The design of any home requires an individual approach. Facade cladding is carried out using a variety of materials - brick, stone, plaster, metal profiles, etc. Decorating buildings not only guarantees their attractive appearance, but also insulates and strengthens them. Cladding a house with brick, the design of which depends on the preferences of the owner, is popular. This material is aesthetic and durable.

Features and Benefits

Facing brick is a type of material intended for finishing the facade.

In this regard, brick is also called “facade” and “facing”. Like any finishing element, brick performs 2 main functions - protective and decorative. The protective function ensures that the material meets the following requirements:

- high strength necessary to withstand mechanical stress, shock and wind load;

- low moisture absorption coefficient, meaning frost resistance, durability of the product, as well as the absence of mold and mildew in the room and on the surface of the facade;

- heat resistance, resistance to low temperatures and sudden thermal changes (brick must withstand the most dangerous changes - jumps from low to high temperatures).

Considering the labor intensity and considerable cost of installing a brick facade, it is rare that an owner will agree to a structure that will last less than a couple of decades. However, if the masonry technology is followed, such a facade has a service life of 50 years or even more.

At the same time, the use of brick for the facade opens up limitless design possibilities. Different types of bricks, many masonry options - all this makes brick cladding a real work of art.

In some cases, the use of this material as a finishing material is unacceptable. Let's look at this in more detail.

Depending on the type, a brick weighs 2.3-4.2 kg, respectively, brickwork with an area of 1 m2 made of material measuring 250 * 65 * 120 mm weighs 140-260 kg. It’s easy to imagine how much weight the facade of even a small house will have.

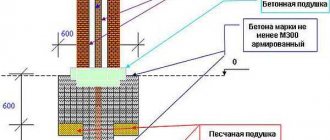

This necessitates the need for a reliable foundation for the façade. It will be possible to use brick only if the existing foundation protrudes beyond the walls by at least 12 cm (the width of a standard brick) and has a suitable load-bearing capacity.

In the absence of one, it is possible to arrange a separate foundation for the façade masonry, connecting it to the main anchors, but this is not always possible from a technical point of view. In addition, the process is quite labor-intensive and expensive. Additional costs will also be caused by the need to redo the roofing system and gables, since with the building area increasing as a result of finishing, they will not be able to fully protect the structure.

When constructing a separate base for the facade, it is necessary to connect the load-bearing walls and cladding. Special flexible polymer bonds or stainless steel analogues, as well as galvanized steel wire, are used as a binding system. One end of the wire is mounted to the wall, the other to the facade. This allows you to maintain the location of the facing row, preventing its removal or “running over” the supporting structures of the building.

An important requirement is the ability of the walls to “breathe”, that is, to allow water vapor that accumulates in the room to pass into the atmosphere. Compliance with this requirement is ensured by maintaining a 2-4 cm ventilation gap between the facade and the walls, as well as equipping the former with vents, which are located in the upper and lower parts of the facade.

Vents are made using special elements, or they can represent several unfilled vertical joints between bricks. The purpose of such elements is to ensure air circulation by taking it in at the bottom and exhausting it at the top of the façade. The fresh air circulating inside the gap seems to blow through it, taking with it some of the water vapor.

Failure to comply with this requirement is due to the technical characteristics of the brick cladding (water vapor when frozen will destroy the brick, causing cracks to appear on it) and insulation (if any in the ventilation space), as well as condensation on the surface of the walls and ceiling inside the building.

At the same time, a layer of thermal insulation material is often laid in the latter to increase the thermal efficiency of the building. In this regard, the width of the gap increases by another 5 centimeters (or 50 mm), which entails an increase in the width of the foundation to 190-210 mm and the need to increase its load-bearing capacity.

However, today there are narrower versions of the material on sale - their width is 85 mm (Eurobrick), and sometimes can reach only 60 cm. When using such bricks, the protruding part can be reduced to 130-155 mm.

If it is impossible to meet the described requirements for the features of the foundation and structure of the building, it is not necessary to abandon the idea of living in a “brick” house. There are worthy analogues of brick finishing - clinker tiles, facade panels imitating brickwork.

How to make white bricks in the interior yourself

A simple way to make imitation brick:

- Take thick foam and thick cardboard.

- Cut out templates from cardboard, and use foam “bricks” on them.

- Cut the resulting brick widthwise into two halves.

- Remove the chamfer around the perimeter of each brick.

- Take liquid nails and glue the foam to a previously prepared surface: markings on chipboard, plywood, in a checkerboard pattern.

- Apply 2 layers of acrylic paint and varnish.

Comparison of all indicators, characteristics of both products and their detailed analysis

Now it's time to take stock. Sand-lime or ceramic brick, which is better?

Let's use the table. Table 5. Difference between sand-lime brick and ceramic brick.

Name of the characteristic indicator Comparison of materials

Thermal conductivity

Regarding this indicator, it is worth noting that when comparing the strength characteristics and ability to retain heat, both materials are at the proper level.

