Currently, plasterboard boards are often used during repair and finishing work. The widespread use of this building material is explained by the fact that when used, the process becomes less labor-intensive and time-consuming. Using drywall, you can quickly level walls, make unusual ceilings, create an original false fireplace, and much more. The building material has a wide range of applications and reasonable prices.

Gypsum plasterboard is a finishing building material consisting of three layers: a gypsum core and two layers of construction paper. Cardboard is needed to provide the required rigidity to the building product, reduce the stress of the gypsum during installation and during further operation, as well as to protect the gypsum from the effects of transportation.

A large number of buyers believe that drywall sheets are presented in one size. In fact, the sizes of gypsum boards are different - their weight, thickness, length and width are determined in accordance with the intended purpose of the product. Optimal selection of material contributes to more economical consumption of sheets and also leads to the best result.

Wall decoration with gypsum board sheets

Scope of application of drywall

The construction of plasterboard partitions is one of the areas of application of the material.

Drywall is a multifunctional material. Used when performing the following work:

- Formation of partitions;

- Creation of structures of various designs;

- Closing window and door openings;

- Leveling walls;

- Warming of surfaces;

- Surface finishing;

- Repair and finishing work of previously erected structures.

Why know the weight?

When doing DIY repairs, few people think about the weight of building materials. The sheet of drywall is solid, has a certain size, and if the building does not have a freight elevator, the question arises of how to lift it to the desired floor, bring it into the apartment and, in general, move it. This also includes the method of transporting materials: whether the trunk of your car can accommodate the required number of sheets, and whether the car can withstand the weight stated by its carrying capacity. The next question will be to determine the number of people who can handle this physical work.

For large-scale repairs or redevelopment, a larger amount of materials is needed, therefore, transportation costs will already be calculated, since the carrying capacity of transport is limited.

Knowing the weight of the sheet is also necessary to calculate the optimal load on the frame to which the cladding will be attached or the number of fasteners. For example, if you calculate how much a plasterboard ceiling structure weighs, it becomes clear why you should not neglect determining the weight. Weight also indicates the possibility or impossibility of bending the sheet to make arches and other decorative elements - the smaller the weight, the easier it is to bend it.

Drywall composition

Diagram of the structure of a plasterboard sheet.

Drywall is made from gypsum, which is covered with cardboard. Gypsum is an important component of this building material. It is this that gives gypsum board such important properties as density and strength. In order to improve quality, certain components are introduced into gypsum. An important part of a drywall sheet is the cardboard. It is used not only for the frame. It is also necessary to provide protection. Cardboard protects the gypsum core from all kinds of damage. Cardboard is great for finishing walls with materials such as paint, plaster and tiles.

One sheet of gypsum board consists of approximately 92% gypsum dihydrate and 7% cardboard. Surface-active substances, starch, and moisture make up 1% of the total mass of the leaf.

Consumers are often interested in whether drywall is dangerous.

GCR is an environmentally safe material. It is made from absolutely natural raw materials. There are no harmful components in it. The product has unique properties - it is hard and at the same time very flexible. That is why it is so valued.

Drywall: general information and composition of the material

With the help of gypsum boards, construction is carried out using “dry” technology, and it is these sheets that serve as the basis for structures. And all other elements are used for their installation, connection and finishing. Each gypsum board consists of a gypsum flat core framed with cardboard on both sides and along the long edges.

The cardboard used, despite its small thickness, has increased strength. It makes the sheets quite rigid, and the core, made of gypsum with special additives, can change in composition to achieve certain goals. For example, he can make gypsum boards moisture-resistant, not afraid of fire, and intensely absorb noise.

Panel dimensions

Dimensions of drywall depending on its type

The standard size of drywall is 2500x120x12.5 mm. They weigh approximately 29 kg. It is possible to order sheets that will differ slightly in size. It all depends on which company produces them.

There are factories that produce not only 2.5-meter plasterboard sheets, but also gypsum boards, the length of which is 3.2 and 1.5 meters. Long drywall is suitable for the entire wall from ceiling to floor. It is necessary to understand that it is much more difficult to work with long products.

Manufacturers offer not only standard gypsum boards, the width of which is 1.2 meters. Products are also produced whose width is 60 cm, while the length reaches up to 2 meters. But the demand for them is small.

The thickness of the sheet directly depends on what it is used for. For a wall one it is 12.5 mm, for a ceiling one – 9.5 mm, for an arched or flexible one – 6.5 mm.

Classification of plasterboard sheets according to GOST

GCR can be classified in two ways:

- according to GOST 6266-97;

- in accordance with GOST 32614-2012.

The differences between these two standards are primarily in the time of their adoption. GOST from 1997 divides drywall into 4 main types:

- Ordinary plasterboard sheets (GKL).

- Moisture-resistant plasterboard sheets (GKLV).

- Fire-resistant drywall (GKLO).

- Combining the properties of fire resistance and moisture resistance, plasterboard (GKLVO).

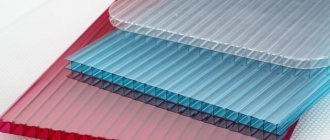

The following photo shows how the main types of drywall differ in color.

GOST, published in 2012, was developed jointly with Knauf. According to it, plasterboard is now called gypsum building boards and is divided into eight types:

- Type A, which is a standard gypsum board.

- H – moisture-resistant boards (the same as gypsum boards).

- F – fire-resistant gypsum boards (or GKLO).

- D – slabs with different densities depending on their operating conditions.

- I – especially hard gypsum boards.

- E - slabs used for facade work and having the properties of minimal water absorption and vapor permeability (GKLV with improved characteristics).

- P – slabs on which it is intended to apply plaster mixtures or lay tiles.

- R is a building material that allows you to create fairly strong bends in any direction.

USEFUL INFORMATION: Do-it-yourself portal for an electric fireplace made of plasterboard (video instructions)

Nowadays, almost all drywall on the construction market is produced under the Knauf brand. These are the same gypsum building boards. GKL from Knauf has better characteristics compared to other manufacturers, however, the price of material from more well-known brands may be higher. The following photo shows one of the types of gypsum building boards of the Knauf brand.

