A flexible water connection is a simple and optimal device for connecting a mixer to a water supply or water heater. A flexible hose for water supply combines plasticity and strength, is easy to install and can be installed even in the most difficult to reach places.

This device is a long tube through which water passes, with connecting elements at both ends for connection to plumbing products or water heating devices. One hose may have two nuts on both sides (nut-to-nut connection type) or a nut on one side and a fitting on the other (nut-to-fitting connection type). Based on this parameter, the product is selected for various types of connected devices. The faucet product can withstand high and low temperatures and is resistant to rust, so it will last for many years if the operating instructions are followed.

Types of flexible water line

To connect water to a water consumer, two popular types of flexible hoses are used:

Reinforced eyeliner

Reinforced flexible hose is a flexible hose, which consists of high-quality rubber and is covered with a special braid made of various materials. The mesh can be made of stainless steel, aluminum, galvanized metal. It is believed that a hose with nylon braid is guaranteed to fit any operating environment.

Bellows liner

Bellows flexible hoses are steel rings that are seamlessly drawn or pressed under high pressure and welded together. The rings are made of stainless steel. Compared to rubber hoses with metal braiding, they are inferior in flexibility. Wall thickness is about 0.3 mm.

Details

Features of sizes

Rigid connections for mixing devices have a length of twenty to fifty centimeters. The flexible hose can have a length of at least thirty centimeters, maximum two meters.

Connection options

There are variations of the connection node. It may consist of:

1. fitting with a union nut, internal thread with a cross-section of 1⁄2 inches.

2. a thread that is suitable for a mixer type M 10, or a half-inch union nut with an internal thread.

3. A non-standard type of connection is rare: in the form of an M 8 fitting, or a nut measuring 3/8 inch or 3/4 inch. To connect a faucet, sometimes you need an adapter or replacement of all plumbing.

Attention! The hose dimensions should be selected with a certain accuracy so as not to complicate the installation work by using non-standard designs.

Installation work

Having chosen the hose size, it should be connected, observing all the requirements.

If the installation is done incorrectly, the hose will not last long. It will have to be replaced. Things to consider when connecting:

1. At the beginning of the wiring, you should install a filter to improve the quality of the water, so as not to change parts frequently.

2.Before installation, the hose should be checked for defects on the sleeve, thread, and surface. If there are doubts about the condition of the elements, then it is worth repairing the part or replacing it.

3. The flexible hose does not tolerate strong kinks; the product should be installed carefully. The radius of bends should not be greater than six times the cross-section of the liner. Otherwise, the hose will be damaged and leak. The presence of small microcracks will lead to leakage in the near future.

4. If the fittings for the connection are tightly screwed, the tightness may be broken and the fitting may be damaged. When tightening, do not use excessive force.

Attention! Despite the presence of gaskets in the fittings, plumbing flax should be wound around the threads.

5. The fittings should be screwed into the holes on the mixer. The hoses are passed through the holes in the sink. To secure the faucet, clamp brackets are used. The hoses are connected to the water supply pipeline using nuts.

6.At the end of the work, you should check the tightness of the system. Turn on the water in the mixer and observe for leaks for twenty minutes. If there are no defects, then the system is working well. If leaks appear, the gaskets should be replaced, tow should be wound, and everything should be installed again.

Type of eyeliner

The connection to the mixer can be of a hidden or open type. The hidden method is chosen for the bathroom faucet. It is carried out during renovation, because it is necessary to trench the walls, or make a special box.

Hidden eyeliner needs to be done professionally so that you don’t have to break the wall again when making repairs. The open system is easy to install. It is necessary to screw the fasteners to the wall, then connect the mixer to the above diagram.

Nuances of selection and installation

To choose the right hose, you should follow the recommendations:

1.Each hose has a label with parameters containing information about the diameter of the product and connection method.

2.weight indicates the material from which the product is made. Aluminum parts are light, steel parts are heavier. Light weight usually indicates a low quality product.

