A shower stall with a “roof” looks massive, the bathroom space is perceived as cramped and uncomfortable. Showers with floor drains look spacious and modern. To protect the room from splashes, it is enough to install a transparent tempered glass partition. This makes the bathroom look spacious and bright. In order not to create an emergency situation and not flood your neighbors from below, it is important to know how to make a shower drain in the floor correctly.

How to make a shower drain in the floor?

Ladders and their main features

Gangways vary in height, appearance and equipment. The grate installed on top of the drain device usually has a round or elongated shape. Materials are selected based on price and purpose. The longest-lasting gratings are made of steel. They are also made from chrome, glass, brass, and plastic. The latter are the most common, but the least durable. Plastic grates serve their purpose well, but will not fit into the interior of some showers.

But the grate is a matter of taste and a decorative thing; we carefully approach the choice of the drain itself. The ladders are divided into:

- Spot . They are a drain covered with a grate through which water flows out. Compactness allows you to install this type of drain anywhere.

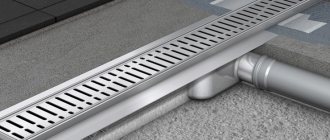

- Linear . Installed along the cabin or in the center, the water leaves evenly due to the drain in the form of an oblong tray.

Linear drain in the shower Source roomester.ru

Linear drains do their job best by distributing water throughout the drain. Accurate calculation of the drained water allows you to adjust the length during installation. Most often they are installed in common shower rooms with a high volume of water consumed.

The shower drain under the tiles consists of several parts:

- durable body;

- gratings;

- sealed drain funnel;

- siphon from unpleasant odors;

- outlet channel at the bottom for draining.

The material of the ladder depends on the nature of the purpose. Cast iron drains are used in bathhouses and swimming pools; despite their weight and complex installation, they are durable and do an excellent job of draining large amounts of water. In buildings subject to high sanitary standards, stainless steel drain holes are installed. It is not difficult to clean them from accumulated dirt and keep them in order. Anti-corrosion and durable plastic drains are perfect for home use. However, steel would be preferable.

Stainless steel drain Source metal-masters.ru

An important role in choosing a drain hole is played by its height. An acceptable value is from 45 to 190 mm. The higher the drain, the more efficiently it drains water. The heat-resistant under-tile floor shower drain copes with high temperatures up to 90 degrees Celsius.

A water seal installed in the siphon blocks odors coming from the sewer. But, if the shower is not used for a long time, the drain dries out and the siphon stops functioning. Therefore, it is important to choose whether to install a dry seal or a water one.

With a dry seal, the siphon will not allow odors to pass through due to additional seals that block the water drain with their weight. For example, it is usually installed when building baths. The sauna drain is an important element. The bathhouse drain forms a water seal and blocks the appearance of gases in the room. The dry bath ladder is manufactured in three variations: membrane, pendulum and float.

Wooden bath drain Source vagonkapol.com.ua

In production and cold rooms, drains are installed with a shutter that is resistant to sub-zero temperatures. It has a separate drainage ring through which drainage occurs if the waterproofing is broken.

When installing a drain hole, it is important to measure the diameter of the pipe from the sewer - it must match the diameter of the outlet pipe. This part of the drain can be vertical or horizontal. In private houses, sewer pipes are usually connected from below, so a drain with a vertical channel is installed. In other cases, a horizontal connection is suitable, which is considered universal for residential buildings.

Sequence of work

If the installation of the drain was planned before the renovation began, then the screed will allow the installation of sewer pipes below the level of the future floor. To complete the work you will need:

- Hammer or impact drill.

- Tile cutter

- Construction level and tape measure.

- Square, marker, ruler.

- Set of keys, screwdriver.

- Rules for arranging a screed.

- Spatulas for laying tiles.

- Tools for preparing screed.

As for the materials, you need to stock up on a plastic or metal drain of the required design and dimensions, a dry mixture for screed (the required amount can be calculated from the consumption amount indicated on the packaging), tiles, tile adhesive, grout for joints, as well as silicone sealant.

