December 22, 2015 Paints, enamels, varnishes, plasters, primers, adhesives, sealants

At a certain stage of construction and repair work, there comes a time when it is necessary to use substances that can give the structure a finished look by sealing joints and making the surface airtight and attractive. The modern construction market today offers a huge number of sealants that are perfect for such purposes. They are adhesive and sealing substances based on polymers, used for sealing building structures and all kinds of moving joints. Sealants are successfully used to seal joints and cracks. In addition, such substances are often used for gluing parts and sealing joints in brickwork.

Currently, sealants come in different consistencies: mortar, paste or putty. Today there is a huge selection of sealants that differ in composition: silicone, acrylic, polyurenon, bitumen and thiokol. In addition, there is a division of these substances into single- and multicomponent. The first group consists of sealants that are completely ready for use, the second group requires mixing of components, and it is important to combine the components in the required dosage, and mixing should be done very carefully. Depending on the type of state of the substance, there is a division of sealants into:

- drying - after hardening it becomes quite hard, while remaining just as elastic;

- curing - after application it becomes rubber-like over time;

- non-hardening - even after a certain time does not turn into a solid state.

Among this variety of sealants, it is important to choose exactly the composition that is most suitable for certain work.

What it is

A distinctive feature of the mixtures is the water content. The moisture evaporates, forming a durable sealed layer. The basis of the products is polymethylacrylate, which belongs to the category of plastics. The formed seam has good elasticity, uniform filling and resistance to stress. Acrylic sealants come in classic white, transparent and colored. The formula of sealants includes several substances:

- To ensure optimal viscosity, thickeners are added to the aqueous dispersion.

- Acrylic sealants are protected from moisture, temperature changes and aggressive environments by plasticizers and fillers.

- Antiseptics give the mixtures antibacterial properties. The composition also includes surfactants, defoamers and ammonia solution.

Manufacturers produce sealing products in the form of pasty and viscous-fluid substances. The scope of use of acrylic sealants is very wide. They are used for industrial and domestic purposes, during internal and external construction work. Thanks to the special properties of the materials, the frozen mass provides reliable protection against the penetration of cold and does not allow moisture and dust to pass through.

Important: Acrylic sealants have a long service life, which is 15 years or more. The compositions are universal, therefore suitable for performing a wide range of repair, installation and construction work.

Purpose of acrylic-based sealant

The product does not contain any harmful substances that emit toxic compounds, therefore it is widely used in Rome for interior decoration. It is allowed to use such seam sealants without additional ventilation and respirators.

Often they are used as a sealing material for sealing connecting lines between wooden beams, reinforced concrete surfaces, and areas where interior items adjoin the wall decoration.

In addition, acrylic gel for sealing is used as an adhesive solution for installing ceiling and floor decorative elements: baseboards, moldings, etc. It is also used for waterproofing tile joints.

Advantages and disadvantages

For convenient use, acrylic sealant is produced in compact tubes. The product is easy to hold while working due to its light weight. Another form of production of compositions is tubes and cartridges, which must be applied using a mounting gun. Professional sealants are used for large-scale work, and small tubes are used for minor home repairs. Some mixtures are supplied in plastic buckets that hold several kilograms. Such products are applied with a spatula, treating large surfaces and bases. The process of vulcanization or polymerization of compositions occurs as a result of moisture evaporation.

Advantages of acrylic sealants:

- Ecological cleanliness. The absence of solvents in the compositions eliminates the content of dangerous toxins, so acrylic mixtures are best suited for interior work. During processing, the substances do not release the characteristic pungent odor and volatile substances into the atmosphere.

- High adhesion to various materials is one of the main properties of acrylic sealant. Universal products interact well with metal, wood, plastic, tile, ceramic surfaces with a smooth base or porous structure.

- Good vapor permeability. After applying the acrylic product, the surface becomes solid, but does not create a “greenhouse” effect. It is allowed to use acrylic sealant to seal gaps in window frames, door structures made of wood, plastic or metal.

