Brick is reliable and durable. This material looks attractive and presentable. But brick walls have one significant drawback: thermal conductivity. Even relatively warm ceramic material conducts heat well and does not sufficiently protect the building from the cold. In our climate, it will be necessary to build walls 64-90 cm thick to provide sufficient thermal resistance. A more rational option would be to make the external walls of the building from other materials with insulation and cladding. How to cover a house with facing bricks? It's not difficult if you know the technology and the nuances of the work.

The house, lined with brick, looks solid and presentable, it is protected from wind and other unpleasant weather phenomena. This finishing option is used for both lightweight concrete and wooden houses.

Covering a house with bricks: Advantages and disadvantages

The advantages of brick cladding include not only externally attractive properties. The cladding serves as protection for the main wall material from the effects of destructive climatic factors.

If we compare facing bricks with facade plaster, they have much higher strength to mechanical stress.

Compared to vinyl siding or painted corrugated sheets (as part of ventilated facades), any type of brick is better able to withstand exposure to solar ultraviolet radiation. And facing the façade with stone tiles or porcelain stoneware can collapse due to poor adhesion of the walls and mortar.

Finishing with facing bricks allows for simultaneous insulation of the facade.

Of course, the thermal insulation properties of dense materials are low, but the use of hollow bricks and a layer of insulation makes it possible to achieve a high level of energy saving when heating in winter and air conditioning in summer.

The disadvantages, in addition to the cost and labor intensity of the work, include the high load on the foundation, which must be taken into account when designing or reconstructing a house.

Technology of finishing frame buildings with bricks

Laying of flat facing bricks is carried out together with thermal insulation sheathing. An air gap is left between the finishing material and the wooden wall. This is necessary to ventilate the wood. Therefore, ventilation spaces must be organized between the wooden frame and the brickwork, because wood absorbs moisture quite well.

When wooden walls are open on the outside, they release excess moisture absorbed from inside the house to the environment. If the frame building is covered with brick, moisture will remain in the wooden walls, which will lead to their rapid deformation and destruction.

Many owners of country wooden cottages, when facing them, insulate the walls with glassine and line them with bricks, but do not leave a ventilation gap between the masonry and the walls. Because of such an error, a frame residential building, lined closely with brick, as reviews from the owners show, begins to become moldy and rot inside.

This process occurs due to the fact that condensation forms in the brickwork from constant temperature changes, which after a certain period of operation of the building completely destroys the wooden frame. The walls inside are first covered with mold, then they begin to rot and, accordingly, gradually lose strength and collapse.

Therefore, the technology of brick cladding of buildings made of lumber necessarily involves the arrangement of ventilation gaps between the walls and the finishing masonry. Brick laying is carried out on a flexible bond with a wooden wall. Reinforcement is performed using steel or plastic plates, resulting in a spatial gap of 3 cm between the frame structure and the masonry, which ensures natural ventilation of the building material.

Features of wall cladding made of different materials

The facing masonry runs in half a brick.

The self-supporting capacity of such a false wall is low. It must literally be tied to the facade. For this, different materials are used: ready-made flexible connections, anchors, nails, strips of sheet metal, masonry mesh.

The method of bonding, the need for insulation, the presence of a ventilated gap and vents depend on many properties of the facade material: strength, vapor permeability, holding force of fasteners, size of building blocks, etc.

Repair of brickwork of external walls

If the brickwork partially fails, it may be considered unsafe. Otherwise, repairs can be made. To do this, the site is cleared and individual bricks are removed. External seams should be cleaned and frayed edges removed. The most convenient way to do this is to use a hammer drill and a grinder. To increase adhesion, priming should be done. New bricks are installed in place of the removed bricks. Their laying is carried out using mortar. The bricks are pre-soaked.

Brick

In this case, everything is relatively simple. Both the wall and the cladding have almost the same parameters, including the dimensions of the brick. The most common fastening method is ready-made flexible connections made of metal or fiberglass.

A flexible connection is a rod that has seals at the ends in the form of a “powder” of quartz sand (to improve adhesion). Such a rod is attached at one end to the horizontal mounting seam of the wall, and at the other to the cladding.

If the seams do not match, then in the facing masonry the rod is placed in a vertical seam. Such cladding usually takes place simultaneously with insulation.

