Many people are familiar with the situation - the flexible hose on the faucet or toilet cistern burst, and all the floors below are flooded. Unfortunately, the problem is quite common, so today I want to touch on this topic in detail.

Let's remember where it began. There has always been a need for flexible hoses. Many minds were haunted by the thought of how to make the installer’s work easier and speed it up, and as always, “foreign” manufacturers were the first to think about this, while domestic ones stubbornly produced the “herringbone” mixer, which can be safely described as: “well, , try to connect!

Eyeliners, as in the photo,

so familiar to us today, in fact, appeared literally in the last decade, having previously undergone a number of changes - at first a copper tube with union nuts, flared at the ends, was produced. For me, this is an ideal, reliable option, but from the point of view of achieving maximum flexibility, it left much to be desired.

The “minds” strained themselves and developed plastic ones, the principle is the same, but they also equipped them with plastic nuts, they proved to be disgusting - they burst on the body. As a result, they were equipped with brass nuts, and the material was improved.

As a rule, such liners were used during state construction, and only when connecting cold water supply to toilet flush tanks, our folk craftsmen, having obtained this miracle through “pull” (it was impossible to find in stores), easily installed it with hot water, and since the material was not designed to operate at high temperatures and accidents often occurred.

Having realized this, the “craftsmen” went further - they began to use oxygen hoses, pressing clamps onto brass fittings. The fittings were sharpened on factory machines, in the quiet of the authorities. The matter can be said to have been put on stream; on the market it was possible to purchase this fitting with the necessary threads (external, internal, proper diameter). At the same time, another type of flexible hose appeared - a high-pressure hose used in hydraulic installations. Believe it or not, people managed to assemble all the wiring around the apartment (house) from such hoses, although there were difficulties connecting union nuts with pipe threads.

The fact is that the threads here were metric, and connections had to be made through specially machined adapters. This material was highly durable, but the downside was technical rubber, so the water coming out of the tap had an unpleasant smell. The next step as a flexible connection was the use of metal-plastic pipes. I note that this material was widely used until the water supply was completely replaced with it, eliminating the ferrous metal, but that is not what we are talking about today.

Flexible water line

A flexible water line is more preferable for the vast majority of people. It is small in size, easy to use and easy to install.

Flexible hose is an elastic, strong hose. Its length usually ranges from 30 cm to 5 meters. At the ends of the hose there are fasteners with a seal, which is a special rubber ring. Most modern manufacturers of plumbing products use this particular liner option for their equipment. This is justified by a number of undoubted advantages.

Installation and maintenance features

The flexible braided water hose must be installed only in such a way that it can always be accessed during further use. This will allow you to track its current condition and, if necessary, repair or replace it. When installing, it is recommended to follow the following rules:

- Before installation, make sure there are no obvious defects in the tube.

- If it is necessary to increase the length of the line, the hose can only be extended by connecting with fittings.

- It is unacceptable to perform installation with twisting, bending, stretching and compression.

- Installation of liners through ceilings is prohibited.

- During operation, no objects should rest or hang on the hose.

To avoid leakage, the flexible line must be periodically inspected and replaced at the end of its service life.

The main advantages of flexible hoses:

- This is their mobility, compared to rigid structures.

- You can also highlight their convenience when installing in hard-to-reach places. In addition, installation of flexible hoses is easy in places with limited space, without compromising its integrity and reliability. Whereas the installation of metal pipes is very complex, inconvenient and time-consuming.

- Almost complete tightness of the structure due to manufacturing from the best quality materials

- Even a beginner who does not have special equipment or special skills can cope with the installation or dismantling of the structure

- Vibration resistance

- If certain rules are observed, flexible water supply has a long service life.

- Low exposure to high temperatures

The flexible type of design is convenient when installing in a large network of pipes, as well as other plumbing fixtures. The same cannot be said about tough types.

Briefly about the main thing

The bellows tube is often made of an inner rubber and outer metal shell. There is also a pure steel corrugated model. Flexible hoses have a wide range of applications - in plumbing, heating and cooling systems, fire extinguishing equipment, drainage and gas appliances. Among its main advantages are flexibility, lightness, installation, and durability. Disadvantages: insufficient tensile strength and limited temperature.

Flexible braided water hoses are classified according to several criteria:

- Purpose.

- Features of the shell device.

- Type of braid material.

- Types of fitting material.

When choosing a liner for a specific application, not only the diameter and length are taken into account, but also its compliance with external and internal conditions, flexibility, weight and harmlessness. Installation and operation of hoses must be carried out strictly in accordance with the recommendations.

Ratings 0

Disadvantages of flexible structures.

Despite all the advantages, this type of eyeliner also has its bad sides. They are revealed already during use:

- Excessive twisting, tension and bending can damage the integrity of the braid, which will inevitably lead to a reduction in service life.

- Installation in close proximity to an open flame source is prohibited

- Fasteners gradually corrode under the influence of water and time. Which will eventually lead to the repair of the faucet or other expensive fittings.

