Plastering the walls of the facade of a house allows you to extend the operational period, improve the thermal insulation properties of the walls, thereby reducing heating costs. Plaster finishing can be done in different ways.

One of the most popular methods today is plastering under a fur coat. Compared to conventional dyeing, fur coat finishing followed by painting is more effective and reliable.

Below we will consider the features of applying plaster under a fur coat, painting the coating, the strengths and weaknesses of this type of facade cladding.

How to paint the facade of a private house like a fur coat

Plastering the facade makes it possible to extend the life of the building walls, increase their heat-saving qualities, and reduce the cost of heating the building.

Facade finishing can be done using various technologies. One of them is under a fur coat. Painting the facade of the house is an interesting option, but shuba plaster is much more economical. Finishing the facade usually requires significant preparatory work, as does applying a fur coat.

But in the second case, they will not be as complicated, because one primer of the surface is enough.

Cladding a facade with a fur coat is a fairly simple task that even a beginner in construction and repair work can cope with if he follows the technology of applying plaster.

What do we have as a result?

In conclusion, I would like to note that the method of finishing facades with fur coat plaster is quite affordable for most homeowners according to the following parameters:

- an inexpensive and reliable means of protecting the outer surfaces of building walls from the negative effects of various natural factors;

- A fairly simple application technology that a home craftsman can handle.

Sources

- https://building-ooo.ru/suxie-stroitelnye-smesi/shtukaturka-shuba-chto-eto-takoevidyprimeneniesposoby-naneseniefoto/.html

- https://stroyka-gid.ru/supplies/dekorativnaya-shtukaturka-shuba.html

- https://DekorShtukaturka.ru/dekorativnaya-shtukaturka/shtukaturka-pod-shubu

- https://1beton.info/shtukaturka/shuba

- https://nikastroy.ru/kak-sdelat-subu-na-dome-samostoatelno-posagovaa-instrukcia/

- https://RDStroy.ru/akademia-rds/kafedra-otdelki-sten/dekorativnaya-shtukaturka-shuba-metody-naneseniya/

- https://kraska.guru/smesi/shtukaturka/pod-shubu.html

- https://dekor.mobi/kak-sdelat-dekorativnuyu-shtukaturku-shuba/

- https://1oschtukaturke.ru/dlia-fasada/sposoby-naneseniya-dekorativnoj-shtukaturki-shuba

- https://PoShtukaturke.ru/steny-snaruzhi/dekorativnaya-shtukaturka-naruzhnyx-sten/dekorativnaya-shtukaturka-shuba.html

- https://1pofasady.ru/shtukaturka/dekorativnuya-shtukaturka-shuba

About simplicity, practicality and weaknesses

It’s easy to find plenty of photos and videos on the Internet that show step-by-step the technology for tidying up the façade of a house. Applying a fur coat with your own hands is quite simple. The price for the building materials necessary for the operation is affordable.

When purchasing them, it is better to immediately attend to the purchase of a tool for applying fur coats. The main building material of a fur coat is cement and colored pigment. The simplest set for applying cement mortar: trowel, broom, stick.

With their help, you can finish the facade of a house very quickly, although such tools are considered primitive. The technology for applying this coating is quite simple.

Fur coat has many advantages compared to other types of finishing. If you pay attention to photos and videos of houses lined using this method, their attractive appearance will not leave you indifferent.

The fur coat not only provides protection to the walls, they can be painted in any color thanks to the added pigments. On old walls of a house, a fur coat will not significantly increase the load and will not negatively affect the technical and operational characteristics.

Before choosing a fur coat as a design solution, you must also take into account the weak side of the coating. In photos and videos of buildings decorated with fur coat, it is usually invisible.

When decorating the facade with a fur coat, some negative aspects of this design may emerge. Property owners will learn about its shortcomings later, after applying the plaster. The fact is that a fur coat is a dust collector.

