To connect water heating equipment, toilets, faucets and other plumbing devices, a liner is required that will connect them to the water supply. This element can have a flexible or rigid design.

Most users prefer the first option. This choice is not made without reason - the flexible connection for the mixer is compact, practical and easy to install. Are you planning to purchase and install such a device, but doubt your own abilities?

We will help you solve this problem. The article describes the features of different types of flexible hoses, indicates the specifics of their application and provides practical advice on choosing the appropriate option. In addition, we have prepared detailed instructions for installing the faucet connection.

Rigid and flexible water supply to the consumption device

I will be objective and will probably remind you, rather than reveal the truth, that flexible water supply did not always exist. Until recently, all connections to plumbing fixtures were carried out using rigid connections, that is, pipes.

This type of eyeliner is practiced and quite popular now. However, due to complexity and increased professional skills, rigid water supply is often replaced with flexible one. Let's see what their essence and difference is.

Hard eyeliner

In the photo you see the classic version of a hard water supply, without changing the diameter of the water supply. In this example, this is the supply of hot water and cold water to the kitchen mixer.

In the modern version, hard water supply looks more aesthetically pleasing.

What are the pros and cons of hard eyeliner?

Among the advantages, I note high reliability, reduced noise, direct movement of water. The most noticeable disadvantage is the more complex and more expensive installation.

Peculiarities

Flexible eyeliner has a number of features, among which the positive ones easily stand out. But negative nuances should also be mentioned in order to avoid an unpleasant aftertaste, a waste of time, effort and money.

The advantages of this flexible eyeliner:

- Complete tightness and protection against leaks;

- Saving space, allowing you to install additional interior items or equipment without having to worry about bulky pipes;

- Ease of changing the location of an object connected by a flexible liner;

- Refusal to use a welding machine;

- Protection of the hose from water hammer. That is, if a pressure surge occurs in the water supply system, a high-quality flexible line is protected from rupture and water leakage;

- Easy to install and operate.

Flexible hoses are typically used for various plumbing connections. Most often it is used in bathrooms (connecting a toilet, faucet, boiler to water) and in kitchens.

Flexible water line

The name “flexible” speaks for itself. However, there are two types of flexible water line:

- Reinforced;

- Bellows.

Related article: Difference between overhead and mortise kitchen sinks

Bellows flexible liner

In the photo you see a classic bellows (corrugated) stainless steel eyeliner.

This type of eyeliner has a 25-year service life (not counting gaskets). It is used in water supply, heating and heating systems, gas and fuel pipelines. A sealed metal hose can vent gases and serve as channels for electrical wiring.

To work with corrugated eyeliner, you do not need a special tool. Eyeliner is sold in various lengths; the length margin for eyeliner should be minimal. You can buy a flexible water line from the kofulso company on the company’s website. Kofulso is a world leader in the production of flexible corrugated stainless steel piping.

History of invention

What is a bellows? This design was invented by an American meteorologist at the beginning of the last century. He came up with a corrugated metal container to trap air particles that could shrink and expand with changes in pressure. He gave the name to his invention from medieval mythology - the spirits of the air were called sylphs. The unique property of the bellows to maintain tightness even with multiple deformations has found wide application in a wide variety of industries. Bellows water line is one of the most common uses of this invention.

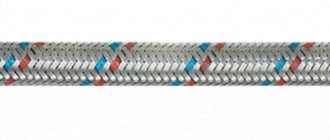

Reinforced flexible liner

In the photo you see the classic version of a flexible reinforced water line. Moreover, such a supply is provided for by the design of the mixer, and the supply pipes are included with the mixer.

reinforced liner

What are the pros and cons of flexible reinforced liner?

Pros:

- Most modern mixers are designed with flexible connections;

- It is easier and faster to install;

- The supply pipes can bypass any obstacle;

- Flexible line lengths can solve the problem of remotely connecting a device at a distance of up to 1.5 meters from a source or pipe;

- She's cheap.

