Various options for applying decorative plaster

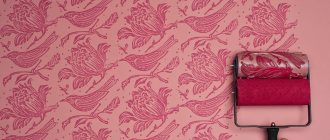

Methods of applying decorative plaster to achieve various effects:

- Wave pattern. First you need to make notches on the recently applied coating, then prepare a more liquid solution and apply it to the wall in strips. After this, use a trowel or a trowel to give the relief design a wavy shape. Before laying the last layer, it is recommended to slightly moisten the wall with water.

- Boulders. To do this, prepare a thick solution, which is 1-2 shades darker than the base layer. Then it is applied using a trowel and shaped using a trowel. At the end it is necessary to trim. To do this, use a brush with stiff bristles, holding it at an angle of 45 degrees.

- Travertine. To do this, you need to prepare the base layer by applying the plaster with short, careless strokes. Then use a trowel to pick up four different colored plaster options and stretch them across the wall. Finally, the surface is subjected to iron plating.

- Furrows. This is one of the simplest, but at the same time effective coating design options. To apply decorative plaster, use a trowel. The material is laid, after which furrows are immediately cut in it using small paper.

- Fur coat. To do this, you will need a metal reinforcing mesh with a mesh size of 1 cm. It is leaned against the fresh first layer of plaster, after which the solution is simply spread with a spatula. You can do without a grid. To do this, soak a broom in the solution and simply “spray” it on the wall.

- Spraying. This method is also popular. It is used to process areas that are complex from an architectural point of view, for example, slopes, corners and decorative elements. How is decorative plaster of this type applied? The secret lies in the use of compositions of different fractions. For example, to arrange the initial layer, mixtures with a filler of 3 mm in size are used, and for the rest - 1 mm. The only “but” is that before applying such decorative plaster with your own hands, you will have to buy or rent a special apparatus for spraying the solution. This procedure must be carried out continuously so that the layers do not have time to dry.

Additional recommendations

To gain useful experience, it is better to prepare the finishing plaster yourself and apply it to the walls by hand. When the process of rough puttying has been mastered, it is easier to move on to the final preparation of walls and ceilings for painting.

Standard recommendations are 2 base coats and 1 topcoat. On a crumbling coating, you need a reinforcing mesh embedded in the starting composition. The topcoat can be applied in 2-3 layers. Marble chips are added to decorative plaster.

The topcoat can be applied in 2-3 layers.

As you can see, there is nothing difficult about mixing the dry composition yourself and applying a thin layer to the surface to be leveled. Upon completion of the work, it is recommended to protect the external walls from the adverse effects of weather and climatic factors with façade paint. In the room, it is enough to complete the renovation by wallpapering or applying decorative plaster.

Types of plaster

First, you should know that there are often 2 types of plaster on sale:

- Dry. This type of plaster is often plasterboard and other covering materials. Experts recommend using it if there are no special requirements for the surface. The thing is that dry plaster is much cheaper than wet plaster, and the result is excellent. The most important thing is that in the end we get a perfectly flat surface, since the cladding slabs are often large in size, and this creates certain conveniences. The bad thing is that to cover walls it is often necessary to equip a metal frame and prepare the surface for fastening the covering. Despite all this, every year drywall becomes more and more relevant material, since it is an inexpensive alternative to other finishing resources.

- Wet. Obviously, this type of plaster is applied using a spatula, and its weight is much greater than that of the dry version. It must be said that the process of applying this plaster to the surface is not an easy task, since it is very difficult to avoid unevenness, as well as many other flaws, especially if the room is large and the ceiling is high. Experts often joke that for such work a person must have a stable psyche, as well as no trembling in his hands, otherwise unevenness cannot be avoided. In fact, mastery comes only with practice. If you apply the plaster in a very thin layer, you can achieve some savings, but this is not always a viable option.

TOP 3 best leveling gypsum plaster for interior work

Volma Canvas

Due to its excellent technical parameters and good price-quality ratio, this domestic plaster is popular among finishers.

The gypsum base is supplemented with unique chemical and mineral additives, thanks to which the mixture has such qualities as rapid drying, the ability to retain moisture and excellent adhesion.

The mixture is suitable for leveling the surface of walls and ceilings with their further painting, under tiles or wallpaper.

The dry mixture is diluted with water at the rate of 650 ml per 1 kg and mixed well and evenly.

Homogeneity is maintained for about 20 minutes, the solution is very plastic and easy to work with.

True, some buyers point out that after drying and the plaster layer there is some color heterogeneity, this should be taken into account when choosing paint.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is rough.

- Layer thickness, mm - 5-30.

- The mixture consumption according to the manufacturer is 9-10 kg per square meter. m. with a layer of 10 mm.

- Water consumption per 1 kg of mixture is 650 ml.

- The viability of the solution is 20 minutes.

pros

- Levels the surface well;

- plastic, easy to apply;

- retains moisture well and does not suffer from mold;

- durable, does not crumble.

Minuses

- uneven color after complete drying.

Prospectors Gypsum

A domestic version of gypsum plaster for leveling the inner surface of walls, which, due to the use of a special filler, has a reduced consumption - from 8 to 9 kg per square meter.

The mixture adheres well to mineral substrates (foam and aerated concrete), as it has good adhesion. True, the water resistance of the sample is low, so it is recommended to use it only in dry rooms with good ventilation.

This plaster is not recommended for beginners or amateurs, since the pot life of the solution is estimated at only twenty minutes.

Repeated dilution with water may result in reduced ductility and tenacity. The minimum layer should reach 5 mm, and the limit will be a thickness of 50 mm (but the layer can be compacted locally). An excellent option for a smooth finishing surface for painting or wallpaper.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 5-50.

- The mixture consumption according to the manufacturer is about 9 kg/m2 with a layer of 10 mm.

- Water consumption per 1 kg of mixture is 550 ml.