For a newly built brick house, this makes it possible to reduce the thickness of the external walls and the total load on the foundation.

If polystyrene foam is used as insulation, then a ventilation gap is not needed. When using mineral wool, there is a need to ventilate water vapor from it.

Therefore, on the side of the facing layer, a washer with a lock is put on the flexible connection, which presses the insulation mat against the wall of the house and leaves a ventilated gap between it and the facing. That is, the flexible connection also serves as a fastening for the insulation (there is no need to use umbrella dowels, as in curtain wall facades).

Number of connections per 1 sq. m walls - 4 pieces (in openings - along the perimeter every 30 cm), minimum depth into the seam is 90 mm, maximum - 150 mm.

Technology

Cladding the façade of a house with brick is done after treating the wood with an antiseptic. You should choose a special composition for impregnation - for outdoor work. It will protect the wall from mold, mildew and other dangerous microorganisms. Next, a vapor barrier is attached to the wall using a construction stapler. Installation is carried out with an overlap of at least 10 cm.

A vapor barrier located on the inside of the wall will prevent moisture vapor from entering the insulation from the room

Facing the facade with brick begins with the installation of the sheathing. The dimensions of the frame bars depend on the required thickness of the insulation. The thickness of the thermal insulation can be selected approximately based on the recommendations of neighbors or the Internet, but it is better to use a special calculation. Using the fairly simple Teremok program, even a non-professional can make thermal calculations. You only need to know the thickness of the wooden wall and its thermal conductivity, as well as the thermal conductivity of the selected insulation. The brick (and all layers after the ventilation gap) are not taken into account in the calculation.

The frame block is attached to the walls with screws or nails. Next, the house needs to be sheathed with insulation. Mineral wool is placed tightly between the sheathing. To do this, the distance between the bars should be 2-3 cm less than the width of the insulation.

Methods for attaching insulation to a wooden frame

Waterproofing and wind protection are fixed on top of the insulation. Fastening is carried out using a construction stapler. After such preparation, they proceed directly to lining the house with bricks.

The hydro-windproof membrane protects the insulation from wind and moisture, but does not prevent excess water vapor from escaping from the wall to the outside

The thickness of a brick verst is usually 120 mm. This is not enough to ensure stability, so the wall must be connected to the main part of the external structure.

This can be done in two ways:

- attaching a reinforcing mesh to the wall and inserting it into the facing layer by half the width (such a mesh is installed across the entire width of the wall with a certain vertical pitch);

Fastening the cladding using reinforcing mesh (steel or flexible) is only possible for new construction - separate special bindings that are nailed to the wall and inserted into the masonry.

The fastenings are located in the places where the supporting frame passes.

The finishing installation technology is also relevant for frame buildings. The only difference is that the connections between the wall and the external materials are attached to the frame posts. In all cases, cladding must take into account the ventilation gap.

Cover the house with brick: Cinder block or monolithic houses made of cinder concrete

Cinder block is a lightweight concrete. Depending on its hollowness, the material can act in different capacities, including as a thermal insulator. Its main disadvantages are its unattractive appearance and low resistance to precipitation and wind loads.

Therefore, insulation of a cinder block house is usually not required, but cladding is required. The best material for this is considered to be brick with low water absorption (for example, clinker or hand-molded).

The vapor permeability of brick is lower than that of cinder block. As a result, in cold weather the dew point may “get” onto the cinder block, and water vapor will not be able to erode through the cladding.

To prevent the main wall from becoming damp and collapsing, you need a ventilation gap and vents at the bottom of the cladding (at the base) and at the top (under the roof).

As a flexible connection, a masonry mesh is used, one edge of which is fixed to the wall with a bracket and dowel, and the second (in the masonry joint of the cladding) should not go out.

The mesh is laid in every fifth row of brickwork.

How to get rid of efflorescence

Efflorescence is a whitish coating on the front surface of the masonry and is in no way related to the quality of the brick. The appearance of efflorescence is determined by additives introduced into the masonry mortar, most often during winter masonry.

Masonry using hard mortars with low moisture content eliminates efflorescence. The use of rigid mixtures is mandatory when finishing with materials with low moisture absorption - clinker or hyper-pressed.

