Putty consists of filler and binder. In the form of the first, limestone or sand is used, and the binder is a substance that connects the filling material into a monolith and guarantees gluing to the plane.

The final putty is a putty with dimensions of less than 0.5 mm in the former Soviet republics - in other words, the one after application of which they proceed specifically to painting work or wallpapering.

Vetonit finishing putty is used in rooms with low humidity. It is used to level the surface of walls and ceilings, using plaster or mineral materials. It dries quickly, creating a perfectly smooth and even surface, allows a layer of more than 0.2 mm, and has a long service life.

Prices for Vetonit LR putty and its other varieties in most cases depend on the binding material (polymer materials, cement, organics) and the size of the package. It is packaged in multilayer paper bags. You can choose Vetonit LR putty 25 kg, 20 kg and 5 kg.

Finishing putty

Problem: the material is difficult to work with, the putty does not stretch well with a spatula, so creating an even coating requires considerable skill even from professionals, and the final coating turns out to be slightly grayish and grainy. When sanding it generates a lot of dust, the graininess does not disappear.

Solution: choose better quality finishing putties. They are easier to apply, even non-professionals can work with them, and the product consumption is less, since it is easier to “stretch” it along the wall. The coating turns out to be much more even, there are almost no visible defects, and when sanding, this putty produces almost no dust.

To show by example how to properly prepare a wall for painting or wallpapering, we selected products popular among professionals: moisture-resistant cement plaster weber.vetonit TT , finishing white putty weber.vetonit LR+ and ready-made super-finish putty weber.vetonit LR pasta . WEBER-VETONIT products were not chosen by chance; this brand enjoys well-deserved popularity among craftsmen and end consumers due to the quality of materials and ease of use.

Useful recommendations from master finishers

Experienced professionals give advice to help beginners better cope with putty work.

- In order for the layer of Vetonit raw material to hold firmly, it is necessary to correctly select the primary means for coupling. It must have deep penetrating ability.

- An important function of the primer is to bind dust and fill microcracks. It is better to apply the solution to the main area with a roller. And treat corners and hard-to-reach places with a long flat brush.

- After drying, the base adhesive composition crystallizes. This is why the quality of grip improves.

- The surfaces must be protected from fungus and mold with an antiseptic.

- It is best to remove dust with a soft, semi-dry sponge so as not to scratch the surface.

- The remaining mixture should not be flushed down the toilet or sink.

Preparing the base

In our case, the surface that needs to be treated has a number of problems: from a large number of local defects on the surface to a significant deviation of the wall from the vertical plane.

Before starting work, it is imperative to prepare the surface: we remove substances such as dust, grease and dirt that impair adhesion; the base must be clean and dry. We protect all surfaces that cannot be treated (windows, doors, frames) with tape, polyethylene or newspapers.

Perform basic surface leveling

Prepare the solution according to the instructions: the weber.vetonit TT from a 25 kg bag into a bucket with 5-6 liters of clean water, mix for 3-5 minutes using a drill with an attachment, let the solution sit for 10 minutes and mix again.

After this, we apply the plaster mixture to the surface manually using a steel spatula or mechanically. Each layer of weber.vetonit TT dries within 1-2 days, and the next layer of plaster can be applied only after the previous one has completely dried. In dry conditions, it is recommended to moisten the leveled surface with water from a spray bottle.

After completing the leveling process, treat the dried surface with sanding paper and remove dust.

Note that if we are talking about smooth walls or ceilings made of plasterboard slabs, then the stage of treating the walls with plaster can be skipped and you can immediately begin treating the surface with white finishing putty.

We carry out the final coating

a solution of white finishing putty weber.vetonit LR+ according to the instructions: pour the dry mixture from a 25 kg bag into a bucket with 8-9 liters of clean water (not vice versa), mix with a drill for 3-5 minutes, let stand for 10 minutes, and mix again.

As a result, we obtain a superplastic mixture, which is very convenient to apply to the surface in a thin layer 1-5 mm thick, either using a steel spatula or mechanically. Depending on the temperature and humidity in the room, one layer of weber.vetonit LR+ putty dries completely in 1-2 days. Then minor defects can be removed very easily with sandpaper.