Also, both lose significantly when comparing specific thermal conductivity with its performance in cellular concrete and many other wall materials.

If we look more specifically, ceramics will still win, since when aging, the thermal conductivity of silicate products can reach up to 0.95, while facing ceramics is characterized by a value of 0.35-0.55.

Frost resistance

Both silicate and ceramic bricks can withstand a large number of cycles of temporary freezing and thawing. Much depends on the composition of the raw materials of the products, the manufacturer and compliance with construction technology.

However, it is still worth highlighting ceramic bricks, especially the clinker version.

GOST also imposes lower requirements for sand-lime bricks.

Durability When following all the instructions in the technical documentation, both materials can last a very long time. But ceramic brick is still somewhat ahead of its competitor. Strength and density

Both products, due to their strength characteristics, can be used in the construction of buildings subject to significant loads.

Ceramics, however, are worth highlighting again, since particularly dense products are used in the construction of the base, which cannot be said about silicate.

Assortment of products Again, the palm belongs to ceramic products. Their range is richer. Architectural possibilities With the help of ceramic bricks, unique construction projects are created. A photo example is presented below. Ease of installation The installation process of products is extremely similar, so we will not highlight any of the materials. Water absorption

Both materials are capable of absorbing moisture. They need protection from its effects. Since this characterizes both ceramics and sand-lime brick, it would seem that there is no winner. However, the percentage says otherwise.

Silicate products absorb up to 16-18% moisture, while ceramic bricks - up to 13%, and clinker products - about 5%.

Therefore, it is worth giving ceramics its due and highlighting it in this regard.

Environmental friendliness According to the manufacturers, both materials are environmentally friendly. Fire resistance Both sand-lime brick and ceramic do not burn Scope of application The scope of application is wide in both cases. However, silicate products have some exceptions, which are mentioned above. Accordingly, ceramics are again ahead. Construction speed is approximately the same. This is due to both the complexity of installation and the size of the products. Ease of production

The manufacture of both materials requires expensive equipment. Sand-lime brick is manufactured exclusively in factory conditions and is inferior in ease of production.

You can make ceramic products yourself, but this requires time and money, which may not always be justified.

Cost of productsCeramic products are more expensive, and some of their types are significantly higher in price.

Architectural possibilities of ceramic bricks

The video in this article: “Comparison: ceramic and sand-lime brick” contains a comprehensive answer to all questions that may arise in the process of choosing one of these materials.

Varieties

Brick walls can be not only natural, but also an imitation of the material. The choice of a specific type depends on the style, size of the room and the characteristics of the tile.

From plaster

It is light in weight and is not afraid of temperature changes. However, it cannot be used in rooms with high humidity.

Made of ceramics

The material is suitable for any room, including the bathroom. Ideally imitates natural brick. It is durable, not afraid of moisture and temperature changes. But you cannot create the effect of “torn” tiles with it.

From porcelain stoneware

It is not afraid of frost and dirt; the tiles are easy to care for. But high-quality porcelain tiles, especially with a white surface, are almost impossible to make at home. The kitchen and hallway look most impressive with this material.

Clinker

Ideally imitates natural brick. Not afraid of cold and sun, suitable for country houses, balconies and loggias. Manufactured only in specialized production.

Kinds

The basis of any building brick is clay and cement. It is divided into single, one-and-a-half with a flat, patterned or double surface. Ease of processing allows you to create different relief shapes. According to appearance, gray brick is divided into the following types:

- with a smooth surface;

- rough, chipped surface, giving the effect of pure rock;

- deeply protruding, birch bark surface.

In construction, facing bricks are divided into categories. Its composition is different.

- Silicate, made mostly from quartz sand with the addition of lime and ash.

- Pressed, obtained by high pressure as a result of a mixture of cement and small rocks.

- Ceramic, made using a firing system of special clay and mineral additives.

- Clinker, which has particular strength, is made by sintering refractory clay.

To make gray sand-lime brick, a special coloring agent is added to its composition, then the entire mass is fired at 200 degrees and high atmospheric pressure. It perfectly insulates sound and reduces heat, but does not tolerate moisture. It is most suitable for interior cladding.

Ceramic gray brick can be of different shades depending on the components. What its tone will be is decided by the source material of the product. It all depends on the type of clay, the admixture of salts and oxides. The combination of such components gives a durable shape to avoid rapid wear or mechanical damage. Such bars can be fired at temperatures exceeding a thousand degrees.

To paint facing ceramic bricks, two technologies are used. The first technology uses white burning or red clay. The latter will give the brick a darker color, and white clay will saturate the material with white, peach and yellow colors. To obtain a different shade, special coloring pigments are added when mixing cement.

The method for making hyperpressed bricks is simple. To produce these gray bricks, crushed limestone is compressed using a hydraulic press to such an extent that the particles of the material become a single whole. The crushed material is then mixed with a solution of cement and water. All this is additionally colored using coloring compounds. Then the already formed bars are dried in a special chamber for up to 20 hours.

