You can make the internal layout of a house or apartment using partitions that divide the space into functional zones. Timber walls are ideal for wooden buildings. They are durable and dense, perfectly preserve heat and protect from extraneous sounds. We will learn how to properly make a partition from timber, how to mount such a structure so that it serves for a long time and reliably.

Sound insulation, resistance to rot, mold and fire

When choosing the type of partition, it is necessary to take into account the requirements for sound insulation, as well as the impact of aggressive factors - dampness, mold, open fire. It is impossible to increase the sound insulation of timber partitions due to the fact that both sides are part of the interior of the house. Therefore, sound insulation is limited by the thickness of the timber or boards from which the partition is made. The sound insulation of plank and frame partitions can be increased by installing sound-absorbing elements - mineral wool, polystyrene foam, foam rubber. The exception is plank partitions, both sides of which have a direct impact on the interior of the house.

To increase the resistance of partitions to fire, rot and mold, boards and timber are treated with special substances. The first time this is done before assembling the partition, the second time before final grinding. If grinding is not required, then re-processing is carried out after installation is completed, and then repeated once every 3-5 years.

Wall thickness requirements

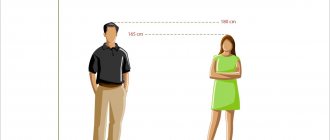

The choice of timber thickness for wall construction depends on the minimum temperature and climate that will surround the building:

- for cold regions where the temperature drops to -40 degrees, elements at least 18*18 cm thick are suitable;

- at -30 degrees, the dimensions of the timber should not be less than 15*15 cm;

- for partitions and non-load-bearing walls, elements of 10*10 and 10*15 cm are used.

You can buy timber of the required thickness right away or create it yourself and cut off the excess using a saw. The cut part is called a slab and is used in the construction of roofs, attic floors and other parts of the building.

Types of partitions and their manufacturing technology

Partitions in a wooden house made of timber or galvanized logs, as well as frame buildings, can be of the following types:

- frame and frame-panel;

- panel and carpentry;

- frameless.

All the above types refer to wood structures. As additional options, you can make fences from plasterboard or tongue-and-groove. They are also fairly lightweight and easy to install.

Diagram for assembling a plasterboard partition

To understand how to make interior elements for a house from timber or rounded logs with your own hands, you need to consider each type separately.

Frame partitions

Such partitions in a wooden house made of timber or logs can be used at the request of the future owner, and for frame buildings they will be the most optimal option.

The manufacturing technology is as follows:

Installation of a frame partition

- Measurements of the room and markings on the floor where the interior structures will be located.

- The bars of the lower trim are made, guided by the obtained dimensions. The elements are secured to the floor with screws or self-tapping screws.

- Next, the racks and transverse elements of the frame are cut out according to measurements. Installing them in the design position with your own hands can be done in two ways: individually or installing the frame after assembling it on the floor. Fastenings are made with screws or self-tapping screws. The end posts are fixed directly to the wall.

- The frame is wedged at the top and secured with fasteners.

- Afterwards, insulation is laid between the frame elements (if it is needed for sound insulation) and the sheathing is performed. It can be sheathed with plasterboard or clapboard. In this case, the sheets and sheathing elements are cut so that their joint falls in the middle of the frame post.

Panel and carpentry

To make interior fencing of this type for a house made of timber or logs with your own hands, you need to follow the following procedure:

Wooden partitions in the house

- Room measurements and markings.

- Production of plank panels (solid) from boards 20-40 mm thick.

- Bars are nailed to the surface of the floor and ceiling, which form grooves for installing shields. The shield can be two-layer or three-layer. When making a three-layer structure, thinner boards are used for the inner layer.

- Assemble a partition from panels in height. By inserting them into the grooves formed by the bars.

- Soundproofing material can be laid between the layers.

The dimensions of carpentry partitions depend on the purpose. They are similar to door leaves and can be solid or glazed.

They are made both to the entire height of the room and with a gap of 30-50 cm from the top edge to the ceiling.

