Construction and repair work, installation of plumbing fixtures are impossible without the use of high-tech compounds. These include solutions for sealing and protecting against moisture. Considering that their curing time varies, and you don’t want to delay the work, it’s worth finding out how to quickly dry silicone sealant. This must be done correctly so as not to destroy the structure of the material. Let's look at all the intricacies of using the drug.

What is sealant

It is a viscous, slightly flowing substance that hardens at room temperature. Due to its consistency, it fills cracks, crevices and other small cavities well. Universal, used for sealing and protecting various materials from moisture. Includes:

- Low molecular weight silicone rubber. Solution base.

- Plasticizer. “Responsible” for elasticity.

- Amplifier. Gives the necessary strength.

- Vulcanizer. Changes the state of a substance from viscous to solid.

- Adhesion primer. Maximizes adhesion to the surface being treated.

- Filler. An optional component that gives the desired color and increases volume. Most pastes are colorless.

Sanitary sealant Tytan Turbo Upg silicone, 280 ml, white

454

Buy

Silicone sealant is universal. Used to seal and protect various materials from moisture.

Rules for applying compositions

For the bathroom, we recommend purchasing a neutral hygienic sealant with a fungicide. This will protect surfaces from mold and other pests. This product is also suitable for installing water pipes. Due to the wider joint between the tub and the wall, the drying time will be longer and take up to two days.

Operating temperature and humidity

The required environmental parameters (temperature and humidity) are indicated on the packaging. As a rule, it is recommended to apply the product in a warm room. Most sealants should not be applied when humidity is above 80% or when it is raining (even if it drizzles) as this can increase drying time and cause uneven joints.

Both acidic and neutral compositions prefer positive temperatures (optimal temperature from +5 to +30°C), but acidic compositions harden faster with humid air, and neutral ones with dry air.

Types of material

The drying time of the drug is determined by its type. Depending on the vulcanizer used, two types of products are distinguished:

- Acidic, which contains acetic or other acid. It is easily recognized by its characteristic pungent odor. It has an antifungal effect, which is important for sanitary products. The main disadvantage is that it renders metal, cement-containing and marble surfaces unusable.

- Neutral. Amides, amines or alcohols can be used as a vulcanizer. In any case, there is no pungent odor and does not emit toxic substances. It has good resistance to high temperatures. Can be used on any surface.

Sealant Moment Sealant silicone universal, transparent, 280 ml

368

Buy

All acid sealants dry faster than their neutral counterparts. This is due to their composition. Drugs are divided into two groups:

- One-component. Available in the form of ready-to-use pastes. Most often they are packaged in special tubes for filling into a construction gun. Designed for home use.

- Two-component. Complex substances produced in the form of two components that must be mixed before application. Thanks to this they have better characteristics. Mainly used in production.

Silicone sealant beige Ultima, universal, 280 ml

258

Buy

General recommendations

Considering that information can only be obtained from the data on the product packaging, you should focus on:

- the basic setting time before which the seam can be smoothed or leveled is no more than 10 minutes;

- Accordingly, the length of the seam to be filled should be such that the master has time to apply and smooth the silicone before it sets. This parameter is determined individually;

- Despite the fact that manufacturers indicate a complete curing time of 24...48 hours, you should not load the structure in which the seams were filled earlier than after 72...240 hours. The duration of the “insurance period” depends on the size of the seam; when filling large and deep cavities, the basic estimated time should be multiplied by 2…3.

How to apply the drug correctly

Silicone sealant is very easy to use. They work with it in the following sequence:

- Preparing the surface. It must be cleaned of dust and all contaminants present, then degreased and dried. The latter is especially important for bathrooms and toilets.

- We cover the areas that should not be exposed to the drug with masking tape.

- If we use the composition packaged in a tube, we insert it into a construction gun. Cut the edge of the cartridge along an oblique line. This way the paste will be spread evenly.

- We bring the gun with the tube inserted into it to the base at an angle of 45°. We carefully apply the product, trying to ensure that the strip is not interrupted and is of the same thickness.

- We remove excess material with a rag, a special tool or a spatula.

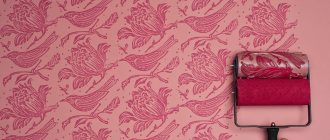

Instagram @kpcarpentry

When working with sealant, it is important that the streak is not interrupted. When applied correctly, a smooth, sealed seam is obtained.

Scope of application

Silicone-based products are considered universal, therefore they are used to protect and seal completely different surfaces and structures. Most compounds are suitable for both exterior and interior use, although some are recommended only for indoor use. Silicone is especially suitable for the bathroom for sealing seams between the bathtub, shower stall, sink and wall or for installing plumbing fixtures.

