Automotive sealant is a paste-like or viscous composition that is applied to joints to prevent leakage of the working fluid (liquid or gaseous) through the gaps. When used correctly, this composition can eliminate the leakage of coolant, water, oil and other automotive fluids. It can also be used to bond various surfaces and fill cracks.

Quickly curing polymer sealants have a number of advantages, practical benefits and economic benefits compared to traditional sealing agents. They are quite easy to use and available for purchase, and their properties make them indispensable in extreme and emergency conditions.

Types of sealants

The main task of any modern automotive sealant is to eliminate all kinds of leaks, punctures, cracks and gaps. Despite the large selection, you should take the purchase of a quality product seriously, having studied the characteristics, chemical composition and temperature conditions of each brand on the market.

Sealant for a car can be classified according to many criteria, but the most extensive of them are: by composition and by area of application.

By area of application, sealants are distinguished for glass and headlights, bodywork, exhaust systems, threaded connections and others. Based on their composition, sealants are divided into anaerobic, silicone, synthetic and ceramic.

What parts is compatible with

It is very important to know which elements can be sealed and which cannot. It’s quite easy to make a mistake that will lead to breakdowns or complete destruction of the structure.

The gasket can be used for:

- Repair of optical elements. With it you can restore the integrity and tightness of the headlight.

- Glass inserts. The windshield or rear glass must be completely sealed, so when gluing, you need to use a high-quality product.

- Replacement of gaskets in the engine. The engine design contains many small elements and connections that constantly wear out. In this case, the sealant will help maintain the integrity and seal the entire engine.

- Fixing a punctured tire or wheel.

- Preventing refrigerant leaks in air conditioners.

- Processing seams of the body part.

Anaerobic

Anaerobic sealants are a special class of compounds consisting of dimethacrylate esters with the ability to polymerize without access to oxygen.

These materials harden upon contact with metal surfaces in narrow gaps where atmospheric oxygen does not enter. If at least one of the specified conditions is not met, the sealant will remain in a liquid state. This property is often considered an advantage, since time during operation is not limited, installation can be carried out without fear of the material hardening.

In order for the anaerobic composition to polymerize, it is necessary to tightly connect the surfaces of the parts to eliminate excess oxygen. Once such a sealant gets into a narrow metal slot, it will harden in 25-30 minutes, turning into a solid polymer.

The advantages of anaerobic compositions also include high resistance to aggressive chemical environments, vibrations, pressure changes and temperatures. The composition also prevents the formation of corrosion, oxidation, gas and liquid leakage.

A disadvantage of the material is the filling of relatively small gaps from 0.05 to 0.5 mm. To polymerize the composition on non-metallic surfaces or at low temperatures, an activator will be needed.

Popular Products

To choose a good automotive seam sealant, you should pay attention to the most famous and high-quality products on the market.

Merbenit XS55

It is a high-strength sealant for the hood, underbody and other parts of the body on a modified silicon base. It has enormous tensile strength (4 N/sq. mm), excellent adhesion to metal and plastic. In addition to sealing seams, it can be used when installing climate control equipment and ventilation. In factory conditions it is used in the automotive industry, carriage building, and in the production of polymers. The advantages of the sealant are undoubted:

- perfect filling of even the smallest cracks,

- possibility of painting the finished seam,

- absence of harmful solvents and unpleasant odors,

- resistance to water, salt, oils, alkali and acid solutions,

- tolerance to vibration, shock, atmospheric influences.

BODY 999

Body 999 sealant can be found at any automotive store. It is considered one of the most common and is sold in 150 ml tubes, 300 ml cartridges, and 1000 ml cans. A polyurethane-based product is used to fill voids and treat machine welds to protect against water and the harmful effects of atmospheric factors. The sealant is great for metal, plastic, and painted surfaces, but it should not be applied to areas exposed to ultraviolet radiation.

The advantages of the material are:

- maintains elasticity for a long time,

- does not shrink

- does not flow on vertical surfaces,

- can be applied even in a thick layer and not crack,

- has a high degree of adhesion to surfaces,

- ready to use, does not require dilution,

- Can be painted after drying.

