Houses made from environmentally friendly materials are increasingly attracting residents of big cities. Of all types of materials, wooden structures are especially popular. Of course, aesthetic appeal, construction time and the low cost of building a house are the main factors. However, there is one significant disadvantage of a wooden house: it is not sufficiently protected from various sounds.

@Shumoizolyatsiya_derevyannogo_doma

There are two types of noise: airborne and vibration. In a wooden house, in addition to airborne sound, you can also hear vibration, which occurs as a result of a truck driving nearby. Today, with the use of modern materials, it is possible not only to reduce the level of airborne noise, but also vibration noise, although for this it is necessary to correctly select the appropriate soundproofing materials.

Content:

- Types of noise

- What materials are used to absorb noise

- Cork sound insulators

- Loaded vinyl or sound block

- ZIPS

- Substrates

- Fiberglass

- Drywall

- Mineral wool

- Foamed polystyrene

- The process of soundproofing a room

- Walls and partitions

- Floor

- Ceiling

- Video on soundproofing a wooden house

The problem of sound insulation is relevant for any home, especially if it is located near busy areas or a road. It is believed that wooden buildings transmit noise more than others. This is due to the fact that wood is a porous material that transmits sound waves of different frequencies. After drying, the material becomes even more vulnerable, as the seams dry out, and, allowing sound to pass through, resonates - amplifying it. This factor can negate all the advantages of living in a wooden house.

That’s why sound insulation in a wooden house is so important, which needs to be taken care of during the construction stage. There are also household tricks that can reduce sound conductivity: the use of textiles in decoration, upholstered furniture, carpets and bedspreads. Conversely, the amount of tiles, metal and stone should be minimized.

Required Tools

Soundproofing a wooden house is not an easy task, and without using the necessary tools it is almost impossible. Depending on the choice of insulation, the appropriate tools are selected. Considering the fact that for a wooden structure the best option would be mineral or basalt wool, for the work you will need: a knife, a screwdriver, a screwdriver and a hammer. As consumables you need to take: waterproofing, insulation, slats. You also cannot do without measuring instruments: a tape measure or a long ruler.

@instrument

Types of noise

Sound vibrations in air are called noise. It can have a negative effect on the human body. There are these types:

- acoustic – propagating in space through air;

- shock - from mechanical influences, impacts or steps;

- combined.

There are standards that determine the permissible sound volume in residential premises.

What materials are used to absorb noise

The noise absorption system must be carefully considered during the construction phase. The following materials are used to soundproof a wooden house:

- mineral plate;

- cork;

- drywall, foam plastic - effective and durable, not subject to corrosion;

- OSB and chipboard - mounted without rigid fastening, which helps dampen noise;

- mineral wool, glass wool - placed between beams and joists in order to eliminate contact between the wooden parts of the house;

- sand - suitable for soundproofing the floor, placed on a substrate;

- expanded clay - used for sound insulation between floors

- felt - used between floors and for insulating joints.

In addition to the function of noise protection, they can cope with the task of thermal insulation of the room. Any of them can be used to cover the walls of a wooden house.

These soundproofing materials make it possible to qualitatively insulate rooms and protect wooden houses from acoustic influences.

When starting work, you should carefully seal all the cracks through which sound can pass with special mastic or putty. All voids provided for electrical wiring and switches must be filled with foam. Using elastic sealants, the entrances of water and gas pipes into the building are sealed.

We work with wooden partitions

Wooden partitions are considered the most reliable and suitable for insulation. These designs allow not only to distribute zones, but also to protect the room from noise coming from other rooms. When designing sound insulation for a house, you need to figure out what is the best way to make insulation, since the abundance of materials is very great.

@peregorodki

If you do not have construction skills, then even such a simple job as installing a partition can take a lot of time and effort, so it is better to entrust the matter to those who are well versed in this matter.

It is important to know! The soundproofing and soundproofing qualities of a structure directly depend on the timber used. If the material does not give the required result, then additional insulation with foam plastic can be done.

