The floor is the coolest surface of the room. Even at relatively warm air temperatures, the floor may remain cold. There is nothing strange about this. Let's remember the laws of physics: cool air always goes down, and warm air always goes up. But that's not all. The cold penetrates into the floors of our apartments through interpanel joints, corner cracks, and damp basements. Up to 20-30% of the heat can escape from a room through a poorly insulated floor! At the same time, heating bills increase, but the rooms are still cold. In this case, it’s time to start thinking about how to insulate the floors in the apartment. This will help reduce heat loss and create a more comfortable indoor climate.

- 2 Insulation of a wooden base

- 3 Insulation of a concrete floor

3.1 Option No. 1 - insulation + screed

- 3.2 Option No. 2 - insulation along joists, without the use of wet processes

Choosing floor insulation

Before purchasing insulation, make sure that it meets the basic qualities of insulation:

- Does not emit harmful substances that affect human health;

- Tolerates temperature changes and various weather conditions well. Not subject to destruction under the influence of sunlight;

- Fireproof;

- Good air permeability. Breathable material;

- Durable material with a long service life. It must perform its function well for a long time without replacing components;

- Easy to install. For a novice builder (homeowners with no construction experience), it is important to use a material that is easy to use;

- It retains heat well and also serves as a sound insulator.

Choosing insulation material

The floor is insulated with materials with high thermal insulation properties, which prevent heat from escaping outside the room. For these purposes, the most popular are:

- Bulk materials (expanded clay, wood concrete, shavings) - have good thermal insulation qualities and are relatively inexpensive;

- Mineral wool and glass wool are effective in terms of heat and sound insulation, fireproof, not susceptible to infection by fungi and rodent attacks, hygroscopic (require mandatory vapor barrier);

- Polystyrene foam and expanded polystyrene are moisture-resistant materials, not subject to deformation, do not ignite, conduct heat poorly, and dampen sound noise.

It is impossible to say which of these materials is the best. You need to choose based on your financial capabilities and the functionality of the insulated room.

Types of insulation

On sale you can find three types of insulation, each of them has its own scope of application.

To insulate the floor with your own hands, it is better to know the properties of each of them.

The following types of insulation are distinguished:

- Mineral

- Polymer

- Wood-based panels

Mineral insulation

Environmentally friendly insulation. There are several types of mineral insulation. Let's look at the characteristics of each of them.

Mineral wool. It is produced by heating rocks and transforming them into thin threads. These threads are subsequently secured with an adhesive. It is sold in the form of rolls of mats.

The advantages of mineral wool include low cost, good noise and thermal insulation. Mineral wool does not harbor rodents or mold. Mineral wool is a breathable material with a long service life.

Mineral wool has several varieties:

- Stone;

- Basalt;

- Glass wool;

- Slag wool.

Glass wool

Glass wool is made by heating sand, lime, soda, and borax to 1400 degrees. The finished composition is passed through the container to form thin strands of string. Subsequently connecting them into a single layer.

- Glass wool retains heat well and does not allow sound to pass through.

- Quite durable material that is not subject to destruction under the influence of vibration.

- It is fireproof and does not burn. At a temperature of 450 degrees it disintegrates, losing its properties.

When working in glass wool you must be extremely careful. Since glass fibers break into small cutting particles under physical impact. When they get on the skin they cause itching. Fibers entering the respiratory tract are extremely dangerous.

Basalt wool

Basalt wool is made from rocks that are heated at a temperature of 1500 degrees. At this temperature, the steam breaks down into fibers, which are then fixed with adhesives.

- It is a good sound and heat insulator.

- Safe to use and does not contain any caustic substances.

- Does not lose shape after a long period of use.

- It is waterproof, does not emit hazardous substances, but when heated to 700 degrees it releases phenol.

- Suitable for insulating wooden floors, walls and roofs.

Slag wool

Made from metallurgical waste. Just like glass wool. When heated to 300 degrees it begins to melt. It deteriorates when exposed to moisture. Service life is from 10 to 15 years. Refers to insulation materials with a low price category.

Foam glass

Like all heat insulators, it is a good sound insulator. Environmentally friendly and does not emit harmful substances. Does not burn under high temperatures and is not afraid of moisture.

Foam glass is not susceptible to the formation of mold and other bacteria. Rodents will also not grow in it.

- Foam glass tolerates various climatic conditions well, maintaining its structure.

