Silicone-based sealants are quite popular due to the variety of types, simplicity, ease of use and moderate cost. These are reliable assistants for repairmen, builders, and ordinary people for working not only indoors. Such a sealing agent, having replaced putties, home-made mastics and bitumen mixtures, which partially satisfied the needs for hermetically sealing joints, simplifies the work and helps improve its quality.

Silicone-based sealing compounds allow you to create strong, moisture-protective layers that last for years without breaking down, look beautiful or are completely invisible.

Silicone sealants: types by composition

Sealing silicone materials are viscous-fluid masses of a dense structure, which are used for reliable joining of areas, sealing recesses, cracks, and gluing surfaces. This good quality product has a density of more than 0.8 g/cm3.

There are:

- single-component - sealing compounds are used more in construction work and repairs at the household level. When using such products, there is no need to mix. They are sold ready-to-use in masses in hermetically sealed tubes, tubes, and file bags. They harden quickly when in contact with air, provided that the layer thickness does not exceed 1.5 cm;

- two-component sealants (silicone compounds) - used more often in the industrial sector. Such professional compositions are offered by construction stores. They have no limits on the thickness of the application layer; they harden with the help of catalysts.

One-component silicone products can be:

- Alkaline - produced on the basis of amines. They have a special purpose.

- Acid - belong to the group of universals with low cost and marked “A”. Here, acetic acid is used as a base; specific aromas are clearly noticeable during the hardening period of the silicone. The negative aspect of this type is considered to be incompatibility with non-ferrous metals, most of them. The corrosion process accelerates. It should not be used for products made of marble and concrete structures where alkaline particles are present.

- Neutral - silicone sealing agents based on ketoxime or alcohol are used to work with any surface.

Materials for sealing with silicone rubber as a base may contain various additives that are responsible for a specific property.

- Plasticizers give the product elasticity;

- Vulcanizers transform paste-like compositions into elastic viscous masses that structurally resemble rubber;

- Natural extender additives are used to reduce the viscosity level of the silicone mixture;

- Fungicides are used to combat bacteria, fungus, and mold;

- Mechanical fillers (adhesion primers) achieve better adhesion. These include quartz dust, chalk;

- Amplifiers provide high strength indicators;

- Coloring pigments make products colored during the production process.

When choosing an assistant to create an airtight layer, you should focus your attention on the additives it contains.

Areas of use of sealing agents

The scope of application of heat-resistant sealants is quite extensive. There are special compositions for different jobs. We list some areas where the use of thermosealants would be justified:

- for the repair of food equipment in manufacturing enterprises and kitchen household appliances, special food sealing thermal compounds have been developed that can withstand heat

- for sealing water and heating pipes (here it must withstand not only high but also low temperatures)

- for repair of electrical and radio engineering products (including as electrical insulation)

- in automotive repair to create sealed seams in the engine, muffler, headlights, etc., to create anti-corrosion protection

- for repair and processing of welds on gas equipment

- for repair of ventilation structures, fireplaces, chimneys, stoves, fire-fighting equipment

- to create a water-repellent coating on parts made of various alloys

Types of silicone sealants by purpose

There are several types of silicone sealant depending on the location of application.

- The automotive type of sealant is used for repairs, various technical works, changing gaskets in cars, and when assembling car parts, including the engine. As a rule, preference is given to black, red, and blue. Among the features of black automotive sealant are the following:

- resists the effects of antifreeze liquids, machine oils, water;

- can withstand temperatures up to +300 degrees for a short time;

- does not spread;

- resistant to the aging process.

The red silicone cures when exposed to moist air. Heat-resistant red compounds are suitable for installing electrical system elements, assembling pumps, industrial furnaces, engines, and heating systems. In addition, they are used in the design of bathrooms and the construction of chimneys.

They are characterized by:

- lack of fluidity during application;

- adhesive structure;

- the ability to remain elastic, resilient at temperatures within the range of -50°C – 300°C.

- The sanitary type is a waterproof silicone product that is suitable for work in rooms with high humidity levels - in bathrooms, toilet rooms, saunas, baths, kitchens, swimming pools. Such sealants seal threaded connections of water pipes, seal bathtubs, showers and other plumbing fixtures. This product prevents the appearance and development of mold and mildew. There are many colors in the palette, so everyone can choose what they need for a particular occasion.

