Exterior finishing work pursues several main goals, among which an attractive decorative appearance is of no small importance. At the moment, many materials are used, but houses covered with siding look the most original and aesthetically pleasing. The products are presented in a wide stylistic variety, which allows you to realize your design imagination.

Description

The material consists of panels, which subsequently acquire an integral system on the facade of the house. The material used to produce products is varied . Accordingly, each type of siding has its own characteristics and performance characteristics.

There are quite a lot of options for implementing the desired design solution; each type of product has its own color scheme and variety of textures. Basically, the products are characterized by a fairly high level of strength and reliability; they are also profitable to use because their price level is not too high.

Beautiful siding for cladding a house - photo:

H-profile assembly

The H-profile allows you to neatly join the panels in the longitudinal direction. Its installation is completely similar to the installation of corner profiles.

The choice of location for H-profiles is dictated by the aesthetic considerations of the owner - they can be installed symmetrically, ensuring the same length of panels, or use some entire panels, trimming another span.

Advantages and disadvantages

There are a lot of positive characteristics of siding material, the main ones are:

- the period during which siding can be used without problems reaches 50 years;

- Thanks to the finishing with siding panels, the house acquires an attractive appearance . Using this material it is possible to create a variety of styles and realize the most daring design ideas;

- the material does not require special care, there is no need to paint it. It is very easy to handle;

- siding is characterized by lightness and elasticity;

- the process of installing panels is very simple, it requires the efforts of only one person, which allows you to significantly save on a team of workers;

- has high resistance to sudden changes in temperature;

- creates a reliable protective barrier for the surface of the facade of a house finished with siding from the effects of negative destructive environmental phenomena;

- condensation does not form under the surface of the panels, since there are ventilation holes in it that remove accumulated moisture;

- the material is resistant to rotting and corrosion processes, and is also not destroyed due to the activity of insects and microorganisms.

As for the disadvantages of this material, it is worth considering the following points:

- The material from which siding is made is completely synthetic. Accordingly, it does not have a sufficient level of environmental friendliness . This does not apply to the wooden variety of panels, although it is not as reliable as the others.

- Flammability of siding . This point is important in the event of a fire. If the panel begins to melt from the fire, then it releases caustic and toxic substances that are dangerous to the health of people and animals. Stewing products is very difficult.

- If low temperatures persist for a long time, the siding panels become very fragile and may begin to crack . It is even possible for parts of the panel to break off.

- The material is not very resistant to mechanical damage . This is especially important for the metal variety, since for it even a scratch on the surface is a significant threat to quality. The panels cannot be restored, which requires the cost of replacing a damaged panel.

NOTE!

For homes that are exposed to sunlight more often, it's best to choose light-colored siding because it's less prone to fading.

How to determine the quality of siding paint

Since this material lasts about 40-50 years, special requirements are put forward for its decorative coating. It should not quickly fade or fade, become scratched, or peel off. High-quality siding retains the same color for 10-12 years, and subsequent fading occurs evenly and almost imperceptibly, so the homeowner does not have to worry about updating the color.

Vinyl Siding UV Test

Field test site

There was no fading and the color was completely preserved

Without the SUNPROOF GL system, the results after a similar time period (2 years) are unsatisfactory

Unfortunately, high demand for siding has contributed to the market being filled with low quality products. Within a couple of years after installation, such panels begin to fade in spots, peel off, and lose their glossy shine. When choosing a material for finishing your home, know:

- the highest quality siding has the same uniform color on both sides (premium panels);

- more budget options are lighter on the back side, but the color should still be even, without the slightest streaks, inclusions or spots;

- panels of dark color and rich bright color are always 1.5-2 times more expensive than pastel and white ones;

- The packaging must indicate resistance to UV radiation (leading manufacturers mark it as “SUNPROOF GL”).

SUNPROOF GL

Kinds

Those who decide to use siding for finishing work on the facade need to familiarize themselves with the varieties of such material.

Highlight:

- Aluminum . It is characterized by a wide range of different reliefs and colors; this variety is intended for finishing office premises or residential type multi-storey buildings. This is explained by the fact that the panels weigh very little, and therefore will not weigh down the facade of a private house.

- Wooden. It consists of wood fibers that are compressed under high temperature conditions with the addition of a special resin. In appearance they imitate natural wood. The price category of such products is quite high. The panels are characterized by flammability.

