To seal the mixers, special rubber rings are used to prevent water from leaking from the gander when the valves are closed. When elements are damaged, fluid begins to leak. An apartment owner who knows how to change the gasket in a bathroom faucet can independently fix the problem in 20-30 minutes.

The gasket is an important part of the valve design; it seals the valve seat and its body.

Gasket location and signs of wear

Rubber O-rings are located inside the faucet to prevent water from entering the gap between the seat and body. The valve design uses a screw or worm that presses the seat with a seal to the body part, which has a channel for supplying liquid.

Additional gaskets are located at the place where the jib is attached to the mixer body and at the points where the device is connected to the water mains. A sign of wear on the rubber gaskets is water leaking from the gander when the taps are turned on.

Reasons for wear of gaskets

The gasket for the mixer is an indispensable element of its device, which is a silicone or rubber seal that visually resembles a ring, the diameter of which corresponds to the diameter of the pipe. It is a consumable material that is used to seal the connecting parts of the crane. The gasket seals the joints, preventing leaks through these most vulnerable areas of the structure. From time to time, these consumables wear out and require replacement. The most common cause of wear on the sealing gaskets inside the bathroom faucet is:

- The size of the seal does not match the diameter of the tap. When installing a faucet in a bathroom, it is extremely important to accurately select the size of the gaskets, otherwise they will wear out faster during operation or even become deformed, losing the ability to perform their function.

Leak - Small grains of sand getting under the gasket. During installation, small particles of metal, rust, and debris may penetrate under the seal. Due to the friction of these elements on the rubber during use of the tap, the gasket wears out and becomes unusable.

- Low quality material. Faucet gaskets are usually made from rubber, latex or silicone. If the product is of poor quality, the material may have lower elasticity, it may deform and wear out.

- Poor water quality. Tap water usually contains a large amount of impurities that have a negative effect on the rubber from which the faucet seal is made. In addition, constant temperature changes lead to deformations and the appearance of cracks.

Note! The service life of the mixer seal is influenced by many factors, ranging from the quality of the material and whether the size corresponds to the diameter of the taps. However, most often the cause of accelerated wear of the gasket is trivial mistakes made by inexperienced craftsmen during installation.

Tools and consumables

To replace the gasket in your bathroom faucet yourself, you need to prepare:

- gas or special adjustable wrench for plumbing work;

- a screwdriver with a flat and Phillips blade for removing the valve head;

- a set of spare rings;

- stationery knife;

- pliers.

Since during the repair process it may be necessary to remove the faucet, you should prepare flax tow to seal the threads. Instead of tow, synthetic tape or a special sealant can be used. For the manufacture of non-standard seals, sheet rubber with a thickness of 2.5-3 mm is used. The part is cut out with scissors or a metal punch of the appropriate diameter.

Replacing a gasket is a very neat job that does not require rushing.

Prevention of breakdowns

To prevent premature failure of the product, adhere to the following rules when working with it:

- Open and close the tap all the way, but do not use much force.

- From time to time, disassemble the mixer, clean it from dirt and lubricate the moving elements. This will increase the operating life of the product by about 3-4 times.

- Install the filter. As a rule, the main reason for faucet breakdowns is insufficiently clean water entering our homes from main water pipes. To solve this problem, install a coarse water filter.

Replacing the gasket in a water tap does not take much time, and this work can be done by any person who knows how to think technically. The above instructions and recommendations will help you cope with this simple task perfectly.

Depending on the quality and hardness of the water, the average lifespan of a bathroom faucet is 5-7 years. If the mixer is not made in China, which also happens, it is possible that the fittings and taps will last 10-15 years. But, in any case, the first symptoms of wear appear after three years, when the faucet begins to leak, and the problem arises of how to change the gasket in the bathroom faucet. Today, most often it is necessary to repair axle-box and cartridge cranes. Mixers of this type are used quite widely, although they are gradually being replaced by valve systems on ceramic discs.

Preparation for repair

Before you start changing the seals, you must shut off the water supply using the valves located on the water pipes. The taps are located in the bathroom or placed in a separate panel at the entrance of the mains into the room. If the apartment valves are faulty, then you need to contact the management organization with a request to shut off the water supply to the house. In this case, the repair begins with replacing the taps. The enameled surface of the bath is covered with sheet cardboard or an old blanket, and foreign objects are removed from the bathroom.