If the design of the ladder does not provide mechanisms for adjusting its height, use available materials

Perform the work in the following sequence:

- Remove the decorative grille from the drain and the container intended for collecting debris from the siphon.

- Attach the siphon itself to the drain. Make sure that the connection angle meets the required parameters.

- Cover all surfaces that will be visible after installation with construction tape. Carry out the same procedure with the siphon hole.

- Install the ladder fasteners.

- Connect a sewer pipe to the device with a slope towards the riser of at least 30 mm at a distance of one meter, and also connect the sewerage to the riser. In case of using a pass-through structure, attach an additional pipe at the required slope.

- Adjust the height of the ladder legs or use available materials to align the ladder in the desired position.

- Check all slopes and levels. We remind you that the grate should be at the same height or 1-2 mm below the tile level. The slope of the floor towards the ladder must be at least 10mm for every meter of surface.

- To ensure that the ladder does not subsequently move away from the screed, degrease its surface.

- Fix the drain with the required amount of solution and let the mixture set.

- If you want to increase the comfort when using the shower and install a heated floor system, carry out the necessary installation.

- Lay the screed taking into account the thickness of the tiles laid on the adhesive. If the design of the ladder provides for the installation of a flange, the screed is made flush with this structure.

- After the solution has completely set, cut out an apron gasket measuring at least 40x40 cm from the “isoplast” with a hole in the center with a diameter equal to the internal size of the flange and press its counterpart with screws.

- Lay the waterproofing, having previously cut a hole for the drain. If you do not install an apron, then simply treat the surface near the drain with a special primer for waterproofing.

- Lay the tiles on the adhesive and seal the seams with waterproof grout.

- Seal where the tile meets the flange using silicone sealant.

- Assemble the siphon and install the grille.

Waterproofing the drain is one of the most important requirements for its installation.

When laying tiles, work should begin from the ladder to the walls. It is better if, even at the design stage, the place for the ladder is selected taking into account the overall dimensions of the tiles and the thickness of the tile joints. This, as well as the use of square-shaped structures, will reduce the amount of cut tiles. By the way, you should only use moisture-resistant tiles and glue.

During the renovation process, tiling work is first carried out on the floor, and then on the walls, but not vice versa.

In this case, it is better to glue all corners near the floor with a special waterproofing tape.

To reduce the thickness of the screed, foam polystyrene slabs can be laid on the floor near the ladder. The density of such material must be at least 35 kg/m3.

Kits for installing drains, which have appeared in the retail chain in recent years, make it much easier to install a shower without a tray. In addition to the shower drain itself, such a kit includes a system of guides made of perforated metal-plastic. The design of the guides takes into account the necessary slopes, so the likelihood of errors is minimized.

A ready-made installation kit will help simplify the process of installing a shower drain as much as possible.

Acrylic or enameled steel flat trays for installation flush with the floor are also becoming popular. When installing them, a pit is selected under the drain, and channels are cut into the floor surface for the installation of sewer pipes, taking into account the required slopes.

Arranging a bathroom in accordance with new trends will not only allow you to enjoy the fashionable design of the shower stall, but will also make it easier for the elderly and disabled to take a shower.

Key criteria when choosing a drain

Drainage devices have a wide range and are distinguished by their diversity, so when choosing, it is worth taking into account the parameters on which the efficiency of the drain depends.

First you need to decide on the direction of the drain. The shower drain in the floor under the tiles with a horizontal outlet element has a small height and is used if the width of the screed is limited. A vertical drain can only be installed in a low-lying sewer system.

Drain with vertical drain Source snabsanteh.ru

See also: Catalog of companies that specialize in swimming pools and equipment.

The drainage capacity must be at least 0.4 liters per second. Recommended speed is 2 l/s. The wider the outlet drain tube, the better it allows water to pass through. The choice of valve in the siphon depends on the frequency of use of the shower stall. A water seal requires a constant presence of a small amount of water in the drain to protect the room from odors, while a dry seal blocks them in any condition.

The height-adjustable shower drain allows you to adjust the size during installation and precisely match it with the tiles on the floor. Cheap models do not have an adjustment function. Lastly, having decided on the functional parameters, they focus on the appearance of the installed grille.

