Epoxy resin ED-20 is a veteran of the Russian epoxy materials market. The history of its release goes back to the Soviet defense industry, and for that time (about 60 years ago) the appearance of this material in wide use was truly revolutionary. And although since those distant years the range of two-component epoxy resins has expanded to several dozen items, and taking into account imports - to hundreds, the old ED-20 is still widely used in some areas, not least because of its low cost.

Note that epoxy ED-20 is not at all inferior to its more glamorous relatives like jewelry resins when it comes to large-scale work associated with pouring large areas: floors, large countertops, and in the manufacture of wall panels called kitchen aprons. And in the manufacture of artificial stone in the form of floor tiles or plumbing accessories, it also has no equal.

For example, an attempt to replace it with a more progressive, although similar in every sense Czech CHS Epoxy 520, will cost the buyer two or three times the overpayment, with almost the same result in terms of strength, labor intensity and aesthetics. The imported one will, perhaps, be more transparent, but does this matter much with a fill layer thickness of up to 10 mm, when the light honey color of ED-20 will be completely unreadable.

Scope of application of epoxy

Epoxy-diane compounds are actively used in a variety of areas of human activity:

- Electrical engineering.

In this industry, the material finds its use as insulators; - Instrument making.

Production of frames and heat-insulating partitions with reduced thermal conductivity; - Radio engineering.

Circuit boards are made from epoxy mixtures; - Shipbuilding.

Production of composite materials based on fiberglass. In addition, with the help of such compounds, boats, boats and yachts are repaired; - Aircraft industry.

Using hot curing technology, epoxy resin is used to make various aircraft components; - Military-industrial complex.

Often used to make lightweight body armor based on Kevlar alloys; - Automobile and tractor manufacturing.

ED-20 is used for repairing body parts and manufacturing interior parts; - Furniture industry.

Production of designer furniture and decorative interior items. The combination of resins with stone, metals, ceramics, glass and other materials has high aesthetic characteristics; - For waterproofing.

Used as a waterproofing layer in rooms with high humidity. In basements and ground floors.

In the construction field, epoxy resins are used in the construction of self-leveling floors, gluing glass, ceramic, wooden and metal structures. In addition, oligomeric materials are included in compound mixtures, composite materials and sealants.

How and where you can apply the acquired knowledge

After completing the entire course, a person will learn how to create beautiful and unique products that can be easily sold through social networks. In the 21st century, handmade things are a trend. They are in great demand. If the product is made of high quality and designed in a certain style, then its cost can be several times higher than the amount spent on the purchase of materials, as well as tools. At the end of the course, teachers help students find their first clients.

Resin can be used in any other creative work. The made balls are used to decorate sewn clothes, paintings and furniture. Using this material, they decorate the floor, vase, dishes, lamp and other decorative items.

Properties and characteristics of epoxy resin ED-20

Composition ED-20 belongs to the category of epoxy-diane resins and is a transparent viscous substance of a yellowish or brownish tint. Epoxy groups account for 20% of the total resin volume. This fact is reflected in the name of the material. Epoxy is based on diphenylpropane and epichlorohydrin.

Performance properties

Epoxy-diane resins have become widespread due to the following performance characteristics:

- Uniform structure and absence of pores;

- increased hardness;

- resistance to mechanical stress;

- high resistance to aggressive chemical compounds;

- heat resistance;

- high degree of adhesion to most materials;

- low specific gravity;

- slight shrinkage.

In addition, epoxy ED-20 has high performance, does not conduct electricity and has high corrosion resistance.

Specifications

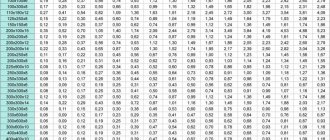

The table shows the main technical characteristics of epoxy-dian resin ED-20.

Instructions for use of ED-20

When using epoxy resins, two curing methods are used: cold and hot.

Cold curing method

Cold curing technology is used when mixing small volumes of resin and hardener. With this method, no additional actions are required when mixing the components. It is enough that the ambient temperature is more than 200C.

When preparing the working mixture, it is necessary to strictly follow the proportions specified by the manufacturer. Violation of these recommendations may lead to a change in the performance properties of the mixture, and for the worse.

Hot curing method

With the hot curing method, the resin is preheated. In domestic conditions, a water bath is often used for heating. A pre-measured amount of resin is poured into a container of the appropriate volume and heated to 45-55 0C. In order to ensure uniform heating, the compound is constantly stirred.

Important! During the heating process, water should not enter the resin. The temperature of the compound should not exceed 55 0C.

After heating, the required amount of hardener is added to the substance. The resulting composition is thoroughly mixed.

Preheating promotes uniform mixing of the components, which improves the performance properties of epoxy mixtures.