The possible appearance of plaque is prevented by the use of water repellents - organosilicon compounds that give the masonry water-repellent properties. Penetrating into the pores of the material, the water repellent creates a film that prevents the movement of moisture, but at the same time depriving the brick of its ability to breathe.

Special construction removers have been created to remove salt deposits. There are traditional methods of dealing with efflorescence: washing stains with a 5% solution of vinegar, hydrochloric acid or ammonia.

Cover the house with bricks: Building blocks made of cellular concrete

Despite the differences in the manufacturing technology of aerated concrete and foam concrete, their load-bearing and thermal insulation properties are similar, there are only differences in vapor permeability (aerated concrete is higher).

Facing for blocks made of cellular concrete is mandatory - the reasons are, in principle, the same as for cinder blocks.

As with cinder blocks, insulation is not necessary, but a ventilation gap is needed. Therefore, the method of attaching the facing masonry to the wall is similar.

Ceramic facing brick produced by Stary Oskol, straw color

Use of single and one-and-a-half facing bricks in masonry. The house is made of single straw-colored brick in combination with decorative inserts, and the fence is made of one-and-a-half bricks

Cover the house with bricks: Wooden houses

This is perhaps the rarest case of brick cladding.

It is almost impossible to veneer a log house with bricks due to the characteristic corner cuts of the crowns. Log houses do not have this problem, but the feasibility of cladding is very doubtful - the acquired advantages are much less than the disadvantages.

Frame (or frame-panel) wooden houses are attractive due to the absence of “wet” work, speed of construction and relatively low cost. Brick cladding is possible and practiced, but it neutralizes these advantages.

In any case, insulation when facing a wooden house with brick is, in principle, not necessary, but a gap is necessary - the lack of ventilation and weathering of excess moisture will lead to rotting of the wood. In addition, it is mandatory to treat the walls with antiseptics.

If insulation is carried out, it is performed using mineral wool mats, which have high vapor permeability.

Installation of insulation is carried out over the lathing, using the technology of ventilated facades - with laying on top of a windproof, vapor-permeable membrane.

When insulating, as a flexible connection, they use not masonry mesh, but pieces of wire attached to the wall with nails or self-tapping screws (at the rate of 4 pieces per 1 sq. m).

Cladding works

Having certain skills in working with bricks, you can cladding the house yourself. Moreover, facing bricks are made with more careful adherence to dimensions than ordinary building bricks.

Since it is desirable for a house lined with brick to be not only aesthetically pleasing, but also warm, various insulation materials are used for this purpose. The best option is sheet mineral insulation. It is produced in various thicknesses and is easy to install. The insulation sheets are attached to anchors appropriately located in the wall, which are driven into the wall every meter and every sixth row of brick. This could be wire cut into pieces. Its length should be enough for reliable fastening in the wall (5 - 8 cm), a layer of insulation (10 cm) and laying in the facing masonry, that is, about 30 cm. Also, the insulation sheets should be pressed with mounting dowels and umbrellas (5 pieces per 1 m. sq.). The anchors provide additional strength and stability to the façade wall.

It is also necessary to ensure ventilation of the insulation. For this purpose, holes (vents) are left in the façade wall along the upper and lower cornices. They are protected with a mesh or special plugs are placed on them for ventilation. You should also worry about the eaves overhang - it should overlap the new wall by at least 25 cm, so you may have to cover the roof.

There are some subtleties when cladding a house made of wood, which relate to the structure itself. Before covering a wooden house, you should make sure that all its elements are in good condition - there is no fungus, signs of rotting, or serious damage. All these places need to be removed/repaired and, if necessary, replaced.

The wood of the walls must be treated with fire-resistant impregnation and an antiseptic (maybe twice). Before you cover a wooden house with bricks, you should ensure its ventilation. Slats are placed along the walls in increments of 1 m, and a vapor barrier is placed directly on them. Holes are left in the façade wall. These actions will ensure air circulation between the façade wall and the wooden elements, which will protect the latter from moisture.