How to choose

Having figured out what a drain in a sewer is, you need to select a sample for an apartment or other room. The main selection criterion will be the height of the podium or screed. If it is small, horizontal structures should be considered. For higher support platforms, vertical (straight) types are suitable.

The choice of material is made based on the load on the drain. If the drain is located under your feet and people will often step on it, it is better to use a steel sewer drain. This option is also good if the entire assembly is poured into the screed. If the drain is located near the wall and will not experience stress, it is easier to choose an inexpensive plastic product.

In addition, it is useful to choose devices with the ability to adjust the height (or depth of immersion in the hole). If the structure is vertical (straight), the size of its connecting pipe is usually 110 mm. For horizontal devices, 50 mm pipes are used.

Step-by-step installation instructions

It is easiest to install a drain for a shower stall under the tiles during construction, since its installation is indicated in the project. In the finished room, you will have to completely remove the flooring for high-quality installation. It is desirable that the sewer pipe is completely visible on the exposed base. Most often, houses have cast iron pipes, the service life of which has long expired, so it is recommended to completely or partially replace them with plastic ones.

Diagram of the installed ladder Source www.aco.hu

Required installation tools

Installing a shower drain in the floor under the tiles involves the construction of a moisture-proof floor covering. Buckets and a mixer will be needed to mix the solution. To apply it evenly to the surface, spatulas and trowels are used. When removing the floor covering, a hammer drill is used.

Full list of recommended tools:

- ruler with a long tape measure;

- tile cutters for tile covering;

- all kinds of screwdrivers and wrenches;

- wire cutters

The most important thing is that the drain is fully equipped, along with pipes and ceramics.

What kind of device is this, what functions does it perform?

A ladder with a dry gate is a modern and promising design that serves as a worthy alternative to traditional hydraulic ones. Dry drains are devices used to collect and discharge wastewater, and less commonly, melt and rainwater into the sewer system. The ladders also perform other functions:

- serve to connect plumbing equipment to the sewer system;

- filter wastewater before disposal.

Vertical siphon McAlpine with dry seal ø50 mm polypropylene MRNRV50-PB. Photo by Leroy Merlin

The design of the drain includes several elements, the main one being the siphon, in which the valve is located , i.e. a valve (damper) that performs the main function, namely, preventing the penetration of odors from the sewer system into the room. The removable gangway grille is the only element visible to the eye. Grilles can have different appearances and configurations, so they successfully perform a decorative function. The drain grate acts as a waste receptacle and prevents blockages. The outlet pipe is connected on one side to a dry siphon, and on the other to a sewer pipe. Through the outlet, wastewater goes into the sewer system.

Video description

How to properly apply insulation, watch the video:

Installation of floor slope and waterproofing

The finished insulation with the drain body is covered with a reinforcing mesh for the screed. To drain water, it is important to mark the slope for drainage. Therefore, special beacons are installed, which are sold in any hardware store. Sometimes, the ladder is already equipped with guide strips that are adjustable in length. They are assembled in the form of a frame, which simplifies the process of pouring the screed at a certain angle to the drain.

After installing the beacons and taking the necessary measurements, the floor is filled with a solution of cement and sand. The drain hole must be completely covered with solution; only the top, the flange, remains visible on the surface.

It is easiest to make a slope towards the tray drain due to its direction of drainage in one direction. To a point drain, the slope is usually made from 4 sides, which is technically more difficult. The screed is dried for 3-4 days. A waterproofing substrate is spread over the dried surface; isoplast is usually used. In this case, it is necessary to cut a hole for the outer hole and secure the material along the edges with screws.

Review of prices for different equipment models

The table provides a reference overview of prices for domestically produced models based on the results of monitoring offers from online construction stores.

| Type of equipment | Material | Average price, rubles |

| Horizontal with water seal | stainless steel | 2900 |

| plastic | 2200 | |

| Vertical with water seal | stainless steel | 4900 |

| plastic | 3700 |

Video description

The following video shows a model of a plastic shower drain:

Final work

A siphon is placed in the mounted drain body. A rubber sealing ring is placed on top, on which a decorative grille is placed. The height of the final flooring layer in the form of tiles is taken into account. It is important to carefully cut the tiles at the joints and use special tile adhesive. The coating dries within 2 days. The installation of the shower drain in the floor under the tiles is completed by eliminating the seams between the tiles.