Possess:

- resistance to detergents with aggressive components;

- the ability to maintain protective properties during long-term use;

- ability to withstand temperatures up to +180°C for a short time.

- Universal silicone products are designed for sealing cracks in window frames made of plastic and wood. Transparent formulations are popular for these purposes, although there is a choice of other color options.

In addition, they seal:

- glass,

- cable channels,

- joints and cracks,

- ventilation systems.

Also used for ceramic tile joints.

They are characterized by high adhesion rates and are not afraid of exposure to precipitation and light.

- The electrical insulating type is used in repair work, assembling electrical equipment for reliable sealing and gluing.

- Aquarium mixtures are water and heat resistant. They are not toxic. This type of sealant is used to hold together parts of aquariums when repairs are necessary. These compositions dry quickly, do not pose a threat to aquarium inhabitants, and have high adhesive ability. They are used in most cases where glass, ceramic elements and parts need to be fastened.

- Heat-resistant silicones are often used in the industrial sector; they are used to fasten components of pumps, motors, heating devices, etc. They cannot do without this type during electrical installation.

If you want to get good results when working with silicone sealing materials, choose the type according to the task at hand. Then, in the future, there will be no problems, since the correctly selected mixture will qualitatively hold the parts together, isolate them from moisture, etc.

Types of high-temperature sealing substances according to release form

Manufacturers mainly produce oven sealants for household use in tubes. They are used together with a construction gun. Manufacturers offer formulations in small tubes especially for treating small areas. The sealing material is squeezed out of them by simply pressing.

More often, single-component sealants are used for stoves and chimneys in residential buildings. They are used without any prior preparation. Such compositions require more time to dry compared to two-component substances. This allows you to correct errors made during installation.

Manufacturers produce two-component sealants in the form of a set consisting of a paste and a hardener. The components of the sealing material are mixed in accordance with the proportions specified in the instructions.

A two-component sealing agent is used in industrial facilities Source ad-cd.net

Characteristics

The properties of silicone sealants depend on their purpose. When choosing a silicone sealant, you should be interested in the following characteristics:

- Elasticity. In silicones it is at a high level;

- Durability. Decent performance under tensile loads;

- Cohesion (adhesion) ability. Well seals connections of ceramic, glass surfaces, as well as wood, concrete, metal;

- Indicators of resistance to ultraviolet radiation, as well as products with aggressive components for cleaning and washing. Silicone has no problems here;

- Heat resistance. Depends on the species.

Pros:

- Silicone sealing compounds from the sanitary group have special fungicide additives that turn the layer into a “shield” against bacteria and fungal infections;

- Tear-resistant coatings created using silicone sealing materials can be cleaned with products containing harsh chemicals. But only after final hardening;

- Do not lose elasticity and elasticity during temperature changes, severe frost (up to -50°C) and heat (withstands up to +200°C, heat-resistant - up to +300°C);

- It is stretchable, so the product can be used for areas with mobility;

- The material, after complete hardening, is able to withstand fairly intense loads. This is due to the presence of silicon in such compositions. The layer is strong and elastic. The silicone layer, due to its elasticity, can be said to compensate for deformation. In this case, temperature and mechanical fluctuations do not threaten destruction;

- Can be used for various surfaces;

- They have good grip performance. Silicone is used to glue different materials together.

#

Flaws:

- According to a number of construction experts and repairmen, some of these products have problems with joining polyvinyl chloride, fluoroplastic surfaces, as well as products made of polyethylene, polycarbonate and polypropylene;

- The presence of components of inorganic origin (especially when there are a lot of them) prevents painting with conventional types of paints;

Areas of surfaces where the sealing agent is planned to be used must be properly prepared - pre-cleaned, treated with a degreaser and completely dried. For the most part, it is not recommended to apply sealants to wet surfaces, as they may lose their properties.

#

Sealing of stove and fireplace masonry and pipes

In order not to spoil the appearance of the brickwork, masking tape is applied to all surfaces, except for the seams or cracks that are to be treated.

Before installing the glue cartridge into the gun, its nose is cut at an angle and so that the diameter of the hole is smaller than the width of the seams.

Further work is carried out according to the standard scheme:

- preliminary surface preparation (cleaning, abrasive treatment, drying and degreasing)

- The sealant is squeezed into the gaps until they are completely filled.