The laying of facing bricks itself differs little from the traditional one. The brick is placed with a spoon in half a brick, using various dressing options. However, you should be extremely careful and, if this is the first time such work is being done, take your time. This will allow you to create a beautiful facade without annoying flaws. You should also follow a few simple rules:

- Bricks of the same color may differ in shade (permissible differences are specified in the technical data sheet of the product). The difference will be especially noticeable over a large area. To avoid this, you can mix bricks from different pallets.

- The solution should not contain impurities, such as lime. Otherwise, efflorescence may appear on the wall.

- The brick should be stored covered from rain - moisture that gets on it will negatively affect the setting of the mortar, and subsequently, because of it, a white coating may appear on the finished wall.

In this video you can watch the process of cladding a house: The alignment of the bricks in the wall affects the final appearance of the facade. It can be individualized by the pattern of the seams and the color of the brick, for example, the base is faced with a darker colored brick. In some solutions, only the long part of the brick is visible, in others, “butts” are also used, that is, narrower sides. Also, the color and shape of the seams is of great importance. The color of the grout can be selected in the store, based on ready-made templates. In general, the field for imagination is limitless.

How to brick a house?

Previously, house construction technology did not provide for the use of insulation, nor the use of finishing materials. Many owners of old houses understand that the time comes when it is necessary to cover not only the outer parts of the wall with insulation, but also the surface of the old foundation. To protect the insulation, high-strength brick is used. Finishing brick is popular, despite the large selection of other materials offered in stores. The answer to the question of how to clad a house with brick is of interest not only to the owners of old houses, but also to modern developers.

Preparatory stage for old houses

For old houses, it is necessary to strengthen the old one or arrange a separate foundation capable of supporting additional brickwork.

- Strengthening the strip foundation. A trench is dug along the perimeter just below the depth of the old foundation. A cushion of crushed stone and sand is poured onto the bottom, formwork is placed on the ground side, the wall of the old foundation is cleaned of dirt, primed with bitumen primer, and holes are drilled for steel bars to which the reinforcement cage is tied. Pour the concrete mixture, not forgetting about the underground vents or basement windows. The expansion of a slab foundation is carried out using the same technology as a strip foundation. If the house stands on a pile or columnar foundation, then a similar one is used for cladding.

In principle, a pile foundation can be considered universal. Its load-bearing capacity is quite enough to support the weight of a half-brick wall.

Another feature of the cladding of old houses is the “poor” geometry of the walls. As a result of shrinkage and settlement of the house, deviations in levels usually occur. If shrinkage is more pronounced in wooden houses (especially those made of materials with natural moisture), then the settlement depends on the type of soil and the weight of the structure.

Therefore, when strengthening the foundation, this factor must be taken into account.

With the “horizon” everything is simple. And the “vertical” for new corners and walls must be counted from the point of maximum deviation of the old facade (taking into account the width of the masonry and the thickness of the insulation).

Preparation for cladding

First of all, you need to understand the foundation design. Brickwork can rest either on the foundation itself (if it is strip or monolithic) or on the walls of the base. So:

- Consider yourself lucky if the basement in your house is higher than ground level and protrudes beyond the plane of the walls by twenty centimeters. In the old days, such a base was called “zavalinka”. It can be covered with brickwork, and even with insulation.

- Why exactly 20 cm? This distance is made up of the width of the brick, the thickness of the insulation and the size of the ventilation gap (12+4+4 cm). Only with such a plinth design can brick cladding of a wooden house be carried out with the masonry resting on it.

- Wooden houses are quite often built on a pile foundation. The distance over which the piles protrude from the ground is often simply covered with a false base, the role of which can be played by corrugated sheets, flat slate, or moisture-resistant plywood.

Wooden house on stilts

- Your task is to remove all this and make a shallow strip foundation around the perimeter of the house, on which you can then rest the masonry. To do this, a groove is cut 20 cm wide and 30 cm deep.

- Along the perimeter of the recess, knock down formwork from unedged boards, the height of which should correspond to the distance from the ground to the lower crown of the house.

- Pour a 5 cm layer of sand, tamp it down and cover the bottom with roofing felt overlapping the walls. Next, fill the formwork halfway with M300 concrete and compact it. Then, lay the steel reinforcing mesh, after which you add the rest of the concrete.

- After a few days, the formwork can be removed, but further work will have to be postponed for 28 days. This is how long it takes concrete to gain strength. Only after this can cladding of the façade of a wooden house with brick begin.