Use of plasticizers

An increase in the ductility of epoxy-diane resins has a positive effect on their performance properties. The addition of plasticizers makes it possible to increase resistance to shock loads, vibrations and other mechanical influences. In addition, when using plasticizers, the elasticity of the coating increases.

Plasticizer DBP

It is the dibutyl phthalate plasticizer that is most often used when working with ED-20 and similar compounds. The addition of DBP prevents the appearance of cracks caused by a significant decrease in temperature and mechanical stress, and reduces internal stresses. The use of this additive in combination with TETA and PEPA hardeners is especially effective. The mass fraction of plasticizer in the working mixture ranges from 2 to 5%.

The disadvantages of the DBP plasticizer include the need for thorough mixing. Heating to 40-50 0C allows you to increase the uniformity of distribution of the drug.

Plasticizer DEG-1

Diethylene glycol, like ED-20, belongs to the epoxy group, but can be used as a plasticizer. The concentration of the substance in the working mixture can range from 3 to 10%. The addition of DEG-1 significantly increases the ductility of the epoxy and prevents cracking.

The substance has a pronounced orange tint, which is transmitted to the working mixture. Unlike DBP, DEG-1 is easily mixed with epoxy-diane resins even without heating.

Plasticizer TEG-1

The plasticizer TEG-1 differs little from DEG-1 in its physicochemical and operational properties. Triethylene glycol is used as a base. The additive mixes well with epoxy resins and has a brownish tint.

Working at home

Independent repair work is carried out using hand-molding technology. No requirements are established here, since there is no proper control over the quality of the work performed. Naturally, the result cannot always be positive, so experienced craftsmen share useful tips that will help improve the quality of fiberglass products.

It is necessary to prepare the surface well. When working with metal, use a rust converter, after which the metal is treated with a brush. Before directly applying fiberglass, the surface should be degreased. Repair of fiberglass products begins with surface treatment with abrasive materials.

Air is a side effect that must be dealt with. Remaining air bubbles will not only spoil the appearance of the product, but will also negatively affect its strength. If you have a vacuum chamber, it is easy to get rid of excess air. At home, rollers are used for this. Fiberglass strips are laid out on the surface and rolled with a roller. After curing there are no special restrictions on actions. The material can be processed in any available way.

Use of hardeners

In order for the polymerization process of epoxy diane resin to begin, a hardener is required. It is added to the working mixture after the plasticizer has completely dissolved. At the time of mixing with the hardener, the temperature of the substance should not exceed 40 0C, otherwise the working mixture may boil.

Proportions and mixing features

The classic ratio when preparing epoxy mixtures is 1:10 (1 part hardener to 10 parts resin). However, depending on the purpose of the product, this ratio can change either up or down.

The hardener should be added gradually, otherwise overheating of the working mixture may occur. In addition, rapid infusion can cause a chain reaction and instant polymerization of the composition. Excessive amounts of hardener also lead to damage to the working mixture.

Hardener PEPA

Polyethylenepolyamine hardener (PEPA) is an available reagent that can effectively start the polymerization process of epoxy-diane resins at a temperature

from +15 to +20 0С without preheating the working mixture. Even high humidity does not affect the rate of polymerization of the mixture.

The drug may have a yellowish or brownish tint. Optimal performance properties of the product are achieved by adding 13.7% hardener, but the operating range is from 10 to 15%.

Hardener TETA

Triethylenetetramine hardener (TETA) is designed to work in the temperature range from +15 to +25 0C. According to the principle of action, it resembles the drug PEPA, but has several significant disadvantages:

- specific unpleasant odor;

- high degree of toxicity;

- requires strict adherence to dosage.

Hardener DEET

The substance is used to work at room temperature without heating the working mixture. Hardening occurs within one and a half hours from the start of the reaction. Unlike hardeners PEPA and TETA, it can react with carbon and water vapor, so the product should be stored in a tightly closed container.

Hardener Etal 45M

Unlike the hardeners listed above, Etal 45M has the properties of plasticizers. When adding the drug, the temperature of the mixture increases significantly less than when using the hardeners listed above. Etal 45M mixes well with epoxy-dian resins, has no unpleasant odor and does not pose a danger to humans and domestic animals.

Popular about popular

In terms of breadth of application, epoxy resins today rival the most common chemicals. Such as:

- Soda Ash;

- Caustic sodium;

- Liquid glass and others.

Epoxy Resin Density

There is a wide variety of types of epoxy resin within their family. So, according to its purpose, we can highlight:

- Self-leveling - for leveling concrete or as a sole “fighter” for the absolute horizontal.

- Low viscosity - for decorative or protective coating of metal, wood or stone. Very often, designers give their preference to these epoxy resins when producing volumetric floors.

