Brick is the leader among building materials. The service life of a brick house, subject to construction technology, can exceed a century, and the construction time, using modern technologies, is a matter of weeks. We will talk about how to build a house from brick, as well as the pros and cons of brick houses in this article.

There are many varieties, sizes and types of this building material. Building bricks are used to form walls, piers, and other structural elements. The surface is rough, with chips, stains and color transitions.

Facade or facing clinker bricks are used as the main material for finishing work on the facade of architectural structures. Moreover, it can be used to create original design installations inside various rooms. Let's figure out which brick is better for building a house.

Types of bricks according to clay type

Ceramic brick

Ceramic bricks are used for construction purposes and as cladding. The material is made from red clay by firing. Materials that do not have decent aesthetic characteristics are used for the construction of walls, arches, and partitions. Brick with decorative relief allows you to create an original decor for a barbecue oven, decorate a fireplace, or simply decorate a wall.

Fire brick

Refractory brick differs from ceramic brick in that it can withstand extreme thermal loads. It is made from refractory clay, fired at more than 1300 degrees. It has a low level of thermal conductivity. It withstands temperature changes. This is an ideal basis for creating heating structures.

Sand-lime brick

Sand-lime brick is made from lime, which gives the material special strength. This is the most common type of building material for building a house, as it has good mechanical properties and a low price.

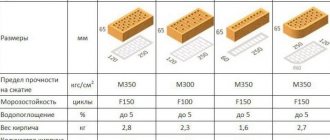

Characteristics of stone material

The two main parameters that determine the quality level of a product are its resistance to low temperatures and labeling. To check frost resistance, simply look for the F mark on the package. The number next to it will tell you how many cycles of complete freezing and thawing, that is, seasons, the stone can withstand. A reduction in strength is allowed only by 20% for all cycles. As soon as the next season affects the strength, reducing it by more than 20%, the shelf life is over.

The marking determines the strength parameter. Indicated by the mark - M. Markers of 75, 100, 125 units are often used. These are indicators per square meter. There are even greater values, but they are worth purchasing only under special environmental conditions or if the planned construction is very heavy, more than two floors. All recommendations will be indicated in the project.

Types of bricks according to design features

Solid brick

Solid brick is equipped exclusively with holes of technological origin and consists of 83 - 91% clay. Advantages of this type: strength, ability to withstand heavy loads. The walls of multi-story buildings are made from this building material.

Hollow brick

Hollow, or as it is also called, effective brick, has special holes (from 10 to 45% of the volume). It can be square or round with through or non-through voids.

Holes make it possible to improve the heat-shielding properties of bricks, save raw material consumption during the production process, and simplify some stages of the technological process. This material is quite lightweight and does not overload the foundation of the structure.

Audibility in houses made of hollow elements is much lower than in houses made of solid brick, since the voids also act as sound insulation.

Super efficient brick

Super-efficient or porous bricks have the highest properties for high-quality thermal insulation and audibility. Manufacturers add sawdust or polystyrene foam to the clay batch, which burn out when exposed to high temperatures and leave closed voids. The products are very light, even despite the fact that their dimensions are significantly larger than those of other types of building materials.

All brick sizes for landscaping and construction are standardized. There are three main types of this building material:

- Single (250x120x65 mm);

- One and a half (250x120x88 mm);

- Double (250x120x138 mm).

These dimensions will be useful to you when calculating the number of bricks to build a house. By calculating the quantity based on the dimensions of the building, you can calculate how much it will cost to build a brick house.

Manufacturing methods: advantages and disadvantages

The properties of the material depend on the characteristics of the production technology and the quality of raw materials. The basis for making the product is clay of a special fraction. To prevent the layers from mixing during mining, excavators with one bucket are used.

- Pros: accurate extraction of homogeneous raw materials, without impurities.

- Disadvantages - the method is not economically profitable, so it is rarely used.

More often, clay is extracted using rotary units. In this case, many layers are captured at once.

- Pros: productive method.

- Cons: Product quality deteriorates.

To prevent mixing of layers from affecting the properties of products, a firing system is used in which the various components are bonded together. Ceramic bricks are fired at a very high temperature. As a result, the technical characteristics of the material are improved.

Porous ceramic block

How to build a brick house

Let us briefly outline all the stages of building brick houses. Before construction begins, a foundation is erected for load-bearing walls, which can be block or monolithic. To figure out what kind of foundation is needed for a brick house, we recommend reading the article about the types of foundations). Then the problems associated with waterproofing the foundation are solved, and only then do they begin the actual laying of load-bearing walls and partitions.

The thickness of brick walls varies depending on the features of the project, the purpose of the house, and the presence or absence of insulation. As a rule, the thickness of the partitions is chosen in the range of 120-250 mm, and the thickness of the load-bearing brick wall is chosen from 380 to 510 mm. In modern buildings, the load-bearing wall pie consists of brickwork of one and a half to two bricks, a layer of insulation and masonry of facade bricks 120 mm wide.

