Automotive sealant is a paste-like or viscous composition that is applied to joints to prevent leakage of the working fluid (liquid or gaseous) through the gaps. When used correctly, this composition can eliminate the leakage of coolant, water, oil and other automotive fluids. It can also be used to bond various surfaces and fill cracks.

Quickly curing polymer sealants have a number of advantages, practical benefits and economic benefits compared to traditional sealing agents. They are quite easy to use and available for purchase, and their properties make them indispensable in extreme and emergency conditions.

Types of sealants

The main task of any modern automotive sealant is to eliminate all kinds of leaks, punctures, cracks and gaps. Despite the large selection, you should take the purchase of a quality product seriously, having studied the characteristics, chemical composition and temperature conditions of each brand on the market.

Sealant for a car can be classified according to many criteria, but the most extensive of them are: by composition and by area of application.

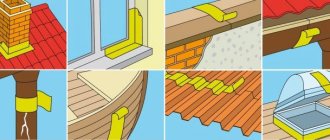

By area of application, sealants are distinguished for glass and headlights, bodywork, exhaust systems, threaded connections and others. Based on their composition, sealants are divided into anaerobic, silicone, synthetic and ceramic.

What parts is compatible with

It is very important to know which elements can be sealed and which cannot. It’s quite easy to make a mistake that will lead to breakdowns or complete destruction of the structure.

The gasket can be used for:

- Repair of optical elements. With it you can restore the integrity and tightness of the headlight.

- Glass inserts. The windshield or rear glass must be completely sealed, so when gluing, you need to use a high-quality product.

- Replacement of gaskets in the engine. The engine design contains many small elements and connections that constantly wear out. In this case, the sealant will help maintain the integrity and seal the entire engine.

- Fixing a punctured tire or wheel.

- Preventing refrigerant leaks in air conditioners.

- Processing seams of the body part.

Anaerobic

Anaerobic sealants are a special class of compounds consisting of dimethacrylate esters with the ability to polymerize without access to oxygen.

These materials harden upon contact with metal surfaces in narrow gaps where atmospheric oxygen does not enter. If at least one of the specified conditions is not met, the sealant will remain in a liquid state. This property is often considered an advantage, since time during operation is not limited, installation can be carried out without fear of the material hardening.

In order for the anaerobic composition to polymerize, it is necessary to tightly connect the surfaces of the parts to eliminate excess oxygen. Once such a sealant gets into a narrow metal slot, it will harden in 25-30 minutes, turning into a solid polymer.

The advantages of anaerobic compositions also include high resistance to aggressive chemical environments, vibrations, pressure changes and temperatures. The composition also prevents the formation of corrosion, oxidation, gas and liquid leakage.

A disadvantage of the material is the filling of relatively small gaps from 0.05 to 0.5 mm. To polymerize the composition on non-metallic surfaces or at low temperatures, an activator will be needed.

Silicone

For personal non-professional use, silicone sealant is more suitable. The composition of the material gives it high elasticity and strength. Silicone sealants differ in the level of elasticity of the resulting sealing layer, temperature conditions, and, for application to glass, in color range.

Polymerization of the sealant occurs due to the moisture present in the air; the average curing time is about 10 minutes, during which it is necessary to install the part.

Silicone-based sealants are oil-resistant and heat-resistant, withstand temperatures up to +300 °C. They can be used for most engine components. The material fills gaps up to 6 mm thick and is resistant to high pressure and operating speeds.

When working with silicone high-temperature sealant for a car, it is necessary to thoroughly clean the parts to be joined, which is a slight disadvantage.

Synthetic

Synthetic sealants for cars are made on the basis of synthetic resins. The composition of the material makes it a universal product that can be used to seal most elements.

Synthetic sealants are a relatively new material that has not yet gained much popularity among auto mechanics and car enthusiasts.

However, this material has a number of advantages:

- High elasticity

- Resistance to high humidity, ultraviolet radiation, mechanical damage

- High adhesive properties, which avoids pre-treatment of the original surface before using the sealant

- Ease of use

- Multifunctionality and versatility

Some auto mechanics and car enthusiasts cite its versatility as a disadvantage of the material. Many people prefer narrow-profile sealants designed for specific elements and components of the car.

How to choose a sealant gasket

Experts note a number of technical parameters that every sealant that replaces vehicle gaskets must have.

This list included:

- Levels of viscosity indicators.

- Thermal resistance properties.