Frameless

When making simple structures of this type with your own hands, work is done in the following order:

Scheme of the simplest frameless partition

- Room measurements and markings.

- Fastening the bottom trim.

- Making a groove trim on a beam by nailing two bars. The groove should be equal to the thickness of the partition boards.

- A triangular beam is attached to the ceiling. It will be an integral part of the groove for fastening from above, so the location should correspond to the lower fastening.

- Install vertical boards, starting with the one located near the wall. It is pressed and nailed to the triangular bar on top.

- Install all the boards one by one. The space between the individual elements is filled with tow, polyurethane foam or insulating cord.

- After the installation of the boards is completed, the second triangular groove element is nailed to the ceiling.

- The partition is sheathed.

Instead of bars, metal corners can be used for fastening to the floor and ceiling.

In order to competently make partitions for a house from timber or other wooden elements with your own hands, you need to choose the right type, install them without deviations vertically and horizontally, and securely fasten the parts of the structure together. For manufacturing, it is recommended to choose first or second grade coniferous wood. All wood is necessarily treated with antiseptics to prevent rotting. If desired, the elements can be treated with fire retardants to increase fire resistance.

DIY installation

You can construct frame internal partitions in a house made of timber yourself. First you need to prepare all the materials, including the strapping made of wooden beams. A frame-type partition can be mounted not only in a wooden house, but also in a brick, cinder block, etc. You choose the design and cladding yourself. With its help, you can divide a room into zones or create another one. To build using timber with your own hands, you will need the following tools:

- level, ruler;

- pencil or pen;

- drill, screwdriver;

- self-tapping screws;

- metal corners;

- antiseptic;

- insulation;

- bars.

Installation of partitions

At the beginning of work, you need to draw up a drawing of the future building - this will facilitate further actions. It is advisable to indicate all exact dimensions on the drawing.

The best option for installing a wooden partition with your own hands is when it is mounted on the subfloor, and not on the finishing coating. If possible, you need to get rid of the topcoat. In this case, all the logs are visible, which, if necessary, need to be corrected for a more durable structure.

If the room has a high ceiling, then the structure will be heavy. To improve stability, it is necessary to strengthen the base with an additional beam.

Mark the room. To do this, stretch a cord along the length of which the guides will be attached. For more convenient placement, fastening should begin from the ceiling, then on the floor and only then on the walls, so the structure will be stronger. The frame ribs must be installed the same size as the sheathing sheets.

Partition made of wooden pallets

After installing the frame, all materials should be treated with antiseptic impregnation to protect the wood from drying out, rapid ignition and ensure moisture resistance.

The space of the internal partition should be filled with insulation and only then begin sheathing, and it is best to use plasterboard. Once finished, you can paint and make your own design.

Now you know how you can make a partition in your house with your own hands. You can not only design it according to your wishes, but also design it however you want. In other words, you will have an extra room that needs to be decorated.

More articles on this topic:

Building a frame house with your own hands: step-by-step instructions and materials

We make a wooden swing for a summer house with our own hands

Budgeting

The estimate is compiled in the form of a table. It includes all materials, tools and equipment, construction work and their cost.

The estimate should include:

- wall construction costs. The amount of financing will depend on what type of timber you purchase and its diameter. Wall costs also include insulation, fittings and fasteners;

- costs for arranging the foundation and subfloor. They are sometimes reduced by using a lightweight type of foundation for the construction of a log house;

- costs for finishing materials inside and outside the building. To determine the financial costs of them, it is important to know the area of the external and internal walls;

- roof installation costs. These include the costs of roofing materials, fasteners, insulation, waterproofing film, timber for rafters and sheathing. The amount is determined by the roof area;

- If you invite specialists for construction, then the estimate also includes financing for their work. If you do the house construction work yourself, then you can skip this section;

- communication costs: electrical wiring, sewerage, water supply.

What are the types of partitions in a wooden house?