Panel weight

Examples of the weight of various drywall sheets

The weight of the panels is affected by the width, length and thickness. According to the standard, fire-resistant panels must weigh 1.6 kg per 0.8 mm. The weight of ordinary and moisture-resistant sheets should be 1 kg per 1 mm of material.

To calculate the load force of the structure being created, you need to know the weight of the sheets. It is necessary to clearly understand the maximum weight the panel used can withstand. This will eliminate possible defects and possible collapse during operation. In the process of working with material, a correct calculation of the load per square meter of material is necessary. This is very important when it is planned to install blind panels or install heavy elements.

Technical characteristics of drywall

The established standard for drywall provides only guidelines that manufacturers should adhere to. In fact, only the overall dimensions of the sheets, some requirements for the quality of materials and the type of drywall sheets are discussed. There are no clear indications of what drywall is made of; manufacturers have fairly wide freedom of choice in this regard.

Drywall sizes

- Width – 625 mm, 1200 mm

- Length – 1200, 2000, 2500, 3000, 3500, 4000

- Thickness – 6.5, 8.0, 9.5, 12.5, 14.0, 16.0, 18.0, 20.0, 24.0 mm

In fact, the only clearly defined format for drywall. Although the nominal rows for various types of drywall are not small, it is quite simple to understand why you need drywall of a particular size.

The width of the standard sheet is 1200 mm, this is due to established traditions in construction. The distance between the load-bearing elements of the sheathing or frame is made equal to 600 mm, thus, one sheet is attached to the frame along three lines: the edges and the center. The width makes it easy to place the sheets when transporting on trucks and does not create problems when lifting to the required floor.

The optimal length of the sheets can be from 2 to 3 meters in increments of 50 cm. This exactly corresponds to the height of the ceilings in most apartments and houses. Longer options of 3.5-4 meters are used in rooms with high ceilings, industrial facilities or public buildings.

The thickness of the sheets determines primarily the weight and strength of the material. Thinner sheets 6.5-9.5 are better suited for cladding ceilings and structures that are not subject to further load. The weight of the sheets is quite low, so they are easier to install and you can get by with a less durable frame. Partitions are usually formed from 12.5 mm plasterboard. Thicker sheets are suitable for walls where a significant load needs to be mounted. Two-layer cladding options are used, for example with 12.5 mm sheets or in one layer with material from 14 to 24 mm.

Drywall weight

The main advantage of drywall is its lightness. Its weight is significantly lower than that of other materials, even of the same volume, given its thickness and the method of mounting on a frame base, the weight of a wall or partition is several times lower than that of brickwork. Definitely, what can be made from drywall is unlikely to be made from aerated concrete and foam concrete, which still have to be laid in rows.

Calculating the weight of a plasterboard sheet is extremely simple. The thickness of the sheet is taken in millimeters, and this will be the nominal weight of one square meter in kilograms. This is for ordinary gypsum boards. For GKLV and GKLVO, the coefficient will be from 0.8 to 1.4 to convert millimeters to kilograms. This is due to the presence of additional additives in the composition of gypsum and cardboard, providing them with moisture protection and fire resistance.

Strength of drywall

First of all, the strength of the material is developed based on the requirements for which drywall is needed. According to the GOST 6266-97 standard, 322 N of longitudinal force and 105 N of transverse force must be applied to a sheet of plasterboard with a thickness of 12.5 mm and a size of 350 mm in order for it to collapse. The parameters are significantly lower than those of brick or aerated concrete, from which partitions are often made, but this is sufficient to build strong and reliable walls that can withstand additional loads.

It is worth noting that the standards describe the lower limit of permissible loads. In order to pass the tests, even not very high-quality plaster is enough, which can crumble or easily burst from making holes in it or during installation on a frame. The quality of global manufacturers, for example Knauf, is many times higher than the acceptable values. So before choosing drywall for repair or redevelopment, you need to take a close look at the quality of the gypsum and cardboard from which it is made.

Drywall categories

The main categories of gypsum boards differ from each other in the color of the sheet.

Plasterboard panels come in two categories - A and B. Most manufacturing companies sell plasterboard of category A, which is why the category is often not indicated in the technical characteristics of the product. Category B slabs are distinguished by the presence of small deviations from standard geometric parameters as a result of the use of old equipment.

The construction market offers the following types of drywall:

- GKL is a standard sheet of drywall with template parameters. They are the simplest type and do not have any additional characteristics. Suitable for use only in dry rooms. The appearance of the material is gray sheets with blue markings;

- GKLV – moisture-resistant plasterboard;

- GKLO – fire-resistant panels;

- GKLVO – products with complex properties;

- EGKL – flexible plasterboard;

- AKGL – slabs with increased sound insulation.

In order to choose the right plasterboards, you need to become more familiar with each type of this material.

Acoustic drywall

Acoustic plasterboard has increased sound insulation and is widely used for finishing shops, concert halls, dance and recording studios, and bedrooms. Acoustic plasterboard differs from universal plasterboard in that holes with a diameter of about 1 cm are made in its surface, and on the back side the sheet is covered with a special sound-absorbing coating that absorbs sound waves well. Acoustic drywall can be painted, but cannot be puttied, so as not to affect its soundproofing properties.

Types of drywall

Carrying out high-quality work using drywall requires the selection of the most suitable type of material. The choice of material depends on the technical and operational parameters and the intended purpose of the sheets.

Wall

The marking of wall plasterboard is applied to it with blue paint.

It is used when working with walls and for the implementation of various structures and niches. It has an optimal thickness of 12.5 mm. Other parameters may vary: length is 2000, 2500 and 3000 mm, and weight is 22.3; 27.9 and 33.5 kg.

Ceiling

Ceiling gypsum plasterboard is used for the manufacture of three-dimensional structures.