- The viability of the solution is 45 minutes.

pros

- can be applied locally up to 100 mm;

- lays flat and easy;

- plastic;

- Helps retain heat and reduce hearing.

Minuses

- no significant ones were found.

Rusean Plaster

Domestic gypsum plaster for manual application and distribution over the entire surface to be treated.

After drying, it has a uniform white tint, allowing you to start painting the walls without puttying, which is necessary for other samples.

Also, a smooth coating is formed at the finish, thanks to which you don’t have to worry about the quality of gluing thick wallpaper or get a textured coating with paints and varnishes.

The model has an adequate consumption of up to 9 kg per square meter, the solution stretches well and quickly levels out, without forming bubbles, and after drying without cracking.

For rooms with high humidity, it is better not to use this sample, even under tiles.

And it is better to entrust the application to a professional, since after 20 minutes it is almost impossible to work with the diluted mixture.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 5-50.

- Mixture consumption according to the manufacturer is 8 - 9 kg per square meter. m. with a thickness of 10 mm.

- Water consumption per 1 kg of mixture is 580 ml.

- The viability of the solution is 20 minutes.

pros

- applied evenly;

- smooth finish;

- no bubbles or cracks form;

- dries quickly.

Minuses

- only for residential premises with normal air humidity.

Features of working with decorative plaster

The technology for applying decorative plasters has the following nuances:

- When working with liquid, already diluted plaster, you should take into account that it very often falls from a trowel or spatula, so it is better to cover the floors with plastic film.

- If coarse materials were used to make the mixture, it can only be applied manually.

- The technology for applying decorative plaster, which was prepared from fillers of various fractions, is quite complex, so it is recommended for home craftsmen to use standard compositions.

- Finishing materials that are diluted with water are more environmentally friendly than plasters made with synthetic substances. At the same time, “aqueous” compositions are more susceptible to temperature and mechanical influences.

Decorative plaster can be sold ready-made or in the form of a dry mixture that requires dilution with water.

There are several more nuances that are important to remember when carrying out work:

Decorative plaster dries faster on cellular concrete or starting plaster. When treating wooden surfaces or walls made of plywood and chipboard, it is important to remember that water-based compounds can deform them. If there are defects on the treated surface, then more decorative material will be required. To avoid corrosion, do not use “water-based” plasters to finish surfaces with metal elements. Most decorative plasters set in a maximum of 5 hours, dry in 1-2 days, and strength gain lasts no more than 9 days.

Kinds

Plaster

The most common are gypsum plasters. The basis of this mixture is gypsum. Plaster can be sold dry or ready-made . The latter is fully suitable for use after opening the container. It is necessary to mix the contents of the components well so that the settled particles are evenly distributed throughout the entire volume of the liquid.

To properly prepare a plaster solution from a dry semi-finished product, you must follow the instructions. It indicates how much water needs to be added to the container in order to obtain a composition with the richest characteristics and resistance to environmental factors. The gypsum composition has very decent characteristics at its low price. The material from which the mixture is made has a natural composition that is safe for humans.

Advice

The only disadvantage of gypsum is the fear of moisture. The material is applied only to the internal parts of the walls in dry conditions. For external work, the finishing layer will have to be additionally coated with a moisture-resistant compound (wax).

When mixed independently, the solution is plastic and easily applied to the surface. It withstands shrinkage and mechanical stress well. It does not crack or crumble during use. In construction stores, gypsum semi-finished products differ in the number of components.

Cement

The composition mostly includes cement . Due to it, the solution is strong, durable, and moisture resistant. The components additionally included in the mixture are safe for health and environmentally friendly. Cement decorative plasters are used for application both indoors and for external facade work.

Attention

Cement mixtures are widely used in conditions of high humidity. They have proven themselves to be excellent in the kitchen, bathroom, and hallway. This plaster will protect any damp places from water.

A significant disadvantage is cracking of cement surfaces as a result of the low mechanical strength of cement. Therefore, the price of the composition is low and affordable for everyone.

There are two types of cement plaster:

- Cement-lime .

Packing: large multilayer bags weighing 25 kg. Wholesale buyers often take larger packages of 50 kg. This plaster is characterized by good adhesion, vapor permeability, and plasticity. The lime composition is not susceptible to fungus and mold. This is due to the content of stone, brick, foam block, cinder block, and fine concrete. In addition to homogeneous surfaces, they can also process complex substrates. They can simultaneously contain stones, shell rock, sandstone in a combination of different parts of the volume. - Cement-sand - reliable, inexpensive. For external work: levels and protects façade cladding. Other functions of the cement-sand mixture are wind protection, heat protection, strengthening and aesthetics. Plaster is relevant for “dirty” masonry, the use of non-facing bricks, the finishing of cement and gas blocks, and the construction of self-leveling walls. This is an economical cladding when used correctly.

Any of these types of plaster is made using a certain technology:

- First, lime (for cement-lime mortar) or sand (in the case of cement-sand mortar) is taken and sifted to a homogeneous composition or the same fraction.

- Cement is added. Good mixing of the components ensures their high-quality adhesion to each other.

- Water is added gradually, with constant stirring.

Polymer

Made on the basis of polymers. Universal plaster with a long service life , which can be used for work both indoors and outdoors. Thanks to its plasticity, it is easy to apply in an even, thin layer. Completely levels the walls.

Important

Additives included in the composition regulate the properties of the mixtures. Available in dry or ready-made form. The most popular are acrylic based. The downside is the high price, but the good quality justifies the inflated prices.

Polymer mixtures can be painted or tinted to a convenient color at the mixing stage . The functions of these finishing mixtures are different, depending on the place of use. There are structural mixtures for decorative design, relief to form the necessary structure, textured, folk and terrazite plaster. The latter is made on the basis of cement, to which glass, mica or marble chips are added. Particle size is 1–6 mm.

