One of the most popular coatings used in residential and office spaces today is laminate. The variety of textures allows the material to be used in any room of an apartment, house, institution or organization. The durability and aesthetics of a comfortable and reliable floor covering will be ensured by the wax for laminate flooring, which will be discussed in this material.

Wax will help ensure the durability of the laminate

Many of us think that laminate is such a “strong” product and will withstand any “invasion” that there is no need to protect it from external influences. Moreover, during the production process it is filled with impregnation. But you just have to think about what the coating suffers from: from heels, furniture, wheels from children's toys and chairs, pet claws...

Helpful advice. These and many other minor defects can be easily masked using a special wax pencil. Now in specialized stores you can find entire sets with a varied palette of shades of such pencils. But there are more serious problems.

Coating defects can be corrected using a special pencil

Impregnation is a good idea, but there is a hint

Yes, indeed, laminate manufacturing technology involves protecting the product with special impregnation. But it is worth remembering that any product consists of several parts that are fastened together by joints. They are also called castles. It is for them that the procedure for additional protection with wax, which is based on paraffin, will never hurt. What are its advantages:

- paraffin, which is used to impregnate butt (lock) joints, will not allow moisture to pass through, which facilitates safe cleaning of floors in any room;

- treating the seams with wax will prevent the texture from swelling due to water getting inside;

- Wax for laminate, preferably liquid, will do an excellent job with a variety of cracks and damage that appear on the coating, which is caused by heels, wheels and animal claws.

On a note. Waxing only covers joints and damaged areas. If the entire coating is subjected to this procedure, it will lead to the appearance of streaks and smudges.

Wax is designed to hide damage to the coating

A gap in the laminate is a violation of the geometry of the planks. Correction

The most common reason for the appearance of gaps in laminate flooring is not the careless work of the craftsman, but the poor geometry of the laminated panels

While working on one of the latest orders, I drew the customers’ attention to the discrepancy between the laid covering boards

Gaps due to crooked laminate

When laying material, even from the same package, the panels were wrapped in different directions. Having asked how long the laminate lay in the room, and the installation took place in a private house, I received the answer - about a month.

Imagine. It's summer, it's hot, and the concrete base of the first floor is cold. Due to temperature changes and unstable humidity, the slats became distorted - they were bent. Moreover, such a situation can happen not only in a country cottage, but also in an apartment. Laminate flooring should not be kept on a balcony or loggia, or near a heating radiator. And in the storage warehouse, conditions may also not fully comply with the proper conditions.

Having laid out the first row of laminate and carefully positioned the spacer wedges, I began further laying the covering.

In the first rows laid, the gaps are usually not visible. The planks are pressed together along the long and end parts along the path of least resistance, forming a line. When the geometry of the panel is broken, this straight line can become curved.

And to this part of the laid floor, which formed the rigidity, we attach a new row. And since the panels are curved when joining, gaps appear between the laminate. Before final mating, they can be along the long and short parts of the lock. But when tamping, the long part is pulled in (often not completely) and the ends do not meet completely, forming a crevice.

The gap at the ends can be of different sizes, depending on the discrepancy in the geometry of the laminated boards and, to a lesser extent, on the skill of the craftsman. The specialist’s task in such cases is to timely staple the end of the laid row to minimize the gap.

Violation of the geometry of the plank, affecting the formation of a gap, can be of several types:

- The board is curved like a boat, the ends point up. (In this case, the gaps along the short part of the lamella are usually small). They are uniform along the entire length. They can be recognized by pressing the joint of the two ends with your finger. If the board sags under pressure and the gap is eliminated, then nothing needs to be done. Over time, the laminate floor will settle under its own weight.

- The bar does not have a 90 degree angle. Such a marriage does occur. When assembling the coating along the end part, a gap is formed that cannot be eliminated. Even after tapping as much as possible, you can only partially remove the gap. It will be redistributed between the end and long parts, becoming less noticeable.

- The die, when viewed from above at the front part, is curved in such a way that the ends are not aligned with the middle. Such a defect cannot be released from the machine. This is the result of improper storage or transportation. When laying, it is necessary to tap the edges of the row with a staple at the ends to reduce the gap. It is rarely possible to completely eliminate a defect.

Gaps in laminate due to poor plank geometry

From a practicality point of view, it is better to purchase laminate with a chamfer and/or non-white tones. On medium and dark colors the presence of such a defect is less noticeable. Which laminate is better with or without chamfer!

Gap in light-colored laminate

What else besides wax

As mentioned above, the first emergency remedy for laminate flooring is a wax pencil. It consists of paraffin, wax and pigment dye, and is an environmentally friendly product. But this option is best for minor mechanical damage; it is recommended to purchase it together with the laminate itself.

For more significant problems, special repair kits have been developed. They consist of putty, latex or acrylic material and a wax pencil. This product is able to protect against the effects of penetrating moisture and facilitates the installation of laminate flooring.