3M 08537

3M automotive seam sealant is also made on the basis of polyurethane. This is a one-component composition, available in black and white, considered universal and suitable for:

- panel connections,

- sealing weld seams,

- processing of arches, thresholds, doors,

- sealing the bottom, joints inside the trunk,

- shock absorber mountings,

- strengthening bolted connections.

The product has a brush application method, is liquid and is available in metal cans. It is resistant to oils and petrochemicals, highly elastic, not afraid of water, does not shrink, maintaining its structure for several years, and dries quickly. After final polymerization, the seam will be hard, but quite elastic. 50 minutes after application it can already be painted with any paint.

Terostat 9320

Teroson line sealant Terostat 9320 is considered a universal “4 in 1” product. This is a sprayable one-component composition based on modern modified polymers, which hardens under the influence of moisture from the air. It comes in black, gray and ocher colors.

After polymerization, the Terostat adhesive-sealant forms an elastic, abrasion-resistant seam, which in appearance will not differ from the factory one. The material has a high degree of adhesion to metals, is compatible with any paints, primers and primers, is resistant to UV radiation, shrinkage, sagging, aging, and hardens quickly in air.

Novol Gravit 630

Novol Gravit 630 sealant is a one-component polyurethane product used for sealing welded joints and soldered areas. It creates an elastic and very durable shell that does not shrink, crack, or wrinkle over time. Novol sealant has good adhesion to metal, as well as to varnished sheet metal. The finished seam can be coated with acrylic paints. The product is applied with a special gun. Its only drawback is its low resistance to ultraviolet radiation.

Reoflex Brush Sealant

Reoflex brand brush sealant is designed for sealing any seams on metal, concrete, wood, and is widely used in body repair. It has high anti-corrosion and sound-proofing properties, is easy to apply and dries quickly. After polymerization, the sealant forms an elastic seam, externally close to the factory one.

Bool

Bool brand polyurethane adhesive-sealant is available in cartridges for a 310 ml gun. It is widely used to strengthen seams between sunroofs, headlight holders, metal parts, and gutters. The finished seam can be painted with all types of varnishes. The product is sold in white, beige, black colors.

APP PU50

This material is one-component, made on the basis of polyurethane. APP has a high degree of adhesion to primed and painted metal, stainless steel, glass, all types of plastic, concrete and aluminum. In body repair it is used to seal welded joints. The method of application of the material is special: you must first put it on the seam in the form of a roller, then spread it with a spatula or brush.

Silicone

For personal non-professional use, silicone sealant is more suitable. The composition of the material gives it high elasticity and strength. Silicone sealants differ in the level of elasticity of the resulting sealing layer, temperature conditions, and, for application to glass, in color range.

Polymerization of the sealant occurs due to the moisture present in the air; the average curing time is about 10 minutes, during which it is necessary to install the part.

Silicone-based sealants are oil-resistant and heat-resistant, withstand temperatures up to +300 °C. They can be used for most engine components. The material fills gaps up to 6 mm thick and is resistant to high pressure and operating speeds.

When working with silicone high-temperature sealant for a car, it is necessary to thoroughly clean the parts to be joined, which is a slight disadvantage.

Instructions for applying sealant

To effectively seal the engine cylinder head, before applying the sealant, the surfaces should be cleaned of old gasket residue, carbon deposits, rust, oil and contaminants. Then degrease them (with solvent, white spirit, purified gasoline) and dry them.

The sealing agent is applied to one side of the assembled assembly manually or by screen printing. The layer should be uniform.

The silicone sealant needs to be given time to “set” (about 15 minutes), and only then press the parts tightly.

With an anaerobic composition, elements can be bonded at any time.

Synthetic

Synthetic sealants for cars are made on the basis of synthetic resins. The composition of the material makes it a universal product that can be used to seal most elements.