After the layer has completely dried, treat the surface with sanding paper and remove dust. If leveling is performed in several layers, each subsequent layer can be applied only after the previous one has dried.

Advantages of weber.vetonit LR+ putty

- Simple: the putty is so flexible and easy to use that leveling the walls will not be difficult even for beginners; just follow the instructions and recommendations of the manufacturer.

- Fast: the superplasticity of the mixture allows you to quickly level the surface and ideally bring the layers together.

- Smooth: a minimum number of layers makes it possible to obtain a smooth and even surface, ready for wallpapering.

In principle, many craftsmen recommend walls treated with a topcoat for traditional painting, but we will use another innovative product to create an impeccable, ideal, smooth coating for high-quality painting.

Product reviews

Most users speak positively about Vetonit.

- Yuri: “Vetonit KR is a cheap and convenient option for putty. Easy to apply and sand. Durability is average. There is a tendency to get wet, so treatment with a primer is required. It is quite suitable for wallpapering, but other modifications are needed for painting. The grain is coarse, so it’s not possible to achieve perfect smoothness.”

- Antonina: “We used LR putty for rough finishing of the walls. The solution is prepared quickly with a construction mixer. It is important that the mixture is not liquid, otherwise cracking is likely. Apply with a wide metal spatula. After drying, you get a strong layer.”

- Maxim: “In my work I prefer ready-made materials, so my choice is Vetonit LR Pasta. It is applied in an even thin layer and dries quickly. In the future, you can apply decorative plaster or simply paint it.”

Vetonit putty is produced on a cement, polymer and organic basis. It is applied to the surface evenly, and after drying it forms a strong, durable layer. There are modifications for external and internal work, as well as for starting and finishing application.

We provide super-finish coating for painting

If we are talking about the best repair, then the wall to be painted should be mirror-smooth without the slightest grain. To obtain such a surface, we will use an innovative high-quality product - super-finish ready-made putty weber.vetonit LR pasta Weber.vetonit LR Pasta is available in a plastic bucket, ready for application, so working with it is doubly convenient. The principle of operation is the same as with finishing putty, the difference is in the thickness of the layers - as a rule, they do not exceed 1.5 mm per application. After drying, the surface is treated with sanding paper and removed from dust.

Methods for applying putty

To achieve the desired result in the finishing process, you need to follow the established procedure.

To properly mix the solution, you need to do the following:

- The components of the putty solution are prepared at an approximate calculation of 1.2 kg/m2 with a layer thickness of 1 mm. A bag weighing 25 kg uses about 8 liters of water.

- The contents of the bag are placed in water, the solution is stirred for about 10 minutes using an electric drill with an attachment; manually the consistency will be worse. The mixture settles for an average of 20 minutes and then beats again. The average shelf life of the mixed solution is about a day.

- For application, narrow (30 cm) and wide (70 cm) spatulas are used.

- The putty mixture is applied in one or two layers. With a two-layer treatment, the second layer is applied only to the completely dry first one.

- For priming, it is best to use an acrylic solution.

Puttying walls

The procedure includes the following steps:

- Preparation. Before applying the putty, the working surface is cleaned of small debris and old finishes. If there are minor defects on the surface, they must be eliminated with starting putty or plaster and then sanded to approximately the same level. Next, the surface is degreased.

- Padding. In order for the solution to adhere more firmly to the wall, it must be treated with a primer.

Features of using putty

Vetonit finishing putty is applied using special equipment or a simple spatula of a convenient size. The procedure for working with this type of mixture is described below.

- The first step is to remove the old coating, if any, or simply clean the wall to remove grease stains, paint, and wallpaper residues. The surface is also washed and dried.

- Irregularities must be marked. You can use a pencil for this. This way, it will be easier to notice areas that need special attention while working.

- Then the wall is plastered with simple putty. All chips, cracks, gouges and other imperfections are smoothed out. The wall is drying.

