The interiors of apartments, houses, offices, public institutions and premises are not complete without the use of mirrors, which not only perform their usual function, but are also placed as a decorative element. A mirror can radically change the appearance of any space, visually expanding it. Mirror mosaic creates bright highlights and unusual effects; it can be used in the bathroom or kitchen as a backsplash. In addition, elements with a reflective surface and glass parts are used when decorating furniture and accessories. A special atmosphere is created by stained glass made from multi-colored pieces.

Mirrors that do not have frames or special fasteners, mosaic mirrors, are fixed directly to the wall using a special glue suitable for most types of materials and textures. Mirror glue is produced by domestic and foreign companies, whose products have a wide range.

This glue creates a strong elastic layer between the mirror and the wall, thereby maintaining the integrity of the back side and the surface as a whole. Even if the mirror breaks or cracks over time, its fragments will not fall or scatter, but will remain attached to the layer. This method of fixation is suitable for objects of light weight and medium size.

Classification of silicone sealants

Depending on the differences in the chemical composition, all sealants are divided according to their technological purpose:

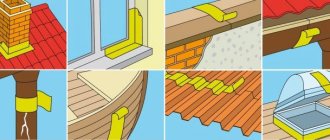

- Construction - neutral reagents are used as glue hardeners. The sealant is used for sealing cracks on the outside of buildings, as well as for interior work: sealing window frames, wooden and plastic structures.

- Roofing – highly resistant to aggressive environmental factors, effective for sealing metal and ceramic roofing coverings.

- Plumbing - the composition is enriched with fungicidal preparations. The adhesive is designed for waterproofing cracks between plumbing fixtures and walls.

- Universal - highly adhesive acid-curing compounds, used for installation of ventilation, drainpipes, window frames and air conditioning systems. It is undesirable to use them in rooms with high humidity, since they do not have antiseptic properties and are not suitable for working with plastic and metal without an anti-corrosion coating.

- Adhesive mixtures for plastics – have a neutral composition and high adhesion to polyvinyl chloride and acrylic.

- Hydraulic sealants – recommended for sealing equipment parts made of non-ferrous metals, cast iron, and ceramics.

- High-temperature with acid curing - for sealing parts of steam heating and hot water pipes, heating boilers, fireplaces.

- For interior and exterior work on sealing joints of building elements made of marble and other natural stones.

- Glass sealants are characterized by high adhesion to glossy surfaces and are used for exterior and interior work. May have a pronounced acid or neutral cure.

- Adhesives with a neutral composition - for joining products made of polyvinyl chloride, acrylic and gluing to plastered surfaces, concrete, glass. They are odorless and do not cause metal corrosion.

Characteristics

Silicone transparent sealant for mirrors Moment Germent is a sealant of the highest quality, ideal for working with mirrors.

It has excellent adhesion to almost all surfaces, such as metal, PVC, concrete, polycarbonate, granite, marble. Also suitable for glazing work, for sealing air ducts, etc.

Elastic sealing when covering mirrors, for aluminum, wood, PVC, etc., joinery. Mounting mirrors. Bonding of materials subject to vibration. Can be used on clear glass, laminated glass and all glazed surfaces

During renovations, you often have to hang a mirror on the wall. If the product has a frame and pre-provided fasteners, the problem can be easily resolved, but if such devices are not available, you will have to think about another solution. When you don’t want to drill into the wall to install holders, you can use liquid nails for mirrors - a special adhesive-sealant that reliably holds the product for a long time.

Are there any requirements for glue in dry rooms and in the bathroom?

Exposure to high or low temperatures can affect the materials used in the mirror and the adhesive to varying degrees.

If the composition of the fixing mixture is not elastic enough, then when the temperature changes, surface tension may arise in the decorative canvas, leading to cracking of the mirror or its separation from the wall.