It is a lighter variation of wall plasterboard, used to create a suspended ceiling, and has a thickness of 8-9.5 mm. The use of this material for ceiling cladding can significantly reduce the weight of the ceiling and use a wider pitch for the frame system. This ensures more economical profile consumption. Ceiling plasterboard has a length of 2 and 2.5 m, a thickness of 8 and 9.5 mm, and a weight of 17.5 and 21.9 kg.

Arched

One of the features of this type of drywall is that before installation there is no need to spray it with water for additional plasticity

. The thinnest drywall is 6.5 mm thick. Thanks to this feature, it can bend well. It is used to form arched openings between rooms, as well as complex shaped structures. Contains reinforcing fiberglass. It has a length of 2 and 3 m, weight - 18 and 21.6 kg.

Acoustic

This type of drywall is quite rare on the market, despite its unique qualities.

It is used to increase the acoustic performance of premises, such as recording studios, meeting rooms and concert halls. They have perforation. Has soundproofing properties.

Fire resistant

It must be borne in mind that fire-resistant sheets are very wear-resistant.

This material is capable of not being destroyed for 20 minutes under the influence of open fire, due to the presence of special additives and impregnations in the composition of the product. Mainly used for the construction of fire partitions and protection of various systems (ventilation, cable ducts, chimneys, false fireplaces) from the influence of elevated temperatures. Sold in one length - 2500 mm, weight is 30.6 kg. The thickness of drywall is 12.5-25 mm. Fire-resistant sheets have a pink tint on the outside. Marking color is red.

Moisture resistant

The moisture-resistant material is more practical in relation to other types of gypsum boards

. Compared to conventional sheets, this drywall has high moisture resistance due to the presence of special modifiers that reduce the level of water absorption and also prevent the development of mold and mildew. Widely used for rooms with high humidity levels, excellent for rough finishing work in bathrooms, kitchens and balconies. Lengths are 2000, 2500 and 3000 mm, and weights are 22.3 and 36.3 kg. The thickness of moisture-resistant plasterboards is 12.5 mm. The outside of the slabs is painted green.

Combined - moisture-resistant and fire-resistant

This plasterboard is the most wear-resistant and practical in construction

. This special type of plasterboard has both moisture-resistant and fire-resistant characteristics. It is often used to repair and make changes to already completed structures made of plasterboard. The markings are marked in red, and the sheets themselves have a green tint.

Laminated

Laminated drywall is a new generation finishing material that was invented in Germany.

The boards are distinguished by the presence of PVC film on the outside. Laminated panels are used for decorative finishing work.

Facade

Facade plasterboard is also an energy-saving coating that stops heat loss.

The peculiarity of facade plasterboard panels is that they can easily withstand sudden temperature fluctuations, various precipitation, prolonged exposure to negative temperatures and sunlight.

Reinforced

This product contains a special layer of fiberglass and is often used for laying on the floor.

These panels have a high degree of strength, which is achieved by reinforcing the slabs with fiberglass, as well as by using multi-layer construction paper.

Types and sizes of drywall

There are several main types. To simplify the process when working with different samples of material, they are made in different shades and with multi-colored markings.

- GCR is the simplest type and does not have any additional properties. Externally, it is a gray material with blue markings, used for repairing rooms with dry air. Typically the thickness of such material is 8 - 9.5 mm. The inner part is made of gypsum, the outer layer is made of cardboard.

- GKLO - is manufactured using special additives that prevent the material from igniting. This type of plasterboard is used to install rooms with particularly high air temperatures. They also install fireplaces and stoves. These are gray sheets with red markings. This type is used very rarely.

- GKLV is a building material, painted green, containing moisture-repellent additives and antifungal agents. Used for renovation of bathrooms and kitchens.

- GKLVO - this type of drywall is both waterproof and fire-resistant, and is marked with a red tint. The leaves themselves are green.

GCRs come with rounded, straight, thinned, semicircular and thinned on the front side and with a rounded and thinned edge on the front side.

How to calculate the required number of sheets

Method for determining the number of plasterboard sheets for a ceiling

To correctly determine the number of panels to perform certain jobs, you need to know the parameters of the sheets. The dimensions of the drywall can only be determined after all measurements have been taken; it is important to be sure to measure the area of the room. For example, for rooms with a wall height of 2.7 meters, three-meter sheets are purchased. A strip of 30 cm is cut from them. It is not practical to use panels 2.5 meters long and add a strip of 20 cm to them. This will increase the number of seams, the number of profiles required and the financial costs.

If the panels are purchased according to size, correct installation of the frame is guaranteed. The design will be reliable. At the same time, the time for repair work will be significantly reduced.

When working with the material, it is necessary to avoid seams. When purchasing panels, it is necessary to correctly determine the length and correctly place the sheets on the frame and on the plane in general.

It is possible to buy sheets, taking into account the surface area that will be processed. But then it is necessary to purchase approximately 15% of the panels additionally. Such costs are unreasonable. You can completely refuse them. To do this you need to know the dimensions. First you just need to do certain calculations.

Some calculation details:

- The thickness of the plasterboard for the walls is 12.5 mm. But the amount of material does not depend on this;

- If there are small door and window openings on the walls, it is not necessary to take them into account when calculating. GKL trimmings can be used to finish slopes;

- If there is more than one opening, the dimensions of the openings are large, or it is planned to use other plasterboard sheets for finishing the slopes, then it is recommended to exclude the area of the openings from the calculations performed;

- In the process of finishing the walls below and above, it is necessary to leave a special gap of 1 - 1.5 cm. Then it is covered with finishing materials or a plinth.

How to distinguish sheets correctly

Let's learn how to accurately determine what kind of “gypsum” we will be dealing with based on the intended purpose of the varieties of gypsum boards and their specific properties.

Despite the fact that there are many manufacturers of the products in question on the market, they all adhere to approximately the same marking of their products, which consists of the corresponding tinting of the cardboard shell and stamped symbols. Define sheets:

— Wall gray with blue markings; — Moisture-resistant green with blue markings; — Fire-resistant pink or gray, with red markings; — Moisture-resistant green with black markings.