- Vetonit finishing putty is applied in a very thin layer. Due to the high quality of the product, this is not difficult to do if you have practice.

- After the finishing layer has dried, they go over it with an abrasive, then everything is polished.

- To ensure that the corners are even, they are additionally treated with a spatula.

The average consumption of this putty is 5 kg of mixture per 5 square meters of area, but this figure may differ for different types.

Subtleties of application

Surface. Before using any Vetonit finishing putty, the working surface must first be leveled. Any imperfections must be filled or sanded down; the finishing solution is not designed to remove them. All excess dirt, dust, old finishes, mold must be cleaned off. After this, you need to degrease and prime.

For each brand of putty, you need to carefully study the instructions, despite the external similarity, the thickness of the applied layer, hardening time, water temperature, setting time and other properties differ. Please note that diluted putty in a closed container is stored twice as long.

Vetonit putty is intended for manual application , although it can be applied by spray. After the applied layer has hardened (24 hours), pay attention to the places where the joints and seams were previously located. Irregularities often form in these areas. After completing the putty work, it is better to immediately rinse the tools with water; after the solution has hardened, this will be much more difficult to do.

When working, it is better to use protective equipment: goggles, a mask or a respirator. Although Vetonit putty mixtures produced in Russia are made from natural raw materials and do not have a toxic effect, the dust generated during the work process can mechanically harm health, for example, by getting into the eyes or lungs. For the “KR” and “LR” brands, it is better to use water at a temperature of approximately +10 C. If it is necessary to obtain a particularly durable surface, use a special mesh.

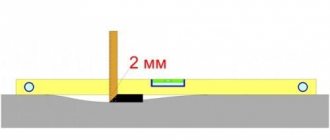

To get a perfectly flat surface, for example, when the finishing putty layer should become the front part of the wall, use beacons. This will allow the mixture to be drawn out more evenly and will reduce the amount of work required for further leveling.

This putty mixture has only positive reviews and is suitable even for difficult substrates. If you decide to carry out renovations or other construction, then feel free to choose this one.

In the following video, a professional shares secrets and tips for applying and choosing putty.

Vetonit is one of the types of construction powder mixtures used for finishing and construction work. Excellent quality has made this brand popular. The main purpose is to work at the final stages of leveling surfaces.

Vetonit putty can make walls perfectly smooth and hide cracks and cracks.

Example of packaging "Vetonit 25 kg"

How to Putty Walls (EASY and FAST)

Puttying walls or how to putty (putty) walls without experience. Support the author (for the development of the channel).

The type of mixture depends on the components - gypsum, cement, polymer. They are capable of covering walls and ceilings of various types - plasterboard, concrete, wood, etc.

Most solutions are universal, used for interior and exterior decoration.

Features of the Vetonit brand:

- Natural, environmentally friendly composition;

- Distributes easily, without visible differences;

- The powdery structure makes surfaces smooth and even;

- Sands without problems, leaving no dust;

- Provides additional sound insulation;

- Applied manually or mechanically;

- Economically used;

- Sold in reliable three-layer packaging of 5 and 25 kg.

On the building materials market, Vetonit putty is offered by the manufacturer in a large assortment:

- “B” (consists of cement) – for rooms with a high percentage of humidity;

- “VX” (base – cement) – waterproof type, used for processing ceilings and facades;

- “T”, “KR” - used in dry rooms;

- “LR Fine”, “LR+” - for work in conditions of normal humidity;

- “VH” (base – limestone, white cement) – for finishing puttying (concrete, brick, plastered walls and ceilings).

Description of Vetonit putty

Vetonite trims the most complex surfaces of walls and ceilings. The solution is applied easily and evenly and dries in a short time. The product line includes several modifications - in paste and powder form, for starting and finishing finishing, for treating rooms inside and outside.

Vetonit putties are compatible with concrete and plasterboard surfaces. Purified limestone is used as a filler, and a polymer-based glue binds all the ingredients.