And for a number of modern styles such finishing is absolutely not suitable. For example, a worn fur coat will definitely disrupt the style of a high-tech building. It is most convenient to use fur coats for houses in traditional classic styles, choosing colors that match them.

To solve the problem simply

The price for finishing work performed by professionals is quite high. If you decide to use your own resources to tidy up the house, the first piece of advice is to choose the simplest methods for finishing or painting.

Compound

It should be noted that the composition of the “fur coat” may differ markedly. If in past years the mineral composition of plaster was predominantly used in construction, today ordinary people are increasingly choosing an acrylic or silicone base. It is worth studying their compositions, assessing the advantages and disadvantages of each.

Silicone plaster

And this is the most perfect composition of the “coat”, which does not have the disadvantages inherent in simpler and cheaper plasters. Polymer resins act as the binding component of silicone plaster, making this material extremely durable and less fragile. Its only disadvantage is the high price, and therefore it is quite obvious that silicone plaster is purchased extremely rarely to cover large areas.

Important! The silicone composition also has one more drawback. The fact is that this surface layer dries 1.5-2 times longer than its “competitors”. It is important to take this into account when working so as not to spoil the material.

Acrylic

Decorative plaster consists of an introductory polymer dispersion, dolomite fillers, as well as pigments and special additives that improve the performance properties of the mixture and also facilitate its application. The building material is resistant to low temperatures, rain and ultraviolet rays and provides microbiological protection.

An acrylic mixture is used for finishing building facades (it cannot be used indoors).

Pros:

- fast setting;

- ease of use;

- high elasticity;

- wide range of colors;

- easy care;

- resistance to deformation;

- low water absorption;

- resistance to abrasion and mechanical damage;

- affordable price;

- good adhesive properties;

- resistance to mold and fungi.

Acrylic facade plaster does not require painting, which simplifies construction work.

Minuses:

- low resistance to ultraviolet rays;

- gets dirty quickly;

- low vapor permeability.

Another disadvantage is that acrylic compounds stain easily. Dirt settles on them faster than on other mixtures.

If the house is located in the city center or on the highway, then it is preferable to choose silicone facade mixture and other types (with a self-cleaning effect). Follow these rules when applying decorative “fur coat” plaster:

- The ambient temperature should be above +10 degrees.

- It is important that it is not raining outside.

- Strong gusts of wind or heat also adversely affect the structure of the acrylic mixture.

Other types of building materials

Advantages of silicate compounds:

- low price;

- high elasticity;

- resistance to fungi and mold.

Minuses:

- low strength.

Mineral plaster is used for finishing insulated facades. The fur coat solution can also be used inside buildings. The composition prevents the growth of harmful microorganisms.

Facade plaster “shuba” is resistant to high and low temperatures, ultraviolet radiation and mechanical damage, and has good adhesive properties. Other advantages of the mixture:

- good vapor permeability (allows walls to “breathe”);

- strength;

- resistance to microcracks;

- low price;

- fast setting;

- long service life;

- resistance to mechanical damage;

- ease of use.

For wall finishing, plaster with a grain size of 1.5 mm is most often purchased.

Cement-lime plasters improve the thermal insulation properties of the wall. Suitable for surfaces subject to mechanical damage. The downside is that they get dirty quickly.

Independent work

To paint the facade of a house with a fur coat yourself, you will need the following materials and tools:

- Roller.

- Brushes for painting.

- Spray gun.

- Cement mortar.

- Mortar for textured plaster.

- Hard brush.

- Wooden slats.

- Paint tray.

When you don’t want to work the old-fashioned way with a broom and trowel, a special machine for applying plaster will help you do the job. The price of the device is relatively small and depends on the complexity of its design.

A machine for applying plaster will speed up the finishing process, allowing you to significantly save effort and time.

She applies the solution to the surface. The layer of plaster is relatively small and neat. In the video, which shows operations using a machine for applying plaster, you need to pay attention to how the specialists hold it correctly.