Gray clinker brick absorbs moisture very poorly and confidently withstands any weather conditions. It can be used for a very long time, maintaining its integrity. A special type of clay is sintered at high temperatures, so a dark color for clinker is the norm. It is produced mainly in hollow form. Depending on the final firing temperature, its future color is formed.

Gray clinker brick is a universal solution. It can be used not only for finishing interior and exterior interiors, but also for creating sidewalks, paths for transport, and platforms.

In which rooms is brick suitable?

White brick interior is an ideal solution for almost all rooms. It is less common in the toilet and bathroom, more often in the kitchen, living room and hallway.

Selection of bricks for cladding

There are special types of bricks that are designed specifically for cladding buildings. These include:

- clinker;

- ceramic;

- hyper-pressed.

There are some peculiarities in the technical/quality characteristics of the types of bricks listed above. For example, when choosing hyper-pressed brick, you will get a neat, tidy appearance of the building. But it should be taken into account that the structure of this type of facing brick is very dense, so there will be no air gap between the facing material and the wall of the house - laying heat-insulating material will not be necessary.

Ceramic bricks are also available in a hollow version - this is what you should choose when purchasing. It makes ceramic bricks light, which automatically reduces the load on the foundation of the building. True, there is also a disadvantage when using ceramic bricks - to lay it you will need a lot of cement mortar precisely because of the porosity of the structure of the facing material.

The clinker type of facing brick is highly durable and resistant to aggressive weather conditions, but its cost will be much higher compared to the other two types of bricks.

Ceramic facing brick produced by Stary Oskol, straw color

Use of single and one-and-a-half facing bricks in masonry. The house is made of single straw-colored brick in combination with decorative inserts, and the fence is made of one-and-a-half bricks

About the sizes of facing bricks

Single size bricks are most often used. Their long part has a size of 25 cm, and the remaining two sizes are 12 and 6.5 cm. One-and-a-half bricks are thicker - instead of 6.5 centimeters, this parameter is 8.8 cm. There are also double products in which the thickness reaches 13.8 cm. These are all domestic measurements.

If we talk about European standards, then they mainly use bricks of slightly different dimensions: 24 cm in length, 11.5 cm in width and 7.1 cm in thickness.

Americans also have their own way: 25 by 6 by 6.5 cm or 24 by 6 by 7.1 cm (the latter option refers to clinker, it is often made in Europe using NF - German standards).

Combination of bricks of different colors

Different shades of material are used in many cases. The so-called is very popular. Bavarian masonry, which combines up to 7-12 different shades and creates a pleasant variegated design from chaotically located bricks of different colors.

NOTE!

A combination of light and dark samples (or other contrasting combinations) is also used, which are intended to highlight the pattern more clearly and clearly and form geometric patterns on the surface of the masonry.

Spectacular examples in the exterior

Cladding houses with brick can be done on the entire surface of the facade or only part of it. Options for combined facades can be represented by a combination of brick and plaster or wood.

Of course, the combination of noble clinker and wood is a win-win, for example, as in the design of this open veranda.

Beautiful facades are obtained by using bricks with a pattern or a combination of single-color and variegated products (some imported bricks within the same batch have, for example, red and red variegated bricks). As a result, the masonry turns out to be voluminous, creating a mosaic effect.

The exteriors of private cottages look elegant and stylish, where façade elements are continued in the design of neighboring buildings, garden paths, and entrance lobbies.

For houses in a classic style, the combination of stone and brickwork, as well as the use of antique bricks, is relevant.

It is also important what the outside color of the house will be. A combination of two or more shades allows you to avoid monotony and add volume to the façade.

A classic technique can be called in which the brickwork is done in beige shades, and the window openings have a darker, contrasting solution.

If desired, you can paint the brick facade by waiting until it is completely dry and treating the surface with a 10% chlorine solution (to remove traces of the solution on the front of the brick). The chosen shade can be any, but the most common are black and white, beige.

The intricacies of choosing facing bricks are described in detail in the video below.

Choice of color and style

With the help of the right color you can transform your home and change its perception. Thanks to the wide selection of brick materials, you can choose almost any shade of brick. Recommendations from experts on choosing a color palette:

- If the roof, windows and doors of the house are brown, then it is better to make the facade yellow.

- For minimalism, it is better to use white and make the roof black.

- Red and brown colors are best used for classic style homes.

- A combination of dark and light shades is suitable for masonry in the melange style.

- Using dark and light bricks, you can make a “frame” that highlights the entrance to the house.

- It is necessary to take into account not only the color of the brick, but also its texture.

Thanks to a wide selection of colors, types and textures, you can create unique facades that will be designed in accordance with a specific style.

The most popular styles that prefer the use of brick when finishing the facade:

- Romanesque. The building should be massive, have impressive walls, arches and colorful decor. Externally, the house should resemble an ancient Roman fortress; brick will become an ideal assistant and an integral part in finishing the facade.