- Some types of flexible structures do not respond well to exposure to too high temperatures (water close to boiling)

Tough

One of the most reliable options for connecting to the water supply network is a hard line. It is made of metal and is a tube. The production material can be:

- steel;

- copper;

- brass.

The method of installing a rigid line is to thread one side of the tube to the pipeline, and the other to the mixer. The metal structure easily withstands high temperatures, as well as exposure to detergents or mechanical loads, shock, friction, etc.

If installed well, rigid liner has the following advantages:

- resistance to rust;

- resistance to chemicals;

- long service life - about 20 years;

- ease of use.

The disadvantages may be the following:

- inability to move;

- complexity of installation.

Depending on the installation method, when connecting the line to the water supply system, additional adapters or special angle valves with connecting elements may be used.

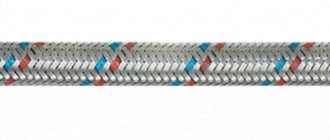

Flexible hose covered with reinforced braid.

It is a hose, very elastic and covered with braiding made of various materials. Fittings are attached to the ends. A fitting is attached to one end, and a union nut with a certain external thread diameter is attached to the other.

One of the advantages is the low price. That is why this type of flexible water line is very often chosen by buyers. The hose manufacturing technology is not too complicated. But nevertheless, this type of eyeliner has a very complex structure. The base is rubber, rubber or reinforced cross-linked polyethylene. The hose is braided with wire thread.

When braiding it is possible to use a variety of materials:

- Stainless steel is the most popular winding material. It is characterized by the most average parameters. It exhibits its properties well at +95 degrees in liquid 10 atm. pressure. Reliable operation is ensured for 10 years. Ideal for connecting the water supply to the toilet cistern.

- Nylon performs better than stainless steel. Operating temperature up to +110 degrees. The working pressure cannot be more than 20 atm. pressure. Stable work for more than 15 years.

- Aluminum is a less stable material for braid production. The temperature of the liquid must not exceed a certain temperature. This is +80 degrees for stable operation of the braid. Pressure no more than 5 atmospheres. The service life of such a braid is about 5 years. Disadvantages include increased susceptibility to corrosion. Products with aluminum braiding should be used in environments with low humidity.

Characteristics, pros, cons

Elastic hoses with metal braid are characterized by the following number of parameters:

- Service life - at least 3 years for a product with steel or aluminum braid, about 10 years - for a stainless alloy, over 15 years - for nylon.

- The maximum pressure in the water supply system - specimens with braided steel and aluminum operate up to 5 bar, with stainless steel - 10 bar, with nylon - up to 20 bar.

- The maximum temperature of the internal environment is no more than 80-90 °C for aluminum, 95 °C for steel alloys, and 110-120 °C for nylon.

Flexible liner differs primarily in diameter Source fittingi-trubi.ru

- The minimum bend length is 60 mm.

- The maximum torque when tightening the connecting nuts is 50 Nm.

- Rubber hardness – 75 units. according to the Shor system.

At the same time, the dimensions of hoses for flexible water supply - diameter, minimum and maximum length - can vary significantly. Thus, their length is in the range of 0.3-5 meters, the diameter of the internal section is 15-65 cm.

Among the main advantages of bellows hoses are the following:

- Flexible, light and compact. The combination of such qualities eliminates the cluttering of space, as happens with the installation of standard steel pipes, which is especially important in small bathrooms, kitchens, baths and showers. This also gives more freedom when choosing a place to install plumbing equipment - since the liner can be made without much difficulty at any distance from the main pipe.

- The ability to rearrange equipment without replacing the pipeline - thanks to the flexibility and elasticity of the liner.

- Elementary installation. Connection does not require the use of complex welding technologies, equipment and tools.

To connect the flexible hose, one wrench is enough Source xn--80ac1bcbgb9aa.xn--p1ai

- Reliability and durability. With initially high quality and compliance with operating conditions, flexible hoses can last for several decades in trouble-free mode.

- The elasticity of the material and the absence of sharp transitions in the structure make the bellows more resistant to water hammer and external mechanical damage compared to a standard pipeline.

However, along with a large number of advantages, the bellows water hose also has a number of specific disadvantages:

- Despite good elasticity and flexibility, a braided hose does not have sufficient resistance to tearing and twisting. Therefore, if such factors are present during installation or operation, it is easily damaged.

- If the hose comes into direct contact with a very hot object or flame, despite the outer metal sheath, the internal structure is destroyed and leads to a leak.

- If the water supply is not properly connected, even a flexible line can begin to vibrate and produce an unpleasant low-frequency background hum.

If used incorrectly, the integrity of the flexible hose is compromised and the liner leaks Source pikabu.ru

Recommendation! The flexible hose is so versatile that it can even be used to drain wastewater, for example, from household washers and washing machines. Large diameter products - 2 or 2 ½ inches - are ideal for this task.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Bellows liner for water.

It consists of flexible bellows tubes with design features.

The advantages include:

- Reliability in operation

- Much longer service life compared to reinforced structures.