- Easy to apply. Acrylic sealant is supplied in tubes, cartridges or buckets. It can be applied using a gun or spatula. The remaining mixture can be easily removed with a clean rag, and if the product has hardened, the excess can be cut off with a knife. The main rule of application is compliance with the temperature regime.

- Resistance to ultraviolet rays and high fire safety. According to the fire resistance class, acrylic compositions are classified as non-flammable mixtures due to the absence of solvents in them. When exposed to sunlight, sealants do not fade or crack.

After the acrylic layer has dried, the surface can be painted. The mixtures are presented in a wide range of colors. They are characterized by high aesthetic appeal and durability of the coating. Another advantage of acrylic-based sealants is their affordability. The disadvantages of the products include low resistance to moisture.

Attention: Despite the fact that “moisture-resistant” sealant may be indicated on the packages, prolonged contact of the composition with water should not be allowed, as a result of which the treated seams are gradually destroyed. Acrylic products are not the best choice for rooms with high humidity - bathrooms, showers, baths, saunas, kitchens.

Varieties

Depending on the behavior after application to the surface, the material is divided into three types: drying, non-hardening and hardening. The first group includes polymer-based compositions. This sealant hardens after a day without additional manipulation. The drying acrylic mixture can be two-component or one-component. Before application, sealant with a complex composition must be thoroughly mixed. One-component material does not require mixing.

Non-hardening sealant is produced in the form of mastic. The elastic mass must be kept at a temperature of 20 degrees for at least a day. The material is resistant to heating up to +70°C and cooling to -50°C. The width of the panel joints can vary from 10 to 30 mm. This sealant is mainly used when decorating building facades, even in regions with harsh climates. The hardening composition is created on the basis of silicone materials. The components of the sealant harden during a chemical process (vulcanization).

In appearance, the compositions are colored, transparent and white. The color of the sealant will practically not change after drying. The transparent silicone in the composition may become slightly cloudy, but the intensity of the acrylic will not change. Some types of sealant are transparent, but with the addition of a coloring pigment. This composition is used when working with glass products. The sealant has light transmittance and adapts well to transparent material.

Siliconized colorless sealant is widely used in the installation of plumbing fixtures. This composition is waterproof, so it is suitable for interior work in the bathroom. The composition protects the surface from leaks and mold. Due to the absence of color, it is possible to obtain a coating without visible seams.

Colored sealant is purchased if the selected surface cannot be painted. To avoid obvious color differences and maintain the integrity of the composition, experts advise giving preference to this type of material. The pigmented adhesive composition is not inferior in its physical properties to the colorless one. The shade palette of the sealant is quite wide. You can purchase either gray, black or brown material.

White sealant is good for painting. It is used for installation of plastic windows and light doors. The presence of pigment helps determine the thickness of the adhesive strip and the uniformity of application. It is much easier to eliminate defects if the composition is visible on the surface. After complete drying, this sealant is painted along with the surface.

There are several types of product depending on the area of use and future operating conditions.

- Bitumen based composition. This type of sealant is used for external work - eliminating cracks in the foundation and tiles. The material is capable of fixing almost any material due to its composition. The sealant is resistant to heating and cooling to critical temperatures, and also does not collapse under the influence of moisture. The undeniable advantage of the material is the creation of strong adhesion.

- The universal sealant does not require special skills during application and is suitable for almost all interior work. The material is frost-resistant, so it is often used when installing windows. The sealant tightly fills the cracks, preventing drafts. When working with wood, craftsmen recommend using a colorless composition.

- Silicone sealant for aquariums. This material must not contain toxic substances. The adhesive is waterproof because after curing it will be in constant contact with water. High ductility and adhesion allow this sealant to be used when installing shower cabins. Also suitable for processing ceramic and glass surfaces.

- Sanitary. This professional material is used for work in wet areas. The composition contains special antifungal components. The material protects the surface from the development of bacteria.

Specifications

The consistency of the acrylic mass is a viscous and viscous substance with minimal fluidity when used on vertical surfaces. After hardening, it acquires optimal strength and resistance to deformation loads. The composition has good adhesive properties and easily adheres to brick, plaster, wood, and plasterboard substrates.