- Foam glass also has a long service life.

It can be used in various regions, even where humidity levels are high or severe frosts occur in winter.

Expanded clay

Burnt clay granules suitable for insulating concrete floors.

- Due to its structure, it does not allow heat to pass through.

- Quite easy to use.

- The material is not subject to fire.

- Refers to insulation materials of a low price category.

- Does not emit harmful chemicals. Tolerates frosts.

The disadvantages include the fact that when working with it, it generates dust; you need to work in a respirator.

Method of thermal insulation of a wooden base

Insulation of a wooden base consists of filling the space between the joists with insulating material. During the work you will need the following materials:

- insulation;

- polypropylene film;

- scotch;

- sheets of plywood or boards.

The amount of insulation is calculated so that the material tightly fills the space between the beams, and the vapor barrier film must be taken with a reserve, because its edges must extend to the walls along the entire perimeter of the room. In addition, if mineral wool is used, the film should be laid on top and bottom of the insulation. For installation you need to prepare the following tools:

- nail puller;

- hammer;

- building level;

- roulette;

- scissors or sharp knife;

- construction stapler;

- screwdriver

Dismantling the old coating

Work begins by dismantling the old coating. Using a nail puller, the boards are removed and the space between the joists is cleared of debris and dust.

Dismantling the old coating

It is necessary to check all the joists for strength, otherwise the new coating may bend.

Waterproofing

If the beams are in perfect order, you can begin laying waterproofing. The film should completely cover the base and extend onto the walls by about 5 cm. If a whole piece is not enough, the film is overlapped by 15 cm, and then the joints are sealed with tape. Do not stretch the film too much, otherwise it will tear during installation of the insulation. For convenience, the edges of the film are secured to the walls with a stapler.

The film should completely cover the base and extend onto the walls by about 5 cm

Thermal insulation

The next step is laying insulating material. The foam is cut with a knife into pieces of the required width and placed tightly between the beams. If mineral wool is used, the width of the pieces should be 2-3 cm greater than the distance between the logs, then the insulation will fill the space as tightly as possible. Expanded clay or shavings are poured onto the film and leveled so that the layer thickness does not exceed 20 cm. After this, the surface is checked with a level and protruding parts are removed.

The next step is laying insulating material

Installation of the second layer of waterproofing and subfloor

The final stage is laying the second layer of waterproofing and subfloor. The film is laid overlapping in the same way, the seams are taped. For the subfloor, you can use thick plywood, boards, and chipboard. The material is first treated with a deep penetration primer mixture and dried. Fasten the base with self-tapping screws or nails to the joists, being careful not to damage the insulation.

The final stage is laying the second layer of waterproofing and subfloor

Polymer insulation

This category is divided into:

- Expanded polystyrene foam;

- Polyurethane foam;

- Foamed polyethylene on a foil base;

- Penoizol-liquid foam.

Useful tips

Before you start insulating the floor, you need to choose the right building material. Before making a choice in favor of one or another heat insulator, it is necessary to carefully study the characteristics of not only the material, but also the building itself in which the floor insulation will be carried out:

- It is imperative to take into account the materials from which the supporting structures are made, and also do not forget about the features of the finishing coating.

- If polystyrene foam is used as a heat insulator, then the gaps formed between the plates should be sealed with polyurethane foam.

- When using mineral wool, you must follow safety rules and remember that this material can cause harm to the skin, respiratory system and mucous membranes. You need to wear special protective equipment when working with it.

- You should not think that the wooden elements of the floor, being under a layer of insulation, will be reliably protected from the harmful effects of the main enemy of wood - water. On the contrary, under the layer of vapor barrier materials, high humidity prevails. That is why all wooden structures must first be treated with special protective compounds.

- When creating a layer of expanded clay insulation, care must be taken to ensure that it is protected from the wind on all sides. The fact is that moving air will reduce the effectiveness of thermal insulation.

If you choose the right material for thermal insulation of the floor in your apartment and correctly install the thermal insulation, you can not only increase the level of comfort in your home, but also reduce financial costs during the heating season.

Expanded polystyrene

Quite a popular type of insulation. Popularly known as polystyrene foam. Due to its low weight it does not add additional load. Withstands moisture well.

When insulating the floor, you can use the small thickness of the sheet. Foam plastic is also one of the inexpensive insulation materials.

When burning, foam releases harmful chemicals.