Types of longitudinal edge profiles of plasterboard sheets

The passport (labeling) of each product can be read on its reverse or end part. Useful information includes: manufacturer, sheet and edge type, overall dimensions, production date and production standard.

Transcript example

KNAUF SHEET GKLV-UK 12.5x1200x2500 12/12/15 GOST 6266-97

, means: Manufacturer - Knauf;

Sheet type – moisture resistant; Edge UK – “boat”, thinned (PC – straight, PLC – semicircular, PLUK – semicircular thinned, ZK – rounded); Dimensions – thickness 12.5 mm , width 1200 mm , length 2500 mm ; Release date – 12/12/15 ; Production standard - GOST 6266-97

Profiles for drywall

The installation of sheets should begin with the installation of the frame, which requires metal profiles. A profile is an important detail, without which it is impossible to carry out high-quality construction of partitions, wall alignment, and ceiling cladding. For the production of profiles, cold-rolled metal sheets are used. The metal is pre-galvanized - this processing method allows you to obtain strong and reliable metal products that have a long service life and are not subject to corrosion.

The metal frame used for working with drywall is characterized by a lightweight design, which consists of horizontal (guides) and vertical (rack) elements.

Vertical profiles

Rack profile (PS)

Rack profiles (ceiling, also labeled as CD or PP profiles) are load-bearing elements of the frame structure, thanks to the optimal selection of which you can use the workspace expediently and economically. During work in rooms of various sizes, the amount of waste is minimal. There are the following sizes of supporting profiles: length – 2500 – 4000 mm, sheet width – 60 mm; shelf height – 27-28 mm.

Horizontal profiles

Horizontal profile (CH)

UD profiles or ceiling guide profiles (CNP) - horizontal or starting frame parts. When performing wall cladding work or creating a suspended ceiling, it is necessary to install these elements around the entire perimeter of the room. It is recommended to use perforated profiles to simplify the passage of drilling tools through them. The dimensions of the starting profiles are: length - 3 meters, height - 2.8 cm, width 2.7 cm. The thickness of the horizontal elements is 0.55 mm.

Arched profiles

Arched profile (PA)

These profiles are presented in curved and concave form. They are used when it is necessary to form a complex type structure with various bends. However, sometimes experts use ceiling profiles for these purposes. Arched profiles have cuts located along the edges; with their help, the profile can be given the desired shape.

Parameters of concave profiles: radius 0.5-5 m, length 2.6-4 m. Dimensions of curved profiles: radius 1-5 m, length 0.4-2.6 m.

Corner profiles

Corner profile (PU)

A corner or corner-protective profile is necessary to protect the corners and ends of partitions made of plasterboard from mechanical injury. There are special holes on the surface of the profile for penetration of the finishing solution. The corner profile is 3 m long and has different sections: 2.5x2.5x0.04 cm, 3.1x3.1x0.04 cm and 3.1x3.1x0.05 cm.

In addition, the following components are still needed for installing drywall:

- Corner connectors. They allow you to make a perpendicular connection of the profile to another rail.

- Anchor hangers. Mainly used for ceiling finishing. Connect the base and the ceiling.

- "Crabs" Connect the ends of the profile into a single-level plane.

- Profile extensions. They are installed inside the profile using self-tapping screws and are designed to extend the rail.

- Two-level connectors. Connect the frame strips crosswise.

- Direct hangers. They are the main elements of the frame and are a rectangular plate. The racks will be connected to the load-bearing floor.

Corner connector

Anchor suspension

Crab connector

Rail for extending the profile strip

Two-level connector

Suspension

Profile selection criteria

In addition to the type and size of the profile for drywall, you also need to choose the thickness of the metal and the manufacturer.

As a rule, when you come to a hardware store, you can see that there are profiles that differ in cost, although their sizes are the same (standard). The most expensive are profiles from Europe, and the cheapest are from China. Profiles from a domestic manufacturer have an average price.

Depending on the thickness of the metal

It is not difficult to understand the difference if you pick up these elements of plasterboard systems. Some, the most expensive, are made of metal with a thickness of 0.5 mm, while others, especially Chinese ones, are made of very thin metal, since they do not withstand various loads well, although in some designs this does not matter much.

The choice of profiles depends on what type of plasterboard building structure is planned to be erected. If this is a partition, then it is better to take these elements as thick and reliable as possible.

The dimensions are standard, but the weight of the same profile may be different - due to the different thickness of the metal from which it is made

Thicker profiles should also be chosen if the height of the walls is more than 2 and a half meters, since the higher the partition, the greater the load on it. The structure of the partition can be strengthened by installing load-bearing profiles more often. As a rule, they are installed in increments of 60 cm, but it is also possible in increments of 40 cm. The main thing to consider here is that the width of the plasterboard sheet is standard and is 1200 mm. The joints of the plasterboard sheets should be located on the profiles. This is especially true if two layers of drywall are installed and the load on the frame doubles.

Depending on the manufacturer

Naturally, well-known manufacturers, such as, are quite scrupulous about the quality of their products, but the quality components of such systems also cost accordingly. It is a pleasure to work with high-quality products, especially since the result is very obvious. Unfortunately, not everyone can afford such a “luxury” and many buy either cheap (Chinese) or domestic ones, which have an average price, although everything is absolutely arbitrary.

This is a screenshot with prices for drywall profiles from one of the online stores

As a rule, domestic products do not meet many quality indicators, especially since there are many manufacturers who are not particularly “obsessed” with their authority and stupidly produce low-quality products that few people want to work with. The main problem is the discrepancy in many sizes, as well as the poor quality of the metal and coating, which is sometimes noticeable to the naked eye. In addition, the thickness of the metal does not correspond to the declared value. In other words, domestic firms are simply deceiving their potential clients. If you count these negative aspects, then the price does not correspond to what the manufacturers set. Despite this, for many, quality is not a priority because savings are a priority.