For more serious problems there are special kits

To smooth out chips, you can also use hard wax, which is sold in hardware stores. To begin work, it is heated, then poured into the required places. After hardening, the remaining material is cut off with a sharp knife. But these actions will only briefly give the floor its “former beauty.” In addition, they will not protect it from moisture.

It is important to know! Any floor protection product must be used in accordance with the manufacturer's instructions. Failure to comply with the specified parameters can lead to an unexpected effect - swelling of the laminate and cracks.

Any product should be used strictly according to the manufacturer’s instructions.

Wax pencil for laminate

This product helps repair chips and scratches. With significant mechanical impact, unpleasant defects appear on the panels. The solution to this problem is to replace the damaged panel. But this option is suitable if the flooring was purchased with a reserve. Otherwise, the shade in different batches of the same manufacturer may differ. Therefore, using a laminate pencil is the most acceptable option.

For restoration, you need to choose the right shade. Laminate has the texture of natural wood, so several shades are available. It all depends on the scale of the scratch. We also recommend reading how to restore parquet with your own hands.

Laminate restoration technology:

Damage is cleaned of fine dust and dirt

It is important to ensure that the sides of the scratch have an even cut. The product is applied to the defect. If several shades are used, then hard wax is applied as a continuation of the pattern on the canvases. Laminate repairs are completed by polishing the surface with a dry cloth.

Such manipulations will help against small and shallow scratches. For large defects, mastics and wax sealants are used.

The material is selected to match the main color of the panel. It’s good if the chipped part remains. This will make the repair somewhat easier. A laminate product with wax is applied to the defect and the broken area is glued. The excess is removed. The composition hardens and is polished.

Super-hard wax is also available on sale. This composition is melted before use. Then it is applied to the damaged areas and polished after hardening.

An important point when choosing a kit for repairs at home is whether the surface will be glossy or matte. Even with small defects, the resulting result will spoil the appearance. One can only imagine a matte stain on a glossy floor. It will stand out significantly from the general background.

The best way to repair is to avoid it

To avoid having to change the flooring soon in the future, you should adhere to several rules:

- Doesn't walk in heels on laminate flooring.

- Provide soft pads for the legs of heavy furniture. Especially if you plan to move it. For chairs, armchairs, tables, make rubber or drape pads.

- Place a rug at the entrance. It will take away some of the sand and dust brought in from outside.

- When caring for the floor covering, do not use abrasive cleaners, scrapers, or metal sponges.

- Perform daily cleaning. It is enough to vacuum the floors. The accumulation of sand and dust negatively affects the surface when moving on it.

- If you spill liquid, wipe it up immediately.

A number of these simple rules will help you avoid difficulties even with simple repairs.

Long service, durable service

The problem of good quality flooring must be solved from the beginning, so many repair specialists advise that when laying the material on the floor, immediately protect it from swelling in cases of moisture by lubricating the joints with liquid wax. The same method will prevent the floor from becoming “creaky”. In some cases, the laminate is already subject to the application of a protective layer during the production process, and this increases the price of the product. It is worth noting that in this version the panels are easier to install and their service life increases.

Some manufacturers apply a protective layer during the production process

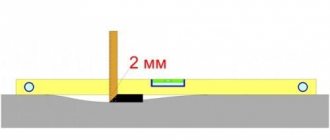

If the panels are without industrial impregnation, it is easy to do it yourself. When laying panels, experts recommend paying close attention to the interlocking joints (joints), which are considered the most vulnerable points. Treating them with liquid wax will help avoid deformation of the surface, which will become more resistant to moisture and durable. Wax can be liquid, solid or paste, but laminate locks prefer the liquid version.

For joints it is preferable to use liquid mixtures

How to work with wax correctly

This procedure is simple and does not require the involvement of specially trained personnel. But when purchasing any composition, you need to not only consult with the seller, but also carefully study the instructions for use.

On a note. Some surfaces require pre-installation treatment, while others require impregnation after installation of the panels.

In some cases, the laminate needs to be treated before installation

. In any case, there are rules that are common to any option that involves working with wax. Before you start you need:

- remove dirt and dust from the coating surface - this will prepare the coating;

- if the wax is liquid, melt it using a water bath;

- Before installing the floor covering, apply liquid wax using a thin brush;

- use a wax pencil or paste to treat the surfaces after installing the panels;

- excess wax is removed with a dry cloth; when it hardens, use a sharp knife;

- The work is completed by polishing with a soft cloth.

After all procedures, it is worth wiping the coating with a soft cloth.

A wax sealant is considered a more durable treatment option. It is easy to apply as it comes in small tubes. It is applied in a large layer directly to the joint and left (as indicated on the package) to dry. Using a rubber spatula, remove excess. Before using this particular material, you should carefully study the chemical composition indicated on the packaging. There are also rules for working with this type of material for processing seams.

Attention! To work with wax you need to wear a respirator. The causticity and toxicity of the impregnation can cause dizziness, headaches and allergies.