- Resistant to vibrations and high pressures.

- Good elasticity.

- Long service life.

- Drying speed.

- Filling depth.

- Resistance to temperature changes, especially high ones.

Ceramic

Ceramic sealants are based on synthetic substances with the addition of ceramic components that increase the strength and heat resistance of the material.

This type of sealant is highly specialized and is used for repairing and sealing the exhaust system with minor breakdowns and a small gap of up to 3 mm.

Ceramic sealants are used to work with connecting pipes, catalysts, cracks, burnouts on metal, especially on the upper casing, which is rarely repairable.

Sealant selection criteria

The properties, composition and scope of application of the sealant are the key criteria when choosing them.

The purpose and operational features of liquid sealants are determined by their composition and their constituent components. You should immediately pay attention to several parameters of the material, the most important of which are oil resistance and temperature range.

To seal the engine, it is necessary to select special high-temperature materials capable of operating at temperatures up to +360 °C. For other components located under the hood, a heat resistance of +200 °C is sufficient. Other elements do not heat above +150 °C.

The shape of the package, volume and curing time of the automotive sealant also matter when choosing a material. Some formulations are available in plastic or aluminum tubes with a dispenser. This form is more convenient and economical to apply. For products produced in special tubes, a gun or other additional tools may be required. You also need to pay attention to the expiration date of the sealant. A large volume is more cost-effective, but if it is not used immediately, it will deteriorate or dry out after a while.

In the service book for new cars, the manufacturer often indicates what materials can be used. Branded sealant will be more expensive than analogues, but guarantees high quality assembly of all components.

The purpose and functional characteristics of automotive sealants depend on the area of application of the material. This will result in different levels of durability, colors and production volumes of the formulations.

Error 2. “Patch the leak without disassembling it”

Silicone sealants ideally polymerize in thin layers between two planes. This is their main task, and it is for this that they are created. But often they try to use sealants to seal a leak of oil, antifreeze or other process fluids from a crack in a pipe, fitting or permanent joint (such as rolled radiator elements), simply by spreading the sealant over the leak point. This application is completely useless... The sealant does not adhere to uncleaned and wet surfaces, and it is almost impossible to perfectly clean a leak of this type. The leak cannot be eliminated like this, and the sealant is not to blame - it is simply not designed for this... Anyone who works a lot with adhesives and sealants knows that the final result directly depends not only on the quality of the glue, but to no less extent on the quality of surface preparation. In the instructions for any silicone composition of any brand, the first line says: “Apply only to a clean and dry surface!”

Glue for glass and headlights

A sealant is used to repair and install the headlight. The composition and manufacturer must be selected according to the recommendations specified in the service book. It is also worth considering what material – glass or polycarbonate – the headlights and glass are made of. Many sealants are incompatible with polycarbonate and can destroy it.

The color of the material does not affect its properties. Automotive sealant, black and transparent, will have the same characteristics, although from an aesthetic point of view, the latter are more often used for headlights and glass.

Before applying and replacing sealant, it is necessary to carry out preliminary preparation of the surface and get rid of the old material. To do this, the material is preheated with a technical hairdryer. The heated sealant can be easily cut with a sharp knife or a thin flat screwdriver. It is recommended to carry out this work in stages to prevent overheating of the plastic. After complete cleaning, a new composition is applied.

For exhaust system

The exhaust system operates at fairly high temperatures, and the muffler experiences the greatest load.

The following negative factors affect the system, leading to destruction and burnout:

- Elevated and high temperatures

- Aggressive gas and chemical environment

- Oscillations and vibrations leading to premature wear

- Mechanical damage when hitting possible obstacles on the road

A heat-resistant automotive sealant gasket is suitable for repairing the exhaust system. When using it, clamps and pipes will not stick to each other, and the sealing of the connections will be reliable.

Sealants in the form of paste, glue and cement (including ceramic compounds) are best suited for repairing the rounded structures of the exhaust system - the pipes connecting the cavities, catalysts and other parts.

Error 5. “Using old sealant”

Today on sale you can find many low-quality automotive sealants with a short shelf life of the sealed packaging. The tube spent some time on the way from China, in customs and warehouses, for some time it lay on the store counter, and the buyer receives it with changed properties. Poor-quality sealant begins to separate into components while still in the tube; this process continues during polymerization in air. As a result, a seemingly neatly repaired unit “sweats” and leaks... To avoid such incidents, use only sealants from trusted brands, such as DoneDeal. All modifications of DoneDeal adhesives and sealants (and there are about a dozen of them for a variety of tasks) are made in the USA and their guaranteed shelf life before use is 5 years. And since high-quality goods do not sit on the shelves, it is almost impossible to buy expired ones!