- Gothic. A very popular style that prefers brickwork. Several types of brick are used for finishing; here they recognize a combination of both different colors and textures or types of this material.

- Baroque. A house that screams luxury cannot do without brick. Here they use only the most expensive and bright types of bricks, which can emphasize the wealth of the house and the wealth of its owner. Often brick is combined with wild stone.

- Timeless classic. Such a house will create a pleasant and cozy atmosphere; a combination of red and white bricks is used to decorate the facade. The shape of such a house will be standard, and the roof will be brown. The facade here is as simple as possible, without any frills or abundance of decor.

- High tech. This style and design of the facade is suitable for those who like to be extraordinary, to express themselves and their “I”. Natural brick is used to decorate the facade, but to maintain the style it must be combined with decorative glass or metal inserts.

Advantages and disadvantages of brick cladding

Facing bricks for facades have advantages and disadvantages. Among the positive qualities of a brick facade, it is worth highlighting the following characteristics:

- facing bricks ensures protection of buildings from the effects of precipitation, especially for wooden private houses, cottages and other outbuildings;

- this cladding gives a rich, monumental appearance. Makes the design richer and more unusual;

- provides additional protection of walls from destruction;

- If insulation is placed in the space between the walls and the brick, the insulation properties increase many times over. The brick retains all thermal properties indoors;

- low moisture permeability - there are types on sale that are intended specifically for cladding the facades of houses, the level of moisture permeability of which is only 14%;

- is not subject to constant sudden changes in temperature. The material for cladding the outside of buildings has increased resistance to frost. It can easily withstand more than 50 winters without changing the quality of its structure;

- various shapes and a varied color palette. Some bricks can be used for windows, they match the shapes and complement every part of the structure. And the colors can be different - white, red, yellow and many others;

- increases the service life of the building many times over.

But, despite the presence of positive qualities, there are also negative properties:

- when installing bricks on the facade, additional pressure is observed on the foundation of the house, it begins to sag over time;

- if piles or pillars are used as the base, then after facing the facade with brick, these components simply collapse due to the pressure exerted on them;

- The facades of houses made of brickwork are quite an expensive pleasure, which not everyone can afford.

Flaws

Hollow bricks should not be used for the construction of load-bearing foundations of buildings.

Despite such an extensive list of advantages, straw-colored hollow bricks also have their disadvantages, among which the following are worth mentioning:

- Hollow brick should not be used for the construction of load-bearing foundations of buildings. In this case, preference should be given to solid products, since they have greater load-bearing capacity.

- Due to the presence of cavities in the structure, the product has a fairly high hydrophilicity. This is the second reason why this material is not allowed for use in foundation construction.

Attention: with direct, constant contact with moisture, the material will begin to absorb it. Over time, it will fill the voids inside the brick, and with the onset of cold weather it will freeze. The water expanding during the freezing process will simply tear the brick from the inside.

- The price of such bricks is quite high, so not everyone can afford to cladding a house with such material.

- Domestic bricks in this category are not of sufficient quality, so it is recommended to use products from European manufacturers.

- To get a monochromatic facade of the desired shade, it is better to buy bricks from one batch. Otherwise, it will be difficult to avoid slight variations in color and choose the right shade.

How to choose?

In addition to bricks, consultants usually suggest purchasing shaped elements for decorating bevels, door and window openings, corners and other architectural elements. Such structures have a curly shape and are much more expensive than bricks for exterior decoration.

If the cladding is carried out by a professional, then he will be able to attractively design the corners and other elements of the facade without the use of figured structures. This type of work will cost more than simple brick laying on a flat surface. However, even in this case, the cost of the craftsman’s work when designing complex elements will be less than the cost of purchasing figured products.

In addition to bricks, you should take care of purchasing mortar. Today, water-based cement-sand mortar is used less and less due to the decrease in water absorption rates of modern bricks.

The construction market offers a wide variety of masonry mortars

It is important to select a composition that matches the type of brick used. Fixing mixtures V enjoy the trust of buyers

OR The range includes mortars for clinker and other types of bricks. Conveniently, these same solutions can also be used for external finishing of seams.

Solutions from manufacturers usually have a rich color palette. You can choose an option that is as close in color as possible to the shade of the bricks or choose a more contrasting combination.

HOW TO MAKE A BEAUTIFUL FACADE OF A BRICK HOUSE

Don’t know how to make the facade of a brick house more attractive? Have you built a large two-story brick house, but the appearance is not pleasing to the eye? We offer a number of solutions for transforming the exterior of facing bricks thanks to facade decor.

Apply large details of facade decor

Large free spaces of the walls of the house require large elements in the design of facade decor. For example, here the window molding has a width along the wall of 18 cm, and the large top of the decorative window cladding is 30 cm high. In order not to additionally cover such a large decorative detail, this element has a steep bevel of the top shelf.