During redevelopment, it becomes necessary to divide a large room into separate sections, for which partitions are installed. If a house made of timber does not have interior decoration, which is not included in some house designs. and retains its structure, then when creating a partition it harmoniously fits into the interior of the room. This applies to both timber partitions and frame partitions, which are easier to manufacture. All partition designs have one thing in common - the need for reliable fastening to walls, floors and ceilings. After all, the partitions themselves do not have the necessary rigidity due to their small thickness, so the load-bearing walls of the house give them rigidity. There are the following types of partitions that are used in timber houses:

For the manufacture of such partitions, timber is used, the thickness and texture of which corresponds to the walls. This allows you to harmoniously fit such a partition into the interior. There are two types of timber partitions. The first ones are installed between two walls, for the second ones they first make a load-bearing frame and then fill it with timber. The frame for the partition is created from a board or timber and attached to the floor and ceiling. This design is used if it is necessary to create not a blank partition, but to embed a door, window or arched opening into it. If the frame design turns out to be too complex for the use of timber, then it is covered with clapboard, the width and texture of which corresponds to the walls. In this case, the lining is fixed with hidden fasteners, so that the partition does not need to be damaged with nails or screws. A “ridge” lock is cut on the frame timber, and a “groove” lock is cut at the ends of the boards. Thanks to this, the frame beam connects all the elements of the partition and gives them the necessary rigidity.

Plank partitions are in many ways similar to timber partitions, the only difference is in thickness. If it is not possible to mount boards in a load-bearing wall, then this type of partition is used where a difference in the pattern of the walls and the partition is acceptable. The advantage of plank partitions is the low cost of materials, which is why they are used in bathrooms and various utility rooms. In this case, the frame is formed by two vertical boards located next to each other, which are attached to the walls or floor and ceiling. It is also permissible to install the frame boards horizontally. Then facing boards are inserted between them. The frame can also be made from one board and covered on one or both sides with facing boards, installing them at an angle of 90°. Cladding boards are secured using nails and self-tapping screws. Also, the frame can be made from timber 2–3 times thicker than the board. In this case, a groove is cut in the timber and the boards are inserted into it. This frame is made in both vertical and horizontal versions. Using this type of frame allows you to embed doors, windows and various openings into the partition. For cladding, a planed board is used, the side edges of which are processed to create a tongue-and-groove lock. This configuration eliminates the appearance of cracks as a result of shrinkage of the boards.

Rules for forming openings

It is most convenient to create door and window openings on a completely finished wall with insulation and waterproofing. Procedure :

- Using a laser level, mark the future opening, taking into account the size of the door/window + framing that will strengthen the structure.

- Using a regular saw, cut through the top layer, remove all excess down to the timber (insulation, frame).

- Use an electric saw to cut the required opening. To strengthen the inside of the building, they make a frame - decorating the doorway with timber around the perimeter.

Openings in contact with the street require additional insulation. To do this, before installing the frame, a groove is cut inside it around the perimeter, insulation is laid, and only after that the reinforcing material is laid.

Installation

In principle, interior partitions made of timber in a wooden house are installed quite easily and quickly, especially if the craftsman has basic experience working with carpentry tools. The operating procedure is logical and simple:

- The timber is selected according to the size of the room that will be fenced off. The profile may differ slightly from the profile of the material from which the walls are assembled;

- It is better to place the beam on the log, it is more reliable. Therefore, you should calculate the floor support in advance so that the joist gets to the right place;

- It's time to attach everything to the wall. There are two main ways to do this. For the first method, a gash is made in the walls; for the second method, a gash is not needed. On the wall, using a pencil and a building level, draw a vertical line along one edge of the beam location, then along the second. Then a neat cut is made into which the beam is inserted. If you don’t have enough skill to make an even cut in a log house, you can do it in a simpler way. In this case, each sheet is attached to the wall with a nail driven diagonally;

- If there is an opening for a door in the wall, you should not forget to leave room for the upper connecting bars.