Thread liquid glue

Threaded connections in cars are subject to temperature changes and vibrations, which can cause problems with their self-unscrewing. To prevent such situations when installing connections, you can use a liquid thread adhesive-fixer.

This type of sealant prevents arbitrary unscrewing of threaded connections without the help of auxiliary materials and mechanical fasteners. It has fixing and sealing properties, preventing moisture, oxygen and contaminants from entering the assembly.

The most popular materials are anaerobic fixatives. Their curing occurs in narrow metal gaps without access to oxygen. How long such a material dries is determined by its viscosity and the conditions under which installation is carried out. The average time to achieve initial strength is about 10-30 minutes.

What sealant is suitable if the radiator is leaking?

It is recommended to use sealant to eliminate radiator leaks only as a temporary measure if it is not possible to call a tow truck or contact a car service center. The sealant will temporarily fix the problem, but it should not be used on a permanent basis. It impairs the passage of antifreeze through the radiator, reducing the efficiency of heat transfer, which increases the engine temperature and creates the risk of overheating.

Most radiator sealants are made from natural organic ingredients and come in a powdery form. They are low cost, but contain large flakes that can clog system pipes.

Another type of sealant is created from metallized polymers. They, together with antifreeze, circulate through the cooling system, and polymer particles cling to the edges of the leaks, closing them. This composition does not settle, does not clog the tubes and is easily removed. Sealants of this type have one drawback: they can only eliminate leaks of small diameters, not exceeding 1 mm.

If a leak is detected while driving or parking the car, the procedure for using sealants should be as follows:

- If a leak occurs, turn off the engine and allow the coolant to cool.

- Apply automotive sealant following the instructions on the label.

- Start the engine for a few minutes, turn it off and check for leaks

- If the leak cannot be eliminated, this means that the hole size is too large. In this case, it is recommended to call a tow truck and contact a car service center.

Mistake 1. “Pile it thicker”

The most common and most fatal mistake. Due to inexperience, many amateur car repairmen are afraid that a thin layer of sealant will not compensate for uneven surfaces, and apply it according to the principle “you can’t spoil the porridge with oil.” After mating the surfaces of the parts lubricated with sealant, its excess is squeezed out inside and outside. The one on the outside can be easily removed with a napkin or rag, but the one on the inside, as a rule, remains inaccessible. Drops and “sausages” of sealant inside the unit break off over time and are drawn into the channels of the lubrication system or into the jacket of the engine cooling system, disrupting the normal circulation of oil or coolant.

Types of body sealants and application

There are several types of sealant, the choice of which should be made based on the intended work.

The most common types are:

- Suture (in a tube). This is the most popular polyurethane sealant for bodywork and seam sealing. To apply it, a special gun is used: mechanical or pneumatic

- Suture (under a brush) - available in cans, consists of a one-component composition, but is applied with a brush. Most often used for filling butt seams, welding seams or gluing body metal elements. Most often it is used to connect the engine compartment and other elements invisible from the outside.

- Adhesive based sealing tape. It ensures the creation of a perfectly even seam, does not require drying, so it can be painted immediately

- Sealant in a tube - suitable for small jobs, as it is produced in small volumes. It is available in different colors, has all the characteristics of the above materials

Main types of cylinder head gaskets

In modern engines, the cylinder head gasket not only performs a sealing function, but also ensures load distribution.

The following types of gaskets exist:

- Asbestos - quite elastic, can withstand high temperatures, and can be additionally reinforced with metal rings; main advantage - low price, disadvantages - instability to vibrations and rapid aging

- Non-asbestos gaskets are a common type of gaskets that are more expensive than asbestos ones; At the same time, they are more resistant to deformation and last longer

- Metal (bimetallic) - consist of several layers of metal or metal with a sealing elastomer; Such multilayer steel cylinder head gaskets (abbreviated MLS) are most often equipped with modern cars

To achieve 100% sealing and increase the life of the cylinder head gasket, special sealing compounds have been developed. When applied under pressure, they create a thin continuous layer that levels the surface. The permanent residual tack of the sealant helps to accurately position and hold even heavy metal gaskets in place.