Separate the base part

If you want to visually reduce the height of your house, using a base strip of a light color, like all the stucco on the house, will easily solve this problem. Also, this detail should correspond in size to the proportions of the house.

Try a massive eaves under the roof

The use of decorative cornice under the roof overhang is the main stage in decorating any home. The shape with a plane at the bottom most closely matches the size and proportions of a large brick house. Corner pilasters will look more natural if they seem to support the lower plane of the cornice.

Use brackets and keystones in window treatments

In addition to large details of the façade decoration of a brick wall, such as moldings, decorative window sills, plinth strips and corner finishing, do not forget about individual decorative elements. Keystones and brackets on the windows will dilute the straight geometry very well. The brackets under the windows, in our case, also visually fill the large spaces of the walls of the facade of the house.

Completely decorate your front door

Of course, don't forget about the entrance group. An entrance door decorated with classical pilasters will be one of the main accents of the facade of a brick house.

Decorate the corners of your home with pilasters

Since your facade already has a “crushed” structure - brick, try using pilasters to decorate the corners of your house. Straight lines of pilasters in contrast with a brick wall will look great!

If you want more ideas on how to beautifully make the facade of a brick house, check out our other articles and videos on this topic. We are sure you will find a lot of interesting things for yourself.

Video: How to beautifully make the facade of a brick house?

Design

Differences between products can be based not only on the material of manufacture, but also depend on the texture of the brick. Bricks are available in the following textures.

Smooth

The most affordable and easiest type of brick to make. It is worth noting the convenience and ease of operation - no dirt accumulates on the smooth surface, no ice forms, and no layer of snow sticks.

Embossed

They have artistic grooves and protrusions that form a decorative pattern. As a rule, they are used for finishing individual elements of the facade - window openings, architectural components. It is irrational to use it on the entire surface of the wall, since the relief surface traps dust and becomes covered with ice.

It is also useful to know that from a distance the relief is not noticeable, but it provides an interesting color effect. Refracting on heterogeneous surfaces, the sun's rays illuminate the façade differently. As a result, it plays with different colors and shimmers.

Glazed

These bricks come in different colors, sometimes absolutely incredible. A similar effect is achieved by applying special clay compositions or a layer of colored glass chips to the surface of the brick. Next, the brick is fired at a temperature of no more than 700 degrees. This causes the top layer to melt and sinter it with the main product. When using clay, a painted matte brick is obtained, and when a glass layer is applied, an elegant glossy analogue is obtained.

Engobed

Externally, engobed bricks do not differ from glazed ones - they also have different colors, matte or glossy surface. However, the weight of the former is less, as is its price. This is due to the fact that the brick is fired not 2 times, but once, which reduces its cost. The dye is applied to the dried product and only after that it is fired.

Finishing methods

In general, there are 4 types of finishing using the following materials:

- Facing brick.

- Decorative brick.

- Copying bricks with PVC panels.

- Corrugated sheeting imitating brick.

Corrugated sheeting and plastic panels are affordable options for finishing the facade of a building. The materials imitate brick and have a similar surface, but they are not practical, they are easy to damage, and therefore have a short service life. The use of decorative and facing bricks will become more popular. The latter is used most often, as it has a large color palette. The facing brick can be either white or red, or sunny yellow. For connoisseurs of the classic style, it is best to use brown brick, which will give the house an “expensive” look. The advantage lies not only in the choice of color, but also in the type of surface. Now there are three types: imitation stone, chopped and smooth surfaces. When finishing the facade of a building, you can use either one type or a combination of them.

Types of bricks for facade cladding

The facades of brick houses can be made of different materials. The best is brick. It can be of different types and colors. In addition, you can find original substitutes for this material on sale; for example, facades made of artificial stone look beautiful. So, what material to choose for cladding the facade of a house? Let's look at popular types.

Classical

This material is also called sand-lime brick. It is often used in construction for the construction of various buildings. In addition, it is often used for cladding the outside of many private houses and windows.

Advantages of this material:

- provides excellent protection of the facade from negative external influences;

- has simple masonry - there are no difficulties during its installation;

- various colors - you can often see facades made of sand-lime brick, which have different colors - light, white brick, red brick, and so on;

- low cost - this material has a low cost, so it is in high demand.

Hyper-pressed

The hyper-pressed type is made from a moistened mixture of crushed stone, limestone and cement. Pigments for color are also added to this mixture; this process is carried out under increased pressure. During hyperpressing, all elements are soldered at the molecular level, which makes it possible to obtain high strength of the material. The finished material can withstand load levels of up to 250 kg per 1 square meter.

Features of this material:

- hyper-pressed porous material is highly resistant to severe frost;

- increased moisture resistance - this type of brick does not allow liquid to enter the walls during rain or snow;

- has high strength and durability;

- the cost is not too high compared to the excellent qualities of the material;

- wide range - on sale you can find material that imitates an artificial stone facade.