Sealants have other applications:

- assembly of products from plastic, metal,

- various works in mechanical engineering, machine tool building,

- construction, major and cosmetic repairs,

- sealing cracks when installing windows, doors,

- gluing tiles, stone blocks,

- different installation steps,

- strengthening of mirrors,

- work with sewerage and water pipes,

- installation of electrical wiring.

Drying time for silicone sealant

Correct application of the drug does not always guarantee a good result. It is important to dry it properly. Silicone mixture is a complex substance, the rate of hardening of which depends on its composition. So, if acids are used as a vulcanizer, drying will take about 4-8 hours. Neutral preparations with alcohol take much longer to dry - up to a day.

At the same time, you need to understand how long a silicone sealant for a bathroom takes to dry is determined not only by its composition, but also by other factors:

- Layer thickness. The thinner the film of the preparation, the faster it will dry.

- Ambient temperature. The optimal option is from +5 to +40C.

- Place of application. Hard-to-reach areas where there is no air movement take longer to dry.

Another important point. The hardening process occurs gradually. First, a thin film sets on the surface of the polymer. This takes about 15-25 minutes. After this time, the material will not stick to the hand when touched, as it would immediately after application. However, the polymerization process is still very far from being completed. On average, the composition hardens at a speed of about 2 mm in depth per day.

Thus, knowing the size of the layer, you can approximately calculate how long it will take for the product to completely dry. Before final hardening occurs, the paste must be provided with optimal drying conditions. It is protected from temperature changes, dust and mechanical influences.

Instagram @laticrete

The hardening process occurs gradually. The thicker the layer of sealant, the longer it takes to dry.

How long does it take for primer to dry?

On average, after 5–6 hours at an air temperature of 24 ° C and a humidity of 60%, the surfaces are ready for finishing work. It is recommended to follow the drying period specified by the manufacturer of the specific brand of primer.

Interesting materials:

What is vac Rinz? What is vanilla extract and what can be substituted for it? What is Wager x20? What is Wager x30? What is a wedding for a great reign? What is uppercase in a password? What is matter in physics examples? What is Vivat Vivat? What is love anyway? What are secondary body cavity examples?

How to speed up the drying of silicone sealant

It is not always possible to have a long wait. Sometimes it is necessary to speed up the hardening process of the material. We offer several proven methods to help you do this.

- Raise the temperature in the room. Silicone polymerizes faster at 30-40C. To do this, you can turn on the heater or use a heat gun. But you need to keep an eye on the thermometer. If the heating temperature exceeds 40C, this will negatively affect the properties of the composition.

- Ensure circulation of air masses. Normal ventilation noticeably speeds up the drying of the material.

- Increase the moisture content in the air. Direct contact with water during the curing period is unacceptable. You can spray the sealant from a spray bottle or treat it with steam.

Acidic products respond particularly well to high humidity and steam treatment. If the part is small, you can dry the silicone preparation very quickly. To do this, place it in a plastic bag along with a cloth soaked in water, seal it hermetically and place it on a radiator or in another warm place. Neutral pastes, on the contrary, “prefer” dry air and good ventilation.

Sealant Moment Sealant high-temperature, red-brown color, 300 ml

436

Buy

Time of initial drying and complete curing

It is impossible to accurately predict drying time, since in each specific case there are nuances associated with temperature, humidity in the room, layer thickness and other parameters. However, based on the experience of builders and repairmen, we can roughly say how long you will need to wait before starting to work with the frozen mass.

| Type of sealant | Application Feature | Application conditions | Drying time | Properties |

| Silicone |

How not to speed up polymerization

Some “masters” try to reduce the drying time in unacceptable ways that destroy the material. These include:

- Exposure to a hairdryer, burner or any other similar device.

- Immersion of parts in water.

- Temperature drop to negative values.

Which silicone is best for the bathroom?

The best sealant for the bathroom

–

silicone

, aquarium grade, it is as elastic and durable as the polymers from which it is made.

Moreover, as a silicone

adhesive-sealant, it is used in bonding surfaces and has no equal in durability and elasticity.

Interesting materials:

How to propagate anthurium from leaves? How to propagate anthurium at home? How to propagate New Guinea balsam? How to propagate barberry by cuttings in summer? How to propagate barberry at home? How to propagate Viburnum Buldenezh from cuttings? How to propagate a money tree from cuttings? How to propagate ficus lyreate? How to propagate ficus leaves at home? How to propagate Ficus Microcarpa?

Dissolve, scrub or cut?

A universal solution for dissolving silicone that can be used on any surface has not yet been invented, so most often it is necessary to use combined methods:

- soften (dissolve);

- cutting down;

- scrape off;

- scrub;

- wash.