Synthetic sealants are a relatively new material that has not yet gained much popularity among auto mechanics and car enthusiasts.

However, this material has a number of advantages:

- High elasticity

- Resistance to high humidity, ultraviolet radiation, mechanical damage

- High adhesive properties, which avoids pre-treatment of the original surface before using the sealant

- Ease of use

- Multifunctionality and versatility

Some auto mechanics and car enthusiasts cite its versatility as a disadvantage of the material. Many people prefer narrow-profile sealants designed for specific elements and components of the car.

How to choose a sealant gasket

Experts note a number of technical parameters that every sealant that replaces vehicle gaskets must have.

This list included:

- Levels of viscosity indicators.

- Thermal resistance properties.

- Resistant to vibrations and high pressures.

- Good elasticity.

- Long service life.

- Drying speed.

- Filling depth.

- Resistance to temperature changes, especially high ones.

Ceramic

Ceramic sealants are based on synthetic substances with the addition of ceramic components that increase the strength and heat resistance of the material.

This type of sealant is highly specialized and is used for repairing and sealing the exhaust system with minor breakdowns and a small gap of up to 3 mm.

Ceramic sealants are used to work with connecting pipes, catalysts, cracks, burnouts on metal, especially on the upper casing, which is rarely repairable.

Selection based on application efficiency

When selecting a sealant, take into account the location of the joint of the mating parts and the temperature background in the joint area. For example, in exhaust systems with catalytic converters and oxygen concentration sensors, it is prohibited to use pastes with acetic acid, which destroys the layer of sensitive material.

When sealing the joints between the head and the cylinder block, mixtures with increased resistance to temperature influences are used.

When restoring the body, special seam sealants are used, which are applied with a spray or brush. The materials are based on rubber and fill small pores and cracks, protecting the metal from the effects of water and aggressive substances.

The hardened sealant retains elasticity and is resistant to vibration loads; the surface allows the application of paint and varnish.

The applied paste should not flow from vertical surfaces and should not crack or chip during polymerization or forced heat treatment.

Sealant selection criteria

The properties, composition and scope of application of the sealant are the key criteria when choosing them.

The purpose and operational features of liquid sealants are determined by their composition and their constituent components. You should immediately pay attention to several parameters of the material, the most important of which are oil resistance and temperature range.

To seal the engine, it is necessary to select special high-temperature materials capable of operating at temperatures up to +360 °C. For other components located under the hood, a heat resistance of +200 °C is sufficient. Other elements do not heat above +150 °C.

The shape of the package, volume and curing time of the automotive sealant also matter when choosing a material. Some formulations are available in plastic or aluminum tubes with a dispenser. This form is more convenient and economical to apply. For products produced in special tubes, a gun or other additional tools may be required. You also need to pay attention to the expiration date of the sealant. A large volume is more cost-effective, but if it is not used immediately, it will deteriorate or dry out after a while.

In the service book for new cars, the manufacturer often indicates what materials can be used. Branded sealant will be more expensive than analogues, but guarantees high quality assembly of all components.

The purpose and functional characteristics of automotive sealants depend on the area of application of the material. This will result in different levels of durability, colors and production volumes of the formulations.

Valve cover sealant requirements

The main characteristic that a sealant must have is heat resistance. A good product should work at elevated temperatures, and the more heat it can withstand, the better. Other requirements for sealants:

- Resistance to chemicals and petrochemicals. The sealant should not deteriorate from aggressive compounds: transmission and engine oils, brake fluid, solvents, antifreeze.

- Tolerance of vibration, mechanical loads, low temperatures. If the strength and elasticity are insufficient, the seam will quickly crumble. The sealant must be frost-resistant, because it will also work in winter when the car is in the garage.

- Ease of application. Sealing the valve cover is quite difficult, so the packaging of the product must be as comfortable as possible for work. Small cans have proven to be the best for application, while hard tubes like toothpaste, on the contrary, are inconvenient.

- Optimal volume. If you only have to seal the valve cover, a minimal amount of sealant will be used, and there is no point in buying a large package of the product.

