assets/from_origin/upload/resize_cache/iblock/f50/600_450_2/f5027ddfcd78eb86d501536f41b52d29.jpg From this article you will learn:

- What heating schemes are used in the apartment?

- How do single-pipe heating schemes in an apartment differ from two-pipe heating schemes?

- What are the connection diagrams for heating radiators in an apartment?

Today, many apartment owners prefer autonomous heating. This heating system is more profitable and efficient than a centralized one. The principle of operation of autonomous equipment is as follows: the water entering the batteries is heated using a gas boiler. What heating connection diagrams in an apartment are used in practice? You will learn about this from our article.

Selection of radiators and pipes

Any heating system has its own characteristic features that must be taken into account in order to know exactly how best to heat the apartment. What makes the choice of heating devices special in all this is that where some batteries are ideal, others will not be efficient or reliable enough.

The simplest and most painless solution related to the choice of heating components is to contact specialized specialists who will conduct a full analysis of specific conditions and select the most suitable elements for them. However, with a competent approach to the matter, you can carry out this work yourself - it will be enough to consider the features of all possible components and figure out under what conditions a certain type of element should be used.

Choosing an energy carrier

The main selection criterion is the cost of energy, depending on the country and region of residence. If in the Russian Federation the undoubted leader is natural gas, then in the rest of the states of the former USSR the picture is different - firewood, briquettes and coal take the first place. Don't forget about electricity supplied at half the nightly rate.

When choosing the right type of fuel, it is worth considering five factors (in addition to price):

- efficiency (efficiency) of heating equipment using this energy carrier;

- ease of use;

- how often the units will have to be serviced, prices for calling a technician;

- storage requirements.

Below is a comparative table showing the prices of various energy sources and how much a kilowatt of heat produced in real conditions costs. Building area – 100 m², region – Moscow region.

Note. The calculation results and prices are given as of February 15, 2018. Over time, the data becomes irrelevant, but the difference in the cost of 1 kW remains.

Based on the numbers given in the table, it is much easier to find a suitable option (or several). Just make an adjustment for the cost of energy in your region. Based on other selection criteria, we will give 4 tips:

- It is most convenient to use gas and electric heating equipment. There is no need to store anything, constantly maintain and bother with cleaning water heating devices.

- Burning coal and wood is the most economical way to heat. Saving money will have to be paid for with labor - sawing, carrying, loading the firebox, cleaning the chimney. It is more comfortable to burn briquettes and pellets, but the price of the boiler installation and the fuel itself increases. Plus you will need storage for storage.

- Diesel fuel or liquefied gas is the best solution for providing autonomous and at the same time comfortable heating when other energy sources are not available. The downside is the decent cost of fuel and installation of the fuel tank.

- A proven option is the combination of 2-3 energy carriers. A common example: solid fuel + electricity at night tariff.

Which fuel is best to use in specific conditions is described in detail in a separate material. We also recommend watching the video and listening to useful expert advice:

Cast iron radiators

Heating appliances made of cast iron have a long service life and fairly high heat transfer. In addition, a very important feature of cast iron batteries is their inertia - cast iron takes a very long time to gain heat, so it takes a lot of time to warm up the system, but if the coolant supply is stopped, the accumulated heat will flow into the apartment for several hours.

A noticeable disadvantage of this type of battery is its heavy weight. This factor, firstly, significantly complicates transportation, and secondly, it places special demands on installation technology. You won’t be able to install cast iron radiators yourself, and they can only be mounted on solid walls that can withstand high loads, since the weight of a cast iron radiator is considerable..

The internal volume of cast iron batteries is quite large, so heating them requires a large amount of coolant. From this we can conclude that using such radiators in combination with an electric boiler is extremely unprofitable. For centralized and gas heating, cast iron heating devices are ideally suited.

Boiler installation instructions

Strict requirements are put forward only for the installation of gas-powered heaters. But we recommend following these rules when installing any heat generators:

- Equipment with a power of up to 60 kW can be placed in a kitchen with ceilings of 2.5 m (minimum). More powerful units are moved to a technical room - internal, attached or free-standing.

- The requirement for furnace ventilation is threefold air exchange, that is, the amount of supply and exhaust air is equal to three volumes of the room in 1 hour. The kitchen window is equipped with a window.