Almost the same thing will need to be done if the foundation of the house is not piled, but strip, only in this case the foundation will have to be dug up and topped up at its depth. In the case of a pile foundation, the basement wall can also be built from brick, but the concrete option is still preferable.

Construction of a decorative wall

We have already mentioned that there should be a gap between the brick cladding and the wall. But the presence of insulation is not necessary. Whether there is a need to insulate the facade or not, it’s up to you to decide:

If not, then the base for the masonry support can be reduced, and be not 20, but 15 cm. But the waterproofing layer needs to be installed. In the case of wooden walls, the best choice would be a rolled membrane.

- The brickwork is necessarily tied together with the wall of the house. For this, flexible connections are used, that is, anchors, but not rigid ones, but made of galvanized wire or polymers. Flexibility allows the masonry not to be disturbed by uneven ground settlement, and to maintain its geometric position.

- As a rule, four connections are installed per square of a solid wall. But if the facade is insulated. then the pitch between the anchors may vary, depending on the type of insulation. Additional anchors are installed along the perimeters of door and window openings, and in the corners of the building.

Flexible basalt-plastic anchors

- The hard end of the anchor is driven into the tree, and the other end will be embedded between the masonry bricks. It turns out that every fourth row of masonry is reinforced with anchors, in horizontal increments of one meter. Brick cladding of the walls of a wooden house is usually done one brick thick, and it can be laid either flat or on edge.

- Before starting masonry, the foundation base is covered with roofing felt. Laying the brick begins from the corner, guided by a stretched cord. The entire subsequent masonry depends on how even the first row is. The horizontalness of the masonry is checked using a building level.

So that air can circulate freely between the cladding and the load-bearing wall, special holes called “vents” are made in the lower rows of the masonry. To do this, the vertical seams are not filled with mortar every two bricks. The same gap (about 1 cm) is left at the end of the masonry, under the roof. In fact, you will end up with a ventilated façade.

Graduated from the Faculty of Architecture of the Penza State Institute of Architecture and Construction. For the last ten years, he has been a leading specialist in a large construction company in Penza, engaged in the construction of multi-storey residential buildings. Total work experience in the specialty is 18 years. Consults on design issues, selection of materials for interior and exterior decoration, and technology for finishing work.

Cover the house with bricks: Types of facing bricks

Facing (or front) ceramic brick differs from ordinary bricks in its improved appearance, including a large selection of colors and textured surface. As a rule, this is a slotted (or hollow) brick that has good thermal insulation properties.

Clinker hollow brick is initially considered to be a facing brick. It has high mechanical strength and very low water absorption.

Hand-molded brick is chosen for retro style. High price and, as a rule, full-bodied format.

Hyper-pressed brick has high decorative properties, but is produced exclusively as solid brick.

The last two types are used either for cladding walls with high thermal insulation properties (for example, warm ceramics or cellular concrete), or together with the installation of a layer of insulation.

Popular colors

The color of the front surface depends on the degree of firing, the composition of the initial mixture, the dyes used, and the finishing method. Different batches of material, even from the same manufacturer, differ in color, so you need to purchase bricks from the same batch, and if this is not possible, then during facing work the master must mix bricks from different batches.

TIP: Body-painted brick is preferable, since even if the facing layer is damaged, the color will remain unchanged.

In addition to colored, facing bricks can have a smooth or chipped surface.

Red

Red facing brick is an ordinary clay ceramic or clinker brick, and the longer the firing time, the more saturated the red color. A silicate or hyper-pressed block may turn red when dye is added. The red color is obtained by applying glaze or engobing.

Yellow

Red ceramic bricks with a glazed or engobed front surface are also produced in yellow color. Silicate, clinker or hyper-pressed material is made yellow by appropriate mineral dyes introduced into the mixture. Yellow bricks are produced in different shades - from light to rich ocher.

White

Sand-lime brick without adding dye is white with a slight grayish tint - this is the most economical option for obtaining a white facade. Pure white can be hyper-pressed material, clinker with special additives, red ceramics with a painted front layer.