- Steel . In most cases, this type is used in industrial construction. The color range is quite wide, the product weighs a lot and is prone to corrosion processes.

- Cement. This variety is one of the newest invented by foreign industry. Has a high level of fire resistance . Made from cement and cellulose fibers. In appearance it resembles wooden boards. Well suited for finishing work in educational institutions and kindergartens. It is also gaining popularity in private construction.

- Ceramic. It is also one of the newest inventions. It has its origins in Japan. The price category of the material is low. Siding contains clay and some other natural materials.

- Vinyl. It is considered the most common and popular because it has an affordable cost, a simple installation process, the ability to hide all defects of the facade surface, and is also resistant to moisture and does not support combustion.

- Metal. A type of siding panels that vary in width. Made from steel (galvanized). During production, a polyester coating is applied to the surface of the product, which protects the material from corrosion. The main advantages of this type are a high level of fire resistance, strength and the longest possible service life . Resistant to a wide temperature range.

CAREFULLY!

When choosing aluminum siding for finishing your house, you must take into account that there is a risk of injury during the installation process. This kind of work should be approached as carefully as possible.

Photos of houses covered with siding of different colors:

Installation of the selected sheathing

First of all, you should mark the area of the walls, mark the axes of the planks in accordance with the pitch of the sheathing. Direct hangers for drywall are attached along the marked axes . The distance between them is about 60 cm; for metal siding, the number of supports can be increased.

Installation of the sheathing begins with the installation of two extreme strips . Their position is carefully adjusted according to the building level or plumb line, after which cords are pulled between them to adjust the plane during installation of the intermediate strips.

Intermediate strips are installed in previously prepared suspensions, their position is adjusted using stretched cords.

Window openings are also decorated with sheathing strips . If the windows are installed in a single plane with the wall, then you only need to frame the opening around the perimeter with slats (usually a double row); if the opening depth is more than 20 cm, it is also necessary to install slats along the slopes, controlling their plane.

IMPORTANT!

If the walls are insulated, then the plane must be ensured on the first, main layer of the lathing, so that the installation of the counter-lattice strips is carried out on a prepared system and does not require adjustment.

Finish options

Moving away from the performance characteristics and protective properties of the siding material, it is worth paying attention to the appearance of the building, which will be achieved through the panels. There are a great variety of finishing options, since the range of this material allows any imagination and fantasy to be realized .

In addition to the fact that it is possible to combine several colors of material on the facade of a building, you can purchase panels of different textures and, for example, create an imitation of wood, brick or stone.

Regarding finishing options based on installation technology, there are two of them:

- vertical;

- horizontal.

With the help of vertical installation of siding panels, the facade of the house is visually stretched, the height of the wall becomes visually larger. Horizontal finishing creates a single, holistic system that looks harmonious and cozy.

IMPORTANT!

To create a more expressive and brighter facade of the house, you can use dark-colored siding on the corners of the building.

Installation of external corner strips

Installation of external corner strips is carried out in the same way as internal ones; it is necessary to ensure the same clearances and tolerances.

If the height of the wall exceeds the length of the corner strip, they should be connected with an overlap of 25 mm , for which the nail strips of the upper profile should be cut to the required height, taking into account the temperature gap. The connection is made in the direction of water flow - the upper profile on the lower one.

Features of care

To maintain the neat appearance of your home, it is necessary to occasionally clean the surface of the siding panels from dirt. If the contamination is insignificant, then it can be easily removed using a strong stream of water . You can use a regular Karcher for this. If more significant dirt appears on the surface, use a soft brush to remove it.

If mold is found on some panels, then after removing it, the panels must be treated with a solution with a 5% concentration of chlorine. It is prohibited to use chlorine in its pure form on panels. You cannot clean the surface if the temperature outside is low.

It is not recommended to use various cleaning products that include abrasive structures, as they can damage the top layer of the material . Chemicals should not be left on the siding surface for more than 10 minutes.

Installation of internal corner strips

Installation of internal corners is carried out immediately after installing the starting strips (simultaneously with external corners and the profile). The corner strip is attached 4-6 mm lower than the edge of the starting strip .

To ensure that the nail strip does not stick out from below, it is trimmed by 4-6 mm . A temperature gap of 1-3 mm is left on top between the corner strip and the soffit . If the corner strip rests on the plinth, then a gap of 4-6 mm .