This is roughly how a wall is made in a wooden house. Watch how to make a partition from timber in the video. Since the description is quite general, you should remember some nuances of assembling the structure:

The bottom bar is nailed to the joist with long nails, for example, 200 mm long. Waterproofing should be laid on it to protect the upper part of the structure from destruction under the influence of water. It is also recommended to take the bottom block from wood with good resistance to water.

Jute fiber laid between the bars will improve thermal insulation and sound insulation

It is especially important to remember about thermal insulation when the partition is mounted in a bathhouse. The use of dowels made of wood or metal will make the structure more durable. The dowels are installed in a checkerboard pattern, at a distance of up to fifteen centimeters from the corners of the walls. After installation is complete, everything should be sanded and coated with an antiseptic.

This operation is best for all walls at the same time. If we are talking about a partition in a wooden house, of course.

Frame

You can make partitions in a house from timber not only by laying rather thick timbers. There are other designs, for example, a frame partition, as in the photo. The frame can also be built in at least two ways.

If the partition is being made in an apartment whose walls are not necessarily wooden, you can use a pre-made timber frame. All that remains is to attach it to the walls, ceiling and floor, for example, using dowels.

If the timber partition frame is installed in a log house, it can be assembled on site. To do this, you first need to mark the walls, ceiling and floor in the place to which the structure will be attached. Then, according to the markings, the bars are attached with long self-tapping screws, which will serve as the basis of the frame. Once they are secured, all that remains is to assemble the rest. It is recommended to use metal corners with holes for screws as fastening materials.

In order to keep the apartment warm, empty spaces in the frame should be filled with foam plastic, mineral wool or other insulation.

You can also install a frame partition in the bathhouse, remembering that the temperature there is high and there should be no metal parts on the surface.

Interior partitions made of timber are an advantageous design, with good functionality and durability, as can be seen in the photo. But in order for the walls to serve for a long time and reliably, you should not forget that a carelessly and carelessly installed and assembled interior partition made of timber with your own hands will not serve for a long time. Inattention to the recommendations of experienced craftsmen and the requirements of instructions and standards will lead to the opposite of the expected effect.

Overview of the main options

Before making partitions in a wooden house, you need to decide what material will be used. We will look at the most popular and popular solutions.

Solid option

The installation of a partition in a wooden house made of timber is most often carried out in parallel with the construction of the box

As the name suggests, a solid structure is erected, for which a wooden beam with a thickness of 50 mm or more is most often used (the most commonly used material is 100 mm thick).

We'll tell you how to do this type of work yourself:

- The elements are fastened together with wooden spikes from 5 to 10 centimeters long; for this, holes are drilled in the material, into which the spike is driven and combined with the second element, and so on.

- The wall is fixed to the floor and ceiling using triangular bars, which act as a limiter. Fastening is best done using self-tapping screws; they hold the system more firmly, and if necessary, they can be unscrewed and disassembled the wall without damaging the wooden parts.

- Since internal partitions in a wooden house are installed independently of the external walls, deformations may occur during the shrinkage of the structure. To avoid this, a deformation groove is made in the load-bearing wall, which will prevent the elements from bending.

The deformation groove allows you to compensate for changes in the size of wooden elements due to changes in temperature and humidity

Frame-panel structures

This option is the most common and in demand, since its price is the most affordable of all possible solutions.

Construction instructions are as follows:

First of all, vertical posts are fixed in increments of 500-600 mm. A beam is attached to the ceiling and floor, to which the remaining elements are attached; you can connect them with self-tapping screws, or you can use perforated corners, this is both simpler and faster.

The frame must be strong and stable

- The installation of partitions in a wooden house continues with the installation of transverse elements; they will give the entire system additional rigidity.

- The entire space is covered with insulation, which will also serve as a sound insulator. The material should be placed tightly - without cracks or voids.

- The surface on both sides is covered with a vapor barrier film and covered with either plywood or plasterboard sheets.

Plasterboard systems

If earlier the question of what to make partitions from in a wooden house was limited to solid and frame-panel options, then these days the option with plasterboard has become very popular.