Cork sound insulators

Cork sound insulators

Cork panels are often used in interior decoration. They serve both a decorative function and protect against noise penetration. If you lay cork slabs in all the walls, you can ensure excellent sound insulation of interior partitions - noise from outside will practically not penetrate into the room.

The advantages of cork include:

- high decorative properties;

- good sound insulation;

- ease of installation;

- durability.

The only drawback of the material is its high cost.

Nuances of the process for improving sound insulation

Before selecting and purchasing materials with soundproofing properties, it is necessary to examine the walls for problem areas. Especially, pay attention to cracks and gaps at the junction of communications. Then, it is advisable to carefully close all holes near the sockets. The best option for this would be fiberglass. Also, the level of sound vibrations can increase:

- If the building materials of a wooden building have a low level of sound insulation.

- Poor quality fittings are used, there are gaps in the window and door frames.

- If you choose the wrong finish, which has weak absorption of sound vibrations.

Principles of distribution

To improve the final result, in addition to finishing the walls with sound-absorbing agents, you need to additionally carry out a number of actions:

- Be sure to replace the old door with an updated one, with sealing pads around the perimeter.

- It is advisable to replace wooden windows with PVC structures or double-glazed windows.

- Attach sealing gaskets to the interior passages.

- In private homes, it is advisable to carry out work on finishing the exterior with a sound-absorbing coating.

- In order to reduce the transmission of structural noise, it is advisable to finish the façade with materials that have reflective properties.

After completing the preliminary work, the level of vibrations inside the room will significantly decrease. Also, most of these materials retain heat well in the room.

Loaded vinyl or sound block

When it comes to insulating a house from sound penetration without taking up a large amount of usable space, loaded vinyl (sound block) is used. This is a modern material that combines the functions of polymer and mineral and exhibits maximum efficiency even with a thickness of 3 mm.

It can be used to soundproof partitions in a wooden house or apartment. Advantages of the film:

- elasticity;

- moisture resistance;

- sound absorption of one layer is 25 dB.

To achieve greater efficiency, you need to use an insulator in two or more layers.

Which is better to use?

In order to conclude which insulator will work better under certain conditions, it is important to know what sound level needs to be dampened.

This is done with a sound level meter and if, for example, it is necessary to suppress Rw = 20 dB.

You should not buy expensive material with protection Rw= 50 dB.

When choosing a scheme, it is better to choose external wall protection, it is more effective with an NRC absorption rate of 0.8 to 0.95.

With an external noise level of 50 dB, with an NRC of the material equal to 0.95, the protection will dampen 50x0.95 = 47.5 dB, the remaining 2.5 dB will be damped by a wooden wall with Rw = 35-45 dB, that is, there is no extraneous noise entering the house will pass.

If we analyze the effectiveness of the material by cost per 1 m2 and the achieved NRC level, we can obtain the following rating.

List of TOP materials for external noise protection :

| № | Name | Price, rub. for 1 m2 | NRC | Rw,db | RUR/NRC | rub./Rw |

| 1 | GREENGUARD ACOUSTIC | 121 | 0,95 | 127 | ||

| 2 | Rockwool Acoustic Butts | 141 | 0,85 | 166 | ||

| 3 | Akulite | 200 | 0,9 | 222 | ||

| 4 | AKUSTIKNAUF | 120 | 57 | 2 | ||

| 5 | Shumostop-K | 298 | 32 | 9 | ||

| 6 | ROCKWOOL Floor Butt | 197 | 0,8 | 246 | ||

| 7 | StopSound BP S | 275 | 0,9 | 306 | ||

| 8 | TECHNONICOL | 260 | 0,85 | 306 | ||

| 9 | Schumanet-BM | 309 | 0,85 | 364 | ||

| 10 | StopSound | 447 | 0,95 | 471 |

Materials for internal sound protection have a higher price, with lower efficiency; their rating is based on the level of cost and the ability to absorb Rw, dB.