Modern hyper-pressed products may have unstable colors. The design of buildings made of yellow, red, or brown material looks quite beautiful. These products can also be used for window cladding.

Ceramic

Ceramic finishing material is considered the most expensive, and it also poses certain difficulties during installation. But despite the fact that it belongs to the decorative varieties of stone, it is able to withstand loads of up to 150-200 kilograms per 1 square meter.

Positive qualities of the material:

- long service life - this material can last more than 20 years;

- has increased resistance to moisture, sunlight, and temperature changes. In addition, it does not collapse or fade;

- has a strong structure;

- The appearance design of ceramic bricks is attractive, so it is often used to decorate the exterior of a home;

- does not require increased care - in order to wash off all the dirt, just rinse everything with water from a hose.

Ceramic material is available in various shapes and surfaces - smooth, rough, wavy, even. It can be used for cladding wooden walls, as well as for decorating windows.

Examples using bricks

Some people like brickwork, and the owner strives to recreate such a facade in any way - using facing bricks or materials that can imitate this cladding. Others try to escape from the standards and disguise brick walls in any known way.

There is no arguing about tastes, since everyone has their own vision of beauty. Therefore, we will consider several options for facades decorated with brick, but in different interpretations and styles.

Universal brick facade

Brick is such a versatile material that it is even used to decorate houses with columns, arches, stucco molding and other facade decor. At the same time, the building will not lose its attractiveness, but on the contrary, it will sparkle with new colors, and at the same time it will not look vulgar or tasteless.

A correctly selected shade of cladding elements, as well as texture, will only emphasize the taste and status of the owner of the house. Therefore, when turning to brickwork as a renovation of the facade, you should not worry about whether the building will be as beautiful. No, it won’t, but it will become completely new!

Painted brick, external walls of different colors

With the help of paints and varnishes they transform a brick facade that has already become boring. But be careful when choosing this method of decorating a private building. The paint penetrates deeply and unevenly into the structure of the brick, and it will be extremely difficult to get rid of it.

As you know, paint is not a material with a long service life, therefore, having painted a brick facade once, it must be maintained in an attractive form every 3-5 years, depending on the type of paint chosen. In addition, some types cover the facade with a durable film that does not allow moisture to pass through from the interior. This will negatively affect the base material.

If this option is suitable and does not frighten the owner, then there are no limits to imagination. On the construction market there are a large number of facade paints that are already tinted or white, which can be pigmented. The pigment is chosen from the same manufacturer as the paint.

No more than three shades are combined on the façade. Contrasting colors are used to highlight window and door openings, porches, and decorative elements. To choose a color scheme, use advice from fashionable construction publications, their online counterparts, or professional designers.

All options have photo galleries where you can select a ready-made option or create a completely new one at the request of the client. It is quite possible to do the painting yourself, but if the building is large, two-story, then it is better to resort to the services of a professional team with the appropriate tools and equipment.

Whitewashed brick

One of the options for painting the facade is to apply whitewash to the brick. This method of decorating exterior houses will achieve an aged effect. Whitewashing of bricks was often used in English villages, so those who are interested in this style cannot do without whitewash.

For whitewashing, a mixture of lime and table salt is used. If you add a small amount of white cement, the layer will be more durable and will last longer.

Energy efficient brick

The energy efficiency of this material lies in the ability to heat up for a long time, and then release heat to the environment for a long time. Thus, we have the following:

- In the summer, the facade warms up in the sun, but the heat does not penetrate into the rooms, so it remains cool there.

- In winter, heated internal walls do not let heat out, but at the same time retain heat inside the rooms for a long time.

Buildings with a long service life require wall insulation. Therefore, when laying decorative bricks, a small gap is left between the main and outer (decorative) walls. Insulating material is placed in this gap, taking into account the ventilated gap.

If this is not done, moisture will accumulate in the thermal insulation material, which will lead to destruction. In addition, the walls inside the rooms will also be damp. And if you leave a gap, then there is no need to additionally ventilate the room.

Natural beauty

Synthetic materials are rarely used to make facing bricks. Therefore, such cladding remains natural and absolutely safe for human health, as well as for the environment. If dyes are added to create brightly colored finishes, they are most likely of natural mineral origin.

Naturalness is always in fashion, and now, when the world around us is stuffed with synthetic substances, I want to lock myself in a country cottage or a city one-story house made from natural ingredients.

Playing with texture

Brick goes well with different materials that have an original texture. It makes no difference whether there are wooden tiles or decorative elements on the metal façade, a stone path or a plinth and corners trimmed with stone. The brick facade will emphasize the originality of the finish.

You can finish several elements with plaster and leave a clean facade, which looks good. In addition, bricks of different types and shades combine well on one house. You just need to skillfully select a separate area.

Mix tiles and bricks

If there is a large amount of green space around a house with an attic, then untreated brick is suitable as a finishing for the facade. The roof is covered with unpainted tiles. This method of decorating the facade will create coziness throughout the entire area and convey the spirit of the forest thicket.