You also need to monitor the expiration date - it must be normal, otherwise the sealing properties may decrease.

Glue for glass and headlights

A sealant is used to repair and install the headlight. The composition and manufacturer must be selected according to the recommendations specified in the service book. It is also worth considering what material – glass or polycarbonate – the headlights and glass are made of. Many sealants are incompatible with polycarbonate and can destroy it.

The color of the material does not affect its properties. Automotive sealant, black and transparent, will have the same characteristics, although from an aesthetic point of view, the latter are more often used for headlights and glass.

Before applying and replacing sealant, it is necessary to carry out preliminary preparation of the surface and get rid of the old material. To do this, the material is preheated with a technical hairdryer. The heated sealant can be easily cut with a sharp knife or a thin flat screwdriver. It is recommended to carry out this work in stages to prevent overheating of the plastic. After complete cleaning, a new composition is applied.

Which brand to choose

Now the market is overflowing with different brands, both high-quality and not so good. To avoid getting a low-quality product, choose the following manufacturers:

- LIQUI MOLY – Germany.

- ABRO - America.

- JETAPRO is a European concern.

- IGLASS - UK.

- DONE DEAL – Germany.

- HI-GEAR - America.

- GERA - Russia.

For exhaust system

The exhaust system operates at fairly high temperatures, and the muffler experiences the greatest load.

The following negative factors affect the system, leading to destruction and burnout:

- Elevated and high temperatures

- Aggressive gas and chemical environment

- Oscillations and vibrations leading to premature wear

- Mechanical damage when hitting possible obstacles on the road

A heat-resistant automotive sealant gasket is suitable for repairing the exhaust system. When using it, clamps and pipes will not stick to each other, and the sealing of the connections will be reliable.

Sealants in the form of paste, glue and cement (including ceramic compounds) are best suited for repairing the rounded structures of the exhaust system - the pipes connecting the cavities, catalysts and other parts.

What's the result?

As can be seen from the above, cooling system sealants from well-known manufacturers can be a good solution in emergency situations. Most of the commercially available compounds cope well even with large damages up to 1 mm, that is, if a microcrack appears, there should be no problems.

Also, the performance of the cooling system is not particularly affected. It turns out that pouring sealant should not be a case where you can only aggravate the situation and overheat the engine after using special equipment. However, using sealant in cars solely for prevention (without leaks) is also not recommended, because unwanted deposits appear one way or another.

Finally, we would like to add that you should not rely on the sealant for long-term use. At the first opportunity, the system needs to be repaired, that is, replace damaged parts, check the functionality of the pump and thermostat, rinse all the elements as thoroughly as possible, and then fill in with new antifreeze from a good manufacturer.

And also, regarding the sealant for the cooling system pipes. In practice, it is recommended not to use this solution, although pipe leaks often appear in the seats. In this case, it is better to replace the worn pipes and clamps with new ones. If the pipes are “fresh” but leak after removal, then you need to securely tighten them with clamps. The fact is that sealants do not cope well with cracks in rubber elements; in the case of plastic, the result may also be unsatisfactory.

Thread liquid glue

Threaded connections in cars are subject to temperature changes and vibrations, which can cause problems with their self-unscrewing. To prevent such situations when installing connections, you can use a liquid thread adhesive-fixer.

This type of sealant prevents arbitrary unscrewing of threaded connections without the help of auxiliary materials and mechanical fasteners. It has fixing and sealing properties, preventing moisture, oxygen and contaminants from entering the assembly.

The most popular materials are anaerobic fixatives. Their curing occurs in narrow metal gaps without access to oxygen. How long such a material dries is determined by its viscosity and the conditions under which installation is carried out. The average time to achieve initial strength is about 10-30 minutes.

Other parameters influencing the choice

If the car owner decides which sealant to purchase to repair units, then you need to pay attention to the following:

- Packaging. Most manufacturers supply materials in an elastic tube with a conical spout. The master cuts off the tip, ensuring that the paste is applied in the required amount. If the sealant is packaged in a plastic cylindrical container, then a construction gun will be required for application.