List of TOP materials for internal noise protection :

| № | Name | Price, rub. for 1 m2 | NRC | Rw,db | RUR/NRC | rub./Rw |

| 1 | ThermoSoundIsol | 396 | 30 | 13 | ||

| 2 | ABEX-M soundproofing self-adhesive membrane | 783 | 50 | 16 | ||

| 3 | SoundGuard EcoZvukoIzol | 1020 | 60 | 17 | ||

| 4 | EcoQuartz | 720 | 36 | 20 | ||

| 5 | Topsilent Bitex | 1025 | 27 | 38 | ||

| 6 | Soundproofing membrane Tecsound 70 | 1670 | 28 | 60 | ||

| 7 | Self-adhesive membrane Tecsound SY 70 | 1894 | 28 | 68 | ||

| 8 | Sonoplat Combi | 1600 | 13 | 123 | ||

| 9 | ZIPS-Vector | 1712 | 11 | 156 | ||

| 10 | ZIPS-III-Ultra | 2488 | 11 | 226 |

ZIPS

Sandwich panels or ZIPS modules are a modern material for sound insulation; they are a slab with basalt fiber inside and a solid sheet of plasterboard on the outside. Their advantages:

- light weight, which allows them to be attached to the ceiling;

- wide range of applications in any type of premises;

- ease of installation;

- corrosion resistance;

- can be used in damp areas.

The use of ZIP panels makes it possible to reduce energy costs by 30%.

Cost per 1 m2

Soundproofing materials are expensive, so they must be selected in the price-quality ratio based on operating conditions.

Cost of the most popular noise insulators for residential buildings:

- Shumanet-BM, Russia, basalt slab, 310 rub.

- StopZvuk BP, Russia, basalt slab, 450 rub.

- Shumostop-K2, Russia, basalt fiber 300 rub.

- ROCKWOOL Floor Butts, basalt material, 200 RUR.

- Rockwool Acoustic Butts, Russia, basalt slabs, 150 rub.

- StopZvuk BP S, Russia, basalt slab 280 rub.

- TECHNONICOL, Russia, Technoacoustic brand, basalt slab 260 rub.

- GREENGUARD ACOUSTIC - sound-absorbing stone wool 150 rub.

- Akulite, Russia, KNAUF brand, basalt mini-slab, 200 rub.

- Self-adhesive soundproofing membrane Tecsound SY 70, Spain, Tecsound brand, RUB 1,900.

- Sonoplat Combi Russia Sonoplat brand, soundproofing panels, 1600 rub.

- SoundGuard EcoZvukoIzol, Russia, SoundGuard brand, 1050 rub.

- TermoZvukoIzol soundproof multilayer fiberglass mat, Russia, TermoZvukoIzol brand, 400 rub.

- ZIPS-III-Ultra, Russia, ZIPS brand, sandwich panel with tongue-and-groove connecting system with fasteners, 2500 rub.

- Soundproofing membrane Tecsound 70 in rolls, Spain, Tecsound brand, RUB 1,700.

- ZIPS-Vector, Russia, ZIPS brand, sandwich panel with fasteners, 1,700 rub.

- ABEX-M soundproofing self-adhesive membrane, Russia, ABEX brand, 783 rub.

- EcoQuartz Standard soundproof seven-layer panel made of cardboard and sand, Russia, Ecoquartz brand, 750 rub.

- Topsilent Bitex in rolls, Italy, INDEX brand, 1050 rub.

Substrates

This is an affordable means of soundproofing a wooden house with your own hands. There are wallpaper backings that are used to cover walls at the preparatory stage. In addition to sound insulation, such wallpaper performs the following functions:

- home insulation;

- level the walls;

- protect against dampness and fungus.

To protect against floor noise, laminate underlays are used, which can also smooth out minor surface irregularities.

Soundproofing of a frame house

It’s good to live away from noisy streets, rushing cars, surrounded by fresh air.

Country idyll - nature, heady air, silence, birds singing. Beauty. When choosing to build a wooden frame house, people are often interested in how quiet the house will be. Is the sound insulation of the walls of a frame house really as good as experts say? Let's consider how the sound insulation of the external walls of the house, partitions and ceilings is arranged. What is the noise absorption coefficient of a frame wall, given its small thickness.