Before you build a partition in a wooden house, you will need to purchase a partition profile; it differs from the standard one in being thicker and more reliable.

The work is carried out as follows:

- First of all, the wall elements are attached; they determine the location of the future structure, so take all the necessary measurements correctly.

- Next, vertical posts are located at a distance of 50-60 cm. To ensure reliability, horizontal crossbars are added to the structure.

A metal profile frame is erected quite simply and quickly

All internal cavities are filled with mineral wool and covered with vapor barrier material. After this, you can attach plasterboard or gypsum fiber sheets.

Installation of a frame partition

Below we will describe the process of creating a frame partition made of wood for zoning with your own hands.

The essence of this design is to create a harness, the role of which is a beam

The choice of dimensions of this important element depends on the dimensions of the future structure. How to make wooden partitions without special tools? This is a rhetorical question, the answer to which everyone knows

So, for this task you need to prepare: a level and a plumb line to regulate the evenness of the structure; a pencil for drawing marks; a drill/screwdriver and a hammer; a saw for cutting wood; a screwdriver; self-tapping screws/screws/dowels/nails; corners for securing the posts; wooden blocks. When all the elements of this list are at hand, you can install wooden partitions with your own hands, or rather, get acquainted with this process. It is best to carry out installation on the subfloor, since all the logs will be in full view. To install the guides, you can choose any direction (along / across the beams). In the case of high rooms, there is a need to install an additional beam, which will take on part of the weight of the structure. Each stage must be accompanied by the use of a level and plumb line. It’s better to double check than to redo the entire structure. A do-it-yourself partition made of wooden slats on the second floor of a private house should be light. We prepare and mark out the area for work. We stretch the cord, which will mark the line for the location of the guides. At the base of the structure there is a beam on a beam and a crossbar. Racks are installed after 40-60 cm, for fastening you need to use screws and metal corners. The structure is carefully treated with special impregnations that will not allow the wood to dry out and deteriorate from the influence of harmful microorganisms. There is sound insulation between the beams. A mesh is installed in the area of the joints. The structure is not built up to the ceiling; it is necessary to leave a distance of about 10 cm.

In this area, beams and fiber of a coarse structure are located. Sliding frame partitions are fashionable, convenient and compact. In this case, constructing a wooden partition with your own hands requires the use of movable elements. To install them, you can choose any side of the structure, including the inside. Above, complete and detailed step-by-step instructions on how to build a frame-type wooden partition have now become clear to everyone.

How to make partitions in a wooden house

Installation of frame partitions

Their installation begins with laying a horizontal beam on the floor. The dimensions of the timber must correspond to the dimensions of the future partition. Then the vertical stand is secured to the wall using nails or self-tapping screws. The lower end rests against the edge of the horizontal beam. The next step is to determine the point on the ceiling where the edge of the ceiling plumb line will be located. For this task you will need a plumb bob.

After installing the horizontal elements, install the vertical ones. The standard distance between them is 55 centimeters. But this is not a dogma; one must take into account the design features of the material and the overall size of the wall, its height. Nowadays, aluminum building profiles are actively used as a frame. The docking itself is carried out in the middle of the racks. Plasterboard sheets, plywood, and fiberboard are used as cladding. Here the hygroscopicity of the material is taken into account. The space between the cladding inside the frame is filled with a noise-insulating substance - foam plastic or mineral wool.

Installation of solid partitions

The first stage is marking the lines of our partition. A plumb line is great for this. Then the design of the guides is prepared. Two bars located parallel are attached to the board. Nails or screws (screws) are used as fasteners. The distance between the guides should be equal to the thickness of the future wall. If the boards are cut correctly and inserted into the guides, only the outermost one can be fastened.

The rest will be deprived of the opportunity to move freely. When constructing interior partitions in a wooden house, the future wall can be sheathed with plywood, fiberboard or chipboard sheets. You can carry out a major version by covering them with shingles and plastering them. Then the structure must have an additional lag that will support the heavier structure.