Repair of a single lever ball mixer

Replacing the gasket here at first will be similar to the option indicated above. Let's look at this in more detail.

- Remove the decorative plug, unscrew the screw and pull it out.

- Unscrew the threaded connection. Remove the ball from the mechanism.

- Replace the gaskets (seals) and reassemble the mixer in the reverse order.

Working with such a mixer must be done very carefully! Sometimes it is recommended to replace the ball itself with a new one, so if you do not understand such complex designs, it is best to consult with a specialist in this matter.

In most cases, it is recommended to replace the springs inside the ball in addition to the seals. I think it becomes clear that the more reliable and modern the mixer, the more complex its design.

Step-by-step instruction

The repair process depends on the valve design; standard screw valves use several gaskets. The elements come into contact with the surface of the brass body, and during operation, wear is formed on the parts. In this case, installing a standard size gasket does not eliminate the leak. The owner can mount a ring with increased dimensions, but it is recommended to replace the assembly.

During repairs, it is necessary to remove the layer of salts and limescale that forms on the surface of the mixer. Household chemicals or vinegar are used to remove foreign substances. The softened coating is removed with water, and then the surfaces are wiped with a dry cloth.

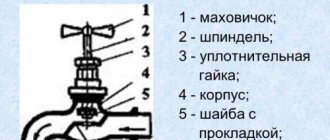

Valve tap

A classic faucet with a worm axle drive is used in budget-class faucets. Water may leak from the O-ring underneath the valve body or leak through the gap between the rotating stem and the faucet's outer shell. Due to a leak, liquid may leak or drip from the gander (with the taps fully closed). Before starting work, remove the plastic plugs from the heads and pry off the elements with a knife or scissors. It is recommended to place the parts on a shelf, since spare parts are not supplied with plugs.

The cause of faucet leakage in most cases is wear of the sealing gasket.

Description of actions step by step:

- Using a Phillips screwdriver, remove the screws securing the valve head. When unscrewing, difficulties may arise due to damage to the head (for example, during previous repairs). In this case, screwdrivers with different blade sizes should be used, and the screw must be replaced.

- Using a plumbing tool, unscrew the valve from its seat in the mixer body.

- Disassemble the tap; the parts are secured with a nut and a locking ring. Disassembly is carried out in a vice; an additional key is required for operation.

- Remove damaged gaskets and install new elements (factory type or self-made).

- Reassemble the assembly in the reverse order and screw the body into the mixer until it stops.

- Replace the head and then check the functionality of the equipment.

Ball mixer

The ball valve is characterized by reduced dimensions; the design uses a steel spherical element with a through channel. The position of the locking part is adjusted using a lever, which allows you to change the water pressure at the outlet of the gander. The design uses gaskets, and a bushing made of a special material is installed around the ball.

Sequence of actions when replacing gaskets in a ball valve:

- Using a sharp tool, remove the plug with the marking indicating the temperature of the water in the lines.

- Unscrew the fastening screw and pull the lever or wing off the slots.

- Using an adjustable wrench, unscrew the clamping nut.

- Clean the hole from salt deposits, and then pull the ball out of the seat.

- Remove the damaged ring.

- Install the original seal, which is located in the shaped groove. It is not recommended to use rings that are not intended for the type of faucet being repaired, since the connection will not be tight.

- Check the condition of the bushing; if increased wear or grooves are detected on the surface of the part, the unit must be replaced.

- Insert the ball into the standard socket, and then tighten the nut. After installing the control lever, you need to make sure that there is no water leakage.

To repair a ball valve, you need to understand its structure.

Single lever design

The single-lever mixer is characterized by reduced dimensions; the design uses a single cartridge with lever control. Deflection of the control allows you to adjust the water pressure and temperature. The lever design uses a fastening threaded element with an internal hexagon. After removing the handle, you need to unscrew the decorative cap and then unscrew the locking ring.

Then the cartridge is removed from the cavity of the mixer, under which there is an o-ring. It is recommended to visually check the condition of the cartridge; if damage is detected, the unit must be replaced. The mixer is assembled in the reverse order; the repair procedure is shown in the video.

Eternal mixer

I’ll tell you a secret: the need to frequently repair plumbing in your own home is very tiring even for professionals. Fortunately, it has long been possible to find faucets on sale that do not require periodic maintenance and have a long service life.