Material cost

Of course, the price issue is always relevant, especially when it comes to large-scale repair work. If we plan to plaster the entire room, then the volume of materials will be considerable. In such conditions, it is quite possible to save on some resources.

Unfortunately, the cost of wet plaster is now very high, and the price tag is growing rapidly every month. In such conditions, you need to choose the most acceptable option, but without sacrificing quality. Most often, experts recommend making a choice in favor of well-known manufacturers of building materials. Of course, in such conditions you may encounter large markups that not everyone is able to withstand.

At the same time, you can pay attention to manufacturers who are just trying to enter large markets. Most often, products from such companies are not too high

But you should also analyze the quality of the plaster, and to do this you can study reviews, go to the manufacturer’s website, or conduct an experiment yourself.

Considering that expensive specialist services can be added to the high cost of the material, repair measures can turn out to be very expensive. You need to be aware of this, especially if your financial budget is limited.

Again, you should always remember that you can find a way out of almost any situation. For example, if wet plaster is too controversial an option, you can always look towards drywall. Of course, this is only a part of the materials that can be found in construction stores. Consultants will always select materials that will be cheaper, but in terms of characteristics and basic properties will be no worse than the above resources. At the same time, you need to know a little about this issue yourself so as not to become a victim of deception.

What materials should I use?

The finishing plaster is similar in composition to the starting plaster . The only differences are in the size of the components and the consistency of the prepared mixture. Due to fine-grained fillers, it makes the surface smooth. This does not apply to decorative plaster, which was created for other purposes and, on the contrary, contains fillers of different sizes that form a decorative coating. At the same time, decorative plaster can be applied with your own hands without any problems, without additional equipment.

If you have time and the desire to experiment, you can try and select the optimal composition of plaster for independent use.

Need to buy:

- fine quartz sand, similar to dust;

- cement 400 grade;

- polyvinyl acetate glue - PVA.

Main types and classification

There are two types of finishing plaster - for external and internal work. Each of them, in turn, is divided into several types depending on the material of manufacture.

Internal

Finishing plaster for wallpaper or painting is applied as a second layer after rough finishing. It comes in several types. It can be cement-sand, cement-lime, gypsum or acrylic-polymer. Despite the fact that all these types differ in composition, they have one common property. Each of these types of finishing plaster for interior work is finely dispersed.

This is interesting: The rough and finishing layers of plaster applied to walls or ceilings should be similar in consistency. This is necessary for better adhesion between materials. Thus, it is not recommended to apply gypsum finishing plaster to a rough cement finish and vice versa.

Walls covered with a layer of finishing plaster look perfect

Facade

Finishing plaster for external use is also divided into several types. It can be acrylic, silicate and mineral in composition. The texture of this material can be pebbly, smooth or granular (bark beetle).

When choosing a material for finishing the facade, it is necessary to take into account the desired degree of sound insulation and presentable appearance

It is important to pay attention to the fact that the outer finishing layer of plaster does not accumulate moisture and allows the walls to breathe

Elegant façade covered with a fine, smooth mixture

Tips for choosing

High decorative properties, environmental friendliness, smooth wall coverings are the main requirements for the quality of interior compositions. The absence of harmful fumes is a guarantee of manufacturers specializing in the production of mixtures from environmentally friendly raw materials.

“Finish” is distinguished by the degree of readiness:

- The dry composition must be diluted with water in the proportion specified in the detailed instructions (packaged in thick paper bags of 5 kg - 25 kg);

- Ready paste (in plastic packaging).

Dry mixtures are more in demand, they last longer and are cheaper. It takes a little time to prepare the mixture. For kneading you need containers and a construction mixer.

The plaster base sets quickly, it is important to knead a little and work quickly.

New mixtures are released every year. By reading the recommendations on the packaging, it is easier to choose an offer that meets all the requirements:

- For the walls of living rooms, any “finish” is suitable, but take into account the material of the walls;

- For rooms with high humidity, a silicone or cement base is recommended;

- Ceilings are leveled with an acrylic compound; it is suitable for wooden panels and beams;

- Cement putties are used under wallpaper on concrete;

- To mask the joint of gypsum board sheets, use a gypsum mixture.

Polymer compounds are used for painting, providing a smooth, even layer.

Dry mixtures are more in demand, they last longer and are cheaper.

For this you need finishing plastering of the walls.

For final plastering of walls, that is, finishing, preference is usually given to those compositions containing more lime, which gives elasticity to the mixture. Although there are now a lot of brands of ready-made mixtures of acrylics and polymers. This is a kind of primer before painting, or in other words, plastering walls with finishing putty. The most important condition for choosing the right mixture is: consistency and dispersion, the second condition is the components of the mixture.

Technology

Do-it-yourself finishing plaster of walls is not a very difficult job, but it has a number of its own characteristics:

- abrasiveness must be reduced to a minimum

- carefully select the components of the mixture so that there are no contradictions

- the consistency should be homogeneous and finely dispersed, plastic

- dry only naturally

- forced drying is unacceptable

- the layer of finishing plaster should not exceed 2 millimeters

- the troweling tool should be no more than 0.75 - 1 meter long.

Finish wall plaster ranges from 137 rubles to 1800 rubles per 25 kilograms, depending on the components of the mixture and the manufacturer. Although finishing plastering walls with your own hands is not a very labor-intensive and inexpensive job, it should be noted that professionally trained specialists will do this work much better and spending less time on this work. The preparation requirements for finishing plastering walls with your own hands are almost identical to the requirements for preparation for applying primer if acrylic-polymer mixtures are used.

If you have to use cement-lime mixtures, then the requirements are the same as when carrying out plastering work on the rough and base layers. This means: sand, vacuum, moisten (if the surface is moisture-permeable) with water, if the wall is brick - clean the seams between the bricks, if the wall is smooth and painted - make notches. Then finishing plaster is applied or plaster is created using finishing putty. The type of putty is selected depending on the purpose for which the room being treated will be intended. It is clear that in children's rooms and in a number of other rooms you cannot use finishing plaster, which takes a long time to dry and emits harmful chemical odors.