The bell of the machine is positioned at a right angle. And one more nuance: facade plaster using this device must be applied in several layers, otherwise the finish will be too thin and unsuitable for long-term use.

Fur coat creation technology.

Simple installation methods

As for the simpler old-fashioned methods, they are usually distinguished by the types of plastering tools. In addition to a broom, a brush and an iron mesh are perfect. Facade plaster is most easily applied using an ordinary broom.

It is soaked in the solution and hit with it on a stick that is held against the wall. The solution is sprayed, distributed over the surface. Then the action is repeated.

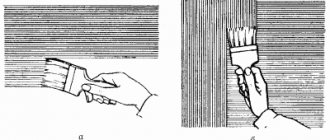

Using a brush, this operation is no more difficult to perform, and in some cases, much more convenient. The dissolved façade plaster is placed in a special container and a brush is dipped into it.

As soon as the tool is brought to the wall, it is turned over and passed along the bristles with a board. The action is performed in the direction “towards oneself”. The operation is repeated until the fur coat is applied.

When looking at photos and videos of finishing work, it often seems that finishing external walls using mesh is a very labor-intensive process. This is far from true if the mesh itself is chosen correctly. It should be light and not difficult to install.

The price of finishing work will be slightly higher, because, in addition to the metal mesh, you will need a wooden frame, where it will be strengthened. Using a trowel, apply the prepared solution onto the mesh. The mesh is removed as soon as all necessary facing operations have been completed.

Brief description and advantages

Shuba plaster is the application of cement-sand mortar to the surface of the house by spraying. This process is easy and even a beginner in construction can do all the work, since you only need mortar, a stick, a broom and a trowel. The application process is not labor-intensive and will take a little time if you compare it with other finishing methods (log house, siding, stone cladding, etc.). Material costs are minimal, and the only thing you have to buy is cement and a colored pigment to color the solution in the required shade.

The advantages of making a fur coat at home are the following:

- No costs.

- Beautiful view of the building.

- Easy to apply the mixture

- Excellent thermal insulation and sound insulation performance.

- Excellent protective properties.

The disadvantages include the fact that the final result (appearance) will not fit into modern garden styles (for example, hi-tech), as well as the fact that such a coating is a dust collector due to the surface topography.

Simple and clear secrets of mastery

Preparing a wall for a fur coat will not be difficult. However, before applying the primer, small notches are made on the main wall using a hammer and chisel - carefully so that no damage is caused to the main building material.

This operation will be required if the wall of the house is smooth; when it is rough, notches are not needed. Do not neglect the primer application stage, as many novice craftsmen often do.

The price of modern types of primers is affordable, and they provide better adhesion of the plaster to the surface. The finishing of the facade of a house where a primer is applied will last much longer.

The primer is applied with a brush or spray. The price of the second device is higher, but it is much more profitable to use in finishing work, because applying the primer will become more economical, uniform, and of high quality.

Preparing the wall and mortar for cladding

Preparing the base for applying the fur coat will not be too difficult. As in a number of other cases, the surface will need to be covered with a layer of soil mixture. However, before this is done, notches will need to be made on the main wall using a hammer and chisels.

This must be done carefully so as not to damage the surface of the facade. Notches are necessary only in cases where the wall is too flat. Surfaces with recesses and reliefs will not need notches.

The soil mixture can be selected at your discretion, preferably from a trusted manufacturer offering the optimal ratio of quality and wall. Plaster applied to a pre-primed surface will last much longer due to improved adhesion to the wall.

You can apply the primer mixture using a regular brush or sprayer. In the second case, the process will take less time, and the primer layer will be more uniform and neat.

You can prepare a solution for plastering the surface at home. To do this, mix cement and sand in a ratio of 1:3. At this stage it is important to achieve the correct consistency of the solution. It is better that the plaster is thick enough to resemble liquid sour cream. It is not recommended to add gypsum to the mixture, since such a coating does not demonstrate the best performance qualities.