- When placing a floor-standing boiler, observe the minimum technological passages - 1.25 m in front, 60 cm on the side, 250 mm in the back from the nearest building structure, as shown in the photo.

- The distances from the wall-mounted heat generator to the walls or cabinets are 20 cm on the side, 45 cm on the top, 300 mm on the bottom. Before hanging, a protective sheet of roofing steel is laid on the wooden wall.

- The height of the chimney is 5 m, calculated from the grate or gas burner, not from the ground. The head of the pipe should not fall into the wind support zone of the roof.

- The maximum number of turns of the chimney is 3, the distance from the chimney to combustible structures is 0.5 m.

Clarification. Double-walled sandwich-type chimneys can be placed at a distance of 38 cm from wooden walls and ceilings.

The heat generator piping depends on the fuel consumed. High efficiency boilers - gas, diesel - are connected to the system directly through shut-off valves. Floor-standing versions are additionally equipped with an external expansion tank and pump.

Typical wiring diagram for a double-circuit wall-mounted heat generator

Solid fuel units must be protected from cold return flow and condensation; accordingly, a small boiler circuit with a three-way mixing valve is provided. Please note: the pump is always installed inside the circuit, on the supply or return line - it makes no difference. Detailed wiring diagrams are shown in the instructions for connecting TT boilers.

Important! In a closed system operating under pressure, there is always a safety group - a pressure gauge, an automatic air vent and a safety valve. The installation point is the supply pipe at the boiler outlet. To prevent dirt and sand from getting inside the heat exchanger, a filter - a mud filter - is placed on the return line in front of the heater.

Aluminum and bimetallic batteries

These types of batteries are excellent for apartments with centralized heating. The fact is that the coolant in such systems has a lot of contaminants and negative features, such as high rigidity. Bimetal perfectly withstands such influences and does not rust due to exposure to moisture and air. Another advantage worth noting is the ability to vary the number of sections, unless these are monolithic batteries.

The main and most obvious disadvantage is the high cost of products made of aluminum or bimetal. The second point, which can partly be attributed to disadvantages, is the weak ability to accumulate heat, i.e. Radiators cool down quickly when the system is stopped. However, if there are no problems with heat supplies, then this factor can be safely discounted.

Where to get the necessary documents

Collecting the required papers can take a lot of time and effort, because you will have to contact many services and organizations.

- For permission to disconnect your apartment from the general heating system, go to the city heating network. A refusal can be obtained only in one case: if the removal of radiators leads to disruption of the operation of equipment in neighboring apartments.

- Specifications for installation of a gas installation are provided by the gas service. To receive them, you need to go to the district housing office, from where a letter with the request is sent to the department.

- The refurbishment plan is handled by the design organization. This document should contain all information about the future system, technical solutions and calculations.

- A completed redevelopment project requires approval from the authorities from which the specifications were received, as well as the fire service and SES authorities.

Steel panel batteries

Heating appliances made of steel are, perhaps, the optimal combination of price and quality. The efficiency of steel radiators is quite high, the service life is quite long, and the price is not so high that it can be considered unjustified. In addition, it is also worth noting the relatively light weight of such devices and, as a result, simple installation.

A characteristic disadvantage of standard steel appliances is their susceptibility to corrosion, which can significantly shorten the life of radiators in the heating system. In order for devices to work properly, they need high-quality and regular maintenance. In addition, to prevent corrosive effects, you should try not to drain the coolant for a period longer than a week - moisture combined with air can seriously damage the internal parts of the radiators.

Basements

As a rule, initially basements in apartment buildings were planned as a place where all the nodes of heat and water communications were collected, ventilation also took place here, and the central sewage system of the building was located.

Currently, basements are often converted into cafes, gyms or shops. Heating the basement of an apartment building is part of a centralized system, which heating network technicians are required to look after. To prevent it from becoming a “black hole” in the budget of the house, it should be carefully insulated and this should be done, as in the entrance, by the heat supplier.

Residents of the building have the right to check how well the work has been done , since they are the ones who pay all the costs for heat, regardless of whether there is a common building meter or not.