Technical characteristics of sealing acrylic sealants:

- Processing seams with a width of 0.6-5 cm, provided that the thickness is equal to half the width of the seam.

- The average material consumption under optimal application conditions is 0.065-0.073 kg/m2, approximately 70 g.

- It is allowed to use acrylic products at a temperature of -40+120°C, application at +4+32°C.

- Primary setting with the treated surface occurs after an hour, complete hardening of the seam with a thickness of 10-12 mm occurs after 3-4 weeks.

- Degree of frost resistance - at a temperature of -15 degrees it can withstand up to five freezing/unfreezing cycles.

- Sealants have good tensile strength, but do not tolerate contact with moisture well.

- The shelf life in hermetically sealed packaging is 12 months, container - cartridge, tube, tuba, plastic bucket.

The widespread use of acrylic sealants is due to the environmental safety of the products and the absence of toxins and solvents in the composition. First of all, it is recommended to use mixtures for interior work.

Consumption of funds

The required amount of acrylic sealant depends on the size of the future seam. In order to calculate it, you should multiply the depth and width of the gap. The result will be an approximate volume of material: it will show the required weight of the product (in grams) per 1 meter.

In the case where the joint is triangular in shape (instead of the usual rectangular), the final value should be divided by two. As practice shows, for 10 m of medium-thick seams, 250 g of sealing compound is sufficient.

Kinds

There are one-component acrylic sealant, ready to use, as well as two-component and multi-component products, which must first be mixed to obtain a mass of homogeneous consistency. All sealants can be divided into several varieties according to different characteristics:

- One-component. A universal composition for sealing cracks indoors at normal humidity in the range of 60-70%. Suitable for painting, distributed evenly, does not lose color saturation during drying. Area of use: interior work.

- Acrylic silicone. A two-component sealant with extenders and fungicides is suitable for gluing smooth surfaces, such as plastic. Can be used on substrates with a porous structure. The silicone content increases elasticity, resistance to precipitation and temperature changes.

- Acrylic latex. The frost-resistant two-component product tolerates exposure to negative temperatures well. The prepared mixture has good viscosity and does not spread over the surface. The introduction of hydrophobic additives into the composition improves waterproof characteristics.

- Acrylic rubber. The product is used for sealing joints in wooden structures. The use of acrylic sealant is especially important for sealing gaps between logs and beams in log houses and other buildings made of natural wood. You can apply the composition to inter-crown insulation.

- Water resistant. It is not a hundred percent natural substance, but it can be used indoors. Demonstrates good adhesion to building materials of various textures. Contains antiseptic additives that prevent the formation of mold and mildew.

If the sealant package says “waterproof,” the mixture must include special hydrophobic additives. Such products withstand moisture well and can be used in rooms with high humidity. Natural acrylic sealants are tensile and effectively resist deformation, but do not withstand contact with water. Their use is not allowed on surfaces that are constantly or periodically subject to thermal expansion.

Note: Some manufacturers produce products containing fire retardants. Such compositions are non-flammable, ideal for sealing joints in wooden structures, and have the ability to localize flames.

Properties

The scope of application of the sealant is quite large. Using an acrylic composition, you can restore wooden parquet and treat laminate flooring. Craftsmen use sealant when installing windows and doors. Without it, it will be very difficult to seal pipe connection lines, seal skirting boards and seams between fragments of ceramic tiles.

The main property of acrylic sealant is elasticity. The plasticizers included in the composition give it an elastic consistency. The material can withstand prolonged vibration without damage. The product is suitable for sealing narrow joints and sealing cracks because it is able to penetrate small holes and clog them. To obtain the required result, simply pour the material onto the surface.

The main distinguishing features of the material are extreme elongation at critical load and wear resistance. After drying, the material may shrink slightly. For good material, the displacement amplitude will not exceed ten percent of the maximum elongation. The greater the irreversible deformation, the less quality the material was chosen. If the stretching of the sealant exceeds the limit value, the material will not be able to return to its original position.

Craftsmen do not advise choosing an acrylic mixture for outdoor work. Sealant for external use must have increased frost resistance, since the material will have to withstand several freezing cycles. This composition, as a rule, is characterized by increased rigidity. The optimal drying temperature for the composition is from -20 to +70 degrees.