Which products are the most fault-tolerant?

Cranes

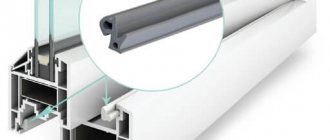

Ceramic valves do not have all the disadvantages of screw valves: they have no wear elements. Silicone gaskets between the non-rotating ceramic plate and the mixer body do not count, since they do not wear out during operation.

Ceramic crane box.

In my memory, not a single ceramic axle box has died due to natural wear: the cause of breakdowns has always been an attempt to forcefully close a tap jammed by scale or sand.

Hint: a coarse filter at the entrance to the apartment completely solves the problem of debris in the pipes.

Switch

The most reliable shower switch is a ball switch , which is a chrome-plated ball with slots and a seal with fluoroplastic rings. This type of switch is easily recognized by the absence of limiters on the handle: it rotates 360 degrees. I've never seen a ball switch fail; Moreover, I can’t even imagine how it can be broken.

The switch handle rotates 360 degrees.

Shower

The rubber core inside the shower hose armor inevitably loses its elasticity due to the salts and lime contained in the water. Having ceased to be elastic, it breaks or tears. However, this problem avoids plastic hoses : they simply do not have a core, the tightness is ensured by the walls themselves.

The only downside to plastic is that as it cools (when you take a cold shower) it becomes less flexible.

The faucet in my bathroom fully matches the description above.

Checking the correctness of the repair

Functionality check is checked by water supply. It is forbidden to turn on the flow at full pressure, since the liquid can damage or tear off the installed gaskets from their seats. The tap opens gradually at 50% of the valve stroke, and then pauses for 1-2 minutes. After this, the valve is smoothly turned in the direction of increasing pressure, while at the same time the absence of leaks is visually checked. After closing the tap, the mixer is inspected for leaks; drops of water and extraneous sounds from the body (humming) are not allowed.

After the tap is repaired, it is checked for leaks.

Repair of worm type crane

The cost of gaskets for such a mixer will not exceed 30 rubles on average. Such mixers were actively used in Soviet times, but are still on sale today, although not in such quantities.

Let's look at the structure of such a crane. Look at the photo below. We see that under the valves there are water supply mechanisms (taps), on which there are gaskets that we need to replace.

So, below is a diagram - instructions for removing the gasket, as well as a text guide.

Let's look at everything in more detail.

While disassembling the faucet, you can periodically take photos to make it easier for you to reassemble it later!

- The plastic plugs must be removed. They are only decorative, so even if you damage them, nothing bad will happen. Pry off the plugs with sharp scissors and set them aside.

- Now you need to remove the mounting bolt! It is located immediately behind the trim, unscrew it with a screwdriver suitable for the parameters, and then remove the wing, which is no longer secured.

- For the next step, grab an adjustable wrench. Carefully unscrew the core to which the gasket is attached, and then, using sharp scissors, remove the worn gasket.

- Now you need to clean the metal from oxides and other unpleasant deposits. To do this, you can use alcohol, window cleaner, or, in general, any mild solvent that you have on hand.

- We put on a new gasket. This must be done tightly so that no water leaks out!

- Now we assemble the faucet in the reverse order, open the valve going to the mixer and check. If all is well, the repair is complete! Well, if problems arise, then you should think about buying a new mixer.

When screwing the core back in, do not use too much force! You risk damaging the new gasket you just installed!

Let's move on to repairing the next type of crane.

Possible problems and their solutions

List of main problems that arise when replacing gaskets in a mixer:

- After installing the axle box or cartridge in place, water leaks through the gaps are observed. In this case, it is necessary to carefully tighten the threaded connection by 1/8 or 1/4 turn, and then check the tightness of the joint. It should be remembered that over-tightening increases pressure on the rubber gasket, it collapses, and water begins to leak again.

- Water leakage due to the destruction of gaskets made of soft or poor-quality rubber. The parts are destroyed by the metal edges when tightened with little force. It is recommended to purchase a set of rings from another manufacturer.

- Filtration of water from the tap assembly due to improper installation of gaskets or the use of non-standard elastic elements. If during the assembly process the rings are installed skewed, then the pressure of tap water squeezes out the parts, and water begins to flow from the faucet body.