- leave the composition until it dries for 24 hours (for heat-resistant sealants this process is faster: the composition is fired with a gas burner, which helps harden the mass)

To prevent the masonry from cracking immediately after repair, before using it at full capacity, you should gradually warm up the structure, avoiding sudden and high heating. In the future, the ovens can be used as usual.

Where to apply?

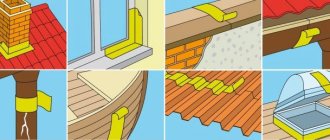

Silicone sealants are used in construction, repairs, and interiors. Their help is used when performing work indoors, for outdoor work and in places where it is very humid and damp:

- when installing mirrors;

- when installing plumbing fixtures, seal the contact areas;

- if it is necessary to connect parts of devices and equipment in which heating to high temperatures is expected;

- when glazing, when double-glazed windows are being installed, window sills are installed, including those made of natural stone;

- when joining the ceiling to plasterboard slabs;

- when facing, when you need to attach vinyl materials;

- when laying both natural and decorative stone;

- when creating glass structures;

- for laying pipes for the sewer system, water supply;

- during construction, roof repair;

- for installing shower cabins for their sealed connection to the wall.

As you can see, the scope of application of a silicone-based assistant is extensive. But this list is often replenished with items, as new ideas for using such a universal material are generated in the minds of professionals in the field of repair and construction. Often, ordinary owners of square meters come up with interesting, effective solutions to everyday problems using these silicone-based products.

#

Consumption

In order for the repair to be done efficiently and all seams and joints to be sealed beautifully and reliably, it is important to know exactly how it needs to be applied and how much material to use. When calculating the most correct consumption of sealant per 1 m of seam, you need to know its thickness and application technology. If we are talking about a corner seam between the bathtub and the tiles, then the best would be a depth of 6 mm and a width of 3 mm. Using such calculations, 20 ml of material will need to be used per meter of area. Often the standard package contains 310 ml, and in order to apply it correctly and economically, it is best to be guided by the indicators given in the table:

| Seam width in mm | |||||||

| Seam depth in mm | 5 | 7 | 10 | 12 | 15 | 20 | 25 |

| 5 | 12 | 8 | 6 | — | — | — | — |

| 7 | — | 6 | 4 | 3 | — | — | — |

| 10 | — | — | 3 | 2.5 | 2 | 1.5 | — |

| 12 | — | — | — | 2.1 | 1.7 | 1.2 | 1 |

| 15 | — | — | — | — | 1.3 | 1 | 0.8 |

If a 600 ml bag was chosen for the work, then the calculations will be different for 1 m of seam:

| Seam width | |||||||

| Seam depth | 5 | 7 | 10 | 12 | 15 | 20 | 25 |

| 5 | 23 | 15 | 11 | — | — | — | — |

| 7 | — | 11 | 7 | 6 | — | — | — |

| 10 | — | — | 6 | 5 | 4 | 3 | — |

| 12 | — | — | — | 4 | 3 | 2.4 | 2 |

| 15 | — | — | — | — | 2.5 | 1.9 | 1.4 |

For a more economical use of sealant, it is better to apply a semicircular seam, which is possible when working with a spatula having an edge of 6 mm; in addition, it is very important to correctly trim the nose of the tube itself, from where the material will come. To do this, you need to attach the spatula to the spout at an angle of forty-five degrees and open the package.

Silicone-based sealant: how to use?

In order for the work done to have a good result, you should follow the instructions for using the building material. Sealing will not cause problems if you know the nuances of the application technique. The key to ensuring that the sealant will be applied correctly, and this is important for extending the service life of the silicone layer and seam, is the prepared surface. The first step is to remove the old layer, if any. It doesn’t matter what kind of sealant you plan to use - a colorless compound or a colored mass, the surfaces should be thoroughly cleaned of various contaminants. Cleaning procedures are carried out using alcohol, acetone, solvent, or a special sealant remover. Next, the treated surface must be given time to dry completely. This usually takes no more than half an hour. In some cases, it is advisable to treat the area where the sealant is applied with a primer, which will improve bonding and adhesion.