3. if the fitting is made of plastic, then the hose is unreliable and will not withstand the load.

4.The product must be flexible. If the hose bends poorly, it means the product quality is low. Cracks will quickly appear on the surface.

5.press – sleeves are made of stainless steel; the products must fit tightly during high-quality pressing.

6.The material for the nuts must be of high quality, which can also be judged by the weight and thickness of the product.

7. The hose should not have a strong rubber smell. If there is one, it means the material is of low quality and will not last long.

8. The red marking indicates that it can be used for hot supply, the blue marking for cold supply. There are universal type hoses with stripes of two colors.

9. The hose must have a reserve length so that it is not stretched during installation. Often faucets are supplied with hoses fifty centimeters long, which is enough for installation in the kitchen. A length of one and a half meters is suitable for a bath. Some specialists use such hoses to increase the length; in this situation, an extra element appears, and therefore the strength of the system decreases. It is better to buy eyeliner of the required length.

Peculiarities

Flexible eyeliner has a number of features, among which the positive ones easily stand out. But negative nuances should also be mentioned in order to avoid an unpleasant aftertaste, a waste of time, effort and money.

The advantages of this flexible eyeliner:

- Complete tightness and protection against leaks;

- Saving space, allowing you to install additional interior items or equipment without having to worry about bulky pipes;

- Ease of changing the location of an object connected by a flexible liner;

- Refusal to use a welding machine;

- Protection of the hose from water hammer. That is, if a pressure surge occurs in the water supply system, a high-quality flexible line is protected from rupture and water leakage;

- Easy to install and operate.

Flexible hoses are typically used for various plumbing connections. Most often it is used in bathrooms (connecting a toilet, faucet, boiler to water) and in kitchens.

The best brands

Among most manufacturers there are the most popular companies. These include German companies Grohe and ProFactor, which produce high-quality products. The products are durable, reliable, but expensive. There is a brand from Italy called Remer, which is a competitor to its German counterparts. You can find fakes from this company; they do not include all the components for the mixer.

Among domestic brands, ST Giant eyeliner from Santrade is distinguished. Reviews about this product are mixed. The company produces products at different prices. Products of low cost are of poor quality, hence the different opinions of consumers.

The Spanish brand Industrials Mateu has high product performance and always controls its quality. Products are manufactured according to international quality standards. The Turkish company Rispa, founded in China, has an affordable price and fairly good quality. The product can operate uninterruptedly for many years. Therefore, if you have a limited budget, you can buy products from this company.

Rules for selecting and installing flexible stainless steel hoses

Flexible hoses braided from stainless steel are used to connect plumbing fixtures, plumbing fixtures, heating equipment and household appliances to water supply system pipelines. The connection with a fitting is used for direct connection to mixers. It is not allowed to use flexible hoses in a constant flow mode - instead of pipelines.

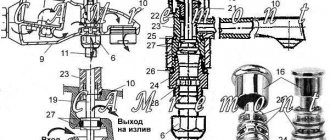

Step 1. Decide on the connection type

Eyeliner B-B

At the ends there are two nuts with internal threads. To connect, use key No. 22.

Eyeliner B-N

At the ends there are two nuts: one with an internal thread, the other with an external thread. To connect, use key No. 22.

Eyeliner with fitting

At the ends there is a long or short fitting. This type of liner is usually sold in pairs and is suitable for connecting a faucet. The fittings are made of different lengths for ease of connection. On one fitting the hexagon for the key is lower, on the other - higher. Wrench No. 10 and No. 22 are used, you can also use an adjustable wrench. It is unacceptable to use a gas wrench - it can damage the union nut.

Step 2. Decide on the length of the eyeliner

| Eyeliner | Possible length, cm |

| V-V or V-N | 20, 30, 40, 50, 60, 80, 100, 150, 180, 200, 250, 300, 350, 400 |

| With fitting | 30, 40, 50, 60, 80, 100, 120, 150, 200 |

Step 3. Buy and install eyeliner

Marking

The flexible liner is marked using colored tapes woven into the braid.

