the manufacturer. The economic benefit of the acquisition is an important factor, which is often decisive. After all, you want to make repairs not only quickly, but also with minimal financial costs.

Tool for working with ondulin

No special tools are required to work with ondulin, but some features need to be taken into account.

Ondulin is cut with a regular wood hacksaw, but it is recommended to lubricate the blade with motor oil first. Otherwise, the bitumen base will stick and the hacksaw will start to get stuck in the ondulin.

You can also use silicone lubricant. And in extreme cases, a bucket of plain water will help, in which you need to lower the hacksaw before each cut.

You can also use a jigsaw or circular saw to cut ondulin. Then they can be cleared of bitumen by sawing an unnecessary wooden board or block.

To mark ondulin, it is better to purchase a colored pencil - a regular one is difficult to see.

List of roofing disadvantages

When erecting an andulin roof, it is important to take into account some of its disadvantages, which are not without any other building material:

- You should not walk on the finished coating, since the gaps formed between the pitched joints are filled with polyethylene-based compounds, which can be deformed due to uneven load, in particular when walking on the roof.

- Over time, the andulin coating may lose its brightness of color, which is explained by the influence of negative external factors.

Photo of an ondulin roof

Kinds

Euroslate is presented in four types.

- Classic material. The dimensions of a sheet of ondulin of this type are 200 by 95 cm, a thickness of three millimeters, and a weight of six kilograms.

- Smart. This is a new generation material that has hydrobarrier locks and is lighter than classic ondulin.

- Ondulin DiY. Its parameters are 200 by 75 cm, thickness is three millimeters, and weight is five kilograms.

- Compact Used for complex roof structures, it weighs 2.5 kg and measures 100 by 75 cm.