Minuses:

- Increased water supply noise;

- Displacement of the flexible hose when the pressure is turned on;

- Difficulty in choosing high-quality eyeliner;

- Relatively short service life.

Product quality and cost

For example, flexible eyeliner from the STOUT brand is an excellent option for those who are used to choosing high quality without the need to overpay. The products are manufactured in factories in Italy, where every stage of the production process is controlled. The same factories supply goods to famous brands in the expensive segment. However, STOUT’s pricing policy allows customers to purchase quality goods at an affordable price - there is no increase in cost due to a well-promoted name.

Flexible hose is available in diameters from 3/8 to 1 ¼ inches, lengths from 400 to 1000 mm. This means that among the STOUT assortment you will definitely find the right product that will reliably serve for many years.

Design of flexible water supply

The basic basis of a flexible water line is a rubber hose. It is covered with a metal braid of the liner and is visible only from the side of the fittings. It is worth noting that the bellows liner corrugation itself is a pipeline.

The purpose of the hose is to pass (supply) water to the device. The quality of the entire reinforced line depends on the quality of the rubber of this hose.

If the manufacturer uses low-quality rubber, then if it is bent too much, it will crack and the liner will become unusable. Also, low-quality rubber dries out over time and also cracks.

Related article: Do-it-yourself installation of a mortise sink with a bulkhead of the lower kitchen cabinet

Equally important is the material and method of weaving the braid of the reinforced liner.

Connection elements are installed at the ends of the flexible line. These can be nuts with internal threads (B, “female”) or fittings with external threads (H, “male”).

Depending on the pairing of nut and fitting, flexible hoses can be of the following types:

- V-V (nut-nut);

- V-N (nut-fitting).

There is no N-N type (fitting-fitting) liner, since a fitting connection of the liner to a water pipe is unrealistic.

Specifications

| Characteristic | Unit change | Meaning |

| Operating pressure | bar | 10 |

| Maximum working pressure | bar | 20 |

| Maximum operating temperature | ºС | 100 |

| Inner diameter of rubber hose | mm | 8,5±0,5 |

| Braided hose outer diameter | mm | 12,5±0,5 |

| Capacity at 3 bar differential pressure | ºС | 100 |

| Maximum operating temperature | l/min | 35 |

| Minimum permissible bending radius | mm | 50 |

| Inner diameter of connecting fitting | mm | 6,2 |

| Recommended maximum tightening torque | N/m | 0,4 |

| Average service life | years | 10 |

Braided reinforced flexible liner

There are four types of flexible hose braid:

- Firstly, it is aluminum braiding. The option is budget, can withstand 10 atm, but lasts 2-3 years. I don’t recommend it because it is afraid of condensation, oxidizes and burns through the rubber.

- Secondly, a braid of galvanized steel wire. Do not take under any circumstances.

- Thirdly, stainless steel braid. An excellent choice that will last for a long 10 years.

- Fourthly, nylon braid or reinforced stainless steel. An expensive option for a super reliable eyeliner.

Bellows

Bellows hoses are more reliable and durable. They are made in the form of alternating rings of different diameters made of stainless steel. During production, the workpiece is selectively crimped, after which it receives a corrugated shape that provides high flexibility. The cost of such a hose is much higher.

The eyeliner is available in two types:

- with fixed length;

- foldable.

The first does not stretch and has a certain size: 20, 30, 40, 50, 60, 70 and 80 cm. For the second, the range of minimum and maximum values is indicated: 140–250, 200–355 mm, etc. It is not recommended to get too carried away with stretching, since this affects the service life of the product.

The disadvantage of a bellows hose is the noise that occurs when water is simultaneously supplied to several consumers, for example, to a faucet, toilet and washing machine. To avoid this, it is recommended to purchase hoses with a plastic coating.

How to choose a flexible water line

To choose the right flexible eyeliner, pay attention to the following:

The weight of a normal eyeliner should not be small. The low weight of the hose means the use of aluminum (silumin) in the design, which is very bad;

Next, take the eyeliner by the edge and turn it horizontally. If the hose does not bend at all or bends very poorly, this is a bad connection with a technical rubber hose. If the free end of the hose calmly falls down almost vertically, this is a good elastic line and can be taken.