Common Methods

There are several methods of floor insulation. The most common is the so-called wet method, which involves creating a concrete screed. Another popular method of floor insulation is called, on the contrary, dry, since it no longer requires the creation of a screed. In this case, dry bulk materials such as, for example, expanded clay are used as insulation. The main feature of such materials is their low density.

If you can perform thermal insulation using a “wet” or “dry” method yourself, then such a technology as “spraying” can only be done by specialists. The fact is that when spraying, the insulating material must be evenly applied to the base. This requires specialized equipment and high skill.

The role of insulation during spraying is usually played by polyurethane. If you urgently need to insulate the floor, but you are chronically short of money for installation, you can use less expensive, but also less effective methods.

One of the low-budget insulation options is the use of carpet or carpet made from natural yarn. However, it is worth remembering that such materials require special care.

Foamed polyethylene on a foil base

Foamed polyethylene is considered one of the best insulation materials for floors. It is produced by foaming polyethylene with liquefied gas. Foil is applied to one side of the composition to reflect heat.

The finished product is packaged in rolls, slabs or sheets.

- The sheet is not afraid of moisture and can be used in rooms with high humidity.

- Can be installed in kitchens and bathrooms and even in baths.

- Retains its original appearance even under high loads. Not afraid of contact with gasoline and various alkalis.

- Installation of foamed polyethylene is quite simple; the sheets are not massive in size.

- The sheet must be laid with the foil side facing up.

Thus, the heat will not only be retained, but also reflected back into the room.

Performing thermal insulation along joists

This method is reminiscent of insulating a wooden base and differs only in that in this case you need to independently make and install logs from beams on a concrete floor. To work you will need:

- timber with a section of 50x100 mm;

- ready-made bitumen mixture;

- insulation;

- plywood or chipboard sheets;

- self-tapping screws;

- screwdriver;

- wide brush;

- roulette and level.

The timber must be selected from dense wood, smooth, dry, without visible defects. It is recommended to treat it with an antiseptic primer - this will extend the life of the tree. Instead of bitumen mixture, you can use plastic film and tape to insulate the joints.

They start by cleaning the base from old screed and debris, then carefully level the surface. Now, using a brush, spread the waterproofing mixture over the concrete. The walls are also coated with mastic to a height of 3-5 cm around the perimeter of the room.

After waterproofing is completed, the beams are laid: the first beam is placed on the edge close to the wall, the next one is parallel to the first at a distance of 70-90 cm, and so on until the opposite wall. The thinner the logs, the smaller the distance between them should be.

After waterproofing is completed, the beams are laid

Using a level, you should check the position of the beams relative to the horizontal so that the finished floor does not have a slope. To securely fix the logs, you need to use anchors, but if the beams rest tightly against the walls, you can do without fasteners. Heat-insulating material is laid between the logs, and plywood or chipboard with a thickness of 10 mm or more is laid on top.

Thermal insulating material is laid between the joists

To avoid deformation of the coating, it is recommended to retreat 15 mm from the walls. It is better to lay the rough coating in 2 layers so that the joints of the lower sheets are completely covered by the top sheet. Both layers are attached to the joists with self-tapping screws. After this, you can lay linoleum, lay laminate or parquet.

Photo of floor insulation

Aerated concrete and foam concrete

Foam concrete resembles swollen and frozen soda in a bottle. This effect is achieved when the mixture is produced using water saturated with oxygen or at low pressure in vacuum installations. Aerated concrete is made in chambers where nitrogen compounds are used instead of air, which gives aerated concrete blocks strength and durability. They can also be used to build load-bearing structures in houses and apartments. These materials are much stronger than vermiculite. You can use it for insulation if you have a lot of leftovers left after construction, but it is better to make insulation from foam plastic.

What to remember when planning insulation work

Incorrectly performed thermal insulation can do more harm than good. Well, at best, the apartment simply won’t get any warmer. As for the most “deplorable” results of incorrect installation, these include:

- Too intense condensation;

- Dampness;

- The appearance of mold, mildew and, as a result, an unpleasant odor.

Do not forget about the extra financial costs that await the apartment owner in the event of incorrect insulation. After all, you must admit, few people will live in unfavorable conditions, saving on correcting shortcomings. But the latter can sometimes cost more than a new installation. Therefore, think carefully before fastening yourself if you lack knowledge and experience. The same applies to the performance of work by “bombers” who are never responsible for anything.