Domestic manufacturers produce profiles with a corrugated surface, which increases the rigidity of the profiles, but the presence of these “bumps” significantly affects the quality of the joints, since these, although insignificant, bulges do not allow the joints to be reliably tightened. In addition, the cost of profiles is almost at the Knauf level, while they are much more difficult to operate. In any case, the owner makes the decision.

Profile for drywall: how to choose and not overpay

Pros and cons of plasterboard sheets

Finishing interior walls with plasterboard

The main advantages of plasterboard sheets:

- Insignificant weight. Transportation costs can be significantly reduced. It is also possible to reduce the unwanted load on the load-bearing elements of the building. At the same time, installation work can be performed much easier;

- Excellent sound insulation for floors, ceilings and walls made from it;

- Quick and simple installation. There are no “wet” processes in the cladding process. This significantly reduces the time required to complete the work;

- Simple processing. The material can be easily drilled and cut. This significantly saves time on finishing work;

- Universal material. Sheets of the product are indispensable in various fields of construction;

- Affordable price.

The main disadvantage of drywall is its low strength and fragility. Heavy objects should not be hung on this material. This requires special embedded elements in those places where hanging furniture or other products will be located.

Another drawback is the likelihood of getting wet. Under the influence of moisture, gypsum loses its viscosity. It's crumbling. This is why it is so important to protect gypsum board sheets from moisture.

Wall plasterboard

This is the most popular and frequently used variety. As you can already judge from the name, this material is used primarily for wall decoration. This is the heaviest of the gypsum boards. The dimensions of a sheet of wall plasterboard are 1.2x2.5 m. There are also varieties of the same width, but shorter or longer: 1.5, 2, 3 meters.

The length of wall plasterboard is 12.5 cm. This allows it to be used as a base for the heaviest finishing materials: tiles, decorative plaster, porcelain stoneware, etc. The size of the gypsum board sheet is 12.5 standard. Therefore, it is not difficult to calculate the number of slabs required in a particular case. You just need to divide the total length of the walls by 1.2.

Making partitions during the redevelopment of a room is also what wall gypsum board is used for. The dimensions of this type of sheet and the thickness of the material allow you to quickly assemble strong and durable structures.

Wall plasterboards are usually mounted on a metal or wooden frame. In this case, the joints are sealed with special means. The result is perfectly smooth walls. Sometimes sheets of this type are also used for ceiling cladding. However, since they are too thick, they are mainly used only to create smooth surfaces.

What to look for when choosing drywall

It is necessary to store drywall in a heated and warm room.

During the purchase process, it is imperative to check the integrity of each sheet. The product must not be deformed or broken. Metal profiles must be selected from high-quality material, the required thickness and rigidity, since the quality of the entire structure depends on the strength characteristics of the frame. Excessively soft profiles bend and break during installation, which only prolongs and complicates the process of fixing the sheets. If necessary, the standard sheet size can be replaced with a more suitable one in a personal order.

Key recommendations from experts when choosing:

- In large and trusted construction stores, products generally do not sit in warehouses for a long time, thanks to this the level of quality is much higher than in construction markets.

- If such a possibility exists, check the storage conditions - increased temperature and humidity conditions in the room are considered the main reason to refuse to purchase.

- Examine each sheet for compliance with the stated characteristics and the presence of various defects.

Properties of GKLO

Fire-resistant plasterboard is a construction and finishing material with unique properties. It has improved characteristics compared to the usual one, while the overall dimensions of the sheets are standard and amount to 2500x1200x12.5 mm. With such dimensions, the weight of the product usually does not exceed 30 kg.

Other characteristics of fire-resistant plasterboard:

- Density – 850 kg/m3, which is more than that of conventional gypsum board (up to 800 kg/m3).

- The thermal conductivity coefficient is 0.22 W/(m*K), while for a conventional one it reaches 0.35 W/(m*K).

The fire resistance of drywall is determined by 4 indicators:

- Flammability group – not higher than G1.

- Flammability – B1-B2.

- Tendency to produce smoke – D1 (produces a small amount of smoke).

- Toxicity group – T1 (does not emit toxic substances when heated to critical temperatures).

Photo 4. Proper storage of gypsum plasterboards in warehouses

The mechanical strength of gypsum board is on the same level as conventional gypsum board, so structures sheathed with it must be protected from direct and strong impacts, after which dents and even holes may remain on the sheet.

Installation basics and necessary tools

If the room has perfectly flat surfaces, the material can be fixed using a specially designed adhesive composition based on gypsum.

Before installing drywall sheets on uneven surfaces, it is necessary to install a frame. It can be built from wooden slats or made from ready-made metal profiles. The sheets are attached to the frame using screws.

For complex structures, the material is pre-moistened with water for greater flexibility and only then attached to the frame. Moistening can be done using a special roller with needles.

Necessary tools and components

When working with drywall, it is necessary to use various components; even the simplest repair work cannot be done without them. One of the most important are metal profiles; using them, a strong and reliable frame is assembled, which is then covered with gypsum panels.

These necessary elements can be divided into three types:

- for cladding walls and partitions;

- ceiling;

- special guides.

Metal profiles designed for finishing walls and partitions come in guides and racks.

- Guide varieties have a special UD marking. Such parts are used for high-quality fastening of racks and guide rails of the frame under drywall.

- The drain profile plays the role of the main rail for installing plasterboard sheets, to which the entire sheathing is fastened. Such elements are marked CD.

Special guides are more narrowly targeted. For example, there are special racks designed only for doorways, to which entire entrance systems are subsequently attached.

There are also special arched options that can be adjusted to the desired configuration.

The combination of all of the above components, fastened with a special material, results in a fairly strong and reliable frame. A well-made structure will easily withstand significant loads, as well as the weight of the entire gypsum cladding. As a rule, the guides are treated with zinc, which protects them from corrosion and slow destruction, which makes the finishing frame almost eternal.

To work with drywall, you should stock up on other necessary components.

- Direct hangers. They are the main elements of the frame for gypsum sheets and are a rectangular plate. These parts are necessary to connect the frame racks to the load-bearing floors.