- Error when identifying a defective element. For example, in addition to wear of rubber parts, metal structural elements may be destroyed. If, after replacing all gaskets and properly assembling the mixer, water continues to ooze from the gander or valves, then disassembling the device is necessary to search for damaged elements.

- Damage to the outer chrome surface of the mixer bodies and knobs using metal tools. To protect parts, a rag or cloth is used, which is placed on the surface of the mixer before starting repair work.

We repair a single-lever cartridge-type mixer

When you go into the toilet of a cafe or restaurant, you will rarely find a faucet there. Most often, a single-lever mixer is used. This is due to its elegance, convenience and simplicity, but even such a mixer is not immune from breakdowns. Let's look at possible repairs.

- Remove the decorative faucet plug and unscrew the screw that secures the lever. Then remove the lever.

- Under the lever you will find a ring - this is a protective screen, unscrew it by hand, the clamping nut will be visible - unscrew it with an adjustable wrench (counterclockwise).

- Remove the old cartridge from the faucet and insert the new one. Reassemble the faucet in reverse order.

The photo below will show what the cartridge looks like, as well as how to insert it correctly. Don’t be afraid to remove the cartridge, because it doesn’t matter to him anymore, it’s broken. Even if some part falls off, don't worry.

Most often, to save a single-lever faucet, it is enough just to replace the cartridge, but sometimes problems with it may remain, in which case it is necessary to call a professional, since the large number of parts and the complex design of such a faucet are not easy for most ordinary people to understand.

Recommendations from experts

Experts recommend using axle boxes and mixers made of non-ferrous metals (for example, brass). Steel structures with an external protective coating have a reduced cost, but are susceptible to corrosion.

It is not recommended to purchase products made from silumin, since the parts do not have high strength and are destroyed when exposed to water. There have been cases of destruction of the mixer body when unscrewing the axle box.

The most convenient mixer to use is the lever design with a replaceable cartridge. The equipment has a simple design; repair consists of replacing the O-ring or cartridge assembly. To increase the service life of the ceramic element, it is recommended to install filter elements that separate scale particles and sand from the water flow. Additional cartridges allow you to capture salts dissolved in water, reducing the amount of deposits on the surface of the mixer.

How to properly check the mixer for functionality after repair

To check the operation of the mixer, you do not need to immediately open the water all the way! This may damage newly installed components.

Never supply full water pressure to a faucet whose parts have recently been replaced!

First open the mixer halfway, then increase the pressure. Thus, you slowly increase the water pressure in small “steps”. Check the areas where the faucet is most likely to leak. Now turn off the water. Make sure that when closed the mixer does not whistle or drip. If so, then there is nothing wrong with your faucet.

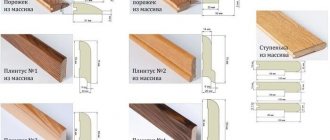

Types of gaskets for mixers. Plumbing gaskets

Over a long period of work, I have encountered a large number of issues related to sealing products - gaskets.

A large number of different types and types of gaskets, the problem of purchasing a larger quantity, the problem with the typology raises many questions... both in supply and in sales...

This topic really requires an article with a detailed discussion of the issue...

Types of materials for plumbing gaskets:

- rubber

- paronitis

- silicone

- fluoroplastic

By purpose:

- for radiator;

- for crane axle boxes;

- for mixer spout;

- for divertor;

- for ceramic faucet axle box.

*in this article, we will not consider rubber and paronite gaskets for flanges.

Rubber plumbing gaskets:

Rubber gaskets are the most common type of plumbing gasket in household plumbing.

Properties:

- high fatigue strength;

- low water permeability;

- low gas permeability;

- high resistance to abrasion;

- insulating properties in relation to electricity;

- cheapness.

Gaskets are made of monolithic rubber.

During operation, the gaskets wear out and require frequent replacement. Often, the rubber gasket is used only once (installation of a mixer line, water line.

It is recommended to compress the nut once, and in this case the tightness of the connection will be better; when compressed again, the properties of the rubber gasket are reduced, resulting in less tightness of the connection), do not reuse it, but replace it with a new one.

Conditions for using the rubber gasket:

The rubber gasket is installed in systems with pressures up to 25 bar (for conventional plumbing, such a rarity for a long time) and temperatures up to 100 degrees.