Where is it used?

Drains with a dry seal are widely used primarily in showers, baths and saunas . Drains are installed under tiles or tiles. But the designs are suitable for installation in bathtubs and swimming pools, both individual and public. They are relevant in rarely used sewerage points, for example, washing machines and air conditioners.

McAlpine shower drain with dry seal. Photo Petrovich

They are installed in laundries, cutting shops of canteens and catering establishments, in laboratories and toilets. Manufacturers also offer drains for technical and basement rooms, boiler and pumping rooms, and ventilation chambers. Thus, ladders are used in residential, public and industrial buildings.

Briefly about the main thing

Shower stalls are popular for their convenience and practical design. An important element is draining the water. The drain in the bathtub flooring can be point or linear.

The ladder consists of the following elements:

- grates and funnels for draining;

- housings;

- siphon and outlet channel.

When installing a ladder, the material from which it will be made, as well as its shape, are taken into account. The throughput of the drainage device must be at least 0.4 l/s, optimally 2 l/s.

The installation process includes the following steps:

- Laying a joint pipe into a sewer pipe and pouring a screed.

- Installation of drainage and implementation of thermal insulation.

- Installation of siphon and grille.

You can do the installation of the drain yourself, although it will take more time.

Ratings 0 Read later

Installation of a drain system

The design of the shower drain system is associated with raising the floor level in the bathroom. To ensure the movement of wastewater towards the drain, the floor surface is made inclined by 15 cm or more. Floor installation will include the following steps:

- laying a layer of polystyrene foam 4-5 cm thick. It will provide noise and heat insulation;

- making a rough screed from a concrete mixture 4-5 cm thick;

- flooring of a sealed membrane made of floating waterproofing;

- making a screed from a concrete mixture to create a slope in the direction of the drain hole;

- laying ceramic tiles on an adhesive solution.

If you plan to cladding the walls, then for better waterproofing it is done after laying the tiles on the floor.

Installation diagram of a linear shower drain

As a result, the plumbing fixtures are built into the floor. The level of the grating should be lower than the level of laying the tiles. If the drainage system is installed in a room located above the basement, then the drainpipe is laid into the basement to the sewer pipe through the ceiling. For bathrooms that are located above living areas, installation is more difficult. The drainpipe must be laid in the floor. However, not all interfloor ceilings will be able to withstand the additional load.

Installed shower drain in section

Preparing for work

Before installing the plumbing drain, you need to calculate the thickness of all layers of the floor. The height of the equipment will determine the lowest point of the sloped floor surface. The recommended difference in floor level is 1-2 cm per 1 m of surface. If you perform installation with a smaller slope, the water will not have time to drain, and stagnation will form.

When choosing a place where you will install a plumbing drain yourself, you need to take into account the size of the floor tiles. The distance of the grate from the shower walls should be a multiple of the dimensions of the tiles, taking into account the tile joints. Floor tiles are laid from the center to the walls. This installation will minimize the amount of cut tiles; there will be only whole tiles in the center of the floor.

Thermal insulation and rough screed

To begin installing the drain system, connect the drain to the sewer with your own hands, adjust the height of the device and the level of inclination of the drain pipe. It is important to ensure reliable sealing of the joints with silicone sealant.

Then, polystyrene foam boards with a density of 35 kg/m2 are installed around the equipment on a concrete base. Expanded polystyrene provides noise and heat insulation. In addition, the insulator will prevent the occurrence of deformation processes in the screed during the interaction of low base temperatures and high temperatures of heated water. For a warm concrete base, the insulation layer does not need to be installed.

If the design of the ladder does not provide mechanisms for adjusting its height, use available materials

A cement-sand mixture screed is poured on top of the polystyrene foam. The thickness of the screed varies according to the height of the drainage equipment. The solution is carefully distributed around the outside of the equipment and the flange. The screed is leveled flush with the flange. As a result of pouring the rough screed, a durable surface is obtained that will well distribute the resulting mechanical loads.