Craftsmen recommend applying the sealant in a layer 5-6 millimeters wide and no more than 0.5 mm thick from the width. If the distance between the panels exceeds six millimeters, then experts do not recommend increasing the layer of sealant. Instead, a sealing cord is used. Its diameter varies from 6 to 50 mm. It is designed to connect panels during installation and protect the joint from moisture.

The hardening time of the coating depends on the density of application. With a sealant thickness of 10-12 millimeters, the curing time reaches 30 days. The material hardens while maintaining constant humidity and temperature. Do not constantly ventilate the room. It is enough to maintain 20-25 degrees and humidity from 50 to 60 percent. If all rules are followed, the sealant can harden within 21 days.

The setting time of acrylic sealant is one hour. But removing the coating from the surface will not be difficult. The sealant can be painted only after it has completely dried. Unopened material can be stored for about six months in a room with an air temperature of +20 degrees.

It is prohibited to apply the composition to a surface that constantly interacts with moisture. If it becomes necessary to apply the composition during rain, it is necessary to protect the outer layer with a sheet of polyethylene. Prolonged contact with water causes depressurization and peeling of the coating.

When purchasing a sealant, you must consider the scope of its application. For each type of work, an individual composition should be selected. The universal material can be used everywhere when working indoors. But it is not suitable for finishing the facade of a building.

Colors

Acrylic products can be classified according to the presence of pigment dyes. Classic clear sealant or acrylic white compound is considered a standard universal solution. But sometimes it becomes necessary to get seams of a certain color so as not to disrupt the design and aesthetics of the structure. In this case, you can choose an acrylic sealant of the appropriate shade:

- Basic colors – white, beige, grey, blue, green, brown, black.

- Non-standard color solutions – light and dark tones of basic colors.

- Shades that imitate wood - beech, honey, wenge, larch, golden pine, rosewood, teak, birch, cherry.

It is easy to choose a colored sealant to match the structure of a wood surface or concrete base. If the color scheme does not contain the desired color, after the product has dried, paint with water-based materials. They are colored and white, which can be tinted with pigments to obtain the desired shade.

Color variety

You can often see white or colorless acrylic sealants in hardware stores. They are extremely popular among users because they fit perfectly with various plumbing fixtures and tiles. It is important to note that transparent compounds are hardly noticeable on treated surfaces. If you want to choose a sealing material that matches the color of the base, you need to buy a pigmented product of the desired color. There are also products in wood shades: oak, walnut, cherry, wenge and others.

A wide range of colors of acrylic sealants for wood makes it easy to choose the material that matches the color when processing any base. Source st3.stblizko.ru

Famous brands and reviews

Domestic and foreign companies produce a huge range of acrylic sealants. Each manufacturer has several product lines - one-component and two-component compositions, colored and non-pigmented sealants, mixtures with additional properties - water resistance, frost resistance, deformation strength.

10 acrylic products that occupy a high place in the ranking and are in wide demand:

- German sealant Zigger. Optimal price-quality ratio, products are manufactured in Germany. The manufacturer’s line includes a product for laminate flooring, produced in a compact tube with a volume of 310 mg. Shade options - gray and imitation natural wood. A white acrylic sealant, available in a 50 mg tube, is specially designed for cracks on walls.

2. Recognizable German brand Henkel. According to customer reviews, the products of this brand have impeccable characteristics. The compositions have good frost resistance, which allows the use of sealants for exterior work in harsh climates. The mixtures can be used to fill the seams of low-moving structures and be used to repair floors and treat walls.

3. Loctite sealants are widely used for household needs, professional repairs, and car maintenance. PL S50 compositions firmly adhere to concrete, brick, and wooden bases. The frost-resistant mass can withstand climate changes and is suitable for processing joints of street structures. Loctite compositions come in classic white and colored.

4. Finnish Makroflex mixtures have received a large number of positive consumer reviews. Acrylic-latex products with high frost resistance are widely popular. The mixtures can be used to seal seams and joints on outdoor structures and indoors. The cost of products falls into the middle price category.