In the bathroom, it is common to use sanitizing mixtures to prevent the formation of mold. Ceramic tiles are used as finishing plaster on walls. After applying the finishing plaster to the walls, they begin with rough grouting, then polishing grouting. For rough grouting, use wooden floats and felt, first moisten it with water, then rub it in a circular motion. For final grouting, use a trowel with a rubber edge or a metal spacer. This grout is used: the first before painting the walls with acrylic paints, the second before painting with oil paints.

What are gypsum plasters made of: composition and properties

To produce this material, a natural, environmentally friendly component – gypsum – is used. It has useful performance properties such as:

- efficiency;

- environmental friendliness;

- fire safety;

- vapor permeability;

- hygiene.

Gypsum is a natural mineral belonging to the sulfate class. By itself, it is quite fragile and is not able to provide the necessary technical characteristics such as strength, adhesion to mineral surfaces, viscosity, ductility, and crack resistance. Under mechanical stress, the hardened layer will crumble or collapse altogether. That is why additional components are introduced into the composition of the dry plaster mixture, and gypsum is called modified, that is, modified, improved.

Modified gypsum plasters may contain the following additives:

- Plasticizers - improve the viscosity of the solution, make it easy to install, promote improved fluidity with the possibility of machine application, increase the volume of the prepared solution and reduce the consumption of the dry mixture.

- Polymers - increase the elasticity of the hardened layer, provide antiseptic (antifungal) properties, enhance adhesion to mineral bases, reduce hygroscopicity, etc.

- Mineral fillers - increase mechanical strength, improve the thermal insulation and sound insulation characteristics of gypsum plaster.

The type and quantity of the introduced component is selected by each manufacturer according to its own recipe. It all depends on what properties of the output product need to be ensured, and in what price niche it will be positioned. In most cases, there is a pattern: the higher the quality of the ingredients used, the more expensive and better the products. Therefore, even recognizable brands have expensive and cheap gypsum plaster. And they differ not only in price, but also in technical and operational parameters.

Features of the wall plastering process

It is worth noting that many people are afraid to plaster walls themselves because of the expected result. Of course, without studying detailed instructions, you can make many mistakes that will definitely catch your eye in the future.

Unfortunately, the current economic situation does not allow you to fully train your skills in applying plaster.

In any case, such experience is desirable, since it is practice that allows you to pay attention to the most important elements of the process

Of course, if you have at least a little extra plaster, you can practice a little, and this will definitely bring a lot of benefits.

If you decide to use the services of third-party specialists, then, first of all, you need to be confident in their qualifications. You should study the reviews, or, if possible, invite guys who have carried out repairs for friends or acquaintances. In this case, we have an example of work, and we can also be confident in the good quality of services provided.

You can use any options for the repair process, but the most important thing is a high-quality result. Don't be afraid to overpay a little.

Many experts recommend first practicing on plastering the ceiling, as it is somewhat easier than plastering the walls.

How to make a surface even

These components are needed to give the surface a smooth and even texture. Conventional finishing compositions are aimed at creating a finish as part of the decor. In this case, the plaster has a translucent color and affects the final result of the finish. Sometimes ground glass, calcite dust or dyes are added to obtain a specific opalescent or marble pattern.

Often, finishing or superfinishing compositions for plaster with an acrylic primer are purchased for work. This solution will be more reliable than experimenting with different recipes. Typically, the consumption of dry mixture per square meter is indicated by the manufacturer on the packaging of the material. It is important to check the package release date and purpose.

Types of mixtures

There are several types of mixtures that differ in composition.

Cement

– often used in damp rooms and on walls where there is no mechanical stress.

Divided into 2 types:

A high-quality mixture of the brand - Rotband. They produce solutions for wet rooms that are resistant to mechanical damage. In terms of price, the material is in the average range. The disadvantages are that cement bases crack, no matter where the work is carried out - outside or inside.

Plaster

– more resistant to damage, has plasticity and does not crack. A good option for interior decoration. Not suitable for outdoor use, as it does not have high moisture resistance.

Polymer

– a universal material for leveling surfaces. There are different compositions of additives that can be used to regulate the properties of the mixture. Very large assortment. The most popular plaster is acrylic polymer.

If we consider the areas of application - for interior and exterior work, then the mixture is almost the same. The only difference is in the additives that are responsible for frost resistance and hydrophobicity.

Plastering process

When the main layer of plaster has completely dried and become a little stronger, the condition of the walls is checked using a special tool - the rule.

The steps look like this:

- The working surface of the tool is applied to the old plaster and, with successive advances, dips or, conversely, bulges on the wall are examined. Once such areas are found, they are marked with a pencil.

- If there are large humps, armed with a mild tool or sandpaper, you need to clean up the problem areas and check the surface again.

- The boundaries of the deepest and crooked places of the wall are marked.

- The surface is primed with an acrylic mixture.

Important! There is no need to cut off a large area with a spatula or other tool, otherwise cracks will appear in the plaster layer. And this can only be done within 60 minutes after finishing the process of leveling the main layer of plaster.

Working with the surface

When working indoors, the temperature should exceed 10 degrees and humidity - 50%. You need to prepare spatulas - wide and narrow, a container for diluting the mixture. It is better to buy ready-made finishing plaster, which only needs to be diluted with water. It is good if you use a construction mixer when mixing.

Types of coatings

According to modern rules SNiP III-21-73, there are 3 types of coatings:

- Low quality. This type of plastering is suitable for finishing walls in non-residential premises. Permissible deviations vertically and horizontally are 3 mm per 1 meter. Also, for every 4 square meters, 3 smooth irregularities are allowed, the depth of which does not exceed 5 mm. Surfaces can be plastered with cheap starting solutions.