- Protective - special compounds to combat atmospheric and chemical effects on products made of concrete, metal or other materials. Along with protection, these recipes have a positive effect on the aesthetic perception of resin-coated products.

- Modified - the main purpose of this group of resins is to be a part of adhesives, an impregnation for glass fabrics, and to prove themselves during emergency and repair work as a reliable and universal binder.

- Special - this group is not large, but each of it is capable of solving problems of such complexity that no other industrial or even laboratory connection can be solved.

On a note

The variety of epoxy resins obliges those who purchase them to carefully familiarize themselves with the scope and purpose of a particular composition.

All of the above groups of epoxy resins nevertheless have a number of identical or very similar qualities and properties, which can be called the main characteristics:

- Strength;

- Heat resistance;

- Waterproof;

- Adhesive properties;

- Resistance to chemical reactions.

The strength of epoxy resin is one of its main advantages. Thus, a solution with a hardener, produced in strict accordance with the recipe, is ready to compete with the strength of concrete.

For clarity, we present a table of several strength values using the example of the most popular brand ED-20

| Epoxy resin ED-20 | Concrete | Polystyrene | Structural steel | |

| Tensile strength, MPa | 40-90 | 1,15-3,15 | 40 | 380-450 |

| Bending strength, MPa | 80-140 | 100 | 380-450 | |

| Compressive strength, MPa | 100-200 | 60 | 35-60 | 380-450 |

The ability to withstand high temperatures is an equally valuable quality both in the home and in production. And even though epoxy resin is far from being fireproof - 200 degrees Celsius - it’s still not a bad result.

Resin in a frozen state does not allow water to pass through. It is on this quality that its priority use is based as protection for reinforced concrete products, structures and small forms made of wood and plaster.

Epoxy resin protects not only from moisture and adverse weather conditions. Its unique formula allows you to be out of danger from most chemically active substances and their solutions. Resin is a dielectric and therefore it is widely used in the production of insulators, as well as in the form of compounds in the electronics and radio engineering industries.

The ability to be a universal glue is another step of “epoxy” to the status of a “anywhere” product. Fiberglass impregnated with this composition allows you to build lightweight and durable hulls of boats and yachts, create elements of park attractions, machine parts and equipment.

Currently, not a single furniture production can do without the use of this two-component adhesive. Moreover, this applies both to the production of furniture made from natural wood, and from chipboard and MDF, both from plastic and with glass elements.

High aesthetic qualities, flexibility during processing and a wide range of possibilities for designers were once noticed by jewelers and artisans. Probably, in the properties of “epoxy” we need to look for the origins of the popularity of costume jewelry.

Epoxy glue is widely used both in modeling and in restoration work. It’s a rare corner of a home craftsman who can do without a tube of this resin and its hardener.

Fillers for epoxy resins

When making jewelry, paintings, decorative furniture and other products, various fillers can be added to epoxy resin. These substances add originality and style to the author's works, and in addition, affect the performance properties of the products. Most often, the following are used as filler:

- cement.

Used to prepare putty. The resulting mixture has high plasticity and adhesion to most materials. After complete polymerization, the surface is resistant to impact loads and aggressive environments. Preparation of the mixture consists of thoroughly mixing 2 parts of cement and 1 part of ready-to-use epoxy resin; - tooth powder or chalk.

The use of such additives increases the hygroscopicity of the finished surface. Such mixtures can only be used in dry, well-ventilated areas; - alabaster or plaster.

The gypsum mixture has high strength characteristics and ductility. To achieve optimal performance characteristics, it is recommended to warm the surface to 50-60 0C immediately after application using a hair dryer. Open fire should not be used for this. - flour.

The advantages of this filler include the fact that after complete polymerization, the putty is easy to process. There are some drawbacks: when adding flour to the epoxy mixture, the polymerization process slows down significantly; - fine sand.

The addition of fine sand significantly increases the specific gravity of the epoxy mixture, but increases the strength and hardness of the surface. Such mixtures can be used for outdoor work: they are not afraid of ultraviolet radiation, moisture and aggressive environments; - fiberglass

When working with fiberglass, you must strictly follow safety regulations. The smallest particles of fiberglass entering the respiratory tract can cause serious illness. The skin also needs protection; - wood sawdust.

After hardening, putty with such a filler is highly hard and difficult to machine. The advantages of such mixtures include resistance to shock loads and vibrations. To prepare putty, it is better to use fine sawdust or wood dust.

You can use glitter, beads, etc. to make jewelry and decorative items.

Epoxy cure time

The curing time of the epoxy mixture depends on the hardener used and the curing method. At a temperature

from +20 to +25 0C, primary polymerization occurs in 45-60 minutes. Complete polymerization of the composition can last from 24 to 48 hours.