- The bellows liner is also very flexible. The design consists of assembled stainless steel rings of different diameters.

This eyeliner comes in two types:

- The first type is folding. It has the ability to stretch in the ranges specified by the manufacturer: from 200 to 355 mm. and from 140 to 250 mm. To avoid reducing service life, care should be taken when stretching.

- The second type is a fixed bellows connection for water supply. Does not stretch and has a certain length. Minimum length 10 cm. Maximum length 80 cm. Manufacturing step 10 cm.

The main negative property of such a liner is the hum that occurs when water flows to many products at once. For example, water is supplied to several plumbing units at once. To avoid this drawback, you should purchase an insulated bellows liner. Or use special anti-vibration types of liners that absorb sound.

How to choose flexible eyeliner.

When purchasing flexible eyeliner, it is better to pay attention to products from well-known brands. Since when buying little-known eyeliners, you can encounter a number of problems.

When choosing a flexible eyeliner among Russian manufacturers, it is better to choose eyeliners from the companies Monolit, Flexiline, and Akvatekhnika. Among the foreign ones we can highlight products from Tucai, Mateu, Uni-Fitt. These foreign companies have the necessary guarantees and the necessary sanitary permits.

- The temperature and pressure characteristics must exactly match the parameters specified in the eyeliner manufacturer's instructions and on the label.

- Understand under what conditions the liner will be used and only then choose the braid material. This is especially important when connecting a washing machine or faucets.

- Estimate the weight of the selected eyeliner. If the product is too light, then most likely low quality materials were used in its production. Or aluminum was used in the production process.

- The eyeliner should be completely free of unpleasant odors. If they are present, there is a significant probability that technical rubber was used during the production process, which is very dangerous when exposed to it.

- Check the elasticity of the selected eyeliner. Low elasticity means that the tubes are likely to burst quickly during installation or when the product is already in use.

- Carefully inspect the fittings. They must be absolutely free of defects. The best materials for their manufacture are nickel-plated brass and stainless steel. Aluminum fittings should not be used. Also, plastic fittings are not recommended for use.

- Check the correspondence of the internal or external threads of the liner with the holes of the connected product. Thread diameter ranges from 0.5 to 1.5 inches.

- The diameter of the liner for sinks, shower stalls and sinks should be more than 10 mm.

- The ideal length for the liner is the one when no sagging or tension is formed after it is connected to the system.

DIY installation instructions for flexible hoses.

Even a beginner will be able to cope with connecting flexible hoses in a short time. You should know that hoses can be installed in the same way for used faucets. If you connect a mixer with a flexible hose, make sure that the hot and cold water are located correctly.

Connecting bellows and reinforced liners is the same.

- First, you need to ensure the integrity of the product after transportation.

- Turn off the hot and cold water supply taps to maintain safety precautions.

- You need a wrench or adjustable wrench that exactly matches the diameter of the union nut.

- It is necessary to place containers for the remaining water under the connections.

- When the hose is disconnected, you need to loosen the fixing nuts of the mixer and remove it.

- Then disconnect the liner.

- To install a new product, all steps are performed in reverse order.

There may be cases where the mixer and hose do not fit together. To do this, you should use special adapters.

The connections can be sealed with fumlente or flax.

A few rules when installing flexible hoses:

- The hose must be straightened before installation. Kinks should be avoided

- Do not use excessive force when screwing the flexible connection

- Access to the installed product should be easy for inspection and maintenance. (period 6-12 months)

- It is better to make connections from similar materials. In the worst case, the development of electrochemical corrosion will be inevitable. It is possible to connect brass and copper parts.

The last stage of installation will be mandatory testing. The hot and cold water supply valves open. And then within half an hour the tightness and free flow of water in the installed product are checked. If moisture is detected at the joints, carefully tighten the nuts with a wrench again.

The last piece of advice should be noted that when leaving for a long time, you should turn off the hot and cold water supply valves to the water supply. Since any flexible liner is always subject to stress and can burst.

Requirements for household water supply connections

If the water supply is used in a communal apartment, the following requirements apply to it:

- The maximum pressure allowed in public cold water lines is 6 bar; for hot networks this figure is 4.5 bar. Accordingly, the hoses must withstand this pressure with some margin due to hydraulic shocks.

- The maximum permissible water temperature in the hot water supply networks of communal houses, according to most regulations, should not exceed 75 °C. If a flexible hot water supply is placed in the corresponding DHW supply line, it must withstand similar temperature loads throughout its entire service life.

- In addition to the two main listed requirements for temperature and pressure parameters, hoses supplying drinking water must be made of environmentally friendly materials that do not harm human health.

- The underwater hose must provide a reliable, durable and airtight connection, and be easy to install and remove with your own hands without the help of a professional plumber.

- The minimum service life of the eyeliners must correspond to the data specified in state standards or special regulatory documents.

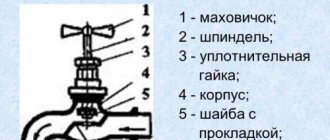

Rice. 3 Types of braided hose connection fittings