- Packaging volume. After the protective membrane is punctured, the sealant inside the tube begins to harden. To reduce repair costs, it is recommended to purchase material in the required quantity.

- Before starting use, it is necessary to analyze the recommendations of the plant that manufactured the vehicle. A number of enterprises do not recommend using pastes instead of standard gaskets, since foreign materials clog the lubricant or coolant supply channels.

What sealant is suitable if the radiator is leaking?

It is recommended to use sealant to eliminate radiator leaks only as a temporary measure if it is not possible to call a tow truck or contact a car service center. The sealant will temporarily fix the problem, but it should not be used on a permanent basis. It impairs the passage of antifreeze through the radiator, reducing the efficiency of heat transfer, which increases the engine temperature and creates the risk of overheating.

Most radiator sealants are made from natural organic ingredients and come in a powdery form. They are low cost, but contain large flakes that can clog system pipes.

Another type of sealant is created from metallized polymers. They, together with antifreeze, circulate through the cooling system, and polymer particles cling to the edges of the leaks, closing them. This composition does not settle, does not clog the tubes and is easily removed. Sealants of this type have one drawback: they can only eliminate leaks of small diameters, not exceeding 1 mm.

If a leak is detected while driving or parking the car, the procedure for using sealants should be as follows:

- If a leak occurs, turn off the engine and allow the coolant to cool.

- Apply automotive sealant following the instructions on the label.

- Start the engine for a few minutes, turn it off and check for leaks

- If the leak cannot be eliminated, this means that the hole size is too large. In this case, it is recommended to call a tow truck and contact a car service center.

When should you change the gasket?

Every engine has a valve cover that is attached to the cylinder head with several bolts. Between the cover and the head there is a rubber gasket that can withstand sudden temperature changes and exposure to technical fluids. Over time, the gasket wears out - its elasticity decreases and small cracks appear. As a result, oil begins to leak into the engine compartment, after which dust and dirt adhere to the spots.

Installing the cylinder block cover on a car engine

To avoid the appearance of stubborn stains, you need to change the gasket in a timely manner and monitor the condition of the engine as a whole. It is usually recommended to do this after 7,000–15,000 km, which virtually eliminates oil leaks and prevents problems with the engine and timing belt. There are other situations in which it is necessary to change the rubber gasket (usually together with repair of the cylinder head (cylinder head)):

- Burnout between combustion chambers. Occurs due to weak contact pressure due to improper tightening of bolts or overheating of the engine. Signs: a violation of the cold start of the internal combustion engine, instability of the warmed-up engine.

- Penetration of exhaust gases into the cooling system and heating of antifreeze. Signs: air bubbles in the expansion tank, white exhaust, frequent turning on of the cooling fans.

- Oil getting into the cooling system. Signs: traces of oil in the expansion tank, under the radiator cap.

- Loss of gasket tightness. Appears when it is installed incorrectly or temporarily worn out. Signs: oil stains on the engine.

In addition, the rubber gasket must be replaced during any repair of the cylinder head, engine, or during maintenance of the timing belt. During installation, sealants are used to improve insulation and enhance the service life of the seal.

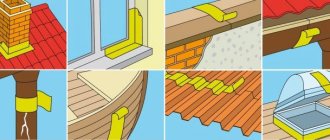

Types of body sealants and application

There are several types of sealant, the choice of which should be made based on the intended work.

The most common types are:

- Suture (in a tube). This is the most popular polyurethane sealant for bodywork and seam sealing. To apply it, a special gun is used: mechanical or pneumatic

- Suture (under a brush) - available in cans, consists of a one-component composition, but is applied with a brush. Most often used for filling butt seams, welding seams or gluing body metal elements. Most often it is used to connect the engine compartment and other elements invisible from the outside.