Cover the house with bricks: Laying facing bricks

The algorithm for laying facing bricks is standard - from the corners, which are used as beacons, with periodic checking of compliance with the levels. A calibrated square metal rod is used as a template for making a masonry joint of the same thickness - this is one of the simplest methods.

If the cladding is carried out without insulation and a ventilation gap, then the solution is applied not only to the brick, but also to the wall itself. If a masonry mesh is used as a connection to the wall, then no reinforcement is done.

In other cases, every fifth seam is reinforced with a mesh or two rods laid in parallel.

It is better to do jointing in the same plane with the surface of the wall, so that water does not collect in the seam, but flows down. The use of colored masonry mortar makes the cladding more attractive.

Every developer, sooner or later, thinks about the exterior decoration of his home.

The modern possibilities of this segment of the construction market are truly limitless. This includes plaster, plastic siding, wall slabs, façade tile cladding, or variations thereof.

But, until now, brick remains one of the most popular facing materials. Consumers have always associated brick with reliability and durability.

And the variety of its colors, textures, standard sizes, and types of masonry allows you to obtain building facades that are wonderful in design. If you cover an old house with bricks, the dilapidated building will turn into a modern and stylish one.

How to choose the right façade brick - step-by-step instructions

Finishing should be done last, but the overall design is drawn up at the construction stage. This is where many people have a lot of problems. The easiest way to solve them is to contact a professional designer. The main thing is to make the final choice regarding the shade (light, dark, textured). Next you will need:

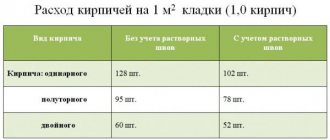

Step 1. Calculate the approximate consumption of blocks (by quantity). It’s easy if you know the size of a standard facade brick – 250x120x25 millimeters (some are thicker, and some are “half”).

Calculation of block consumption

Step 2. Decide on available finance. Naturally, it is better to buy clinker bricks. But ceramics will cost almost ten times less .

Deciding on a budget

Step 3. Check out the offers in the nearest construction stores. Consider a design that matches the chosen tone (taking into account the price category). From all of them, select brands that will be “potential” options for purchase.

Choosing a design

Step 4. From the design options chosen, decide which brand of brick is more reliable and durable. Reviews on thematic forums will help with this It is possible to fully evaluate the quality of the material only after 3–5 years of its operation; there is no need to trust sellers “in words”.

Deciding on a brand

Important nuance! Accounting for the consumption of cement mortar should not be lower than the strength grade of the brick itself. For this reason, using hollow M250 or higher façade bricks is not the best option. All the finishing will cost no less than a high-quality solid M250 , but in the latter version the amount of work will be much less .

A popular brand in the Russian Federation is facing ceramic bricks from the Ryazan Brick Factory. The average cost of a block is from 7.5 to 11 rubles

What brands of facade bricks do experienced builders recommend using? Manufacturer brands Terca from the Safari, Trees, Nordic, Milano series. The brands No. are often distinguished from Muhr. 13, Canyon. The average price is from 50 rubles per block. If it is expensive, then it is better to consider Russian options - there are a lot of decent brands there at a price of 12 rubles per block and above (ceramic). of the Ryazan and Golitsyn are in demand .

If you want façade brick cladding, but finances simply don’t allow it, you should consider this option. Ceramic facade tiles

Prices for various types of glue Osnovit Maxiplix

Glue Osnovit Maxiplix

Video - How to choose the right brick for construction

What brick to cover the house with?

Regardless of the material from which the facing brick is made, it must meet the following requirements:

- Correct shape geometry Clear edges Uniform coloring There should be no cracks or delaminations on the surface Frost resistance: F25, F35, F50, where the numbers show the number of cycles of alternating thawing/freezing, during which the products show no signs of visible damage, and the decrease in compressive strength does not exceed 20%. Products with frost resistance F25 are used in the southern regions of the country, F35 is suitable for central Russia, F50 is suitable for more northern regions. Water absorption - at least 6%

If you read the manufacturer's annotations, you will remember the proverb: every sandpiper praises its swamp. Those who produce ceramic bricks extol its characteristics in every possible way and belittle the advantages of silicate bricks.

And vice versa. This is understandable - competition. What do the facts say?