Wear a mask, the impregnation may be toxic

Examples and effect of using some compounds

No matter how good the laminate is, its joints are the most vulnerable place. To increase moisture resistance, products are used to treat laminate joints. Wax does not fill the seam, but only creates a film, lubricating it on the edges of the tenon and groove. This film prevents moisture from seeping through. Gels for laminate joints just seal the seam, filling it. In this regard, it is better, since dust and small debris do not get into the seam. But they cannot be used with all varieties. You need to look at the description of the coating.

Which laminate sealant to choose: wax-based or gel

Wax-based moisture impregnation for laminate flooring

Wax sealants for seams are just that: impregnation. They penetrate a little deeper, but mainly create a protective film on the surface. It prevents moisture from penetrating into the base of the laminate. But the connection does not seal. But they lubricate the lock, which prevents squeaking that may occur when walking.

Seam wax impregnations are good for chamfered laminate

One example of a wax sealant for laminated flooring is Rico AquaStop, which is produced by a St. Petersburg company. Bottles of 500 ml, tubes available. Apply either with a brush on both sides of the lock, or with a strip from a tube on one side. The treatment gives a good result; there were no problems with swelling in the hallway or kitchen. If it gets on the skin, there are no unpleasant consequences; it can be washed off with rags or paper napkins. You can permanently remove it with dish soap. But it’s inconvenient in the sense that stains will be all over your clothes. So keep that in mind.

Sealants

Regardless of the base, the properties of seam sealants are the same. When applied, it is a gel-like substance that is applied to the ridge or groove. When connecting, it is distributed over some part of the lock, the excess protrudes to the surface and then (after partial hardening) is removed. It turns out that the laminate gel fills all the free space. And since it is water-repellent, it simply does not let water into the seam. Therefore, continuous application is required for reliable protection.

Pay special attention to this point. Any omission is a bloating in case of problems

Gel-treated laminate joints can be separated if necessary

After polymerization, the gel becomes thicker while remaining elastic. That is, the use of gel for seams binds the planks together. But it's not glue. And you can separate the treated boards. It is not a fact that there will be no damage at all. There may be microchips, or part of the lock will peel off somewhere. It depends on the quality of the laminate.

There are many gel sealants for laminate seams. All properties are declared to be similar. But there is a difference. Some sealants contain solvents. If such a composition gets on a foamed polyethylene substrate, holes appear. How the composition behaves when it gets on the protective film depends on the sealant and the film. But this effect carries a potential threat. The protective film may dissolve or develop stains that cannot be removed. In general, such compounds should be avoided.

It is recommended to apply it to the ridge, but it can also be applied to the groove

If you bought just such a sealant, it is worth conducting preliminary tests on scraps. Apply according to the instructions, assemble the lock, wait as long as told. If there are no problems, you can use it.

- Click Guard. The smell is insignificant and does not dissolve the substrate. Apply to the comb.

- Aqua Stop.

- Clic Protect (Bostik) - just corrodes the substrate. It's polyurethane based, so you have to work quickly.

- Tytan (Titanium) - also corrodes the substrate, irritates the nasopharynx, but is applied and removed better than Click Protect.

- Homax click.

- Soudal Parquet (Soudal).

- MasterFix (Masterfix).

Restoration in pencil

The most common material for removing small defects on laminate is a wax pencil - this has already been discussed above. However, this material also has nuances in use. Cosmetic restoration using a pencil will eliminate minor scratches. Construction stores offer pencil blocks of various colors and shades. But you also need to be able to use them correctly.

Using a pencil can remove small scratches

Rules for using a wax pencil

| №1 | application is possible only on a dry and clean surface; |

| №2 | The shades of the pencil and the floor covering must match; |

| №3 | the damage is painted over with a pencil; in case of deep defects, the material is applied repeatedly; |

| №4 | each previous layer must dry; |

| №5 | After removing excess material, the surface is polished and wiped with a soft cloth. |

On a note. Processing seams, if they have cracks or chips, is also possible with a wax pencil. This product is almost an ideal option for prolonging the wear resistance of the floor covering.

Minor defects at joints can be corrected with wax

A drop of wax is no problem, there is always a way to clean it

One wrong move, and the sticky wax composition may end up in the wrong place. But this small problem can be easily dealt with if you pay attention to it in time. The most important thing is to remove it before it hardens. To avoid scratching the material, wipe the surface with a soft cloth. If the moment is missed, then do not despair - there is a way to correct the situation.

When the wax hardens, you need to cover the stain with a moisture-absorbing material (paper towel) and rub it with a hot iron. Heated wax can be easily removed with any wax-free cloth.

Wax can be removed with any cloth

You can melt the wax composition using hair dryers by directing a hot jet at the dirt, and then collect it using the above method or using a rubber spatula. In any case, after the cleaning procedure, polishing follows.

It is important to know. Metal objects should not be used to remove wax stains to avoid damaging the surface.