- Average quality. In this case, the requirements for surfaces are more stringent: vertical or horizontal deviations should not exceed 2 mm per 1 m. As for smooth irregularities, their number is limited to 2 and their depth to 3 mm. This way you can plaster the facades.

- High Quality. The requirements for this type of coating are the most stringent. Horizontal and vertical deviations should not exceed 1 mm per 1 m, and there can be no more than 2 smooth irregularities, while their depth cannot be more than 2 mm.

VIDEO:

TOP 3 best thermal insulating gypsum plaster for interior work

Rusean Termoplast

White thermal insulating gypsum plaster, which can be applied to any substrate with different porosity levels.

It perfectly eliminates unevenness, after drying it has a uniform color and does not require additional putty. With a layer of 10 mm, from 8 to 9 kg per square meter is consumed, the permissible layer thickness starts from 5 and ends at 50 mm.

After preparation, the solution can be used for 20 to 30 minutes; repeated dilution with water is excluded, as this will reduce the durability and convenience of the material.

Thanks to their thermal insulating properties, they can replace special mineral wool and provide an optimal microclimate in the room, protecting it from drafts and temperature changes.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 5-50.

- Mixture consumption according to the manufacturer is 8 - 9 kg per square meter. m. with a thickness of 10 mm.

- Water consumption per 1 kg of mixture is 550 ml.

- The viability of the solution is 30 minutes.

pros

- affordable cost and low solution consumption;

- plasticity, dries evenly and does not crack;

- smooth surface without the need for putty.

Minuses

- no significant ones were found.

Unis Teplon Reinforced

Many finishing craftsmen prefer to work with this plaster, as it is plastic, stretches well and is easy to apply.

It has virtually no shrinkage, due to which the risk of cracks is reduced to a minimum. Thanks to the use of perlite, the manufacturer was able to reduce the specific gravity, so this solution can be used to safely treat the surface of the ceiling; the layer will not overload the base.

Perlite also affects additional thermal insulation properties, so this sample is often used in rooms where it is not possible to use specialized mineral wool to insulate the room.

It is allowed to lay this plaster in rooms with high humidity, but only if tiles are planned to be laid on top.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 5-50.

- The mixture consumption according to the manufacturer is 4.5 - 5 kg per square meter. m. with a layer thickness of 5 mm.

- Water consumption per 1 kg of mixture is 500 ml.

- The viability of the solution is 120 minutes.

pros

- with perlite, moisture-retaining;

- good white shade;

- cheaper than many analogues;

- the solution does not harden for a long time, it is convenient to work without dilution.

Minuses

- no significant ones were found.

Perfecta Gipstar

Popular and high-quality gypsum plaster for leveling walls and ceilings in residential areas with normal humidity.

Sold in 30 kg paper bags, the finish gives a white and smooth surface.

After mixing, the solution can be used for two hours, so this sample is loved by both professionals and beginners in finishing work.

You can stick wallpaper on top of the plaster, apply several layers of paint, or lay tiles. The mixture is applied manually; it is not suitable for the machine method.

It has decent thermal insulation properties, high ductility and adhesion, and some users also indicate good sound insulation abilities.

The permissible layer thickness is from 5 to 60 mm; with a layer of 10 mm, up to 9 kg of mixture will be needed per square meter.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 5-60.

- Mixture consumption according to the manufacturer is 9 kg per square meter. m. with a layer of 10 mm.

- Water consumption per 1 kg of mixture is 550 ml.

- The viability of the solution is 120 minutes.

pros

- white, smooth surface;

- good solution consumption;

- the solution is suitable for use for up to 2 hours.

Minuses

- not suitable for rooms with high humidity.

When not to putty

But there are also cases when puttying is not necessary.

- If you have smooth concrete walls with a single color, and you use thick or textured wallpaper, then it is quite possible not to putty the wall before gluing it.

- It is also not advisable to use putty if you are doing decorative plaster on the walls.

- Do not putty the walls before finishing them with ceramic tiles.

- In technical and utility rooms where minimal finishing is required, you can paint the walls directly over the plaster without putty.

- Often brick or aerated concrete masonry is painted without any preliminary preparation at all - if this is not necessary, or it is a design decision.

Glazing

Glossing is carried out using a soft sanding block. The plaster layer that has set, but has not yet dried, is generously moistened with water and then rubbed in a circular motion. Then a wide spatula is used horizontally and vertically along the treated wall, removing all dust and particles of plaster. After such preparation, you can paint or glue wallpaper without finishing putty.

TOP 3 best gypsum plaster for interior work for machine application

Volma Gips-Active

The solution, which, when properly mixed, remains suitable for an hour and a half, can be applied to walls and ceilings either manually or by machine.

The permissible layer thickness is from 5 to 30 mm, but in some areas it is possible to increase the thickness to 50-60 mm.

This plaster is always applied over a primer, which will protect the mortar from cracks, ensure a perfectly smooth smoothing and provide a high degree of durability.

The plaster has good plasticity indicators, so even a beginner can work with this sample, especially since the consistency after mixing retains its main properties for up to 1.5 hours.

Suitable only for rooms with normal humidity; in the bathroom or kitchen it is not able to last long.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 5-30.

- Mixture consumption according to the manufacturer is 8 - 9 kg per square meter. m. with a layer of 10 mm.

- Water consumption per 1 kg of mixture is 650 ml.

- The viability of the solution is 90 minutes.

pros

- good adhesion to the wall;

- plastic;

- suitable for decorative plaster;

- optimal time to work with the solution.

Minuses

- no significant ones were found.

KNAUF MP-75

A dry mixture based on fine-grained gypsum, which was intended for machine application to interior walls.