Handmade brick

Now all bricks are made in factories and in large batches. Previously, everything was done manually without the use of sophisticated equipment. If you want to make your house stand out from the general mass of buildings, you can do everything the old fashioned way.

Mix the solution, pour into wooden molds and fire over a fire. By washing away the unevenness on the bricks with sand, they create an original velvety texture. Such blocks will aesthetically embellish the facade and convey the spirit of an ancient mansion.

Modern brick

The versatility of the brick facade allows it to be used for modern buildings in the minimalist style. Various colors and textures are suitable for creating an accent both on the facade and indoors. In addition, there is nothing wrong with completely covering the facade.

Light brick wall and other materials: the best combinations

In addition to the obvious combination of brickwork and painted walls in the interior, you can find a good match for this design among other materials. The most harmonious union with white brick will be:

A combination of several types of finishes on one accent wall

- light wood - in the form of furniture or decorative slats;

Combination of white brick and light wood in the interior

- raw concrete - ideal for loft-style interiors;

The combination of white brick walls and concrete floors in the interior

- metal (as lamps and decor - black, golden or brass);

Decor of a white brick wall with lamps in a brass shade

- mirrors of various shapes - from traditional round to exotic options;

Combination of a white brick wall and a mirror in an original frame

- wallpaper in light colors with a contrasting pattern - floral, floral or geometric.

Imitation of white brick and wallpaper with floral print in the bathroom

How to choose a pattern to make the masonry look impressive

This type of masonry is a very labor-intensive process, so the work will progress much slower than with conventional cladding.

The main difficulty lies in choosing a pattern. Bricks must be laid in a certain sequence, otherwise the visual effect will be reduced to zero. Therefore, the work begins with drawing up patterns - ready-made sketches with suitable options.

To completely compose a picture, you need to make 5-10 drawings, where all shades of color are used, but located in a different sequence. Then the sketches are mixed together in random order, creating a visual scale of the wall.

The colors will be combined arbitrarily, but the desired ratio will be maintained perfectly.

Rules for creating a pattern

- Bricks of identical color should not be joined.

- The exact color scheme is observed: there should be no areas on the wall with prevailing dark or light tones.

- The bricks alternate randomly, without repetition.

- Color balance is maintained on the scale of the completed wall.

The procedure for constructing the facing wall of a house

Before you start facing the house with brick, you need to calculate the need for materials. While this is quite easy to do for insulation, how many bricks are in 1 m2 of masonry is more difficult to determine. The area of a single product is determined as the product of its length and height. This turns out to be 0.01625 m2. Since facing walls are usually built with half-brick masonry, 61,538 pieces are required to fill 1 m2. It is also necessary to take into account the thickness of the seams, which is on average 9 mm. Taking this into account, brick consumption is reduced to 52 pieces per 1 m2. Knowing this, all that remains is to calculate the entire area of the walls minus the area of the openings and multiply the resulting number by 52. Taking into account the error and the inevitable “breakdown” of the material, another 5 to 10% must be added to the final quantity, depending on the volume of construction.

Hyper-pressed brick with the texture of natural stone

Installation of the insulating layer

After all the calculations have been made and the material has been purchased, you can begin work. First, pour the foundation to the required width. Then they begin to install the insulating layer. Mineral wool slabs or polystyrene foam can be used as insulation. The joints between the foam plastic are foamed with polyurethane foam. The insulation is attached to load-bearing walls using special anchors, which at the same time serve as a connecting link between the wall and the facing masonry. A vapor barrier film must be secured over the insulation to prevent steam condensation.

Finishing the facade with “stone” gives the building a monumental look

Mortar proportions for bricklaying

To avoid drying, do not prepare a lot of solution. It can be purchased at the store and made according to the attached instructions. Those who wish can prepare it themselves. This requires cement, sand and water. If necessary, you can add a dye of the desired color to the mixture. In order for the consistency to be optimal, the following proportions of the brick laying mortar must be observed:

- To prepare a mortar of grade 100, take one part of M400 cement and four parts of sand. For elasticity add 100 g. detergent.

- If M500 cement is used, then to obtain the same solution you need 5 parts of sand for one part of cement.

- If you need a denser mortar of grade 200, then take one part of M400 cement and two parts of sand.

The viscosity and plasticity of the resulting mass should be convenient for work. It is regulated by the amount of water.

An excellent combination of different types of bricks when finishing the entrance area

Laying facing bricks

For strictly horizontal masonry, a building level is used. First, each layer is laid without mortar to identify irregular and damaged bricks. Then the solution is applied so that no more than 1-1.5 cm remains to the edge of the brick. For this, a special template is used. The bricks are laid so that the vertical joints are no more than 10 mm, and the horizontal joints are no more than 12 mm. This is regulated by a special device or a bar of the required thickness.

The combination of stone and natural wood will always be in fashion

If the solution gets on the front part, it must be removed. The same is done if it gets into the space between the load-bearing wall and the cladding.