1. Ceramic brick – clay filler.

The technology for its preparation is more complex and time-consuming than that of silicate, which is why it is more expensive. The price of one brick ranges (depending on texture, shape, color) from 10 to 25 rubles. Its positive properties:

Water absorption – from 6 to 14%.

GOST allows you to increase this indicator depending on the type of clay used. Frost resistance - F25, F35, F50. For clinker products, this indicator is 100. Low thermal conductivity - 0.3 - 0.5 W/m°C Wide selection of standard sizes, textures and colors of products, which allows you to cladding not only walls, but also columns and arches. Density - 1300 - 1450 kg /m3, clinker - up to 2100 kg/m3. This indicator is important for calculating the bearing capacity of the foundation.

2.

Sand-lime brick. Filler quartz sand. The cost of the product varies from 7 to 16 rubles. Its properties:

- Water absorption - 6-8%. Frost resistance - from 15 to 50 cycles, depending on the manufacturer. Thermal conductivity - from 0.38 to 0.7 W/m °C Wide range of textures and colors of finished products. Density - 1500-1950 kg/m3.

A comparative analysis of the characteristics shows that both types of facing bricks have positive and negative properties. Ceramic products are superior in density (with the exception of clinker versions) and thermal conductivity. Not as radically as is commonly believed, but still.

Therefore, if it is necessary to increase the thermal conductivity of a house (this applies more to building structures made of cinder block, brick, etc.), or when cladding an old house to reduce the load on the foundation, then ceramic products are used.

But sand-lime brick is more affordable in price, has better sound insulation characteristics and absorbs moisture worse. The color scheme and texture of the products are not very different, but ceramic products have a much larger choice. The quality of finished products directly depends on the integrity of the manufacturer.

3. Bricks that are made using semi-dry hyperpressing technology. For example, products of the Bassoon brand, with shell rock fillers.

With other indicators almost equal to ceramic brick, it has frost resistance of up to 100-150 cycles and increased density. Price from 17 to 38 rubles. per product.

Dimensions

If ordinary brick is used for cladding a house, it will have standard dimensions - 250 x 120 x 65 mm. But decorative products can have a variety of dimensions. Flexible stone, for example, is supplied in separate sheets.

When using decorative brick-like tiles for work, you should lay them after there is a layer of thermal insulation and additional steam and wind protection on the frame. As for the sizes of such products, their height can reach 15 cm and length – 24 cm. The thickness of such stones does not exceed 25 cm.

HOW TO MAKE A BEAUTIFUL FACADE OF A BRICK HOUSE

Don’t know how to make the facade of a brick house more attractive? Have you built a large two-story brick house, but the appearance is not pleasing to the eye? We offer a number of solutions for transforming the exterior of facing bricks thanks to facade decor.

Apply large details of facade decor

Large free spaces of the walls of the house require large elements in the design of facade decor. For example, here the window molding has a width along the wall of 18 cm, and the large top of the decorative window cladding is 30 cm high. In order not to additionally cover such a large decorative detail, this element has a steep bevel of the top shelf.

Separate the base part

If you want to visually reduce the height of your house, using a base strip of a light color, like all the stucco on the house, will easily solve this problem. Also, this detail should correspond in size to the proportions of the house.

Try a massive eaves under the roof

The use of decorative cornice under the roof overhang is the main stage in decorating any home. The shape with a plane at the bottom most closely matches the size and proportions of a large brick house. Corner pilasters will look more natural if they seem to support the lower plane of the cornice.

Use brackets and keystones in window treatments

In addition to large details of the façade decoration of a brick wall, such as moldings, decorative window sills, plinth strips and corner finishing, do not forget about individual decorative elements. Keystones and brackets on the windows will dilute the straight geometry very well. The brackets under the windows, in our case, also visually fill the large spaces of the walls of the facade of the house.

Completely decorate your front door

Of course, don't forget about the entrance group. An entrance door decorated with classical pilasters will be one of the main accents of the facade of a brick house.

Decorate the corners of your home with pilasters

Since your facade already has a “crushed” structure - brick, try using pilasters to decorate the corners of your house. Straight lines of pilasters in contrast with a brick wall will look great!

If you want more ideas on how to beautifully make the facade of a brick house, check out our other articles and videos on this topic. We are sure you will find a lot of interesting things for yourself.