5. Petersburg produces universal acrylic white sealant in a small package - a 50 ml tube. Every buyer will be able to buy an inexpensive product. The elastic, airtight and moisture-resistant composition is not inferior in quality to imported analogues. The manufacturer produces mastics and paints and varnishes.

6. Domestic-made sealant “Accent”. The company produces one-component sealants (Accent 117), siliconized substances (124), and compositions for wood processing (128, 136, 140, 125). Accent products are classified into household and professional acrylic sealants, which can be used to cover seams of different thicknesses.

7. The Slovenian brand Belinka produces high-quality products that meet European standards. The manufacturer's line of products includes a universal composition and a separate sealant for parquet. Environmentally friendly products have optimal properties and characteristics. The universal sealant and parquet cleaner are supplied in 300 ml packages.

8.Compositions of Soudal. The mixtures are easily smoothed with a spatula and fill seams and voids well. The cartridge has a convenient dispenser spout. Acrylic sealant Soudal for sealing joints and seams fits neatly on horizontal and vertical surfaces made of different materials. After complete drying it can be painted.

9. Russian Cosmofen products are produced under the Penosil brand. The company produces acrylic products of three modifications - Cosmofen ca 1 universal, Cosmofen plus hv for sealing plastic structures, Cosmofen plus-s for processing foam and PVC. The compositions have pronounced adhesive properties and can be used as a fixing adhesive.

10.The popular sealant CERESIT CS 7 has waterproof qualities, therefore it is used when installing plumbing fixtures. Despite the acrylic base, the product provides reliable insulation of joints from moisture and does not crack upon contact with water. According to reviews, Ceresit brand products are reasonably priced and of good quality.

Viscous-flowing and paste-like sealants with a polymer acrylic base are produced by many companies in Russia and abroad. The characteristics of most products meet the requirements of buyers and are reasonably priced. Before purchasing, you need to pay attention to the area of use of the sealant (outdoor/indoor) and the type of surface to be treated.

Second – ZIGGER

A German company that has been producing and selling its own products for more than 20 years. It enjoys enormous popularity on the Russian market due to its high quality and certified products.

It is worth noting that the polyurethane foam and sealants of this company occupy leading positions in the construction market. One of the reasons for this demand is our own production and a strict approach to each technological stage in the manufacturing process.

Regarding the cost, it is higher than that of the first contender. But at the same time, the middle price segment is offset by the highest quality of the material.

Among the most popular, it is worth noting the following products:

- one-component sealant in the form of a 310 ml cartridge - excellent for treating laminate and other types of flooring, including parquet. There is a wide variety of colors to suit individual interior features;

- a special construction sealant made from a multi-component base - excellent for sealing seams, joints, and significant cracks. Available in two colors: white and transparent.

It is not without its drawbacks, namely susceptibility to fungi and mold. They are caused by specific features of the internal structure of acrylic itself, and not by a negligent attitude towards production.

Criterias of choice

The main purpose of sealing compounds is to seal joints, cracks, seams of movable and fixed structures and surfaces. Walls, flooring, joint gaps, deformations, voids, cracks - acrylic sealant can be used for a variety of purposes. To carry out household repairs, it is enough to buy a small package of one-component sealant; for professional use, larger-capacity formulations with the inclusion of fillers (additives, modifiers) are needed.

How to choose acrylic mixture:

- Area of use - porous or smooth surface, joints of moving or fixed structures, interior or exterior work, type of material (metal, plastic, PVC, wood, concrete). You can choose a composition for specific work or a universal product.

- Operating conditions – the probability of periodic changes in temperature and humidity, ingress of precipitation and moisture, and mechanical influences (shocks, loads, vibrations) are taken into account. For wet rooms and outdoor work - sealants with fungicides, for heated surfaces - heat-resistant, fire-resistant mixtures.

- Composition and technical characteristics - there are ready-made products and substances on sale that require mixing. You need to study the manufacturer's instructions - temperature of application and operation, width and thickness of the seam, setting and complete drying time, consistency and properties, method of application.