Selection of heating pipes

Only a few types of pipes are used for heating systems, so there will not be any particular difficulties in choosing them:

- Steel pipes . This material has very high mechanical strength, so it is not afraid of various external damages. Another thing is that steel is susceptible to corrosion, so it can be damaged from the inside. Steel pipes accumulate heat well and partially influence the intensity of convection in the room. Installing heating in an apartment using steel pipes requires welding, so this work requires relevant experience or a good specialist.

- Metal-plastic pipes . One of the most inexpensive and easy-to-install pipe options for a heating system. The disadvantage is the large number of connections, which greatly increases the likelihood of circuit leaks. To reduce the likelihood of leaks to a minimum, you need competent heating wiring in the apartment and careful monitoring of it during operation.

- Plastic pipes . Another relatively inexpensive option that has a lot of positive qualities. Among the advantages are resistance to rotting and corrosion, as well as the highest reliability of the connections - they are processed using soldering, and if the work is done correctly, the seams will never leak. This material has no particular disadvantages, but you need to pay close attention to the characteristics of specific products when purchasing them.

When trying to decide which pipes to use for heating in an apartment, we can conclude that the best option, other things being equal, would be plastic pipes, which are excellent for self-installation. Radiators can be selected individually - they are connected in exactly the same way, and the whole difference lies in the individual compatibility of the heating system and the specific type of radiator.

How to choose a heating unit

Factors influencing the choice of a boiler (or several water heating devices):

- energy carrier used;

- heat generator power;

- dependence on external energy sources;

- price;

- functionality, ease of use.

Note. The heater selection criteria are arranged in order of priority. It is important for the user that the unit consumes cheap fuel and produces enough heat. Price plays a secondary role; comfort and functionality come in third place.

All household boilers are usually divided into groups according to the type of fuel (energy carrier) burned:

- gas;

- electrical;

- solid fuel;

- liquid fuel, consuming diesel fuel and waste oil;

- universal, operating on 2-3 types of energy carriers.

Each of the listed groups is divided into varieties according to the operating principle, installation method and other criteria. We will review existing boilers and give a number of useful recommendations.

Types of gas boilers

To organize heating in private homes, 3 types of units using natural gas are sold:

- Atmospheric. The combustion chamber is open, combustion air is taken from the boiler room. The operating efficiency is in the range of 86...88%.

- Supercharged (aka turbocharged). Air is forced into the closed firebox by a fan controlled by an electronic circuit. Boiler efficiency is 90...93%.

- Condensation. Structurally similar to turbocharged heaters, but the heat exchanger and burner are designed in such a way that in a certain mode the boiler uses the latent heat of combustion of the fuel. Efficiency – 95%.

Reference. All heat generators are capable of burning 2 types of fuel - natural gas and liquefied propane-butane mixture (LPG). To switch to LPG, the fuel jets are replaced and the automation is adjusted.

Boilers are manufactured in wall, floor and parapet versions. The first group is ready-made mini-boiler rooms, equipped with their own expansion tank and pump. The second type is high-power units, or those that do not depend on electricity. Parapet models are placed near the outer wall, the chimney goes directly to the street.

Among the large assortment of gas water heaters, it is not easy to make the right choice. Our recommendations are:

- If you are on a limited budget, purchase an atmospheric wall-mounted boiler. But remember - open-chamber heaters require a traditional chimney.

- To work together with the gravity system, you will need a non-volatile floor-mounted atmospheric unit.

Floor-mounted non-volatile heater equipped with a single-stage burner, mechanical automatic safety system EuroSIT and a cast iron heat exchanger - It is better to install a forced-air heat generator in an apartment or cottage without a ready-made chimney. Organize the removal of combustion products through a coaxial pipe laid through the outer wall.

- To supply hot water to 1-2 consumers, buy a dual-circuit model. If the consumption in the DHW network is high, you will need an indirect heating boiler connected to a conventional single-circuit heater.

- Read the detailed description of all gas heaters presented in a separate article.

A condensing boiler is the most economical among gas-using devices. The disadvantage of the unit is the complexity, high price of the equipment and its repair.

Electric hot water installations

A feature of electric boilers of any type is their high efficiency, reaching 99%. The second positive point is the low installation costs and purchase of the heaters themselves. The units should be used as auxiliary heat sources, operating at night at half the light tariff.

