Brick is considered the most reliable material for external cladding of facades.

The material is distinguished by its strength, ability to withstand external influences of an aggressive environment, durability and environmental friendliness.

Brick material can have different compositions, and therefore the color of different types differs from each other.

Also, depending on the composition, the brick has different properties, prices, and characteristics.

To decorate the structure in a non-standard version, yellow brick is used.

Description of yellow facing brick

Yellow brick for the facade is a fairly popular type of facing brick products, as it creates a feeling of light and warmth, creating a great mood even on gray rainy days.

The production of the yellow species involves the use of various types of raw materials, which determines the variety of color shades of this species.

The yellow type contains the following elements:

- high quality clay;

- lime;

- sand;

- water;

- iron oxide pigment.

The production of this type consists of pressing a mass of the above substances under high pressure, due to which the material is provided with frost-resistant characteristics, as well as hydrophobic properties.

Since natural substances are used in production, and there are quite a few additional components and impurities, this material is environmentally friendly and harmless to health..

After pressing, the material is fired and, if necessary, glazed.

It is the yellow look that is distinguished by the correctness of its shape: each element is made in the shape of a right parallelepiped with a clear outline of the edges and even corners. In addition, any shade of color is resistant to fading. Elements of a yellow hue have a meager variety of shapes and textures, but they differ in many shades precisely in the yellow segment of the palette.

IMPORTANT!

When purchasing facing bricks, you should choose material from one manufacturer.

In addition, you should purchase goods from one batch, since the color of different batches may differ slightly, which will affect the appearance of the cladding.

Photo of a yellow brick house:

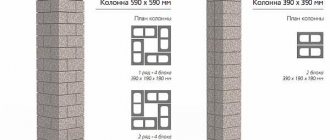

What can be built?

It is possible to build a private house or cottage out of cement. At the same time, they combine different colors and finishing materials. Brown and yellow brick houses look beautiful and elegant. Using various shades, you can clad the building with dark or light inserts, creating a column, arch, or ledge. Another type of practicality and excellent taste is a house made of beige bricks and a brown roof.

You can create the image of an estate from the last century by using red and coffee-colored material. Often houses are built lined with yellow or other light bricks, and dark inserts are used for the corners. The melange effect is created if the house is lined with different shades: lighter and darker. If the building design includes a house lined with yellow facing bricks and natural stone, it is important to choose the right shade so that there is harmony.

Advantages and disadvantages

An undeniable positive property of yellow brick is its decorative effect. A house whose façade is made of yellow brick will always stand out among other buildings.

In addition, this material has other advantages:

- good sound insulation;

- color fastness . The coating does not fade and is not exposed to sunlight;

- does not require special care, does not attract dirt, and also prevents the formation of mold or fungi;

- frost resistance. This type of cladding can be used in any region, regardless of temperature;

- strength . When exposed to any mechanical and impact actions, the cladding remains unchanged, does not deform, does not crack;

- resistance to any weather conditions. Rain, hail, and strong winds cannot negatively affect brick cladding;

- hydrophobicity. The production technology ensures the material is moisture resistant and incapable of absorbing moisture;

- fire resistance . Brick does not burn and does not support combustion in any way, does not ignite or melt;

- environmental friendliness. Due to the use of natural components in manufacturing, brick cladding is absolutely harmless to humans;

- durability _ The cladding may not lose its properties for many years; in comparison with suspended facade structures or decorative coatings with plaster or paint, it is the most durable and wear-resistant.

The disadvantages of brick cladding include cost, since the material is quite expensive compared to other types of external cladding . In addition, yellow brick is not varied enough in shape: the main element of the yellow type is a parallelepiped.

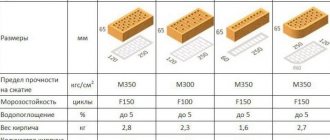

Brick photo:

Apricot and peach colored facing brick

The decorative component is almost the main priority of facing materials, and only then the technical characteristics are considered, so manufacturers of yellow types of brick products are trying to expand the range of color solutions.

The color is influenced by the type of clay, pigment, and the properties of iron in the clay . The professionalism of the manufacturer and the firing method are important, since the similarity of colors across batches depends on this.

Among yellow shades, apricot and peach are the most popular: the shade is quite warm. Using this color, you can not only cladding the façade advantageously, but also use elements of the material to lay out various pattern combinations. Apricot and peach go well with gray, brown or straw shades.

In addition, windows or individual parts of the facade can be decorated with warm-colored details..