In practice, these are indicators that minimize noise penetration. This effect is achieved thanks to the peculiarities of construction technology.

To understand the issue, let’s take a short theoretical excursion..

Noise can be different; the following characteristics of sounds are distinguished:

- percussion is a hammer, steps, rearrangement, the sound of rain on the roof, etc. This type of noise works in horizontal and inclined planes (floor, roof);

- acoustic (air)

Well, everything here is clear from the name - these are voices, machines. Acoustic noise affects walls and glass surfaces. And finally

- structural noise - spreads throughout the entire space of the house. It is characterized not by its source, but by its area of influence. By its nature it can be shock or airborne.

Therefore, to make a quiet home, it is necessary to reduce impact, acoustic and structural noise to the maximum. Let's start with the simplest, acoustic.

Soundproofing walls in a wooden house

Pie walls and sound insulation

The frame structure of the walls perfectly protects against acoustics, as it has a three-layer structure. The internal cavity of the frame is filled with a soft fibrous material that has high heat and sound insulation properties.

The most commonly used are mineral and ecowool, foam insulation, isover and other dense fillers. Their supply on the construction market is quite large.

Soundproofing of walls and partitions in a private house is usually installed during the construction stage. The frame wall is made of wooden posts located at a distance of 0.55 - 0.6 meters (standard width dimensions for many heat and sound insulating materials). Sound insulation is tightly placed between the posts of a frame house. If necessary, they pass along the perimeter of the frame with silicone sealant or foam. The tighter the insulation is laid, the better the sound protection will be.

Soundproofing of internal wooden walls of a wooden house

Frame wall design: insulating soundproofing material is placed between the studs; the outer cladding is made of plywood, chipboard or OSB.

The internal frames can be covered with plasterboard. This is a very high quality material in terms of noise reduction.

If you want to soundproof the walls in a wooden house with your own hands, it’s not difficult at all, just by selecting the right materials. If it is quite easy to cope with acoustic noise during frame construction, then reducing impact noise requires additional effort.

Elimination of impact noise in walls

Frame walls are not very reliably able to protect against impact noise. Even tightly installed soft insulation does not prevent the spread of sounds of this kind, spreading throughout the house and driving away the silence.

It is good if the house is located away from a busy highway or railway tracks. In this case, impact noise does not appear often.

To increase the level of impact noise absorption, polyurethane foam frame fillers, synthetic rubber, latex and fiber materials are used. The main criterion: the greater the elasticity of the material used, the higher the sound insulation properties from impact sounds. It is good to use glass wool and basalt insulation for soundproofing partitions. They provide sound absorption and have increased fire safety.

Soundproofing floors in a wooden house

Wood is used in the floors of a frame or wooden house.

Beams, floorboards, ceilings, the floor of the second floor, covered with clapboard, add environmental friendliness, but at the same time have excellent permeability of sound waves. The hardware used during the installation process (screws, beam supports, mounting angles), being metal products, increases the sound permeability of the floors. Quite often, impact noise (the sound of footsteps, even slight movement of furniture, moving a chair away) can cause discomfort.

Although a person is such a creature that he can get used to anything, nevertheless, protection from impact sounds must be equipped when installing floors. During operation, without additional investments, reducing the level of such noise will be problematic and costly.

Imagine this: on the top floor someone dropped a slipper, and you woke up, staring at the ceiling and with effort remembering literary words. Do you like this situation? I doubt. And all because an important construction rule was violated: YOU CAN’T MAKE HOLLOW COVERS INSIDE THE HOUSE, categorically.

The sound insulation of the floors is combined, the material is laid tightly, completely filling the cubic capacity of the floor.

We must remember that sound bridges (contact of wooden elements) are the same disadvantage as cold bridges. Their presence will reduce all efforts to install sound insulation to zero. Materials with a dense structure (fiber, jute mats, tow, mineral and natural wool, expanded polystyrene) have good noise-absorbing properties. But this may not be enough to completely eliminate impact noise.