Finishing putty Vetonit LR+ (25 kg)

The products are presented on the building materials market in packaging weighing 25 kg. It consists of rare white limestone and high-quality polymer materials.

The putty is intended for leveling surfaces in dry rooms. It turns yellow with prolonged exposure to moisture, and is applied to clean and treated surfaces of various types.

This is what the manufacturer's packaging looks like

To create the ideal effect, you will need a solid, clean (from dirt, grease) and dry workspace.

By mixing dry Vetonit LR+ with water, a thick, homogeneous white mixture is obtained. The finished composition is used within a day.

The putty is applied in a layer of 1-5 mm. For a large area, 1 mm is recommended, and for a smaller area, 3 mm.

Apply the putty with smooth movements from bottom to top. The room temperature should be maintained from +10 to +30, and ventilation of the room should be ensured.

Universal putty Vetonit TT

This is a basic cement putty that is successfully used in both wet and dry rooms. As a rule, it is used before applying finishing putty or laying tiles. The material is also used to level the outer surface. The product is sold in three color variations - gray, light gray and white.

Universal for interior and facade work

The adhesion strength reaches 0.5 MPa. Separately, it should be noted the parameters of moisture resistance and frost resistance. The material is excellent up to 75 cycles of maximum freezing, which allows its use in regions with cold climatic conditions. 1 month after creating a layer of plaster, it is able to withstand loads of up to 6-8 MPa.

Main technical characteristics

| Layer thickness, mm | Recommended 2-10, maximum 30 |

| Fractions, mm | 1 |

| Operating temperature, ºС | 5 |

| Liquid consumption, l/kg | 0,24 |

| Maximum drying time, days | 2 |

| Consumption kg/m2 | 1,2 |

| Price per bag 25 kg, rub. | 300-500 |

Application area

It is used for preliminary leveling of the surfaces of internal walls made of mineral materials, concrete, lightweight concrete, expanded clay concrete blocks and bricks.

Method of application and consumption

The product is applied with smooth movements in the direction from bottom to top. The room temperature should be at least 10°C, it is advisable to ventilate during application.

Apply the composition from top to bottom using even movements. The yellowish tint of the paste makes it easy to determine which area has already been treated and which is yet to be treated. Consumption of Vetonit TT putty per 1 sq.m is within 1 kg of paste. The price of TT 25 kg is 450 rubles.

Vetonit LR (25 kg)

Vetonit LR (25) is based on polymeric substances. It is used to cover plastered and concrete surfaces.

The task performed by finishing putty is the treatment of walls/ceilings of various types. It is distributed mechanically or manually. For independent work, choose a wide spatula and use it to adjust the thickness of the layer.

Vetonit LR easily levels surfaces, preparing them for further processing, and is applied in one layer.

Vetonit VH

The properties of this finishing putty are not affected by the humidity factor. Applying decorative plaster to a painted wall? Area of use: concrete, brick and facades.

This composition does not adhere to surfaces treated with water-soluble and lime-based products.

Vetonit VX

The wall/ceiling is pre-cleaned of dirt. Preparation of the solution: pour water into a clean container and add putty, beat it with a powerful electric drill for five minutes and let it sit for three hours.

Apply the composition with a standard size spatula using smooth movements. The remaining solution can be reused. If application is carried out in several layers, you should wait for each layer to dry.

It takes 2-3 days.

Facade putty is applied in two layers, each of which is no thicker than 3 mm. After drying, imperfections are rubbed off with abrasive materials.

Advantages and disadvantages of Weber-Vetonit

All options for finishing putties have the same number of advantages. The list of advantages is quite extensive, which is why the Vetonit brand is in great demand among consumers. The features of the product include the following factors:

- putty for exterior facade work and for interior cladding consists of environmentally friendly raw materials, due to which at different temperatures it is simply not capable of releasing harmful substances;

- the material has a high level of resistance to moisture, so the building material is successfully used in the construction of swimming pools;

- facade putty with a snowflake symbol on the packaging is intended for use at low temperatures;

- the prepared consistency, previously diluted with water, can retain its properties throughout the day.