Floor waterproofing

As a waterproofing material, you can choose the floating insulating material “isoplast”. The canvas is reinforced with fiberglass, elastic and can withstand mechanical loads well. Installation of adjacent panels is carried out overlapping. The joints are heated with a burner to soften them, then sealed hermetically. The isoplast pressed into the flange will act as a reliable seal.

When laying the material near the shower walls, an overlap is made on the wall to the level of the second screed. The edges of the canvases are heated and firmly glued. As a result of laying isoplast, a reliable waterproof membrane is obtained.

A siphon with a grille is installed inside the device body. A tight connection is ensured by an O-ring. When assembled, only one part of the plumbing equipment remains removable - the grate.

Waterproofing the drain is one of the most important requirements for its installation.

Finishing screed and finishing

A special feature of making an inclined screed for a plumbing drain is the absence of guides along which the cement mixture is distributed. They can be replaced with thin blocks of wood, but after drying they are dismantled. It is recommended to use guides made of plastic polymer; after the screed has dried, they will be used as expansion joints.

The guides are beveled similar to the angle of the floor. The width of the guide elements near the siphon should be lower than the height of the siphon by an amount equal to the thickness of the floor tiles. The joints at the corners are sealed with sealing tape for waterproofing. The grooves from the dismantled guides are sealed with mortar.

Floor membrane flooring

Pouring a screed with a slope

After the concrete mixture has dried, the final stage of installing the drain begins - laying the floor tiles. The lining material for the shower floor should not absorb water. For ordinary tiles, the allowed water absorption rate when completely immersed in water is equal to 11% of its own weight, for shower floor tiles no more than 1.5%.

It is recommended to choose ceramic tiles with a corrugated surface; glossy products are very slippery when wet. The tiles are laid using a special contact adhesive. After hardening, it forms a durable and strong adhesion of the tile to the floor. Moisture-resistant grouts are used to seal tile joints.

Ready shower drain

The plumbing drain is actively used for various premises. A drain system installed in accordance with all installation rules is safe for use. The equipment's water seal will eliminate the possibility of unpleasant odors entering the room.

Installation of a shower with a floor drain

Anyone considering a shower with a floor drain should first check to see if there is enough space in the floor to allow the drain to be recessed. Home craftsmen who decide to install such a shower themselves should remember that all joints between the wall, floor and drain must be waterproof.

Installation of a shower with a floor drain

The job can be done quickly and cleanly using a special fiberglass waterproofing sheet laid over a layer of regular tile adhesive. Then the floor and walls can be tiled on top. But here each manufacturer has its own installation instructions.

1. Part of the drain embedded in the floor rises above the base, since a plate of rigid foam about 4 cm thick will need to be laid on the floor. It will be covered with a concrete screed (the ready-mix is sold). | 2. The drain must be sealed. Therefore, the junction of the drain neck with the monolithic floor is carefully sealed. |

3. The slope is already provided in the cover plate, which is installed with a small amount of installation adhesive applied to the underside. | 4. The fiberglass seal between the shower element and the screed floor is sealed with regular tile adhesive. |

5. The fold in the corner provides a watertight connection to the wall. You can't cut the canvas here. The fold is carefully glued to the wall. | 6. Temperature expansions are compensated by means of a tile joint strip installed between the shower element and the monolithic floor. This prevents the seam from cracking. |

Purpose of emergency drainage

The emergency drain system is becoming more and more popular every year. It is recommended to install it when renovating an apartment, as it is not only convenient, but also allows you to successfully solve the following problems:

- remove excess water from the floor directly into the sewer;

- make a shower anywhere in the bathroom;

- reduce the risk of flooding of neighbors below;

- reduce damage from accidental plumbing leaks.

Installing an emergency drain also has its disadvantages. One of the main ones is that you will have to raise the floor level, which will reduce the height in the room. However, if the size of the bathroom allows this, then the design will become a reliable assistant and protection against surprises in the form of leaks.