Important! The polymerization process of epoxy-diane resins is irreversible, therefore, when working with ED-20 and its analogues, it is advisable to carry out a test batch. This will allow you to determine the curing speed and evaluate the performance properties of the product.

What determines the adhesion performance?

After adding the catalyst-hardening agent, the resin must be used immediately. The declared adhesion and bonding quality indicators depend on this. This period varies for different brands and qualities of epoxy. On average it is from half an hour to an hour. And when adding ETAL-45, this period increases to 2–3 hours. Complete polymerization of epoxy takes 1–3 days.

The resin takes a long time to harden.

Material consumption per 1m2

The consumption of ED-20 is a relative value and depends on many factors. First of all, this is the type of surface being processed. When covering a porous surface, the average material consumption is approximately 150 ml/m2. If the surface is glossy, significantly less mixture will be required, about 100 ml/m2.

The above values can be considered conditional, since the thickness of the layer, method of application, consistency of the working mixture, temperature and humidity in the room are of great importance.

Quality

In its raw form, the resin has its own specific characteristics that are directly related to the further quality of the finished product. These characteristics are always described by the manufacturer.

You can influence the quality by adding various fillers and components to the solution, and the price ratio directly depends on the effectiveness.

From this we can conclude that it is not worth saving on fillers.

How can I replace epoxy resin ED-20

There are several modifications of epoxy resins that are similar to ED-20 in operational properties and physical and technical characteristics.

ED-8

In its chemical composition and scope of application, ED-8 is similar to ED-20. The material is widely used in aircraft and automotive industries, construction, radio electronics and electrical engineering. The main difference is the content of epoxy groups in the finished mixture, which is 8%; increased primary polymerization time is 3 hours at room temperature.

ED-16

As can be seen from the name of the resin, the number of epoxy groups included in its composition is 16%. In terms of purpose and properties, ED-16 is practically no different from ED-20, but it hardens longer and contains more chlorine. The advantages of the material include the high strength of the adhesive seams.

ED-22

It differs from ED-20 in the number of epoxy groups (22%) and gelatinization time - 18 hours. The dynamic viscosity index can vary from 8 to 12 PA/sec.

E-40

The production technology of E-40 resin has its own characteristics. Unlike the ED series compounds, E-40 is produced by condensation of diphenylolpropane and epichlorohydrin in an alkaline medium to which toluene is added. Polycarboxylic acids, their anhydrides and polyamines can be used as hardeners.

E-40 is used in the paint and varnish industry. In addition, the semi-finished product is used for the production of various modifications of epoxy resins. The material is characterized by plasticity and moisture resistance. After complete polymerization, the mixture is resistant to acidic and alkaline environments.

Technical specifications

The epoxy gelatinization time is 8 hours, and the complete curing period is 24 hours. The description of the highest grade of material contains the following technical characteristics:

- density during cold curing – 1110–1230 kg m3, during hot curing – 1200–1270;

- mass fraction of chlorine ions – 0.001%, saponified chlorine – 0.3%;

- mass fraction of hydroxyl groups – 1.7%, volatile substances – 0.2%;

- dynamic viscosity – 13–20 PA/second;

- temperature for softening is up to 60 degrees.

Precautionary measures

Epoxy-dian resin ED-20 belongs to substances of the second hazard class. You should work with the semi-finished product wearing protective gloves, goggles and a respirator. If the mixture gets on the skin, the affected areas should be washed with running water and soap, and then treated with castor or vaseline oil.

All types of work involving the use of epoxy should be carried out in a well-ventilated area or outdoors. The mixture is not explosive, but may ignite when exposed to open flame.

Epoxy resin ED-20 is a universal semi-finished product, widely used in many areas of human activity. High performance properties and ease of use, combined with affordable cost, allow the material to be used in industry, construction and the domestic sphere.

Security measures

Working with all epoxy resins developed 30 or more years ago, when environmental and medical requirements and GOST were not as strict as they are now, requires special attention to your own safety and the safety of the environment.

Only fully polymerized epoxy material has no effect on humans, animals and nature. In liquid form, before work begins, and especially during work, when the compound and hardener are still in the stage of active interaction, substances harmful to health are actively released from the mixture.

Therefore, it is necessary to ensure reliable protection of the eyes and respiratory organs from the vapors of the substance. Such protection should be greater, the larger the area of the surfaces being poured or otherwise treated. A respirator, insulating glasses, and disposable gloves must be a mandatory attribute of work carried out with epoxy. It is also useful to have acetone or ethyl alcohol, which is safer in comparison, on hand in order to quickly remove drops of the polymerizing mixture that get on the skin of your hands and face, as well as on clothes.