- Connectors for CD guides (also known as “crabs”). This element is necessary to connect the ends of the profile in a single-level plane.

- Two-level connectors. They are necessary for connecting the frame slats crosswise.

- Anchor hangers. These parts are needed for the base for drywall. As a rule, they are used when finishing the ceiling. The main task of anchor suspensions is to connect the base directly to the ceiling.

- Profile extensions. These elements make the frame slats a little longer. They need to be installed into the inside of the profiles and fixed with self-tapping screws.

- Corner connectors. These parts can also be T-shaped. Such elements should be addressed if you are making a perpendicular joining of the profile to another rail.

To work with plasterboard sheets you will need various tools:

- screwdriver - you can use it to fix the frame, for example, on the wall;

- hammer drill - this tool is necessary for more reliable fastening of the frame to the wall, ceiling or floor; it must have sufficient power for such work;

- electric drill;

- the grinder is useful for cutting profile parts and cutting off unnecessary parts of the resulting structure;

- a circular saw or electric jigsaw is useful for cutting drywall;

- electric scissors are indispensable for cutting metal if you need to build a large structure with plasterboard panels;

- a mounting gas gun is needed for automatic fastening of self-tapping screws, which saves time on installation of the structure.

For hand tools when working with drywall, you will need:

- special knife for drywall;

- knife-saw for drywall;

- hammer;

- pliers for fastening profiles;

- profile punch;

- plane;

- edge plane;

- needle roller.

When working with GLK sheets, you may need other devices that will significantly simplify and speed up the installation process:

- a device for resting on the ceiling, which is a special lever with a lock, with its help you can hold the panel in the correct vertical position;

- carrying handles - curved steel handles necessary for safer carrying of plasterboard sheets;

- tape measure, which requires accurate measurements;

- building level;

- mounting belt;

- lift for plasterboard sheets;

- special beating cords;

- runners or boards for leveling the metal profile;

- corner and pencil or marker;

- sealing tape;

- putty for puttying drywall corners.

All tools and components must be of high quality and reliable, otherwise the structure will not last long and may become deformed.

Manufacturers and prices of drywall

Currently, you can purchase plasterboard sheets in various price categories. At the same time, the thickness of the sheet affects the price much less than its intended purpose and the manufacturer’s brand. All the largest companies strive to improve their own products to the greatest extent, which leads to an increase in their cost, but not always to a significant increase in technical and operational indicators. Therefore, let's study in more detail the features of drywall from the most popular companies among consumers.

Knauf

Knauf company emblem

One of the leading manufacturers of plasterboard sheets on the Russian market. The product of this company is very popular among consumers. The company creates various variations of drywall - from conventional to acoustic. The company also sells a wide range of products in various sizes - plasterboard comes in lengths from 1500 to 4000 mm and widths of 600-1500 mm. The cost of a regular sheet (2500x1200x12.5) is 310 rubles.

According to experts, the main advantages of Knauf plasterboard are:

- Impeccable product geometry;

- Higher density and strength than other manufacturers;

- Long service life.

Volma

Volma company emblem

The domestic manufacturer of plasterboard panels Volma produces high-quality products at an affordable cost, which is approximately 10-20% lower than the products of the Knauf company. The range includes standard, moisture-resistant, fire-resistant and combined materials, but there are no special gypsum boards - for example, Volma does not produce acoustic sheets. The cost of a regular sheet of drywall (2500x1200x12.5) is 275 rubles.

The main advantages of sheets from this company:

- Reliability;

- Stable technical and operational indicators;

- High bending strength.

Volma's plasterboard is gaining increasing recognition among buyers year after year due to the optimal combination of high quality and affordable price.

Magma

Magma company emblem

The material of this brand is almost not inferior in quality to Knauf products, but at the same time its price is 20-30% lower. The main advantages of Magma plasterboard include sufficient strength and reliability, ease of processing and good flexibility.

Counting the number of profiles

Before you go to a retail outlet for building materials, you need to correctly calculate the number of all profiles, especially if you know the purpose and type of these profiles. Although this process takes up some useful time, it is necessary to do this in order to imagine what the entire structure will look like. To do this, you need to take a piece of paper and draw all the profiles on it, indicating all the sizes. In any case, it is better to take elements of plasterboard systems with some reserve.

How to calculate a profile for drywall

Calculations for one wall

Uneven walls can always be leveled using drywall. To do this, it is enough to mount the frame, aligning it strictly to the level and sewing it with sheets of plasterboard. At the same time, we should not forget that plasterboard systems take away part of the living space, which is especially critical for our apartments, which are not large in size and every centimeter counts.

Calculations are carried out according to the following principle:

- Profile guides (PN) are located along the perimeter of the wall, so it is enough to measure its length and height, multiplying, after adding these indicators, by two. If there are windows or doors, the dimensions of these elements should be added to the calculations.

This is what the frame for the partition looks like - Rack profiles (SP) are installed every 0.6 meters, but this figure should not be reduced. If the outer opening is at least 10 cm larger than 60 cm, you should definitely install another rack profile. It is imperative to take into account the height of the wall, although this figure is unlikely to be more than 3 meters.

- The presence of jumpers, which are made from a rack profile. They are placed at a distance of 75 cm from each other, and the upper jumper should be at the junction of the plasterboard sheets if the sheets are not long enough in height. Therefore, the dimensions of all jumpers are added up and added to the rack profiles.

Considering this calculation method, the number of profiles can be easily calculated for any wall or for several walls at the same time. We should also not forget about additional elements of plasterboard systems, if necessary.

Calculation of the number of profiles for the ceiling

The calculation methodology is almost the same, with the exception of the type of profiles used.

The calculation approach is as follows:

- The total length of the guide profiles (UD) must correspond to the perimeter of the ceiling. The length and width of the ceiling are added together, after which the result is multiplied by two. In any case, you need to take profiles so that there are enough of them. If you need 14 meters of profiles, you will have to take 15 meters, since the length of each profile corresponds to 3 meters.