- Red - for hot water.

- Blue - for cold water.

- Red and blue are universal.

Recently, only universal-purpose eyeliner has been on sale.

Installation

Before installation, it is necessary to visually inspect the liner for the quality of the sleeve crimp, the quality of the end fittings, the presence of a gasket, the absence of damage to the thread, the integrity of the braid and the possible presence of other defects that may arise during storage and transportation of the product. Installation of flexible hoses with defects is unacceptable!

The connection nut in the flexible connection does not require any additional sealing. Reinforcing this area by winding flax or using fum tape is a common mistake that leads to cracks in the nut. In practice, the existing rubber gasket is sufficient. Sufficient access must be provided to flexible hose connections.

During the installation process it is not allowed:

- Exceed the tightening torque (see table “Technical Specifications”). If you use too much force, you can cut the gasket and the connection will leak.

- Twist the eyeliner.

- Allow tensile forces to be applied to the liner.

- Pull the liner through holes with edges that can damage the braid.

- Bend the liner to a bending radius less than the permissible one (minimum permissible radius 50 mm).

- Electrolysis is not allowed (when copper and iron come into contact). During installation, it is recommended to connect pairs: brass and brass, copper and brass, steel and steel.

After installation and supply of operating pressure, it is necessary to observe the operation of the liner for 30 minutes. If drops are detected at the joints, they must be tightened.

It is recommended to install a flexible connection along with the tap at the beginning of the connection, so that in the event of a breakthrough, you can quickly isolate the leak.

Installation

Installing the liner does not require any expensive tools, spare parts or seals. One adjustable wrench and a 10 mm open-end wrench are enough to connect the fittings to the valve body.

To connect the hose to the mixer, perform the following sequence of operations:

- Completely remove the old faucet from the sink, unscrewing the hoses from the water supply pipes.

- Connect the liner to the mixing body.

To facilitate the work, prevent the formation of limescale on the threads and in the future easily unscrew the hoses from the kitchen faucet when replacing it, additionally use any type of machine or technical oil. The fittings are coated with grease and screwed into the threaded holes of the body, lightly pressing half a turn with a flat wrench.

- Thread the faucet body into the mounting hole of the sink along with the hoses and fix it from below, depending on the design, with a union nut or a plate on a stud.

- Lubricate the threads of the water pipes with oil and screw the American hot and cold water union nuts onto the ends, lightly pressing them half a turn with a wrench.

- Turn on cold and hot water by turning the cartridge handle and make sure that the water supply is adjusted at the usual position of the handle. If the supply of cold and hot water is mixed up, turn it off in the apartment or using the taps under the sink, swap the hoses, twisting them on the pipes.

- Turn on the water and check the line for leaks using a piece of dry white cloth. It is passed along the braid from top to bottom; if water drips, the fittings or union nuts on the pipes are tightened at the mixer.

Stages of installing the water line

The most popular among consumers is the flexible water line for faucets with metal braid - its low cost justifies its service life of 10 years or more. Other types of expensive bellows and rigid connections, while reliable, do not always provide easy connection in limited space or are difficult to install with your own hands.

Operation and Maintenance

- The line must be operated without exceeding the parameters (nominal pressure and temperature of the working medium) set out in the “Technical Specifications” table.

- During operation, exposure of the liner to mineral oils, solvents, liquid hydrocarbons and other liquids that are aggressive to the liner materials is not allowed.

- It is prohibited to operate the liner at sub-zero temperatures and in close proximity to objects with a surface temperature of more than 200ºС and open fire.

- During operation, the liner should be protected from mechanical damage.

- The quality of tightening of the liner connections should be checked at least once every 6 months.

- When reinstalling the flexible hose, check the integrity of the rubber gaskets. Gaskets should be replaced if they are significantly worn or damaged.