The finished solution is usually applied in several layers. The first two layers can be simpler without special artistic refinements, while the creation of the last one will require some work. You can add a coloring pigment directly to the solution; it is possible to paint a layer of fur coat plaster after it has dried.

Please note that painting looks especially stylish using a solution to which not only pigment is added, but also pieces of broken colored glass.

Also, the painting will be spectacular if you add a little coal, red iron ore and white marble to the mixture.

Practical, reliable, aesthetically pleasing

Preparing the solution will not be difficult if you use the traditional method. Standard cement-sand mortar (where the ratio of sand and cement is 1:3) is the best way to solve the problem.

The density of the solution is an important issue. It is best if its consistency is like liquid sour cream. But it is better not to use plaster for fur coats; such a coating will be short-lived, since it is not intended for external finishing work.

The solution itself is usually applied in three layers. The first layers are basic and do not require any special artistic refinements. But with the decorative one (the latter) you will have to work especially carefully.

Pigment can be added to the solution, but there is another way: dyes are applied on top of the third layer. Decorating a house with a fur coat is considered stylish when pieces of broken glass are added to the colored plaster, becoming a kind of highlight.

When carrying out finishing work, it is necessary to take into account weather conditions; operations are not carried out during rain or when the sun is shining brightly. To decorate the house, it is better to choose a cool, cloudy day.

All three layers of fur coat are applied one by one, without allowing the previous layers to dry out much. The coloring of the solution for the decorative layer of a fur coat can be done using crushed red iron ore, white marble, or coal.

The top layer of plaster, painted with the addition of manganese or fine cobalt glass, looks very original.

Source

Special devices

The solution does not have to be applied manually. There are devices that can make your life much easier:

- compressor;

- plastering machine;

Compressor

Construction companies usually use this method, since it allows them to complete fairly large volumes of work in a short time. The method of action is simple - the solution is ejected from the container with compressed air, which allows you to obtain a uniform coating. In addition, the droplets turn out absolutely identical, and as a result, the fur coat on the wall of the house looks very beautiful and neat.

Plastering machine

This machine has a drum with blades. The blades throw the solution onto the wall. This method is popular among small companies involved in the construction of individual houses. It is more labor-intensive, but such a machine costs much less than a compressor.

Spray gun

A separate approach is required for painting a house under a fur coat with a colored solution. It is not always possible to achieve an even tone manually. In this case, you should strictly follow the general rule - the wall must be painted at a time with the same composition.

Important! In addition, novice craftsmen often have difficulties with uneven walls - even the slightest depressions lead to the coat of paint being distributed unevenly. A spray gun will help out in such a situation. It very effectively breaks drops into tiny particles, which results in a more even surface.

Plaster coat: what is it, types, application, methods of application, photo

The huge variety of building materials that are used today to decorate walls often confuses people. Therefore, in this article I would like to talk about fur coat plaster - a fairly popular method of finishing wall surfaces. That is, let’s figure out what this plaster solution is, why this finish is called that, its advantages and disadvantages, and also consider the method of application.

Peculiarities

The traditional solution for applying plaster under a fur coat is a mixture of sand and cement, taken in a ratio of 1: 3 and diluted with water to the desired consistency.

The sand is selected in accordance with the requirements for the surface being formed: when making a rough, rough “coat” you should take mountain or ravine sand, and to obtain a smoother texture you should use fine-grained quartz.

Sand should be sifted before adding to the solution. Lime, gypsum and clay can be used as the main binder.

The advantage of this composition can be considered the low cost and wide availability of the constituent components, while the disadvantages include the low ductility of the material and the likelihood of cracking when the layers dry unevenly.

The most modern and convenient to use are ready-made dry mixes based on acrylic . The material is available in white, gray and colored versions, which allows you to purchase a ready-made composition of the desired shade or paint it yourself. Coloring is done using coloring powders and pastes.