The upper self-tapping screw is screwed along the upper cut of the nail bar hole, preventing the element from going down. The remaining screws are screwed in the usual order, in the middle of the holes.

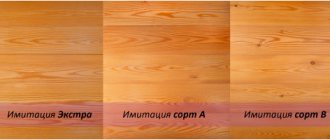

Imitation of natural wood

A polyethylene film with a pattern of wood panels is glued onto a durable vinyl base. The model has a smooth surface, a variety of shades - from light brown to walnut.

For decoration, this option will be an excellent solution, since the imitation is almost impossible to distinguish from real wood.

Imitation of log beams

Another of the original options for the external cladding of a private house. It is most often used for decorative decoration of buildings made of old bricks or blocks that have ugly facades.

Models with an imitation of galvanized timber are presented to the attention of buyers on the building materials market. They are distinguished by their original decor, rich color and texture.

It should be remembered that the cost of the material is higher compared to previous models.

WOODEN SIDING – WOOD SIDING, LOG, BEAM

The following type of siding is ideal for houses located near a forest or included in green landscaping - rural homesteads, cottages, country houses. Of course, this is wood siding. The question immediately arises of protecting the tree from the proliferation of parasites and mold? To protect your home from this problem, wooden siding is dried very well when manufactured in a factory or treated with special antiseptics.

Advantages of wood siding:

Let's highlight all the advantages of wooden panels. First of all, it is environmentally friendly, because wood is a natural material that will give a very aesthetic appearance to your home due to the high quality of the wooden texture. And also good thermal insulation.

If we talk about disadvantages, the first disadvantage of wood siding panels will be similar to vinyl - not durability. Wooden panels are not a cheap pleasure for the client, and one should not forget about constant maintenance (painting). And the last, no less important disadvantage is the fire hazard and tendency to deformation.

Fastening the guide elements

At this stage, guide rails are additionally attached to the frame elements. They are positioned along a horizontal or vertical axis, depending on how the sheathing will be laid.

Disadvantages of using the material

Despite all the positive qualities, this coating is not without its drawbacks:

- When exposed to high temperatures for a long time, the pores of the material expand, which leads to deformation of the coating.

- The PVC base is unstable to mechanical deformation - a blow of sufficient force will lead to the formation of cracks on the surface.

Obviously, there are much fewer disadvantages of practical application, but they play a huge role when choosing material for cladding a house.

Installing the finishing strip

The finishing strip is installed before installing the top siding panel. It is usually placed close to the cornice or soffit; the top siding panel is cut along the nail strip and placed under the curl of the finishing strip profile .

From below, the top panel snaps into the lock of the previous panel in a standard manner, thus completing the installation of the section of the canvas.

White brick walls

As a rule, a decision is made to paint brickwork in case of defects, cracks, mold or chips. But keep in mind that newly laid brick should not be painted. It is required that the surfaces become dealkalinized and all processes are completed.

To paint brick walls white, you need to prepare them very carefully: clean the dust https://alfacom.kz/chistka-ot-pyli, wash the walls with a hose, remove fungus and mold using antiseptics, dry thoroughly, then apply a primer and only when it is completely dry can you paint the brick wall. Choose moisture-resistant paint with a porous structure to preserve all the advantages of bricks.

White thermal panels for the facade of a private house

This is a two-layer material for cladding buildings, consisting of clinker tiles and insulating polyurethane. The material is also called sandwich panels. The thickness of such material can be from 4 to 10 cm, it all depends on the thickness of the walls of the house and the severity of winters in your climate zone.

The features of thermal panels include their affordable pricing and ease of installation.

Types of material

Depending on the function performed and the area of application, three types of material are distinguished:

- Model for covering the base.

- Model for strengthening walls.

- Auxiliary models.

Each of the presented models has a strict scope, shape, texture and cost. Before carrying out repair work, you should carefully familiarize yourself with the purpose of the selected type of material.

Installation of row panels

Siding panels are usually installed from the bottom up (although sometimes it happens the other way around). The first panel is inserted into the sockets of the corner and H-profiles (or two corners), snaps into the lock of the starting strip from below and is secured with self-tapping screws along the upper nail strip .

CAREFULLY!

A 6mm temperature gap must be left on each side; tight installation is prohibited.

The next row of panels is installed in a similar way - from below it is snapped into the lock of the previous panel, from above - fixed with self-tapping screws . This way the entire canvas is installed to the top.