When all the preparatory work is completed, feel free to proceed to the main task. First you need to cut off the cap (professional craftsmen recommend a 45-degree cutting angle when filling small and large seams). To fill a gap of equal thickness along the entire length, the best option is when the diameters of the gap and the cut are approximately the same. Thanks to this, the sealing compound can be distributed more accurately and evenly.

Treatment of surfaces and seams with silicone sealant will be successful if you take into account the above and follow the algorithm of actions:

- Before starting work, it won’t hurt to change into work clothes or a construction uniform. Be prepared for it to get dirty. You can work with silicone without protective equipment, but it is not recommended to neglect safety precautions;

- At the first (preparatory) stage, the surfaces to be treated are cleaned of dirt, dust, degreased, and dried;

- The second stage involves directly applying a layer of silicone to the joints or other areas of the surfaces being treated. The workflow requires strip continuity. Application according to all the rules allows you to get smooth, sealed seams. They are conveniently sealed using silicone mass dispenser guns. They are “charged” with tubes with sealant, the ends of which are pre-cut and a dispensing tip is put on. Next, the flow of the product is adjusted;

- After applying the composition, you should level the filled surface, which is convenient and quick to do with a spatula. Don't forget to remove excess silicone from surfaces with the same spatula or a damp cloth. Hands can be rinsed in soapy water;

- If you need to remove excess silicone after drying, use solvents. But you can remove excess mechanically.

Colored, white and colorless compositions are applied the same way. Unused silicone sealant can be stored for 5-6 days. But you should release a small amount of sealant and quickly close the tube or bottle, securing it securely with mounting tape. Any cool place where there is no access to direct sunlight is suitable for storing previously opened substances.

#

Application rules

The sealant is applied to a clean, grease-free surface.

The base is cleaned of dust, oils, and dried. For degreasing, use gasoline, solvent, and acetone. Smooth surfaces are sanded to increase adhesion. Paper tape is glued along the edge of the joined planes which is removed after the seam is opened.

Operating procedure:

- the nose of the tip is cut at 45° so that a strip of the required thickness is extruded;

- the tip is unscrewed along the thread and a hole is made in the tube so that the mass comes out, then put on again;

- the cartridge is installed in the gun, the paste is squeezed into the seam by pressing the trigger;

- fill the gap tightly, since the sealant does not expand during the polymerization process;

- Use a spatula to shape the applied strip (within 15 minutes after application).

Recommended strip width is 6 – 30 mm, depth – 2 – 12 mm. Excess mass is removed with a damp sponge or cloth. High temperature sealants are not toxic materials, but the room must be ventilated during operation.

How long does silicone sealant take to dry?

After applying the composition, the film appears in about 15-20 minutes. The mass does not stick to your hands when touched, but this is only the initial stage of polymerization of the composition. Complete drying of neutral compounds based on silicone with alcohol occurs within approximately one day. Acid silicone sealants dry in 4 to 8 hours. Some compositions can dry in 1-3 hours. There are some nuances here. How long it takes for silicone-based sealants to completely dry (harden) is affected by:

- The thickness of the layer applied per 1 linear meter means that a thinner layer will dry faster;

- type of product by component composition;

- density of the sealing mass;

- ambient temperature (optimally from +5 to +40 degrees);

- place of application. A hard-to-reach area with no air circulation takes longer to dry than the surfaces of a ventilated room.

The average hardening time of the silicone mass to a depth of 2 mm is approximately 24 hours. Knowing the thickness of the layer allows you to calculate the time for complete drying. During the process of drying and hardening of the mass, it is necessary to create optimal conditions by protecting it from changes in environmental temperature, dust and mechanical influences.

When it is not possible to wait a long time for final polymerization, you can speed up the hardening. Effective and proven methods:

- Raising the room temperature using heaters or thermal pillows, but not higher than 40°C. Higher temperatures may degrade the properties of the formulations;

- Providing circulation of air masses. Faster drying can be achieved by normal ventilation of the room;

- Increasing air humidity is also an effective way. Since silicone cannot come into contact with water during the polymerization period, spraying the sealant with a spray bottle or steam treatment will help.

Only proper acceleration of the curing process of silicone products is permissible. Otherwise, the material may collapse and lose properties.

#

Rating of the best

Today there are more than 200 brands of silicone sealants. Not all of them meet the stated characteristics.