In order to remove silicone mechanically, you will need the following devices:

- scraper;

- putty knife;

- sandpaper;

- abrasive composition;

- knife.

It is most convenient to work with silicone with a shoe knife, and ordinary salt can be used as an abrasive composition. During mechanical removal, a thick layer of silicone is first cut off, and then an abrasive is applied, and the remaining sealant is scrubbed off using a scraper. Silicone solvent can be used on some surfaces. After using it, all that remains is to wash off the remaining traces.

Peculiarities

The sealant is a paste-like or viscous composition based on polymers and oligomers. This mixture is used to work with bolted, rivet and other joints to prevent leakage of working fluid through existing gaps. This material is also used for waterproofing and sealing various objects.

If we talk about the features of this product, you should familiarize yourself with the main advantages that are inherent to the sealant.

Using the example of a silicone mixture, the following advantages can be highlighted:

- the mixture has a high degree of resistance to humidity and steam, temperature changes and UV rays. Therefore, sanitary sealant is actively used for sealing bathrooms, automobile components, mirrors, as well as when treating window frames;

- Using this sealant, you can provide high-quality sealing of seams in the bathroom or eliminate drafts in a window opening, since the material has high adhesion. You can also apply the mixture to an untreated surface;

- the material can easily bond non-porous surfaces and aluminum elements;

- the mixture is not exposed to aggressive detergents;

- long service life;

- the sealant is able to withstand temperatures up to +150 degrees;

- the substance may have a transparent or any other shade;

- the mixture has an aesthetic appearance, which allows it not to spoil the appearance of the objects being processed;

- white sealant is considered a universal substance that is suitable for working with any surface.

There are several varieties of caulk, each designed to work on a specific area.

- Acrylic. Such sealants belong to the category of the most affordable materials, since they can only be used for interior work. The material is not resistant to precipitation, temperature changes and is not able to withstand mechanical loads. However, such sealants demonstrate excellent adhesion to materials with a porous surface. It can be used to work with wood, brick, concrete, foam concrete, aerated concrete, plasterboard and plaster. Based on the quality of the mixture, it can be used when installing wooden baseboards, doorways, and also during flooring.

The sealant is suitable for any internal treatment in rooms where high mechanical stress is not observed.

- Polyurethane. This material is an elastic mixture with adhesive properties, which is characterized by an increased level of adhesion to metal, stone, ceramic, plastic, wood and concrete surfaces. Craftsmen use this type for external and internal work. The mixture is not afraid of temperature changes, as well as exposure to precipitation. It is highly resistant to corrosion and can be painted.

This type of sealant is often used during installation and repair work on roofing, air conditioning and ventilation systems, as well as when sealing polyvinyl panels.

- Thiokol. It is characterized by high resistance to solvents, acids, alkalis, gasoline, kerosene and other oil lubricants. The mixture can withstand exposure to precipitation and is also able to withstand temperatures from -500 to +1300 degrees. Due to its special qualities, the sealant is used for activities with objects that require the exclusion of contact with various substances of chemical origin.

It is actively used for sealing work at gas stations, fuel stations of various types and in garages. Also, thiokol sealants are often used during repair work on metal roofs.

- Bituminous. This material is often used during construction work. It has high-quality adhesion to surfaces made of foam concrete, brick, metal, wood and other roofing materials for waterproofing. When choosing a bitumen sealant, keep in mind that it is not resistant to elevated temperatures and takes on a liquid form.

The sealant is actively used when equipping foundations, drainage systems, when installing roofs, eliminating cracks in the roof, and also as waterproofing for pillars made of metal and wood.

- Silicone. This type is a universal material that is in high demand. Its popularity is due to its high quality. The mixture withstands any weather and aggressive conditions well. It is able to maintain its characteristics at temperature ranges from -300 to +600 degrees. The material is also characterized by a high level of elasticity, moisture resistance and long service life.

Once the silicone hardens, it cannot be painted. This is because the paint will peel off. For this reason, you can find sealants of different colors on sale: black, white, gray and even red.

There are two types of silicone sealant:

- acid;

- neutral.

Acidic products are not suitable for working on metal objects because the ingredient list contains acetic acid, which can cause corrosion. It is also not recommended to use this type of material when sealing cement objects.

The neutral mixture is considered universal. It is used in various fields. It can be used to seal a car engine and mirrors. The material also has another name – glass sealant. There are heat-resistant varieties on sale that can withstand up to +4000 degrees.

If the silicone sealant contains fungicides, the material is called “sanitary” or “plumbing”. It is able to prevent the appearance of fungi, so it is actively used when working in the bathroom, kitchen and swimming pools. This is the best joint sealant that can make your shower room as airtight as it was at the time of purchase.