Fitting

When installing any type of pipes during plumbing work, you cannot do without fittings, which also include all kinds of taps and valves. These can be soldered ball valves, straight or angle valves (with American type). Brass ball valves (crimp, with butterfly handle) are used, which are characterized by good anti-corrosion resistance. When connecting such a tap to a pipe, a split brass ring is used to crimp the pipe; rubber (ethylene-propylene) is used as a sealing material. Similar ball valves are three-way, with external thread, with internal thread, for connecting pipes at right angles.

Ball valve connection diagram

No special tools are required to install these faucets.

Specifications

| Characteristic | Unit change | Meaning |

| Operating pressure | bar | 10 |

| Maximum working pressure | bar | 20 |

| Maximum operating temperature | ºС | 100 |

| Inner diameter of rubber hose | mm | 8,5±0,5 |

| Braided hose outer diameter | mm | 12,5±0,5 |

| Capacity at 3 bar differential pressure | ºС | 100 |

| Maximum operating temperature | l/min | 35 |

| Minimum permissible bending radius | mm | 50 |

| Inner diameter of connecting fitting | mm | 6,2 |

| Recommended maximum tightening torque | N/m | 0,4 |

| Average service life | years | 10 |

Flexible hose design and materials

| Pos. | Item name | Material |

| 1 | Inner tube of flexible hose | Ethylene propylene rubber |

| 2 | Outer braid (8 steel threads) | Stainless steel |

| 3 | Connecting fitting | Brass |

| 4 | Union nut | Nickel-plated brass or stainless steel (depending on manufacturer) |

| 5.1 | Union | Nickel-plated brass or stainless steel (depending on manufacturer) |

| 5.2 | Connection for mixer (17/45 mm) | Nickel-plated brass or stainless steel (depending on manufacturer) |

| 6 | Crimp sleeve | Stainless steel |

| 7 | Sealing gasket | Ethylene propylene rubber |

Remember! It is not allowed to use flexible hoses in a constant flow mode - instead of pipelines.

How to choose a faucet hose?

Experts recommend that when choosing flexible hoses for installing plumbing fixtures in the kitchen or bathroom, pay attention to the following details:

- Having a label with the specified technical characteristics will help prevent mistakes. Make sure the diameter and type of fastener matches your equipment.

- Be sure to pay attention to the weight of the product; if it has an aluminum braid, the hose will be much lighter than one that uses steel (in most cases, such products have a fitting of dubious quality). As practice shows, they quickly fail, literally within six months, or even earlier.

- You should discard the liner if it is equipped with a plastic fitting; such a mount is not designed for the load required for domestic purposes.

- If the hose is insufficiently flexible, you should also not purchase it, since this sign indicates poor quality. As a rule, this causes several microcracks to appear in the braid, which can cause deformation.

- Pay attention to the sleeve press; stainless steel should be used as the material for them. It is important that their tubes are held tightly - this is an indicator of high-quality pressing.

- Check the design of the union nuts; if they are very thin or light, it means that this is a low-quality product and there is a high probability of problems when using it.

- Low-quality rubber has a sharp, characteristic odor; if you find one, discard this model, since such material will begin to leak quite quickly.

- When choosing hoses for hot water, do not make a mistake with the color marking; they should have a red or red-blue thread; those with a blue mark are not suitable.

- Choose an eyeliner of the appropriate length; it is not advisable for it to sag or be stretched.

- Many branded devices (for example, Damixa or Hansgrohe) include 50 cm hoses. To connect a faucet in the kitchen, the length is quite enough, but to connect other equipment they may be short, for example, the standard placement above the bathtub is 150 cm. In this case, you can remove them and screw on the liner of the required length or use it as an extension cord. The last option is not entirely successful. This is due to the fact that an extra connection will appear in the extended hose, which means reliability will decrease.

- Which product to choose, imported or domestically produced, does not really matter; we note that our products are sometimes better and more reliable than foreign ones.