Paronite plumbing gaskets:

Paronite is the result of pressing asbestos, rubber and powder ingredients.

note

The main task of paronite gaskets is to seal plumbing connections.

Paronite gaskets are especially widely used when connecting flange joints, which is not the topic of our article. In household plumbing, this gasket is also widely used.

For example, complete with eccentrics for a bath-shower mixer, for sealing the connection between the mixer and diverter, etc...

Conditions for using paronite gasket:

Pressure up to 40 bar, temperature up to 200 degrees.

Silicone sanitary seal:

A more expensive material than rubber, it is actively used for the manufacture of gaskets in household plumbing.

Silicone gasket is an elastomer made from high molecular weight organosilicon compounds, similar in appearance to ordinary rubber.

Conditions for using silicone gasket:

Temperature - 100 + 350 degrees, pressure up to 500 bar.

Fluoroplastic sanitary gaskets:

One of the rare options for plumbing installation. Due to its properties, primarily chemical resistance, such a gasket is actively used in petrochemical pipeline systems. It has also found its application in heating systems, in particular - a gasket for an aluminum radiator.

One of the interesting properties of the fluoroplastic gasket is its non-twistability; in other words, even with strong twisting of the connection, the gasket will not be squeezed out. It will remain to seal the joints and retain its properties. Also, when replacing the connection, it is easily disconnected.

Conditions for using silicone gasket:

Temperature - 120 + 150, pressure up to 160 bar.

Gasket for crane axle box:

Rubber gasket “Step” of imported ceramic crane axle box

Rubber gasket “Step” of imported ceramic crane axle box

Rubber/silicone rings for imported faucet spout 14*19 mm

Rubber/silicone rings Ø 16mm for American 1/2 and for ceramic valve axle box

Rubber silicone paronite gasket for water supply 12 or 38

Rubber silicone paronite gasket for washing machine connections 34

Rubber silicone paronite gasket 1″

Silicone paronite gasket for intersectional radiator 1 14″

In this case, the main types of gaskets used in household plumbing are given. In addition to the gaskets themselves, there are various sets with gaskets... to be continued..

In case of emergency

We continue to consider how to replace the gaskets. Daily sanitary products tend to be poorly absorbent, which is why they won't be suitable if you suddenly get your period. To make a gasket from scrap materials, it is recommended to use only hypoallergenic

Another important condition is that the material must allow air to pass through well.

Microfiber, gauze, or flannel can be used as an absorbent layer. The simplest option, which does not require much time, is to make an envelope from natural hypoallergenic fabrics, inside of which an absorbent layer is placed. However, it should be remembered that this product can replace the gasket only for a short period of time, a maximum of an hour and a half. But this option will be ideal if you soon have the opportunity to purchase a standard gasket.

But how to replace pads during menstruation if the discharge is heavy? In this case, you will have to add an additional layer to the materials described above, which will have good water resistance. The simplest way is to use ordinary polyethylene. To do this, you need to cut the bag, after which it is placed under the fabric. If necessary, these two materials can be bonded. If you are at home, you can stitch them along the edges. When using homemade pads, it is recommended to wear underwear that fits snugly to the body and has elasticity. Thanks to this, the homemade gasket will not move or leak.

Preparatory activities

So that nothing distracts from the work process, you need to prepare everything in advance for disassembling and assembling the mixer, as well as for replacing faulty parts. You will need a set of tools:

- adjustable water wrench;

- hex key;

- knife;

- screwdriver;

- hammer.

In addition, you will need FUM tape, lubricant, and rags. It is necessary to buy new spare parts to replace old parts: for a faucet with one lever - a cartridge, ring seals, for a two-handle mixer - a faucet box. The most common gaskets are paronite gaskets. If this spare part is not at hand, you can make it yourself. For this:

- you need to take a piece of sheet rubber (microporous is not suitable, a heel pad will do) or leather;

- cut a circle with a diameter slightly larger than the valve seat;

- insert it in place of the old gasket.

For greater reliability, in the place where hot water is regulated, make a gasket from leather or from a piece of a tire with cord. Its thickness should be about 3.5 mm. If you cut the edge of the part at an angle of 45 °, then the noise when using the tap will disappear, because the gasket, in this case, is pressed more tightly to the saddle, due to which the mixer will work quietly.