Before laying, make sure that the foundation is absolutely level. To do this, check measurements for slope, verticality, horizontality. There are the following schemes for laying building bricks:

- Chain type of masonry with tied seams in each row;

- Plain brickwork with continuous jointing;

- Lightweight type of brickwork with added insulation.

Below is a small infographic with the main types of brickwork:

We also suggest looking at the process of masonry brick work.

Minuses

Now we get to the negative sides. There were much more points about advantages. But this is thanks to the stone itself; it has collected many positive features.

The first drawback that catches your eye is the weight. Compared to wood, aerated concrete will, of course, be lighter. But we still need a serious foundation, as already mentioned, usually of the strip type. If we are talking about a two-story building. It’s a shame that some landscapes simply do not allow the construction of a foundation other than a pile one. Severe slope or marshy terrain. And then heavy construction will have to be completely excluded from the plans.

Most often, when the advantages and disadvantages of a brick house in construction are revealed, the price issue is considered negative. And this is the harsh truth. Modern modular or frame models can give a serious head start in this matter.

Insulation of brick houses

Insulation of external walls is an important stage in construction, which can significantly improve the performance properties of the building.

To insulate architectural structures made of brick, mineral wool or polystyrene foam is used. Plaster is applied over the “coat”, securing the heat-insulating layers, giving the structure an attractive appearance. Among the latest innovations, the “wet facade” is popular, which combines the functions of insulation and decorative finishing of external walls.

Proper installation of insulation determines how much home owners can save on heating in the winter and reduce energy costs on air conditioning in the summer. There are external and internal types of insulation. The first option is often used, which is less expensive and convenient in practice.

The disadvantage of houses made of brick compared, for example, with buildings made of aerated concrete, is the presence of a large number of cold bridges in the form of seams in the brickwork. This may result in increased home heating costs. To avoid this, you don’t need to skimp on additional insulation.

A couple of additional redstone bonuses

Separately, I would like to note that mold and mildew, which become sources of various disorders and diseases, simply do not settle on such a surface. But on a tree, especially if there is high humidity outside, they appear with considerable frequency.

If a house is being built in a place where serious humidity is observed most of the time of the year, it is simply impossible to come up with other analogues. Other types of buildings simply will not survive in such an environment.

What is noteworthy is that the aesthetic side can also be included in the positive aspects. Specifically, red ceramics look simply magnificent after external finishing. And hiding it under something would be completely illogical. But the white counterpart made of sand and lime, alas, cannot boast of such aesthetic properties. And it would be logical to decorate it in some way later.

How to decorate the outside of a brick house

Now let's look at the issue of exterior decoration of a brick house. To decorate a brick wall, the most ordinary plaster is suitable. The master will be able to achieve both unusual relief and an absolutely smooth surface. This finishing improves the fire resistance of the structure and has a positive effect on sound insulation qualities. To finish the base, plaster is used less frequently.

The outer side of a brick wall is often decorated with natural or decorative stone. It looks very solid and respectable. This material is very strong and reliable, capable of maintaining its original appearance for centuries. In this case, it is best to decorate the base with natural stone.

Another popular type of decorative finishing of brick walls is modern thermal panels. The facade is particularly dense and looks aesthetically pleasing and elegant. A special advantage is that the thermal insulation properties of the house are improved several times.

Let's talk about the advantages

It's time to move directly to the topic of our review. We have already figured out what kind of building material this is and what it is best used with. Now let's see what advantages it will bring if you choose it.

- If you look at historical monuments, sights that have stood for centuries, they are often made of brick. The thing is that such buildings really have an extremely long service life. And even now in every city there are a lot of buildings dating back to the 50s.

- Indifference to the environment. If you always have to select not only resources, but even the type of building depending on the weather in the area, then in this case there is no need for unnecessary fuss. The stone tolerates almost everything. Constant humidity, rainfall, frost, heat and direct rays of the sun will not pose any threat to it. There is no geographical location in the world whose climate could cause such a house any significant damage.

- Clean material. No harm is done to the person. Sand and clay, what could be dangerous here? No harmful emissions are released during any period of operation.

- No repair needed. From the word “absolutely”. If the structure is built correctly, it will remain in an acceptable form for centuries.

- The advantages and benefits of brick houses relate to resistance to all kinds of pests. Insects do not breed in this building material, unlike its closest analogue - wooden dwellings. There, even with special treatments and impregnations, there is still a serious risk of infection with woodworms and other unpleasant neighbors.

- The danger of external fire is almost completely eliminated.

Manufacturing methods

Brick manufacturing technology determines its properties and characteristics.

Plastic molding involves the use of plastic types of clay with sand.

- Pros - strength (when heated, clay acquires the properties of stone).

- Disadvantages - high energy consumption during production, which increases the cost, disadvantages of the geometric shape of the brick.

Semi-dry pressing - the use of clay of low plasticity.

- Pros: economical consumption of electricity, no need to add additives to the clay, correct brick shape.

- Disadvantages - increased water permeability, low strength, insufficient frost resistance.