- Decorative component - classic transparent and acrylate white sealant can be used for any type of insulation. But if you need a colored composition for a complete design, you can choose a product of the desired shade or paint the basic white sealant after drying.

It is worth paying attention to the brand and reviews about the quality of the manufacturer’s products. If large-scale work is planned, you need to buy mixtures with a reserve. If there are deformations or uneven differences on the surface, the composition consumption per square (or linear) meter will be greater than the average value specified by the manufacturer.

Tip: Before purchasing sealant, you need to read the expiration date on the packaging and check the integrity of the container. Most manufacturers indicate a shelf life of 12 months for products in sealed original packaging.

On video: Acrylic sealant for sealing joints, corners and cracks.

How to choose the right sealant?

When choosing a sealant, you need to proceed from what materials you will be working with in the future. So, when working with plastic (Teflon, polyethylene), keep in mind that this material is characterized by a low level of adhesion to sealing agents. Therefore, to increase adhesion to such a surface, it is advisable to purchase suitable sealants or use primers.

When working in an aggressive environment, it is best to buy products that contain fungicides. Do not forget that it is advisable to use them in non-residential rooms. If the need arises, it is best to use a clear or white aquarium sealant that is not only water resistant but also not harmful to living organisms. If you have to carry out work at elevated temperatures, it is also advisable to buy a high-temperature sealant with a working temperature of at least +300 °C.

With this product, you can easily seal seams and cracks in fireplaces and stove structures, without fear that the product will lose its elasticity or crack under the influence of high temperatures. And do not forget to request a quality certificate when purchasing acrylic sealant - its technical characteristics must be fully displayed in the document.

Application of mixtures

Elimination of installation gaps, formation of joining and insulating seams, tight fixation of structural fragments, creation of a protective barrier are the main areas of use of acrylic mixtures. Since the component composition includes auxiliary substances, the scope of application of the products varies.

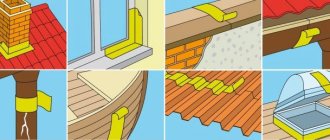

What is acrylic sealant used for:

- Filling joints in wooden structures – buildings made of logs and beams.

2. Removal of cracks and deformations in concrete surfaces - walls, ceilings, cement screeds.

3. Elimination of installation gaps in door frames and window frames - structures made of plastic, metal, wood.

4. Filling joints when installing plasterboard partitions and false panels.

5. Sealing joints between tiles and plumbing equipment - siliconized mixtures.

6. Restoration of flooring made of parquet, laminate, boards, porcelain stoneware.

7.Fixation of ceiling plinths, MDF panels, baguettes, foam boards.

8. Removing cracks in window sills, restoring cracked furniture.

The varied use of acrylic sealants is due to the properties and characteristics of the materials. The compositions are suitable for forming insulating seams or gluing small products - skirting boards, slabs, heat-insulating materials - to the base. In this case, the product must be applied to the surface of the glued fragment and pressed tightly to the base.

Important: Acrylic sealants do not release toxins into the air, therefore they are safe for health. It is allowed to use the products when sealing seams on surfaces in contact with food. You can use sealants in finishing children's rooms.

Where are they used?

Acrylic sealants do not contain solvents or harmful components, which is why they are best suited for interior work. Moreover, they can be applied in a closed room. There is no need to use protective equipment.

Acrylate sealants are often used for:

- sealing joints between beams and logs;

- filling joints between concrete elements;

- sealing the places of contact of individual elements with walls;

- replacing construction adhesive (for example, when attaching skirting boards to shelves);

- gluing fillets, baguettes, as well as high-quality sealing of seams between the latter and the base.

Advice! Acrylic sealant can be used for installing ceiling tiles and filling gaps.

Acrylic sealant is often used to seal the places where individual objects come into contact with walls Source gidpokraske.ru

Instructions for use

To properly seal seams with acrylic compounds, no special skills or special equipment are required. The mixtures are harmless, so the use of personal protective equipment is not a prerequisite for performing the work. If the product gets on the skin, it can be easily washed off with warm water.

Stages of applying sealant:

- Remove debris and dust from the surface to be treated, rinse, degrease and dry if necessary.