In order not to be mistaken in quality, we offer a list of manufacturers and brands of adhesives that have long proven themselves:

MAKROFLEX NX108

Transparent silicone sealant MAKROFLEX NX108 is a one-component waterproof composition. Has the widest range of uses. It is used for fixing and sealing joints of elements in bathrooms, saunas, swimming pools, and sealing cracks. With its help, installation and repair of refrigerator and freezer units, repair of ships (motor boats, yachts) and automobile units are carried out. Sealing of window and door openings.

Produced in Russia using Finnish technology. Application temperature from 7 to 45 ˚C. Wide operating temperature range from -38 to +140 ˚C. Setting time 15 minutes, until complete drying 48 hours. The neutral chemical composition does not cause corrosive changes in the material. Packaging: a convenient tube with a cone dispenser. Package price 290 gr. – from 280 rub.

Moment Silicone neutral

Moment Silicone neutral – gray one-component adhesive. High-quality and reliable domestic composition. Used for installing mirrors, glass, ceramic, sanitary ware in bathrooms, showers, and lavatories. Suitable for repairing refrigeration and ventilation systems, watercraft, and automotive components. Not recommended for working with natural stone and aquarium equipment.

Application temperature from 7 to 40˚C. Operating range from -38 to +140˚С. Setting time 15–20 minutes. Does not stain mating surfaces. Time until complete curing is 48 hours. Resistant to UV rays. Available in a tube with a 280 g dispenser, package price starts from 280 rubles.

CERESIT CS 24

Universal silicone sealant CERESIT CS 24 is an acidic one-component adhesive. Designed for processing the perimeter of door and window openings, shop windows, double-glazed windows, colorless. Resistant to the formation of fungal and mold deposits. Can be used for exterior work without primer.

Produced in Russia using German technology. Not for use on surfaces made of zinc, copper, iron, marble, limestone. Application temperature from 10 to 35˚C. Operating range from -40 to +120˚C. Curing time 20 minutes, until complete setting 48 hours. Price per package (tube with dispenser) 280 g. from 220 rub.

Liqui Moly "Silicon-Dichtmasse"

Black silicone sealant Liqui Moly “Silicon-Dichtmasse”. German brand Liqui Moly, specializing in the production of automotive oils and lubricants. A one-component, high-temperature composition, which, upon polymerization, forms sealing connections between elements made of glass, wood, plastic, and porcelain. It is used for repair and maintenance of automobile components, watercraft, installation and gluing of glass parts.

Resistant to vibration loads. Application temperature from 5 to 40˚C. Operating range from -60 to +300˚C. Film formation time is 8–12 minutes, until complete drying 24 hours. Price for 80 ml packaging. from 500 rub.

Ravak Professional X01201

Ravak Professional X01201 is a transparent sealant from the Czech manufacturer of plumbing fixtures of the same name. It is designed for sealing plumbing fixtures and lining materials in bathtubs and showers. Retains antifungal properties for a long time. Reliably fixes aluminum, acrylic, glass, stone, ceramics, varnish. Non-toxic, does not change color over time.

Temperature for installation is from 10 to 40˚C. Operating range from -20 to +120˚C. Curing time 20 minutes, until complete adhesion 48 hours. Sold in tubes with a 310 ml dispenser. Package price from 720 rub.

Popular brands

Since 2022, TK Ant-Snab LLC has been the official partner of the Belgian company Soudal in the Moscow region (Moscow and the region). The history of this world-class manufacturer of products dates back more than 50 years of successful work.

Soudal sealants are popular due to a wide variety of types, packaging, and packaging along with good characteristics. We recommend using time-tested sealing materials that have long proven their best performance:

- Soudal sealant is a product that is produced taking into account the requirements of the ISO 9001 quality certification system. The modern technological base ensures excellent performance characteristics and harmlessness.

- Profil sealant is a product of the Economy line of Soudal. The low price of the product is due to a decrease in the volume of filling, but not to a deterioration in the characteristics of the materials. Sanitary and Universal sealing products are produced.

Silirub sealant is a neutral one-component product from Soudal. Depending on the area of application, they are produced: Silirub 2, Silirub AC (for glass and windows), Silirub Color (the palette is pleasing, allowing you to find the best options for any surface color), Silirub AQ (for aquariums and display cases), Silirub sanitary is not produced like this, You can add Silirub Cleanroom, it is used for sterile areas (kitchen, bathroom and places with high humidity).