In addition to the requirements for adhesive properties:

- The glue must be safe for human health. Before purchasing the mixture, be sure to read the information on the packaging: the product must be intended for indoor use or have universal use. “Street” types contain more harmful substances.

- The glue must have a structure that ensures a tight fit of the mirror to the plane of the wall.

- A significant factor in the choice is the polymerization time - if the composition hardens for a long time, a supporting structure will have to be installed to fix the mirror.

- If the reflective sheet is installed in rooms with high humidity, the mixture must have high moisture resistance and fungicidal properties. The use of universal glue may cause the mirror to come away from the wall.

- The composition for fixing mirrors should not contain alkalis or acids, so as not to destroy the amalgam and not deteriorate the reflective ability of the product.

How to remove a mirror from liquid nails

To remove the glued product without damaging it, you need to act carefully. You will need a strong thin wire longer than the width of the mirror. It is carefully moved from the wrong side of the canvas, starting from the top, while an assistant holds the mirror to prevent it from falling. Move the wire diagonally, from right to left, in other directions to crumble the dried glue. Afterwards, you can remove the mirror and clean it of any remaining sealant, if necessary - then the product can be used again.

What types are used for installation?

Depending on the properties of the surface on which the decorative element will be installed, all adhesives can be divided into several types:

- Solvent-based mixtures are easy-to-use materials that are inexpensive. They may contain substances that destroy the reflective layer, so when purchasing, always read the information on the packaging: the adhesive must be designed to work not only with glass, but also with mirror surfaces.

- Silicone is a chemically neutral material, most suitable for installing decorative panels.

- Based on hybrid polymers - provides high adhesion to joined surfaces of any type, but are significantly expensive.

Best Solvent Based Mirror Adhesive

"Soudal 47A"

Completely ready-to-use adhesive from a Belgian manufacturer for mirrors and glass products. Contains a weak solvent and synthetic rubber - this base does not harm the silver layer of amalgam. Demonstrates the high strength of the resulting connecting layer, moisture resistance, and rapid hardening.

Interacts well with most building materials, concrete, brick, plastered surfaces, porcelain stoneware, ceramic tiles. The exceptions are polypropylene foam and polyethylene. Available in 300 ml packages.

The average cost is 250 rubles.

Soudal 47A

Advantages:

- firmly fixes decorative elements, mirror mosaics;

- temperature range from -20 to +60 degrees;

- gentle interaction with high quality silver layer and sensitive surfaces;

- dries quickly;

- can be used as a sealant.

Flaws:

- has a specific smell.

Proper Use

- Using the sealant during work is simple and convenient: you need to install the tube in a special gun, cut off the tip of the spout with a knife and screw on the dispenser that comes with the glue.

- The substrates to be joined must be thoroughly cleaned of dust and dried.

- Excess material must be removed immediately with a wet cloth and from hands with soapy water. Dried sealant can only be removed mechanically.

When working with some types of adhesives (for example, Moment Montazh), after applying the composition, the mirror must be pressed to the base and immediately removed, and after 3 minutes installed completely.

How can I mount it on the wall?

You can decorate a section of the wall with small, lightweight items using double-sided tape. Adhesive tape is also useful for mounting heavy products as additional fixation:

- Pre-level the surface of the base;

- clean and degrease the back of the mirror and the wall;

- stick strips of tape onto the reflective layer;

- remove the protective film from the tape and apply glue to it spotwise;

- Place the mirror on the installation site and press lightly.

On the cabinet door

Using reflective sheets, you can decorate the insides or sides of cabinets:

- remove the door and lay it horizontally;

- mark the future location of the mirror;

- stick several strips of adhesive tape, apply glue in solid lines between the adhesive tape;

- remove the protective layer from the tape, place the mirror on the door and press it.

If the product is light, after 30 minutes you can hang the door back on its hinges. Leave a large mirror in a horizontal position for a day.

How to glue a mirror to chipboard?