- Adhesive based sealing tape. It ensures the creation of a perfectly even seam, does not require drying, so it can be painted immediately

- Sealant in a tube - suitable for small jobs, as it is produced in small volumes. It is available in different colors, has all the characteristics of the above materials

Main types of cylinder head gaskets

In modern engines, the cylinder head gasket not only performs a sealing function, but also ensures load distribution.

The following types of gaskets exist:

- Asbestos - quite elastic, can withstand high temperatures, and can be additionally reinforced with metal rings; main advantage - low price, disadvantages - instability to vibrations and rapid aging

- Non-asbestos gaskets are a common type of gaskets that are more expensive than asbestos ones; At the same time, they are more resistant to deformation and last longer

- Metal (bimetallic) - consist of several layers of metal or metal with a sealing elastomer; Such multilayer steel cylinder head gaskets (abbreviated MLS) are most often equipped with modern cars

To achieve 100% sealing and increase the life of the cylinder head gasket, special sealing compounds have been developed. When applied under pressure, they create a thin continuous layer that levels the surface. The permanent residual tack of the sealant helps to accurately position and hold even heavy metal gaskets in place.

What to use

Automotive manufacturers produce a wide range of sealants. Substances differ in composition and rate of hardening. Which sealant to place the engine sump on is chosen depending on the purpose, versatility and quality of the product.

"Stop-flow"

Sealants of this category are intended for engine lubrication systems; they are poured directly into the engine. The composition does not allow oils to leak out of the engine. One of the most popular products is Hi-Gear 9041 (or 9043) Engine Sealant. Does not come into contact with an aggressive oil environment, restores the elasticity of oil seals and seals, and is suitable for preventive purposes. Hi-Gear engine oil system sealant is compatible with different types of motor oils, the scope of application is gasoline and diesel internal combustion engines.

Metal-ceramic sealant eliminates antifreeze leakage through the cylinder head gasket. You can repair aluminum and cast iron cylinder heads so as not to use welding. It withstands vibrations, shocks, deformations, high temperatures and pressure, and is in normal contact with engine oil and coolant.

Loctite 574

Loctite cylinder head sealant is produced by the famous brand Henkel. It is an anaerobic flange compound that hardens at temperatures between +15 and -25°C. Loctite 574 is used to fix metal surfaces, but access to oxygen must be prevented for complete polymerization of the substance. It is best used for hermetically sealing parts with a minimum technological gap, tightly pulled together.

Dow Corning Q3-1566

The highest quality and most effective American-made product. It is the best sealant for engines and has impeccable heat resistance characteristics - from -70 to +345°C. Scope of application: cylinder head, transmissions, water pumps, manifolds.

The product is resistant to motor oils and does not withstand the effects of antifreeze, water, or lubricants. It has good resistance to vibrations, shocks, deformations, and overheating (but you should not “boil” the engine). The product can be used to prevent internal combustion engine depressurization.

ABRO 11-AB

A classic example of good quality at an affordable price. Red (ABRO 11-AB universal engine sealant) - it can be used for almost all power units and components of the car, as an effective sealant. Main advantages:

- The maximum temperature resistance limit is up to +343°C.

- Waterproof, neutral to aggressive environments.

- Good resistance to mechanical stress.

ABRO 11-AB allows you to form a fairly strong elastic layer on the treated surface that can withstand any load.

FÖRCH K157

The FÖRCH K157, K158 and K161 series of motor anaerobes have good characteristics. The substances work effectively under conditions of high temperature extremes and high pressure, when the engine experiences extreme loads. Areas of use: motor flanges, threaded connections.

Among the advantages of FÖRCH sealants are elasticity, adhesion and sealing strength, and chemical resistance. But for the composition to completely harden, it requires exposure to high temperatures from +80 to +100°C. Use strictly for its intended purpose, does not replace the gasket between the cylinder block and the cylinder head.

The brand's silicone sealants, K165-167, have good properties for sealing the engine oil pan. The main characteristics are good adhesion and elasticity of the coating.