The disadvantage of self-dyeing is the need to strictly adhere to the proportions of the dye, deviating from which there may be a difference in shade between solutions of different batches. In order to avoid problems with coloring the mixture, you can resort to the method of painting the finished surface after it has dried . Painting is done using moisture-resistant and light-resistant facade paints, which not only solve a decorative problem, but also do an excellent job of eliminating small cracks.

Additional Tips

Please note that you can only apply paint to the plaster when it is completely dry. Depending on the material and location, the plaster can dry from 8 to 48 hours. Only after this can you begin to give it a different color.

If you want to make the surface original, you can use all kinds of stencils. They will help you create different ornaments, patterns and designs on the wall. In addition, you can use masking tape to achieve smooth borders. They can break the wall into certain sections and paint each cell a different shade. Here your imagination can run wild.

Finally, the painted wall can be additionally treated with a protective layer of varnish. It must be applied to the paint itself after it has completely dried. Use water-based varnish. It is diluted with water in a 1:1 ratio and will penetrate into all the recesses of the material. It is better to apply the mixture with a wrung-out wide brush in 2 or 3 layers, waiting for the previous one to dry. Usually the varnish dries quickly. Thanks to it, the plaster will acquire an exquisite shine, the color will become more noble, and caring for such a surface will be a pleasure.

Types of plaster

The use of fur coat plaster is still relevant today. Builders using this method try to save on materials, which is not at all necessary, since currently in any hardware store you can find dry decorative plaster under a fur coat at an affordable price.

The main advantage of this material is the fact that its performance properties are higher than those of its homemade counterpart. Due to the wide selection of finishing materials presented by brands for sale, you can find plaster on store shelves in the form of a ready-made mixture. It is sold mainly in buckets. The cost of this material is higher than its dry counterpart, as are its performance qualities.

This decorative plaster received its unusual name due to its similarity to fur: when finished, it has a rough texture. This look is obtained thanks to the simple technology of mixing plaster with small stones. The size of the stone can be varied, it all depends on the purpose pursued during the repair. By using larger stones, you can get a more prominent wall. The opposite result can be achieved by using small stones.

Fur coat plaster in the form of a dry mixture must be diluted with clean water at room temperature. This type of decorative plaster today has white and gray colors. It is a budget type of such finishing material; this option is used mainly for covering larger surfaces. One of the main advantages of this material in powder form is the ability to paint the composition in any desired color.

The composition of the finished paste plaster in buckets includes synthetic polymers , which gives the composition increased softness and strength. Plaster of this design can have absolutely any color. It is advisable to use this expensive plaster for interior work (in order to save money), and it can also be used for final coating of surfaces. It is also important to use expensive plaster to cover individual parts of the interior (for example, arches, columns, borders). In this case, the concept of high cost is relative: if repairs are carried out for oneself, the use of high-quality materials should be the main principle of work.

In addition to all the listed properties, the plaster decorative material under the fur coat has good thermal insulation and sound insulation properties, which justifies its name. It protects walls from the negative influence of the environment. The use of this plaster greatly facilitates and speeds up the preparatory work, as it allows you to hide defects in the working surface. Installation can be done independently (without the participation of a qualified technician).

It is important to mention that plaster damaged during use is easy to restore. The material allows this possibility, and the updated area will not stand out from the overall finishing fabric. A sufficient number of advantages of using fur coat plaster in wall decoration have been noted. For example, this composition can be painted using silicone or acrylic paint. Now you need to figure out how to apply it to the surface of the walls.

Choosing paint

The first step is to decide where the work will be carried out: outside or inside the room. Her choice depends on this. Both interior and facade paints are made on the basis of organic solvents. They can be:

- silicate paints;

- silicone;

- acrylic paints.