First, guide ceiling profiles are installed - The footage of load-bearing profiles (CD) is calculated in almost the same way as for walls, but one should take into account the fact that it is better to place ceiling profiles not every 0.6 meters, but every 0.4 meters, which makes the structure more reliable.

- Jumpers are made from the supporting profile, which pass at the joints of plasterboard sheets. When the supporting profiles are located every 40 cm, there is no need to fence any grids. The lintels are mounted taking into account the length of the plasterboard sheets, so they can be placed every 2 meters and every 2.5 meters, since you can purchase ceiling plasterboard with dimensions of 2000x1200 mm and 2500x1200 mm. We should not forget about the hanging elements, which must be sufficient to support the weight of the suspended ceiling and ensure that the entire structure is strong and reliable.

How to distinguish sheets by external features?

How to find out the nature of the sheet and distinguish gypsum board from gypsum board? Everything is simple here:

- ordinary sheets are covered with white cardboard;

- moisture-resistant material is painted green;

- the fire-resistant version is covered with pink cardboard;

- fire-resistant and moisture-resistant panels are painted pink and marked with green inscriptions;

- The gypsum fiber sheet has no wrapper at all.

Drywall is standard, moisture-resistant and fire-resistant.

In the end, to decide, look at the wrapper and the color of the inscriptions and choose the option you need. Which one? We will talk about this in detail in the next paragraph.

Installation Features

If plasterboard is mounted on flat walls, then it can be attached with a special mounting adhesive, which is based on gypsum.

To overcome various differences and irregularities, a different, more thorough approach is required. The first step is to fix a frame made of a metal profile or wooden slats with a thickness of 2-2.5 mm to the wall. After this, you need to attach the drywall to it using simple screws, but you need to pre-drill the holes for the screws.

To create a concave or convex design, you must first wet the drywall and firmly fix it to the template until it is completely dry. To help water penetrate inside better, you can use a special roller with metal needles. It is necessary to roll the bend with a roller, pressing it very tightly against the surface of the drywall so that the needles make a large number of holes. After this, you need to place a damp cloth over the entire surface with holes. To avoid breaking the sheet, it is necessary to wet the fabric several times after it has completely dried.

You should leave gaps of 3-5 mm between the sheets, and then putty them. To prevent cracks from appearing at the joints, the sheets must be placed so that the joints fall on the profile, and before puttying, the joints themselves must be glued with sickle tape or a construction bandage.

To attach wall and ceiling lights, cabinets and shelves, you must use special dowels. They should be selected based on the thickness of the plasterboard sheet and the weight of the load (6 kg per 1 m2). If you need to secure a heavier load, then during the creation of the frame it is necessary to fix an additional metal strip in those places where the load will hang.

What is drywall made from?

The main material that makes up a plasterboard sandwich is gypsum. It is a natural salt that is formed naturally from sea water.

In order to obtain plasterboard sheet (GKL), the extracted raw materials must undergo pre-processing, which includes two processes:

- burning. The temperature at which this process takes place is approximately 180–190°C;

- grinding

To make gypsum boards of the desired shape, a solution with water is mixed, and sometimes fiberglass is added. It is a component that significantly increases the deformation resistance of gypsum plasterboards, and also has a positive effect on fire-resistant qualities. Cardboard is fixed on both sides of the gypsum sheet, which is environmentally friendly. Such cardboard is made from cellulose and impregnated at the production stage with special fire-retardant additives.

The size of the drywall sheet is selected based on the area that needs to be covered

Tips for the buyer - selecting material for your case

Do you have an arch, column or multi-level ceiling of complex design? Pay attention to the 6mm flexible plasterboard from Giprok. Such a sheet can be rolled into a tube without the risk of damaging the structure. A slightly thicker, almost centimeter sheet is not suitable in this case. It bends a little, but it is easy to break, violating the integrity of the entire wall, ceiling or column.

Are you filing a flat ceiling? Buy 9.5 mm sheets of ordinary or moisture-resistant plasterboard. They do not load the structure and have high rigidity. Thanks to this, it is possible to reduce the number of profiles in the frame. The flexible option is not useful here - it can sag without serious sheathing. A deeper version will require even greater reinforcement of the frame, since the difference between millimeters results in a difference in weight, measured in tens of kilograms.

Are you covering the walls? Choose sheets with a thickness of 12.5 or 15 millimeters. They have good rigidity and will help level the surface even without profiles. There is no need to lay anything more serious on the wall, since a nail or self-tapping screw will not be driven or screwed into the plaster, but into the dense building material of the supporting surface - brick, concrete or wood.

Are you building interior partitions? Choose a gypsum fiber sheet with a thickness of 15 millimeters or more. Otherwise, your wall will not be functional. You can’t screw a self-tapping screw into a thin gypsum plasterboard, and you can’t hang a picture or a shelf, but a 2-centimeter gypsum plasterboard allows even that. Tips and recommendations for use

Before purchasing a sheet of drywall from a hardware store, you should make sure that it is of proper quality. Pay special attention to the conditions of its storage, since many sellers store the material outdoors without any coating to protect it from adverse atmospheric conditions, or in warehouses with high humidity levels. Constant exposure to moisture and temperature changes causes a deterioration in the technical and physical parameters of the material, which impairs its performance characteristics and in the future leads to the appearance of defects and collapse of structures.

Keep in mind that technical conditions strictly prohibit installing pallets with gypsum boards on top of each other. Increased load causes cracks, chips and deformation in the gypsum core.

Dragging sheets of drywall over the ground or uneven surfaces is not allowed. This can damage the top layer of cardboard, reducing the strength and durability of the material. It is the violation of these conditions that causes a large number of defective products in warehouses, and the buyer, especially when purchasing gypsum boards for the first time, may not even notice the damage at the time of purchase.

A few recommendations:

- Buy products only in large construction stores with a good reputation and high traffic and fast turnover. There should not be any stale goods there.