The peach-apricot color is ideal not only for finishing multi-story facades, but also advantageously emphasizes the practicality of one-story houses.

Which colors fade faster in the sun?

Over time, sun rays can irreversibly damage any color, and you need to remember that the resistance of a material to fading depends on its color. The brighter and more saturated the shade, the stronger the color stabilization can be. But in the age of technology, manufacturers manage to create materials that can withstand solar exposure. For roofing, the uncompromising leaders among materials are natural clay tiles and composite metal tiles. These materials received more than 50 years of resistance to ultraviolet radiation due to their natural composition in the form of clay in the first case and natural stone chips in the second. As we all know, neither stone nor clay change color.

Specifications

In accordance with the standard, manufacturers must adhere to the basic characteristics of the yellow type of facing brick:

- surface type - smooth, glossy or matte;

- product length - 25 cm (standard);

- product width - 12 cm (standard);

- height - 8.8 cm (standard);

- weight of one element - from 2.2 to 3.5 kg;

- strength marking - from 100 to 200;

- hollowness - from 30% or more;

- water absorption - no more than 20%;

- thermal conductivity - 0.4 W/ (mC).

There are non-standard types (European) of facing elements; they may differ in width, length, height. This does not affect the quality of the product in any way. Many European manufacturers (Finnish, for example) even win in terms of quality, but the cost of the material is several times more expensive than domestic ones .

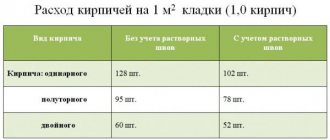

Other types of facing bricks

Facade bricks come in different varieties based on production technology, color, shape, filling, and size.

If we consider each parameter, we can classify the material as follows:

- according to the material of manufacture - ceramic, silicate, hyperpressed, clinker;

- according to filling - full-bodied and hollow (lightweight);

- by type of front surface - smooth, embossed, as well as matte or glossy. The texture may include engobe (ceramics), mineral chips, glaze;

- in shape - rectangular, with curves on one or both sides of the element of various degrees, with side cuts, bevels of different degrees, with a profiled surface, semicircular, with convex surfaces for decorating corners, cornices, openings, protrusions.

Regardless of the composition of the facade cladding, its color range is very diverse: from white to dark brown and black . The color does not affect the quality of the material, since natural coloring pigments are used.

Briefly about what makes a brick façade attractive

Brickwork perfectly combines beauty, traditional severity, solidity, elegance and refinement of taste with incredible practicality and high quality finishes.

Using the example of our built houses, we will show the most popular options for brick finishing in our opinion.

Brickwork perfectly combines beauty, traditional severity, solidity, elegance and refinement of taste with incredible practicality and high quality finishes.

Facing ceramic and clinker bricks for facade finishing are attractive for their operational and aesthetic properties. Real good quality brick:

- Natural.

- Long lasting.

- Lasting. This indicator is indicated by the brand of brick - the number next to the letter M. The higher the indicator, the higher the strength. Clinker brick has a strength of M400.

- Frost-resistant, that is, able to withstand alternating cycles of freezing and thawing in a state of water saturation. We use bricks that are frost resistant for more than 50 cycles.

- With a low level of water absorption (for clinker bricks less than 6%), which means that the brick facade can withstand excess moisture.

- Resistant to any environmental and weather influences (moisture, temperature changes).

- Not afraid of mechanical influences.

- Does not require special maintenance during operation - you can simply wash the facade with water from a hose.

- Over time, its color does not fade.

- Does not fade in the sun.

- Meets the requirements for operation in Russia.

- Makes it possible to realize unimaginably beautiful designs.

- Looks great.

- Maintains the attractiveness of the façade for a long time.

- Gives the facade a unique individual look.

- It has a wide variety of shades, rich colors and structural surfaces (smooth, rough, chipped).

- It has different formats, of which 250x120x65, 250x85x65, 215x100x65, 240x115x71 are popular on the Russian market.

- It has limitless possibilities for combining colors, laying, sizes, creating patterns and ornaments.

Manufacturers

To ensure that batches of yellow and its shades do not differ, you should adhere to a special firing technology, use certain dyes and have high-tech equipment. Not all brick manufacturers produce yellow facing bricks.

Popular businesses are:

- Golitsyn ceramics plant;

- Zheleznogorsk brick factory;

- LSR. Wall materials;

- Markinsky brick factory;

- Kirov brick factory.

NOTE!

When purchasing material from distributors and factory dealers, you must check the certificate confirming the status of an official representative from the manufacturer.

Otherwise, there is a risk of running into low-quality material..