- Prepare tools for work - a mounting gun for cartridges or a spatula of the required size.

- One-component compositions are immediately ready for use, and two-component mixtures are mixed in the specified proportion.

- Apply the sealant evenly into the gaps and seams, trying to immediately remove the excess with a spatula.

- Within 1-3 hours a film forms on the surface. At this time, you can adjust the layer, for example, trim it.

- Final hardening begins within 24 hours and may take several days, depending on the composition.

After complete drying, the treated surface can be painted. But until the final hardening, the mixture must not be exposed to moisture or mechanical stress. Two-component compositions harden faster, so you need to prepare the solution in small portions.

Methods for removing traces of product use

During the application of sealant, part of the mixture remains unnecessary. It’s easier to immediately remove excess mass before the composition dries. But if the mixture has completely hardened, it can be removed using special means and mechanical action.

How and with what to remove acrylic sealant:

- If the product has completely dried, remove it with a sharp blade of a construction/stationery knife or razor.

- The frozen mass is cut off gradually, layer by layer. The remains of the acrylic mixture are swept away with a paint brush.

- You can remove traces of sealant with a solvent or white spirit, leaving the product on the surface for a while.

Before using special removers, you need to check how they affect the treated base. To do this, the solvent is applied in an inconspicuous place. If there are no traces or darkened spots left on the product, the product can be used to remove the remaining acrylic mixture.

How to apply

In order to start working with silicone sealant, it is important to prepare and purchase everything you need. The first point will be protective clothing, which should completely cover the skin of the hands, and if possible it is better to wear construction overalls and a long-sleeved jacket to protect the entire body

There are formulations with a more aggressive composition; for them it is advisable to use a protective mask over the eyes and nasopharynx.

The second stage of preparation will be to obtain the necessary knowledge, with the help of which you will be able to quickly and correctly do all the necessary work.

Sequence of work.

Preparation of special clothing and necessary materials. Working with the surface to which the sealant will be applied

It is important that it is clean, dry and grease-free. If there are decorative elements, it is better to hide them under masking tape to prevent silicone glue from getting on the surface. To use sealant, you will need a mounting gun, which will simplify application

To install and operate it correctly, simply read the instructions on the package. The tip of the spout on the sealant bottle must be cut off at an angle. This option allows the material to flow evenly and be used economically in work. If you cut off a straight edge, the shape of the flowing substance will be round, and with an oblique cut it will be elliptical, which will minimize the waste of excess material. Silicone is applied to the surface when the balloon is at an angle of 45 degrees. Apply in thin strips so that the glue dries faster. After completion of application, the remaining unnecessary material must be removed using a spatula.

The drying time depends on the type of glue that was chosen and the thickness of the layer that was applied to the surface. It usually hardens completely within a day, and the first signs of hardening are visible after twenty minutes. When applying chipboard and fiberboard to the surface, it is better to use a spatula and squeeze out a very small amount of the substance. If the goal is to create a perfectly flat surface on these surfaces, then it is best to dilute the sealant with gasoline or white spirit, the amount of which should be small.

In order to more accurately understand what exactly needs to be done with the sealant, the first thing you should pay attention to is the instructions indicated on the packaging. Most often, manufacturers indicate everything that a worker should know when interacting with a silicone product.

If the quality of work is extremely important, then before purchasing a sealant you need to pay attention to the timing of its production, and if they are stitched, then it is better not to purchase the product

If the choice is made correctly, then working with silicone glue will be quite simple and comfortable.

Once the required amount of product has been applied to the surface, it is important to ensure that all excess is promptly removed. This can be easily done with your own hands, but it is important to know the sequence of actions

For fresh solutions, it is best to use mineral spirits, but you need to make sure that it is safe for the surface itself. If this is the case, then as quickly as possible it is applied to the area that needs to be cleaned, and all excess is promptly removed.

The most dangerous way to coat the coating is to use a knife or spatula, with which dried silicone is removed from the surface. These products must be used very carefully and without undue haste. Using solvents, you can only remove fresh or thin areas of silicone, and for denser ones you need to use a mechanical option.