There are 3 types of electric boilers (all are available in wall-mounted versions):

- With traditional tubular heaters - heating elements. Modern devices are equipped with an expansion tank and a circulation pump.

- Electrode. Heating of the coolant occurs due to a chemical reaction resulting from the passage of current through the water layer between the 2 electrodes.

- Induction. Here the coolant is heated by the steel core of a sealed coil, which creates eddy currents in it.

Sectional view of a heat generator with tubular heaters (TEH)

To install electric heating, it is better to take a classic heating element boiler that does not require serious piping. The device is reliable and easy to repair - you can always replace a burnt heating element yourself. An induction heat generator is expensive and cannot be repaired in the event of a breakdown, and an electrode heat generator is highly dependent on the salt content in the coolant.

Advice. Don't listen to salespeople who call induction boilers energy-saving. All electrical installations heat water equally efficiently - losses do not exceed 2%, the rest of the energy is converted into heat.

Classification of solid fuel boilers

For heating country cottages, 3 types of solid fuel units are used:

- direct combustion - atmospheric and turbocharged;

- pyrolysis;

- automatic pellet and coal.

There are many myths about the efficiency of TT boilers. Manufacturers of pyrolysis heat generators claim an efficiency of 85-86%, pellet heat generators - up to 90%. In reality, the figures are much more modest: traditional wood-burning units - 75%, pyrolysis units - 75%, boilers using pellets and coal chips - up to 86%.

Construction of a direct combustion boiler with a fire tube heat exchanger

Reference. In addition to the listed types of heaters, there are long-burning TT boilers with an increased size of the firebox. How to distinguish such installations from classic wood-burning heat generators, read the corresponding publication.

Recommendations for choosing a solid fuel boiler:

- A steel direct combustion apparatus equipped with a chain draft regulator is perfect for burning wood, coal and briquettes. Turbocharged examples are automated and burn wood better, but rely on electricity.

- Pay attention to the volume of the firebox of a traditional boiler - the duration of combustion depends on this indicator.

- Automated pellet units are a good solution for lovers of comfortable heating. You don’t have to chop and carry wood, remove coal dust, just clean the firebox and burner weekly.

- Do not mess with pyrolysis TT boilers, they are a priori more expensive than conventional ones, demanding on the quality of fuel, and in addition they consume electricity.

- Avoid models with water-filled grates if you plan to burn with coal. The temperature difference forms a hard crust on the surface of the grate, which is not easy to knock off.

Grate of a TT boiler made of pipes filled with coolant

When choosing a heat generator, remember the old saying “the miser pays twice.” It is better to take a high-quality classic device with a cast-iron heat exchanger than a cheap “pellet generator” with electronics of unknown origin.

Diesel and combined models

This heating equipment is used much less frequently than gas, wood and electric boilers. Diesel fuel is more expensive than other energy sources, and waste oil is a specific fuel that is clearly unsuitable for the average homeowner. Accordingly, such heating devices are operated only in certain conditions when access to other resources is limited.

Multi-fuel boilers from different manufacturers combine 2-3 energy sources, for example, wood + electricity, gas + coal. Advantage: you buy one heat generator and get two. Disadvantage: the unit cannot boast of high efficiency and functionality. The most popular option is shown in the photo - a TT boiler, equipped with a heating element unit for electrically heating water after the flame in the firebox has died out.

Electric wood heater from the Russian company Teplodar

Heat generator power calculation

To select a boiler based on performance, you should find out the load on the heating system of the house. That is, calculate the heat losses of the building. We propose to calculate this indicator in a simplified way:

- If a living room is separated from the street by one wall with 1 window opening, then 0.1 kW of heat is consumed to heat a square meter of area.

- A room with two external walls (corner) and 1 window – 0.12 kW/m².

- The same, with 2 light openings - 0.13 kW/m².

An important nuance. The calculation is performed for each room separately, then the results are summed up.

The algorithm is suitable for buildings with floor heights up to 3 meters. If the ceilings are higher, heat consumption is calculated based on the volume of the room. Accordingly, in a room with 1 fence and a window, the volume value is 35 W/m³, in a corner room – 40 W/m³, in a corner room with two openings – 45 W/m³.