Share on social media networks:

- The best adhesive composition

- Glue the mirror

- Video material

A mirror is a very important attribute in a room, both practically and aesthetically. Many people, when purchasing a cabinet, only then thought about whether to attach this decorative element to it and how best to do it. From this article you will learn how and with what to glue a mirror to chipboard and other materials.

The best adhesive composition

Many craftsmen claim that the best glue for mirrors is silicone sealant. There are two reasons for this:

- Resistance to external irritants. For example, dust, temperature fluctuations, humidity and other factors.

- This composition is of very high quality - it has a long shelf life, it is tensile strength, mobile, hard, and also has a high density

Important! What should we know about silicone sealants? They are all vulcanized materials that are designed to seal.

Classification of silicone sealants

Such compositions can be classified as follows.

When ready for use:

- There are one-component sealants. This means that they are ready for immediate use.

- Two, three or more components. This means that they must be mixed before use.

Based on composition:

- Made from silicone.

- Polyurethane.

- From thiokol (polysulfide).

- Made from acrylic.

Important! The compositions were listed in descending order of qualities useful in construction.

Sealants in construction

So is it possible to glue a mirror with silicone sealant? The answer is yes. It is not surprising, since silicone sealants are widely used in construction work.

Important! It is also worth noting that sealants are widely used in structural glazing - they are used to strengthen materials for glazing facades and windows. Sealants are also often used as construction putty.

Silicone adhesives have many advantages:

- UV resistance.

- Resistant to changing weather conditions.

- Resistance to aggressive environments.

- High adhesion to many types of building materials. You don't even need to use a primer (primer).

- Excellent motion accommodation.

- Valid at any temperature.

- They have a complex composition.

Glue the mirror

So, we have already figured out how to glue a mirror to chipboard or laminated chipboard. Now is the time to figure out how to do it correctly.

Let's say you need to glue a mirror to the door of a closet. This is not as difficult to do as it seems. However, before the procedure you need to prepare the following materials:

- Mirror.

- Pencil.

- Solvent (to degrease the surface).

- A piece of fabric.

- Silicone sealant, glue gun.

After all the materials have been prepared, you can figure out how to glue the mirror onto the chipboard:

- Place the mirror on the surface where it will be glued and trace it with a pencil. As a result, you will get a marking line.

- Wipe the surface with the prepared degreaser and carry out the same procedure on the inside of the mirror.

- Apply silicone adhesive in strips to the inner surface of the mirror.

Important! Do not apply too thick stripes (especially closer to the edges of the mirror plane). Otherwise, the glue may leak onto the edges of the decorative element and ruin the whole impression. Also make sure that the sealant does not get on your clothes - it is very difficult to wash off.

- Place the mirror surface on the previously drawn marking line.

- Now you can carefully lower it, trying to make sure that the contours of the marking line coincide with the contours of the mirror.

Important! Do not hesitate to seek help from loved ones. Your partner will monitor the accuracy of the positioning of the mirror surface while you lean it against the cabinet.

- So, the desired item is glued, but the glue has not cooled yet. This is an excellent opportunity to move the glued object if it does not lie flat on the marking line. The drying time of the adhesive you use is written on its packaging.

Video material

Any mirror surface in a room is not only beautiful, but with its help the room visually increases in size. From this article you learned about a proven method, which tells you how and with what to glue a mirror to plywood and other similar materials.

Storage recommendations

The polymerization process of the sealant begins immediately after opening the package. There are several ways to protect the glue remaining after use from hardening:

- remove the acid-based product from the tube and place it in a glass jar, tightly closing the lid;

- select a self-tapping screw so that the size of the head matches the diameter of the hole in the container with glue, and screw it in, after squeezing out a little silicone;

- Wrap the neck of the tube with polyethylene and screw on the lid.

Mirrors have a fairly long service life. One of the important factors influencing the reflectivity of products is the correct choice of adhesive composition that will be used when installing the product.