Victor Reinz

Two main compositions are popular - REINZOPLAST (blue) and REINZOSIL (gray). The characteristics of the substances are almost identical, but for internal combustion engines Reinzoplast is preferable:

- Neutral when reacting with oils, antifreeze, fuels and lubricants, water.

- Retains properties even with sudden temperature changes from -50 to +250°C.

- Short-term withstands extreme exposure to +300°C.

Victor Reinz sealant is a universal sealant for the engine pan, with a high hardening speed (10-15 minutes). It is enough to apply the composition to a previously prepared surface, wait the prescribed time, and then install the gasket. After half an hour, you can start the engine.

Elring

The manufacturing company produces effective and durable motor sealants Dirko HT and S Profi Press HT with similar properties. Perfectly withstands aggressive influences of oils, fuels and lubricants, water, antifreeze. Particularly resistant to mechanical and stress and strong vibration, withstand temperatures ranging from -50°C to +220 +250°C, for a short time - up to +300 degrees.

The manufacturer’s line includes another sealant, Dirko Spezial-Silikon, specifically designed for treating automotive oil pans and crankcases. Works well with surfaces subject to strong vibrations. It takes 5-10 minutes for the composition to harden.

Table 1 shows sealants that are also suitable for sealing internal combustion engine parts and their main advantages

Table 1. Engine sealants

| Product name | Type | Peculiarity | Advantages |

| Permatex Anaerobic Gasket Maker | Anaerobic | Aluminum surface treatment | Vibration resistance, elasticity |

| CYCLO HI-Temp C-952 | Silicone | Metal parts | Strength and reliability of the connection |

| Curil K2, Curil T | Silicone | Crankcase | High temperature resistance |

| MANNOL 9914 Gasket maker RED | Silicone | Cylinder head | Neutral to aggressive media |

| Soudal | Polyurethane | Engine oil pan, flanges | Fast hardening time in its product group |

| Hylomar M | Polyurethane | Universal application | Resistance to technical liquids |

Packaging and equipment

For convenient use and storage, sealants are packaged in small tubes. The packaging ensures long-term preservation of the valve cover sealant. Most manufacturers produce products in compact tubes, up to one hundred grams. To make it convenient to apply the sealant to the oil pan, the tubes are equipped with caps with dispensers, which has undeniable advantages:

- Fixed amount of composition.

- Uniform distribution on parts.

- Preservation of qualities and properties for a long time.

To use the gasket sealant again, it is enough to remove some of the dried product from the dispenser with a sharp, thin object before repairing the engine. Professional compounds for service stations and repair shops are produced in bulk packaging, and the products are applied with a pistol.

The best sealants for an anaerobic engine

Anaerobic sealants are designed to seal joints between engine components (for example, when installing a water pump housing), as well as between power unit crankcases.

When using materials, it should be taken into account that the gap width should not exceed 0.2-0.4 mm; if this condition is violated, the quality of the connection deteriorates.

Automotive anaerobic sealants are chemically inert and can withstand prolonged contact with heated petroleum products and coolant.

Permatex 51813

The Permatex 51813 pad former is packaged in a plastic elastic tube with a capacity of 50 ml (price from RUB 999). The material is used to seal joints up to 0.4 mm wide and withstands contact with gasoline, motor oil and antifreeze. The polymer retains its strength characteristics during prolonged heating to +204°C.

Advantages:

- high quality of the formed seam;

- ability to fill gaps with increased width (in accordance with manufacturer's tolerances).

Flaws:

- counterfeit products are found;

- polymerization is slow.

Loctite 574

Loctite 574 is designed to seal rigid flanges (such as the interface between engine and transmission housings). Hardening occurs inside the joint in the absence of atmospheric oxygen; the seam can withstand heating up to +150°C.

The material is not destroyed under the influence of fuels and lubricants; the permissible gap between mating planes is 0.25 mm.

Advantages:

- high connection strength;

- filling the gap with a width increased to 0.25 mm.

Flaws:

- the need to clean and degrease the surfaces to be joined;

- high price (from 2.4 thousand rubles for a 50 ml plastic bottle).