Having determined the need for thermal energy at home, we select the power of the boiler installation according to the instructions:

- The performance of a unit operating only for heating is taken with a margin of 20%. That is, we multiply the found amount of heat by a factor of 1.2.

- The heat generator providing hot water supply must be taken with a reserve of 50% (coefficient 1.5).

- For TT boilers, the increasing coefficients are 1.5 and 2, respectively.

If you live in an area with a mild southern climate, then the coefficients should not be used. Conversely, residents of the northern regions should increase the initial heat loss figure by 1.5-2 times.

Calculation of heat losses by volume of residential premises

Tools and materials for installation

In addition to pipes and batteries, the choice of which was discussed above, installing a heating system in an apartment requires tools, the set of which is as follows:

- Fittings and taps;

- Silicone sealant or tow;

- Fastening elements for system elements;

- Set of screws and dowels;

- Soldering iron for pipes;

- Pipe cutting shears;

- Set of wrenches;

- Screwdriver;

- Hammer;

- Construction and water level;

- Tape measure and pencil.

This set of tools is sufficient for arranging a heating system. If you are planning a one-time job, then it is advisable to rent specialized tools (like a soldering iron for pipes) rather than buy them - the cost of such devices, especially professional ones, is quite high.

What to do when permission is received

If everything was done correctly and you managed to get a positive response, the next step will be to purchase equipment and conclude an agreement with an organization that will install autonomous heating.

When, finally, the re-equipment is completed, and all the work on installing the new system has been carried out, all that remains is to go through several more city organizations and receive an acceptance certificate. This will be the end of the official registration of the installation of individual heating.

If there are no financial restrictions, you can save yourself from visiting offices and, for a separate fee, entrust the preparation of all approvals and documents to the design service.

The following video discusses the operating features of the most popular heater model - a gas boiler.

Installation of a heating system in an apartment

Do-it-yourself heating installation in an apartment includes the following steps:

- Before turning on the heating in the apartment, you need to mark the places where the elements of the heating system will be located. Radiators are most often mounted at the same level, for which it is enough to move the first mark to all other installation points of heating devices.

- Next, you can install radiators. This work is not particularly difficult - all you need to do is prepare holes in the walls, secure the fasteners with dowels and hang radiators on them.

- The next step is preparing the pipes. At this stage, you need to determine the distances between the radiators, where the pipes will be located, and also solder these pipes in a suitable way. If the work is not carried out alone, then an assistant can be sent to screw fittings into the radiators.

- System assembly usually begins from the point at which heated coolant is supplied to the circuit, as well as from the point at which the coolant returns. A special feature of these sections is that there is no need for soldering - the steel pipes of the boiler usually have a thread cut into them, the connection to which is carried out using adapters. Subsequently, these adapters are soldered to plastic pipes.

- Further work consists of laying all other sections of the supply and return pipes. The last stage is the installation of bends to the radiators, installation of corner valves and connection of radiators with pipes.

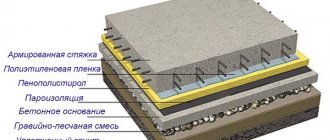

Floor insulation for hidden wiring

Removing heating pipes out of sight is tempting from an aesthetic point of view. To prevent hidden heating wiring from subsequently causing the righteous anger of heating engineers with accompanying sanctions, it is advisable to prepare the floor accordingly. If the decorative flooring is laid on joists and additional floor insulation is not required, then the pipes are simply laid between the joists, and removable access hatches are installed above their connections.

Otherwise, the pipes must be laid in the floor. Methods for floor insulation are described in the corresponding article, and for this case we can recommend the following:

- We lay pipes.

- We form an additional warm screed from foam concrete. We fence the pipe connections until the concrete hardens with boards according to the required dimensions (see at the end).

- We lay 12-18 mm plywood flooring directly over the warm screed, gluing the joints with liquid nails or assembly adhesive. We cut out openings in the plywood above the pipe joints.

- We restore the finished flooring. We cut out the hatches for access to the pipes larger than the openings in the plywood - they will simply be removed.

The second method is somewhat more expensive, but it is easier to work with and provides access to the pipes along their entire length. To do this, we use foam concrete or aerated concrete slabs with cement-sand mortar as a warm screed. The rest is the same.