If we compare this sample with plaster from the Rotband company, then there is an undeniable advantage - the use of defoamers, plastifiers, thanks to which the solution stretches better, and hardening retarders.

Therefore, this product is considered an excellent option not only for a professional master, but also for a beginner.

The solution can also be applied manually; after mixing, it does not thicken for two hours. Smooths out quickly and easily, fills unevenness and cracks well.

At the same time, it remains even and smooth, without bubbles or other surface damage.

The mixture is suitable for horizontal and vertical substrates, and with additional protection it can be used in the bathroom or kitchen, that is, where humidity is usually high.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 8-50.

- Mixture consumption according to the manufacturer is 8 - 9 kg per square meter. m. with a layer of 10 mm.

- Water consumption per 1 kg of mixture is 650 ml.

- The viability of the solution is 120 minutes.

pros

- the solution does not thicken up to 2 hours;

- stickiness, plasticity;

- the surface becomes glossy and smooth;

- Suitable for machine application.

Minuses

- difficult to find in regular chain stores;

- takes a long time to dry (up to a week until completely dry).

Prospectors Optimum

Gypsum plaster from a domestic brand, produced in 30 kg paper bags and intended for treating interior walls and ceilings in dry rooms with normal humidity levels.

The thickness of the layer can vary from 6 to 60 mm, the mixture has good plasticity and excellent stretch, allowing it to be quickly and evenly distributed over the surface. After preparation, the solution is suitable for use for 90 minutes.

The plaster can be applied either manually or by machine, which indicates its versatility and good technical characteristics.

After drying, the shade is uniform, without bubbles or cracks, the coating does not peel off and is in good contact with paint, wallpaper and tiles.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 6-60.

- The mixture consumption according to the manufacturer is 10 - 11 kg per square meter. m.

- Water consumption per 1 kg of mixture is 400 ml.

- The viability of the solution is 90 minutes.

pros

- Rubbing to gloss is allowed;

- duration of use of the finished solution;

- does not crack, durable;

- low water consumption.

Minuses

- high mixture consumption;

- takes a long time to dry.

What is needed for plastering walls, selection of tools

To carry out work on plastering walls with your own hands, you do not need special expensive equipment, as, for example, with mechanized plastering. The necessary materials and equipment include the following set:

- Plaster mixture. The required number of bags of plaster can be approximately calculated by reading the manufacturer's information. Typically, the consumption of plaster per 1 square meter of wall, with a layer thickness of 1 cm, is indicated on the back of the bag.

- Container for mixing the mixture. Such containers of varying capacities are sold in all construction hypermarkets. A container with a volume of 70-100 liters will be enough for one person so that the mixture does not have time to dry out before applying it to the wall.

- A drill with a mixer attachment for mixing the mortar, or a construction mixer.

- A hammer for cleaning rough masonry from mortar buildup and excess debris.

- Plaster beacons as guides during plastering.

- Construction level and square for the correct placement of beacons and the formation of corners in the room.

- A quick-drying mixture, such as alabaster, for displaying and quickly fixing beacons. For these purposes, you can use a regular plaster mixture, but you need to wait until it hardens before you can start plastering. Otherwise, when passing the rule along the beacons, they will be pressed into the plaster.

- A set of spatulas for applying mortar to the wall and a trowel for fiche sanding.

- Building rules for different sizes for leveling plaster mortar on the wall. A short rule will be convenient in places of difficult accessibility, and long ones in straight, wide areas.

- Water-based primer or concrete contact, brush or roller for application.

- Protective work clothing, gloves.

As you can see from the list, specialized and expensive tools for plastering are not required, so you can start working on your own.

Finishing Tools

To work with finishing plaster for painting, a ready-made or self-prepared mixture is used. Place the finished paste in a small wide container, from where you scoop it up little by little, working with 2 spatulas.

To prepare the dry mixture you will need:

- Cement or mineral mixture of a suitable brand;

- A set of spatulas plus a wide rule and a trowel;

- Clean water at room temperature;

- Plastic bucket for kneading;

- Construction mixer or drill with an attachment;

- Vessel for washing instruments;

- Paint float or mesh.

The mixture should not be poured with water; it will immediately form into a lump. Gradually pour the required amount of dry powder into a container with the indicated volume, stirring by hand, the last mixing using a drill with a mixer.

The mixture should not be poured with water; it will immediately form into a lump.

Wall plastering process

Surface preparation

Before applying plaster to the wall, you need to pay attention to the following stages of the repair process, without which it is unlikely that you will be able to get an excellent result:

- complete surface cleaning;

- removal of defects;

- surface treatment for plaster.

First we need to get rid of everything that remains on the surface. Often this is old wallpaper that needs to be removed from the wall by any means. Wallpaper removers are often used and are extremely effective. You will also need a spatula for this process.

If you need to remove old plaster, then in most cases the material is simply moistened with water at room temperature and kept in a closed space. After this, the plaster can be easily removed using a spatula.

When it comes to removing defects, this often means cracks or small depressions. There can be a lot of such problem areas on the surface of the wall. Small defects can be corrected using gypsum primer

It is especially important to get rid of all problems existing at the baseboard level. A fungus often forms there, which can negatively affect the entire surface that will be ready for finishing.

Spraying the walls

As for spraying walls, this is a process necessary to create a retaining relief. The bottom line is that we throw a little mixture on the wall, and only then, when plastering occurs, the mixture will best fit on the surface.

For this task we will need a trowel on which to lay a little plaster. After this, using a strong swing, the pieces of material should stick to the wall. The height of each such lump should reach no more than 7 mm.

It is important to note the fact that the plaster should not harden. You need to let it set a little

In order not to miss a moment, you should check the condition of the material by pressing it with your finger.

Plaster without beacons

If you decide to plaster walls without beacons (applying a thin layer of material), you need to arm yourself with a falcon. Using a trowel, a small amount of material is applied to it. The plaster is applied to the wall at an acute angle and distributed evenly over the surface.