Carrying out brick lining work on your own home yourself will save significant financial resources.

Existing methods of bricklaying

There are only two ways to lay facing bricks:

- Method 1 – joint, involving a connection between the facing and ordinary layers. It is not very popular, as it involves the presence of an excessive amount of interlocking bricks on the outside, which reduces the decorative appeal. This masonry option is applicable only for the construction of new housing.

- Method 2 – separate, in which the facing layer is located at a short distance from the load-bearing walls. Communication with them is carried out through anchors and metal fittings. This method makes it possible to additionally insulate the walls and create ventilation between the layers.

Clinker bricks come in different colors and shades.

It is preferable that the construction of the facing wall be designed in advance. There are situations when it is necessary to brick an already built house. In this case, you need to add foundation to create a load-bearing surface.

On a note! When building a new house, it is necessary to foresee in advance the possibility of erecting brick facing walls, since in the future such a desire may arise, even if the facade is covered with siding.

A house lined with brick “to look like stone” looks very reliable.

How to build a house made of yellow and brown bricks

During the design process, costs and possible ways to reduce costs are preliminarily calculated. Next, choose the foundation, because it bears the entire load of the house.

Foundation

Before pouring the foundation, depending on its type, prepare a foundation pit, trench ditch or pits. The bottom is covered with a layer of sand and gravel mixture. The composition is well compacted and covered with a waterproofing layer.

Before installing the foundation, utilities are installed. Check the functionality of the water supply and sewer systems. Waterproof communications.

A yellow brick house is placed on one of three foundations. More often on tape or slab. The following foundations are chosen for the base of the building:

- Medium recessed tape. It has good load-bearing qualities with a thickness of 50-70 cm. Reinforcement is carried out before pouring. This type of foundation is installed at a water level of 1.5 m and below.

- Monolithic slab. This foundation is installed under brick, block houses or in case of ground movement. The concrete base evenly distributes the load from the house over the entire surface. Make a base with a thickness of 30-50 cm, pre-reinforcement is carried out

- Columnar foundation with grillage. This option for a concrete base is used less frequently. The reason for its use is the high level of soil freezing.

Concrete mixture is poured into the prepared formwork. After complete drying, waterproof the surface on all sides.

Base

The base is a visible transition from the foundation to the walls, which takes on most of the influence of the external environment (temperature changes, rain, melting snow). For the base, solid ceramic bricks with a strength grade higher than M150 are used. For regions with high humidity, M250 brick is used, which is resistant to moisture and does not always require cladding. When building a basement, adhere to the following rules:

- The thickness of the plinth must be 500mm or more and may be greater than, equal to or less than the walls

- Waterproofing is laid on the foundation (usually roofing felt in 2 layers).

- The brick is laid flat, overlapping the seams of the bottom row.

- The laying is carried out along the cord, controlling the evenness with a building level.

- To ensure a smooth surface of the base, I start working from the corners of the house.

- Ventilation holes are laid at a height of 150mm from the blind area.

- After 6-8 rows, the base is vertically and horizontally waterproofed with roofing material or liquid solutions.

- They are insulated with polystyrene foam and finished.

For a more durable structure, reinforcing mesh is laid on the first and fourth rows, on the brick, and mortar is poured on top. The composition is placed tightly between the bricks, leaving no voids.

Walling

Walls for non-residential premises are laid with a thickness of 1 brick (250 mm), for residential buildings - 1.5; 2; 2.5 brick blocks. Internal masonry can be made using cinder blocks or aerated concrete. All load-bearing structures and partitions are carried out after laying the external walls.

The walls are installed, like the plinth, from the corners, shifting the brick in each next row by half. After 5 rows I perform a transverse arrangement of the stone. Bandaging at the corners is done in the same way (the seams should not be on the same line). Throughout the entire masonry, the verticality of the wall is controlled by a plumb line. External seams are decorated with a special groove.

White clinker

Sand-lime working brick has good density. A building constructed from such material is endowed with all the necessary qualities for people to live in it. The house is strong, durable, retains heat, protects from noise and environmental influences. But for complete completeness and an aesthetic appearance, it lacks an elegant finish. White clinker brick is an excellent facing material.

A perfectly flat and smooth surface is ensured by the low porosity of the stone.

Unlike sand-lime brick, clinker brick almost does not absorb moisture. This feature makes it resistant to the external environment; it does not react to precipitation, frost and icing.

Thanks to the high technical characteristics of the facing stone, the decoration of buildings occurs impeccably. Precise geometry, neat shape, absence of scratches and chipped corners meet the most stringent requirements for appearance.

Models of facing bricks that imitate chips and reliefs have the same ideal angles and contour lines as standard clinker.

The building looks great with brown window frames, lined with snow-white decorative brick. Such buildings are reminiscent of English country house designs.

Cladding with clinker protects the working brick from destruction and preserves the attractive appearance of the building for many years.