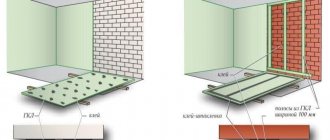

An excellent option for protection against impact sounds is a floating floor. The insulation is installed so that there is no rigid connection between the structural elements of the house (floors and walls). Damping resonators are arranged along the joists and beams of the structure. The logs lie freely and are not connected to the floor beams. The space between them is densely filled with soundproofing material. The subflooring is mounted to the joists. You can additionally lay a backing on the joists to increase efficiency. The noise level is also reduced by the lining under the beams in the places where the pieces of rubber support.

To prevent the spread of sounds, interfloor ceilings and flooring should not be adjacent to the wall. The small gap left is filled with fiberboard, ecowool and similar materials. Then primed with water-based acrylic paint to completely fill the voids. In the interfloor layer, it is imperative to use a waterproofing film, which also effectively absorbs noise.

Fiberglass

The principle of making fiberglass is as follows: recycled glass is melted at high temperatures and pulled into very thin fibers. Due to the fiber length (150 m or more), a high degree of sound absorption is ensured.

It comes in the form of slabs and mats, and is characterized by ease of installation and a minimum number of joints. Fiberglass will be an ideal solution for soundproofing attics, attics, and walls.

Drywall

Drywall is often used to insulate walls from noise and cold, but this material itself is useless. For effectiveness, it is recommended to combine it with some kind of filler, for example, mineral wool. A modern development is plasterboard acoustic sheets in which there are a large number of holes, and a non-woven fabric is glued to the surface. Thanks to these details, maximum damping of sound waves occurs.

It is worth considering that the use of drywall “steals” square meters of the room.

Foamed polystyrene

Expanded polystyrene is an environmentally friendly, heat-resistant, safe, soundproof material. Its quality characteristics have been known for a long time and are in great demand.

When using penoplex and expanded polystyrene to insulate wooden houses, a number of positive aspects can be highlighted:

- ease and ease of processing;

- possibility of use without additional precautions;

- non-susceptibility to deformation.

However, it should be remembered that polystyrene foam is afraid of exposure to chemicals.

Floor

The “floating floor” technology is used, which makes it possible to reduce the impact of impacts and steps when soundproofing between floors. To increase the level of sound insulation of the floor you need:

- increase the thickness of the screed and the thickness of the insulation layer;

- limit the screed with spacers on the sides.

It is recommended to use mineral wool as an insulator.

If we are dealing with a floor on joists, then we need to increase the surface mass of the wooden covering and the height of the joists. For installation, use elastic fasteners, and fill the space between the joists with insulator.

Installation and design of partitions from boards

If at the end of the construction work there are wooden boards left, then they can be used to make an interior partition with your own hands. It is necessary that the dimensions of the beams match the requirements of the partition. The length of the board should be 1.2 meters and the width 60 centimeters. The entire structure is assembled using tongue and groove. Before installing the exterior finish, the surface of the structure should be sanded.

@peregorodki

Using boards, you can also make shields, which are then assembled into a single structure. Boards of various sizes can be used as material. Today, the use of different textures and sizes is quite popular when creating interior design. Waterproofing materials with a sealant are laid inside the structure, and everything is sewn up.

It is important to know that when making a partition it is necessary that it rests on a reliable base. In such cases, additional beams are installed. They can be installed either in the middle of the house or in the foundation. If a house is being designed from scratch, then the partition can be planned initially. When installing a partition, you should allow the material to take its natural shape. If the floor of the house is made on the basis of beams, then you can try to place the structure directly on the support, thereby ensuring reliable fixation.

Ceiling

For interfloor insulation, it is recommended to use suspended ceilings covered with plasterboard. To increase the protection of the ceiling structure from sound penetration you need to:

- use fasteners with a low resonant frequency;

- increase the thickness and weight of the ceiling;

- use flexible facing material.

The greater the distance between the floor covering and the ceiling cladding, the more insulation will fit between them and the higher the sound insulation performance will be.

After the insulator is installed, you can begin finishing the premises. The use of modern technologies and high-quality materials in the construction of a wooden house allows you to create a comfortable home without overloading it.