It must be borne in mind that this process is quite complex, since it is not always easy to provide a thin layer of material, especially if the wall has some unevenness. Accordingly, it’s unlikely to be possible without experience.

Plastering on beacons

Often, beacons are long metal elements along which the plastering process will be carried out.

Beacons are installed vertically using self-tapping screws or mounting glue

It is important to keep in mind that uneven walls make it difficult to attach beacons, and in such situations, outside help may be needed

Most often, it is necessary to install the first beacon, and on its basis a plumb line is lowered. Obviously, it is necessary to ensure the same level of arrangement of the elements so that the plaster is best positioned on the wall.

It should be noted that with the help of self-tapping screws it is possible to ensure the most suitable level of beacons for plastering, since the fasteners can be adjusted quite flexibly by changing the position of the beacons.

Accordingly, after we have achieved the correct location of the beacons, we can begin plastering the walls. To do this, again, you will need all the above tools.

The most important thing to pay attention to is the fact that this process may require quite a lot of plaster, especially if the height of the beacons is considerable. It is advisable to choose a spatula that corresponds to the distance between the two beacons

This way we get the opportunity to provide a perfectly flat surface, without particularly paying attention to the rest of the wall.

Beginners have the most questions when plastering corners and slopes. Experts recommend using an angled spatula, which is best suited for such hard-to-reach places. Even though you have a tool, some experience in this matter will not hurt.

Separately, I would like to note that you can find many varieties of beacons on sale that will allow you to easily cope with the tasks. This or that type of beacon for finishing work may be suitable for one room and not suitable for another. This information needs to be seriously studied.

https://youtube.com/watch?v=gaNcLQEGL0Y

Main stages of preparation and application

You need to carefully prepare the surface .

All walls are examined for roughness, the presence of flaws, and areas of cracking. If there are depressions or recesses, they are cleaned additionally in order to increase contact with the material, which will cover all irregularities and flaws. Before interior work, you need to warm up the building from the inside for 2 days so that it maintains the optimal temperature for work (20–25 degrees). It is possible lower (up to 10 degrees), but it is not advisable. The humidity in the rooms should not exceed 60%. After the process is completed, such conditions must be maintained for at least one day. External work is carried out only in dry weather at a temperature not lower than -50 0C.

All furniture inside the building is covered with special material . Prepare the solution according to the instructions on the package. The work algorithm is as follows:

- The finishing mixture is diluted in a special container in precise proportions and applied with a trowel onto a wide spatula. They apply it to the surface, and use a narrow tool to level the plaster.

- The solution is laid step by step, moving from one small area to another. It is best to take 1 sq. m and apply the solution to it with quick movements of the spatula. The plaster is pulled back 1-2 times, then moved to the next area so that the remaining solution does not have time to harden.

- The finishing layer should be about 1.5–2 mm thick. If you exceed this figure, then the likelihood of cracking the plaster will be high. The recommended layer thickness will completely smooth out all irregularities and make the surface smooth.

AttentionA layer of 2 mm will be ideal for gluing non-woven or vinyl wallpaper. If you plan to paint the topcoat, you will have to do double work: apply layers on top of each other twice, but just wait until they dry well.

- To work in corners, corner spatulas are needed. They pass well through all hard-to-reach areas and spread the plaster quite evenly and smoothly.

Types of plaster mixtures

Two types of materials are used to level surfaces. Their main difference lies in the base on which all the characteristics of the solution depend. It could be:

- cement;

- gypsum.

Quartz sand of different grain sizes, plasticizers and other fillers are added to the base, which determine the purpose of the plaster paste. Thus, coarse sand allows you to level out significant differences, while fine sand is used only for applying the last layer, covering small roughnesses.

Instagram

Plastering can be done with a mixture based on gypsum or cement.

Let's look at the pros and cons of each type of material.

Cement compositions

They are particularly durable and resistant to mechanical stress. They are not afraid of moisture and can be used in rooms with special conditions: bathrooms, toilets, kitchens and outdoors. They are not destroyed by temperature changes, are durable, have a low cost and can be made by hand. Even significant differences are well leveled. If a layer thicker than 20 mm is applied, a reinforcing mesh must be used.

Lime, clay, and gypsum can be used as fillers, imparting plasticity and antiseptic properties. Among the disadvantages, it is necessary to note the large mass of cement mortars. They place a significant load on the base, which must be taken into account. Low ductility leads to shrinkage and possible cracking. For the same reason, it is quite difficult to apply such paste. Moreover, it does not fall on all bases. Cement takes a long time to dry and completely hardens only after a month.

TOP 3 best gypsum plaster for interior work by price/quality for 2022

KNAUF Rotband

If you ask any finishing specialist to name a few of the best plasters, you will definitely hear this sample on the list.

A high-quality gypsum-based mixture is used to level internal walls and ceilings both in living rooms and in the bathroom or kitchen. The main feature of this plaster is the ability to apply a layer on top of any base, including concrete or brick.

Special polymer fillers increased adhesion and made the application process easier.

The sample has many certificates of conformity; experts consider this plaster to be one of the best in terms of fire resistance (and, therefore, fire safety), environmental friendliness and vapor permeability.

Yes, the price is slightly higher than that of competitors, but the quality is beyond doubt and guarantees ease and safety of finishing.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 5-50.

- Mixture consumption according to the manufacturer is 8.5 per sq.m. (layer 10 mm).

- Water consumption per 1 kg of mixture is 0.6 liters.

- The viability of the solution is 25 minutes.

pros

- dries quickly;

- It is used quite economically;

- plasticity, stickiness;

- Suitable for leveling strong defects.

Minuses

- due to quick drying, it is more suitable for specialists;

- very popular, fakes are often produced.