Installation of plasterboard walls

How to properly make interior partitions in a wooden house from plasterboard? The main advantage of drywall when performing this task is its ability to level the walls. The job can be completed very quickly

It is important to take into account that a wooden house almost always shrinks. This should not affect or destroy the drywall.

Work begins with markings, drawing the line of the future wall on the ceiling. Then they project it onto the floor using a plumb line.

The frame is made using an aluminum profile. Wooden beams are used less often, although the design is cheaper and more environmentally friendly. When installing plasterboard sheets directly, it must be taken into account that the structure will move slightly. If the sheets are mounted tightly end to end, they will collapse. It is necessary to leave small gaps to compensate for expansion due to temperature and humidity. The following can be used as a base for installation:

- wooden walls,

- wooden slats,

- wooden beams,

- wood sheathing,

- wood frame,

- the wooden wall itself or the floors.

There are several methods for attaching the drywall itself to the lath. To do this you will need dowels, a screwdriver, self-tapping screws, a file, and an electric or mechanical drill. A beam with a cross section of 50×100 mm or 50×74 mm will serve as slats. The optimal place for fastening is the middle of the slats or bars. The best gap between the screws is 15 cm. The fasteners should be slightly buried in the drywall. Ideally, joints should be sealed with adhesive reinforcing film. If the dimensions of the joints are more than 3 mm, then they should be puttied and then sealed with reinforcing tape.

When installing wall partitions made of glass and other materials, all of the above principles are used. And the installation of designer partitions depends only on the structure itself and is developed directly by the designer or architect.

Read how to build a house cheaply and quickly here

By making partitions in a wooden house with your own hands, you can perfectly demonstrate your abilities and construction talents. These works are easy to perform with minor installation skills and abilities. The main thing is ingenuity, logical thinking, and compliance with the simplest construction rules. If you make mistakes, it won’t be difficult to redo and correct them. Well, there shouldn’t be any consequences other than waste on damaged material.

Frame construction technology

As a rule, 100x100 mm timber is used for the construction of frame houses. In the case of the construction of multi-story structures, its cross-section can be increased to 150x150 mm or 200x200 mm. For crossbars, a rectangular beam or board is used. Frame parts are made of pine, spruce, cedar or larch.

Most often in construction, ordinary massive timber is used. This material is relatively inexpensive and easy to process. But ordinary timber has a significant drawback: it is very sensitive to changes in air humidity. If you use natural moisture timber in construction, then after a few months it may become cracked and warped.

Glued laminated timber is more practical. It is made from well-dried boards. The boards are arranged with fibers in different directions and glued together. Such products do not react to dampness and pressure. Their only drawback is reduced vapor permeability due to the use of glue.

The following technologies are used during construction:

- Vertical. The assembly of the structure is carried out in stages. First, the racks are installed, then the crossbars and the top trim are secured. This technology requires high accuracy of operation and control of the verticality of the racks.

- Horizontal. In this case, the individual modules are pre-assembled on the ground. After assembly, they are lifted using levers, a winch or stops and installed in the desired location.

To assemble frame houses, you need to prepare equipment and tools.

Partition material

There are many options for the material, but you should immediately exclude the use of brick, cinder block and other building stone. First of all, it's pointless. Secondly, to build such a powerful partition, a foundation will be needed. In our case it is unlikely to exist. The materials for partitions in a wooden house are varied. There are a number of typical options:

- Wooden, standard partitions. This type is the most convenient, reliable and functional. These partitions will perfectly decorate your home and give it coziness. Wooden partitions are durable; they can be used to mount wall ceilings, hang shelves, cabinets, and racks. This structure can be plastered or subjected to decorative treatment. Such a wall can easily be treated with fireproofing and anti-rotting agents, which is very desirable.

- Plasterboard partitions. They are economical, lightweight and not expensive. These partitions are quickly erected and form seamless surfaces. Drywall has good soundproofing properties and fire resistance. The free space inside the wall can be used for electrical wiring and other utilities. The material is environmentally friendly.