The rule for preparing the solution states that water is poured into the container, and the dry mixture is added to the water. Not the other way around!

Another advantage is the price of Vitonit, which is significantly lower than the competitive price. Despite many positive reviews about the product, it also has disadvantages, which include:

- the need for preliminary preparation;

- difficulties of application, this mostly applies to dry mixtures;

- long drying of layers;

- the need for some experience in working with this building material.

VIDEO: Application rules and tips for working with the composition

Execution steps

To achieve the desired effect, the surfaces are treated with an acrylic primer.

Prepare the solution, taking into account the consumption - for a layer of 1 mm it is 1.2 kg/m². The contents of the bag (25 kg) are mixed with water (8 l), using a drill with an attachment, taking into account that the powder is poured into the water, and not vice versa. To obtain a homogeneous thick mass, beat for 10 minutes, then leave for 20 minutes and repeat stirring . You can use the prepared mixture at a temperature of +10 0 for 24 hours.

Execution example

For work, take two spatulas - one 70 cm wide and the second 30 cm wide. The putty is applied in one or two layers, provided that each one is completely dry.

If the room has normal humidity and temperature, there is ventilation, the layer dries in 2-3 days, after which they move on to decorative surface finishing - painting, wallpapering.

Puttying ceiling and wall structures

Vetonit putty has proven itself to be an excellent leveling agent. If the ceiling is rough, it should be cleaned and made perfectly smooth.

Puttying drywall seams

Sequence of actions when repairing the ceiling:

- First, apply a primer suitable for the given surface. Do this carefully, using a roller. Afterwards, all places where the composition came into contact are thoroughly cleaned.

- Fill the bucket with water and pour out the putty, mix with a drill. Using a narrow spatula, transfer the solution onto a wide one, then distribute it over the ceiling area. How to properly apply putty on a wall before painting video? The first layer is the starting putty, and the second is the finishing layer. The overall result of the repair depends on the quality of application.

- Ceiling sanding.

Stages of wall processing:

- The walls are cleaned of old finishes.

- Cover with primer and wait for it to dry. Cracks and irregularities are plastered. Afterwards, the surface is treated with sandpaper and re-rolled with a primer.

- The number of layers of putty depends on the type of decorative finish. The composition is distributed carefully, with smooth movements from left to right.

- When the putty has dried, it is sanded with sandpaper, then the dust is removed. The wall is primed again before the next layer of finishing putty. How to apply putty on a wall before painting video? After applying it, repeat the sanding and priming steps.

- Start wallpapering or painting.

Application methods

Leveling surfaces using putty can be done in several ways:

- spraying using a special device;

- manual application using different spatulas.

The manual method is often used for polymer putty. There are no strict requirements here; it all depends on the construction tasks and personal preferences. The thickness of the putty layer should not be more than five millimeters, otherwise the coating will dry unevenly and for a long time.

If several layers are applied, then before applying the next layer, you need to wait until the previous one has completely hardened.

Breeding recommendations

The number of types and brands of putties is huge. At different stages of leveling, different types are used - starting, finishing.

The rules for preparing the solution are indicated on the packaging; adhere to the manufacturer’s recommendations. Having calculated the consumption, take a bucket, pour the required amount of water into it, add the contents of the bag and knead for several minutes with a construction mixer. Now you can get to work, remembering that the mixture thickens during the day and its elasticity cannot be prolonged; you will have to mix a new one.

Structure

Tips for making a solution

In order to achieve optimal consistency and structure, dry putty must be diluted with water, adhering to the proportions noted in the instructions. The result should be a mass of homogeneous composition of medium viscosity.

Before mixing the components, remember that water must be added to the solution in small portions. Its temperature should be approximately 20 degrees.

Experts give some advice on this matter:

- Ten to fifteen minutes after preparing the mixture, it needs to be mixed with a construction mixer.

- Several hours (no more than 24) should pass before the composition is used after mixing. If you neglect this rule, the mixture will harden and lose its performance properties.

- The dry mixture should be stored in a dark, dry and cool place.