There are water-based products. All you have to do is choose the one that suits you and purchase it. To find out how many cans it will take to paint the entire surface, measure the area of the walls. Typically, the paint can itself indicates its consumption per 1 m2. For example, the consumption of facade paint is 160–250 grams per 1 m2. If you need to paint 15 m2 of wall, then the consumption will be as follows: 15 × 200 (average consumption) = 3 liters of paint. It is clear that this is an approximate number, since everything depends on the thickness of the layer. It is better to add 15–20% to this volume to be on the safe side.

Advice! A special feature of decorative plaster is its relief. The larger it is, the more paint of one color or another will be required.

One more nuance: when painting plaster in two colors, you need to buy 2 types of coating. It is applied in two layers, base and finish.

Application area

“Fur coat” plaster is suitable for finishing the following surfaces:

- facades of private houses and municipal buildings;

- walls in rooms;

- street fencing;

- columns and bas-reliefs;

- basement rooms.

Important! Practice shows that textured, pronounced reliefs with coarse stones are used for finishing facades. If the walls are finished indoors, fine-grained plaster is usually used, giving a smoothed relief.

By the way, depending on the type of plaster, the “coat” can be applied both to a concrete or brick wall, and to drywall.

Painting art and its secrets

To make painting easier and learn how to process plaster with minimal loss of material, you should learn some of the subtleties of painting art. To begin with, it is important to take care of the appropriate tools. It is best to work with a construction roller. They can easily apply paint of any color to the wall, while making a thin and uniform layer without smudges. And in order to use the paint itself economically, you cannot do without a roller tray. Thanks to it, the roller will have as much paint as necessary for an even layer, without excess.

Another point is the protection of furniture and other surfaces. This applies to indoor work. In order not to cover up windows, furniture, floors, doors, jambs, etc., it is better to cover them. Polyethylene can easily cope with this task. It’s better to take the furniture away altogether, if possible. When it comes to outside work, you can protect your windows, front door, and walkway from splashes. Having taken this into account, you can begin to carry out work.

Advantages of decorative plaster “fur coat”

The fact that the textured finish in question has not lost its popularity over the years allows us to talk about the serious advantages of this material. These include:

- Cheapness. Among all decorative and finishing materials, “fur coat” is considered the most affordable. In addition, to decorate a building with such a mixture there is no need to purchase special tools, which also allows repairs to be made with minimal investment.

- Additional heat and sound insulation. In addition to acquiring a pleasant appearance, buildings with applied decorative plaster acquire additional insulation and decent sound insulation. Important! Here you need to understand that to use a “fur coat” as insulation, it is necessary to apply a thick layer of plaster, which is quite expensive.

- Easy to apply. Even a person who has never encountered plaster mixtures in his life can master the technology of applying a “coat”.

- Decent appearance. Perhaps the “fur coat” cannot boast of such sophistication and aristocracy as Venetian plaster, but such a finish looks quite dignified, fresh and attractive. In addition, such plaster can be painted in any color you like without any problems.

- Maintainability. According to experts, there is no other plaster that, if necessary, could be so easily restored, returning it to its previous appearance. In this regard, the “fur coat” is surprisingly repairable.

- Excellent vapor permeability. Despite its apparent density, the plaster in question allows the walls to “breathe”, and therefore helps maintain a healthy microclimate in the house.

- Light weight. It is worth saying that this façade coating has a low specific gravity, which means that before applying it there is no need to strengthen the foundation.

- No seams. Finally, a coating such as “fur coat” has no seams or joints, so this material does not let cold into the house and does not accumulate moisture, and it lasts longer than finishing materials with seams.

Conclusion

You could see that to paint decorative plaster you do not need to be a skilled painter who has many years of experience behind him. It is enough to purchase the material, stock up on tools and start performing the work according to the instructions. This way you can make your home original and attractive.