- Frame-panel partitions. This is the most popular and practical type of design. For production, a 50×50 mm beam is required. For increased sound insulation, timber 50×100 mm is used. You can apply the profile. This structure can be sheathed with plasterboard or plywood. Fiberboard is not the best option.

- Solid partitions. They have a very heavy structure and are made of boards. If the boards are more than 50 mm thick, additional support in the form of a log will be needed. It will compensate for the weight of the partition. The boards are mounted vertically, in prepared grooves - top and bottom. The cross-section of the structure has the letter “P”. Leave a gap of no more than 2 centimeters at the top in case of subsidence. The boards can be sheathed or decorated with stain and varnish.

- Glass partitions. There are many available design options for glass partitions and sliding doors. They can also be used on the veranda or terrace. With their help, you can easily and quickly change the parameters of the room.

- Designer partitions. When constructing them, the principle of space of options works; this is an opportunity for a creative person to show his design abilities. The material can be wood, plastic, metal profile, chipboard, paper. This is an excellent opportunity to separate part of the room and use partitions. Designer partitions include forged and fabric partitions.

What kind of partitions are there in a wooden house if it has more than one floor? In this case, one must proceed from the load-bearing capacity of the floor on which the partition will rest. In this situation, the principle works - the lighter, the better. A strength calculation will be required. Even if the ceilings can withstand the partition, they can bend and change the geometry of the structure. Additional support or reinforcing structure will be required.

Partition on a wooden frame

Plasterboard dividing walls in a wooden house are often made of timber. This is justified from the point of view that the materials must match each other in structure and thermal conductivity. It is worth taking into account the fact that poorly dried timber can ruin the entire structure, it can “lead”

The second point that is worth paying attention to is that insect pests can grow in the tree.

Construction of a wooden frame partition made of plasterboard

Before installing the partition frame in a wooden house made of timber, the wood must be impregnated with antiseptic compounds. The calculation of materials is carried out similarly in the same sequence. The length of the timber strips ranges from 2 to 4 m. The principle of the structure is the same as that made from a metal profile.

Scheme of a wooden frame

Additionally you will need:

- metal perforated corners that will attach the racks to each other;

- wood screws 35 mm;

- timber for guide supports 40 x 60 mm or 50 x 80 mm;

- for racks 30 x 50 mm.

Sequencing:

- The markings are carried out in the same sequence as for the frame for the profile. Check it using a level or plumb line.

- Guide beam 40 mm x 60 mm (50 mm x 80 mm), attached first to the floor, then to the ceiling, walls. Guide strips to the floor and ceiling. Use dowels 40 mm-45 mm long. First, you need to drill a hole in dry wood with a drill, the diameter is slightly smaller than the fastener.

- Install wooden posts; timber 30 mm x 50 mm is suitable. They are attached to the guide posts using metal corners and 30 mm-40 mm wood screws. The step between them is the same as for metal profiles (60 cm). It is only necessary to take into account that the last racks must be installed from the wall at a distance of at least 10 cm. A small gap in height of 8 mm-10 mm (from the ceiling) is left between the guide beam and the racks. Then, using metal corners and wood screws, attach transverse hangers between the posts.

- The wooden frame is ready, then plasterboard sheets are attached to the timber, the joints are sealed with sickle tape, and putty is applied. The process follows the same scheme as for partitions based on profiles.

A selection of photos of the design of plasterboard partitions in the house

Application of dowels

If wooden dowels are used in the construction of timber buildings, it is important to make them from the same type of wood as the timber itself.

It happens that for greater reliability, the timber is tightened with metal dowels. In this case, such a solution will be significantly more expensive, which may affect the overall cost of construction.

Installation of dowels occurs by analogy with brickwork. A hole several centimeters in diameter is drilled for the pins so that they can be inserted without effort. The installation of dowels should be done at a distance of one and a half meters from each other.