Note! When looking for a contractor, do not be fooled by the low price and fancy words in the ad. It’s better to take the trouble to check the reputation of the potential performer 7 times. Read reviews, ask to send photos of the work or a link to social networks where the contractor shares his results.

Types of floors in the apartment and features of their insulation

If the decision to insulate the floor has been made, first of all, you should decide how exactly the floors are arranged in a particular house. The method of thermal insulation and the choice of insulation depend on their design.

The following types of floors are available:

- reinforced concrete slabs, prefabricated or monolithic;

- ceiling on wooden beams;

- floors on the ground (ground floor).

The last two categories are, of course, not as common as reinforced concrete, but in old houses this is not at all a rare case. Wooden beams are perhaps the most problematic option. As a rule, houses with this type of flooring are quite old and the condition of the floor structures is not very good. It is necessary to completely change many components and lay a new floor on wooden joists.

Types of floors

Attention! Reinforced concrete floors are the easiest and cheapest to insulate. There are a lot of design options for insulation.

Replacing heating radiators

It is also cold in high-rise buildings due to the low efficiency of old heating radiators. Therefore, having asked the question of how to insulate an apartment, it is certainly worth thinking about replacing them. This is done in the warm season, before the start of the heating season. The order of work in this case is as follows:

- Old radiators are cut off.

- Markings are made on the wall and brackets are nailed.

- The new battery is hung on the wall. The nuts included in the kit are screwed onto all four outlet pipes.

- Next, the inlet and outlet valves are screwed onto two of them (diagonally at and below) by wrapping tow and coating the threads with paste.

- Opposite the first one, on the back side of the radiator, a Mayevsky tap is installed.

- The remaining pipe is closed with a special plug.

The method of connecting radiators described above is called diagonal. There are also side and bottom mounts. In the first case, both taps - inlet and outlet - are screwed on one side of the battery, at and below. The air release device and the plug, respectively, are installed on the other. With a bottom connection, both valves are attached on the right and left to the lower pipes. The Mayevsky tap is always installed opposite the coolant supply element.

Concrete screed

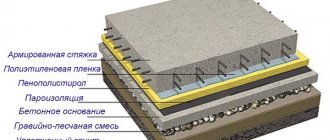

If there are slab reinforced concrete floors, the floor of the first floor is easiest to make using wet screed technology. Design features are:

- minimum layer thickness – 3 cm;

- construction material – sand concrete (proportion 1/3, cement, sand, respectively) or ready-mixed concrete with a fine filler fraction (crushed stone 5/20 mm);

- waterproofing - applied on top of the floor slab, extending onto the walls by 15 - 20 cm, carried out using coating or pasting technology in a continuous layer;

- insulation – foam glass or extruded high-density polystyrene foam.

Wet screed with a layer of insulation.

The main advantage of a wet screed is the ability to add heated floor contours and acoustic material to the design.

Important! The thickness of the screed is calculated from the last (upper) layer located inside it, that is, from the insulation or water-heated floor pipes. The technology has been thoroughly developed by generations of developers and does not have complex operations:

The technology has been thoroughly developed by generations of developers and does not have complex operations:

- finding the top point - in all rooms at an arbitrary height, a laser plane builder creates marks of a single horizontal level, the distance from the line to the ceiling is measured, the smallest value will be at the top point of the structure;

- waterproofing - two layers of bitumen or polymer mastic or a waterproofing membrane;

- laying insulation - a 5-10 cm thick layer of EPS with a continuous layer, filling the cracks with polyurethane foam;

- installation of a damper - the walls at the junction points with the slab are covered with rubber tape or strips of insulation 2 cm thick are installed;

- reinforcement - wire mesh is laid with an overlap of at least 5 cm on polymer spacers that provide a protective layer of concrete;

- heated floor - used as needed, pipes are attached to the wire mesh with clamps or twisted wires;

- beacons - the profile is installed on a quick-hardening starting putty in a single horizontal level to ensure a screed thickness of at least 3 cm at the top point;

- pouring - concrete is placed between the beacons, the excess is removed using a rule or a vibrating lath;

- grinding - in order to reduce the thickness of the layer and level out possible unevenness of hardened concrete, the surface is processed with a grinder.

Screed on a warm floor.

Instead of sanding, you can use a thin layer (5 - 10 mm) of self-leveling floor. which can simultaneously serve as a finishing coating.