Related article: Which is better, ball valve or gate valve

In a good liner, the rubber of the hose is not technical rubber, not toxic rubber. It is better not to take eyeliners with aluminum and plastic nuts.

Criterion 3. Connection

High-quality crimping of the tip is a good indicator of the reliability of the entire liner. The tip is one of the most important parts of the structure. The service life of the liner and its safety depend on the quality of its manufacture and crimping.

One type of defect is weak compression of the braid. This can happen either due to poor-quality liner material, or due to the lack of special equipment at the manufacturer.

Manufacturing tips and connections from low-grade metal is fraught with deformation, rapid oxidation and corrosion, which ultimately leads to structural failure. Connections can be:

- brass LS-59 coated with nickel-chrome - lasts up to 15-20 years;

- made of stainless steel AISI-304 without protective coating - lasts up to 15-20 years;

- made of ordinary steel, coated with nickel-chrome - lasts up to 1-3 years. To determine the type of metal, just scratch the surface of the braid. If it is made of plain steel, the scratch will be silver, and if it is made of brass, it will be silver-yellow.

Flexible liner installation

The flexible water supply is mounted (both with a nut and a fitting) without the use of linen or foam winding. The connection is sealed with a flat rubber washer on the nut or two round gaskets on the fitting.

When connecting a flexible line, do not allow it to twist axially along the length of the braid. This is true when one end of the line is already connected.

In practice, with a new gasket, you can tighten the liner nut by hand, without a wrench. Some modern eyeliners are sold with a plastic key that limits twisting (see photo).

The liner should not be mounted under tension, and it should not twist or loop.

Criterion 8. Dimensions

When determining the dimensions of the eyeliner, it is important to know two main parameters:

- diameter. When choosing it, you need to focus on the expected water consumption. Standard values for various equipment: for installing a toilet - 8 millimeters, for connecting a faucet in the kitchen - 10 millimeters, in a bathroom - 15 millimeters;

- length. When choosing the length, the distance from the plumbing equipment to the water supply pipe is taken into account. The hose should not be stretched or bent too much. Any mechanical deformation will shorten the service life of the liner.

Dimensions

Before purchasing a product, you should determine the required length. Most branded models come with a 50 cm hose included. This is enough to connect a faucet in the kitchen.

It is important to take preliminary measurements, since the layout of the room and the placement of water supply points may differ. The diameter of the union nut is also important. It can be ⅜ - 1”. The fitting has a standard value - M10.

Recommendation : A large family will benefit from a double sink like the N200. It will fit twice as many dishes.

The method of connecting the hose to the faucet in the kitchen may differ:

- Petal Latch + Fitting - Simply push the tube into the bottom of the faucet until you hear a click.

- Thread - the part is simply screwed in.

- The push-in connector is a cylinder-shaped sleeve, which on one side is divided into 4 petals. By rotating the nuts, they bend towards the center, which ensures fixation.

Educational program: What does a kitchen faucet consist of: 5 different models

Material of manufacture

Regardless of the type of connection chosen, the main selection criterion is quality. Of course, this affects the price, but it’s not worth saving: a good hose for a kitchen faucet means both a low probability of leaks and durability.

Things to consider:

- Appearance of the product. It should not be deformed or too thin.

- The manufacturer is also important: unknown companies are too risky a choice. They often make a cheap but not reliable product.

- It’s good if the seller is ready to provide quality certificates.

Tip : to avoid lifting heavy pots of water, you can purchase Novara-Plusс. It is equipped with an exhaust hose.

Features of materials used in the manufacture of eyeliner:

- Steel - durable galvanized pipes are not afraid of rust. May expand slightly at high temperatures.

- Copper is ductile, does not rust, disinfects water, and remains operational at +250 °C.

- Brass - withstands up to +300 degrees, resistant to chlorine, high pressure (up to 400 atmospheres).