Adviсe

Sealants are used to seal seams of different widths and thicknesses. The main requirement before processing is to carefully prepare the base. You can apply the compositions manually or using a gun. Recommendations from experts on how to use acrylic sealant:

- Deep joints require a large amount of mixture. To reduce the waste of material, you can lay an elastic polyethylene cord at the joints.

- It is necessary to carry out sealing work at the optimal ambient temperature - +4+32 degrees. The room should have normal humidity.

- Acrylic-based sealants are suitable for “sealing” joints with a width of 6 mm to 0.5 cm. If work takes place outside, the structure must be covered with polyethylene to prevent precipitation.

- Mechanical impact and moisture on the treated seams is not allowed until the sealant has completely dried, otherwise the integrity of the joints will be compromised.

- When painting seams, it is allowed to use latex paints and varnishes. The decorative coating can be applied 3-4 weeks after sealing the gaps, having previously sanded the surface.

Experts recommend using open sealant completely, since the compositions have a short shelf life. If the mixture is two-component, you must strictly adhere to the instructions for mixing the substances. Otherwise, the finished solution will not have the declared properties.

The use of acrylic sealants helps solve various repair problems. The compositions have good adhesion and elasticity, have a universal purpose and are inexpensive. Acrylic-based mixtures are environmentally friendly and durable, therefore they are in great demand among buyers.

How to use acrylic sealant (2 videos)

Types and uses of acrylic sealant (26 photos)

Features of the use of acrylic sealants

No special knowledge or tools are required to apply the material. It is only important to carefully prepare the base: clean it from grease, dirt, peeling coatings, then dry it well. If the seam is thick and wide, it is worth purchasing a sealing polyethylene cord in advance or filling the joint with another sealant. This will make the connection more reliable, reduce thermal conductivity and reduce sealant consumption by 40–70%.

Acrylic can be applied even without using gloves, as it does not irritate the skin of the hands. It is strictly not recommended to dilute it with water or any solvent - this will reduce the quality and cause rapid cracking of the seam. For application, you can use a special gun into which cartridges and tubes are conveniently inserted. It is better to spread sealant from a jar or bucket with a small spatula; from a tube, simply squeeze it out, directing the thin spout to the desired place.

After application, the product can be given any shape within 10–15 minutes. Then a polymer film will begin to form and repairing the seam will be difficult and impractical. Curing of the sealant lasts 24 hours, but at low temperatures the process may take 2 days.

To increase your work efficiency, you should consider the advice of professionals:

- if sealing is carried out in the bathroom, you must wait at least a day before using the surface, otherwise the top layer of the seam will blur;

- Do not touch the joint until it is completely dry: the surface film may be damaged;

- The humidity and temperature in the room cannot be changed until the polymerization of the sealant is completed;

- After opening the package, you will have to use the entire composition, otherwise during storage it may lose its basic properties.

What kind of jobs is sealant best suited for?

Acrylic is suitable for various jobs in everyday life, at construction sites, and in repairs, but it is optimal to apply it to low-moving or fixed joints that are not regularly in contact with moisture. Examples of work with this composition:

- repair of cracked furniture;

- restoration of parquet, laminate;

- linoleum gluing;

- installation and repair of doors, windows, balcony blocks;

- installation of skirting boards, baguettes;

- sealing tile joints.

Sealing tile joints with acrylic sealant

Consumption of funds

To calculate the required amount of sealant, you need to know the dimensions of the future seam. You can multiply the depth of the seam by its width, resulting in the approximate volume of product per meter in grams. If the joint is triangular rather than square, the final figure is divided in half. On average, 250 g of sealant is enough for 10 meters of not too thick seams.

Removing traces

It happens that the product gets on various surfaces in the house. It will not be difficult to remove it before it hardens: just wash the base thoroughly with soap and water. If the composition has hardened, you can use a sharp knife or razor. Remove the product layer by layer, cutting it off carefully so as not to damage the product. The remains are rubbed down with fine sandpaper, steel wool or pumice. Remove sealant from delicate surfaces with a wooden scraper. After finishing work, wash the item with soap and other detergent and dry it.

Uncured traces of sealant can be easily washed off with water.