Volma Layer

Domestic dry mixture on a gypsum basis, which contains lightweight aggregate, modifying additives and mineral fillers, thanks to which it was possible to achieve optimal operating time, high adhesion and good water-holding capacity.

It is recommended to use for leveling walls and ceilings in rooms with normal humidity; the permissible layer thickness is determined by a framework of 5 to 30 mm, but in some places it can reach 60 mm.

When properly mixed and applied, the plaster after drying gives a glossy surface, on top of which no additional putty is required.

The mixture is for manual application only. The solution does not change its texture within 20 minutes. It can be applied without priming, but in this case the base must be wetted with water.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 5-30.

- Mixture consumption according to the manufacturer is 8-9 kg per sq.m. (layer 10 m).

- Water consumption per 1 kg of mixture is 650 ml.

- The viability of the solution is 20 minutes.

pros

- fits well even at low flow rates;

- suitable for quick repairs, does not require additional putty;

- dense, plastic texture;

- holds up well and doesn't fall off.

Minuses

- batches have different quality;

- not suitable for machine application.

Weber Vetonit Profi Gypses

Plastic plaster on a gypsum basis, which includes microfiber, which provides good viscosity and consistency.

The solution dries quickly and evenly, without cracking or shedding. Finely ground gypsum is easier to apply and level; with a layer of 10 mm, from 8.5 to 10 kg per square meter is consumed.

Due to increased adhesion, peeling does not occur even in those places where a thick layer is used.

Apply to any surface, including concrete, brick, gypsum sheets. This is a domestically produced plaster, packaged in 30 kg paper bags. It masks defects well and is suitable for painting, wallpaper or under tiles, but only in rooms with normal air humidity.

It takes up to 5 days for complete hardening; the period can and will decrease with uniform ventilation of the work room.

Main characteristics:

- The base of the mixture is gypsum.

- The surface texture is smooth.

- Layer thickness, mm - 5-50.

- The mixture consumption according to the manufacturer is 8.5 - 10 kg per square meter with a layer of 10 mm.

- Water consumption per 1 kg of mixture is 550 ml.

- The viability of the solution is 40 minutes.

pros

- easy to mix;

- dries quickly;

- strong, holds well, does not crumble;

- easy to apply in an even layer.

Minuses

- no significant ones were found.

How to apply gypsum plaster

The solution can be made according to instructions from folk craftsmen, but in this case the user takes responsibility for the final result. In particular, in the process of mixing the composition they use: gypsum, tile adhesive, PVA, chalk, plasticizers and other ingredients. The components are added in different proportions and a thick mass is achieved.

Basic rules for applying gypsum plaster.

- The prepared solution is applied from top to bottom.

- It is advisable to take the thick mass onto the instrument in large portions and overlap it.

- To avoid bubbles, a grater is used.

- The construction rule is to spread the mixture. Lighthouses serve as landmarks.

- Wavy lines are made with the sharp edge of a trowel along the entire length. All stripes are processed this way.

- Allow time for the first layer to harden.

- Then the actions are repeated, but with the condition that the walls will be treated in sections.

- The surface must also be smoothed between installed beacons.

- Then the gypsum plaster is given a period of time for adhesion and after 45 minutes the finishing touch is performed.

- The beacons are removed and the holes are covered with material.

At the last stage, the seams are trimmed and other defects are removed.

What surfaces can be plastered?

Rice.

1. Plastering brick walls Plastering before painting is not always required. Below are the cases when it is necessary.

- Brickwork for painting. Plastering in new buildings is carried out in case of unevenness, if there are voids in the seams that are not filled with mortar and for better thermal insulation. For old housing stock, another reason is relevant - the presence of cracks.

- Concrete for painting. Since it has a smooth surface, before applying cement mortar it is necessary to install a reinforcing mesh and carefully prime the base.

- Aerated concrete blocks, foam concrete for painting. Plastering before painting should be done due to the fact that these materials are highly porous. Plastering aerated concrete blocks and foam blocks will improve thermal insulation and prevent the accumulation of moisture in voids.

- GKL (plasterboard sheets). Plaster becomes a protective shell for fragile plasterboard sheets, helps align joints and disguise fasteners.

Requirements for surface quality before painting

If you look at the paint plate carefully, the first thing you will notice is its small thickness. Colorful compositions form a thin film that fits the surface of the base, sensitively repeating the slightest bulges, sagging in depressions or large pores. By giving sections of the wall a uniform tone, the thin film conveys the texture of the surface to the viewer, making every bump or crack more noticeable. Therefore, the main task of the finisher is to achieve the maximum evenness and smoothness of the painted surface. To do this, the surfaces are leveled.

walls prepared for painting

Taking this into account, standards for finishing work were developed. In particular, according to SNiP 3.04.01-87, the plaster surface intended for painting must be:

- smoothed (no roughness is allowed on it);

- with sealed and leveled cracks (they should be opened by at least 0.2 cm, puttyed, sanded);

- free from grease, construction dust and dirt;

- without irregularities larger than 1 mm (only 1 defect per 2 m2 is allowed);

- no drips or traces of a trowel;

- primed, dried (humidity up to 8%).

Emphasizing the validity and importance of each listed condition, we provide information explaining how to level a wall for painting with your own hands.

Preparatory work

Before applying gypsum plaster, you should prepare the base:

- Remove previous decor;

- Get rid of debris and dust;

- Fill defects with mortar: chips, cracks, potholes;

- Apply primer;

- Install beacons to control the thickness of the layer.

Perforated slats are used as beacons. Metal fixtures are installed using waterlass. The size of the step depends on the length of the building code and should be wider.

When working with gypsum plaster, you will need the following tools:

- construction mixer with attachment;

- set of spatulas;

- trowels;

- steel lighthouses;

- building code;

- graters, graters;

- ironers;

- plaster corner.

You need to prepare buckets of different capacities, rags to mix the solution and wash the plastering tools from the mixture.