- Try to visit the warehouse and get acquainted with the storage conditions of gypsum boards. If you feel that the humidity in the room is high, you should refuse to purchase from this place.

- When loading and delivering slabs, inspect each sheet for chips, cracks, and dents.

- Be sure to supervise the actions of the loaders, this will serve as a guarantee of protection against damage to the goods.

- If you are planning to buy a large batch of gypsum plasterboard, then first take one sheet “as a test” - cut it with a knife and evaluate the degree of its uniformity

To avoid unpleasant consequences from purchasing low-quality plasterboard, give preference to products from trusted manufacturers.

- Gyproc is one of the world's leading manufacturers of plasterboard, as well as gypsum-based building mixtures. The company has 65 factories and 75 quarries located around the world. The company places increased demands on product quality and tirelessly strives to improve the consumer characteristics of gypsum plasterboards. The main advantage of this brand of plasterboard is its light weight - the company specializes in producing lightweight sheets that are 20% lighter than their analogues.

- Knauf is the undisputed leader in the plasterboard and building mixtures market, the most popular brand of all those present on the market today. The company produces sheets with a thickness of 9.5 mm, 12.5 mm and 6.5 mm. The range includes 4 types of sheets: regular, moisture-resistant, fire-resistant and moisture-fire-resistant. The greatest demand among consumers is the ordinary sheet, which is officially adopted throughout the world as the gypsum plasterboard standard. The advantages of Knauf products are obvious: the products are light in weight, easy to process, easy to bend, sandable and easy to cut.

- Volma is a domestic manufacturer of gypsum boards; the products of this brand have received wide recognition among Russian consumers. The advantages of gypsum boards from Volma include: ease of installation, bending strength, and the presence of an edge to prevent the product from crumbling. Drywall of this brand is wear-resistant, it is made from natural, environmentally friendly materials and has an affordable price.

At the same time, consumers also note a number of disadvantages of the material - the sheets are quite heavy, there are no marking lines, and the layers themselves often have a wavy surface.

- LaFarge is a well-known manufacturer that for several decades has persistently occupied one of the leading positions in its segment of the finishing materials market. A distinctive feature of the company is the production of products with a semicircular chamfer and edges processed with cardboard on all 4 sides. This technology allows the sheet to be used to create the ideal coating geometry. GKL LaFarge is characterized by lightness, strength, wear resistance, and also exhibits excellent sound and heat insulation characteristics. Separately, the company has launched the production of sheets for bending, which are characterized by increased plasticity and are used to create arches and arc-shaped interior compositions.

At the same time, the choice of sheet sizes for this brand is quite small. As a rule, these are standard parameters - 1200x2500 or 1200x3000.

- Magma is another Russian brand. The products of this concern have good performance parameters. It is light in weight, cuts well, and is as strong as products from more well-known brands.

For information on how to choose drywall, see the video below.

Plasterboard sheet and its varieties - GKLO or GVLV?

Gypsum plasterboard (GKL) appeared on the domestic market in the mid-twentieth century. However, a patent for this building material was registered back in the 19th century, describing the technology of gluing 15 layers of paper and a layer of dry gypsum plaster. Modern gypsum board is no different from its ancestor from the 19th century - it is still the same flat sheet made from gypsum and reinforced with paper wrapping. Moreover, the size of the plasterboard sheet depends on its functional purpose.

In the century before last, this material was used only for interior decoration and was produced in paper factories, so the dimensions of gypsum boards depended on customer requirements. Nowadays, the scope of application of “dry plaster” has expanded, and the parameters of the sheet have been optimized and standardized. In the twenty-first century, plasterboard factories produce the following types of building and finishing materials:

- GCR is, in fact, the same “dry plaster” from the nineteenth century, used as an interior finishing material. It is used to make ceiling lining, interior partitions, or used for interior decoration. Therefore, the thickness varies within a centimeter, and the height corresponds to the standard ceiling level.

- GKLV is a modified version of “dry plaster”, trained to be afraid of moisture. Thanks to this, paper-wrapped cardboard began to be used in previously inaccessible places - in bathrooms, kitchens, toilets and other damp areas of the house. The dimensions of moisture-resistant plasterboard do not differ from the dimensions of the usual version, because we still have the same finishing material, only with a wider scope of application.

- GKLO is a special version of conventional material that is not afraid of flames and high temperatures. This is a completely different drywall. The thickness here is much greater than standard and reaches 3 centimeters. And it is used in the decoration of fireplaces and other hot places.

- GVL and GVLV are the next generation of “dry plaster”. The gypsum fiber sheet developed the idea of gypsum board by reinforcing the inner layer of plaster with cellulose fibers. Thanks to this, it gained strength and abandoned the cardboard wrapper. Moreover, the moisture-resistant material (GVLV) is not afraid of not only loads, but also water. From the previous generation of GVL building materials, only standard sizes were inherited.

Sheets of plasterboard

There is also “acoustic” plasterboard - a finishing material with reduced sound permeability. Because of this, it costs more than the regular option and is used only in special cases.

Material advantages

Before purchasing GC sheets, you need to familiarize yourself with the pros and cons of the material:

- Thermal insulation. A leveled surface with material saves on heating costs. This is especially true if insulation is laid under the gypsum board.

- Flexibility. Drywall bends under a certain radius, this allows you to make decorative elements.

- Fire resistance. If a room catches fire, only the top layer that is not covered with a gypsum board finish will burn out - the gypsum does not burn.

- There are certain types of material used in the kitchen, bathroom, and balcony.

- When leveling the wall with material, communications, wiring and other cables are carried out behind the sheets.

With all the advantages of gypsum boards, there are disadvantages:

- fragility of the material. It breaks and crumbles, so installation work is carried out with caution;

- if you install the usual gray color in the kitchen or bathroom, it will absorb a lot of moisture and subsequently become deformed;

- before installing gypsum board on the surface, it is necessary to determine how thick it should be and whether the wall will be weighted;

The listed advantages show that the use of plasterboard is beneficial for leveling surfaces and creating other surfaces.