Decorative plaster for interior wall decoration

Decorative plaster Parade

What to do after plastering walls

How to apply decorative plaster correctly

Disadvantages of decorative plaster "fur coat"

- Not too long service life. The sand-cement composition of the mixtures suggests that such external coatings are not durable. Silicone-based “fur coat” is the most durable in this regard, but it is not a serious competitor to other finishing materials for the facade.

- Moral old age. Numerous reviews say that “fur coat” is an outdated type of decorative finishing. And this, against the background of the variety of modern finishing materials, does not testify in its favor.

- Rapid contamination. The textured surface of the plaster quickly attracts dust and other contaminants. Therefore, such a façade should be washed periodically.

Where to start painting at home?

First, clean the fur: comb it, remove dust and other small debris. If you do not do this, foreign particles will not allow the paint to lay down evenly. Then choose the product you will work with. Remember that even the most durable options will only maintain a given color for 1 season. By the time the next one begins, there will be no trace left of the painting.

How can you dye fur?

Most often, housewives turn to either professional dyes designed for use on fur products, or regular hair dye. The latter will have to be purchased in large quantities. Especially if the pile is long, thick, and the fur coat is not a shortened model.

also

worth conducting a compatibility test . Apply the purchased dye to an inconspicuous area of fur. Follow the allotted time. Rinse it off. Wait a couple of days. If nothing bad happens to the item during this period and you are satisfied with the resulting shade, proceed with full-scale painting.

What is needed for the job?

List of items and materials that will be needed in the process:

- salt, soda;

- glycerin, ammonia;

- specialized product for washing fur items;

- water.

How to make plaster under a fur coat

In order for your fur coat plaster to turn out to be of high quality in all respects, the issue of preparing materials, tools and necessary components must be taken very seriously. Since there are several ways to apply fur coat plaster to the surface of walls, the set of materials and the required tools for application will be slightly different.

A specific method of applying plaster to the wall surface is selected based on what area needs to be treated, what layer thickness you want to obtain, etc.

Preparation for work and necessary tools

In order for your fur coat plaster to last as long as possible, you must strictly adhere to the simple rules for its application.

First, you need to prepare the surface on which we will apply the coat of plaster with your own hands:

- If your house is a new building, then when laying the walls it is not recommended to do jointing, leaving gaps between the bricks (blocks, etc.). If you are applying plaster to a building built several years ago, it is advisable to make notches on the surface of the wall. All these recesses will strengthen the adhesion between the wall and the plaster, significantly increasing its reliability and durability.

- Next, having finished all the “dirty” work, the wall must be cleaned of dirt and dust, which can be done with a metal brush.

- Once absorbed, it will increase the strength of the top layer of the wall surface, preventing it from further crumbling, and will also enhance adhesion to the fur coat plaster. The primer is applied to the surface using wide brushes, a roller or a sprayer. The choice of tool depends on the amount of work and the size of your budget.

- For maximum effect, when applying the primer, make sure it gets into all the cracks and cracks. After it has completely dried, you can begin applying plaster.

What material is used

The simplest and most inexpensive option for preparing a plaster mixture is to use sand, cement and water. Sometimes gypsum is additionally added to increase strength, but it absorbs water well, which is bad for exterior finishing work, so you will have to additionally paint the resulting “fur coat” well.

If your aesthetic tastes require something more, and your financial capabilities allow you to realize this, then you can pay attention to the market for ready-made modern dry mixes.

Ready-made mixtures are distinguished by ease of preparation, increased elasticity, improved penetration into crevices and cracks, increased resistance to sunlight, increased sound and thermal insulation coefficients, etc.

Typically, ready-made mixtures are sold in large plastic buckets, which makes the process of preparing them easier - add water and stir it with a construction mixer - and the façade plaster under a fur coat is ready!

Fur care after dyeing

Over time, the hairs of old fur can become stiff and dull even after dyeing. To eliminate the problem, you can periodically rinse the product with hair balm. It is better to take the product that comes with the paint (you can buy inexpensive paint and take out the balm). Spraying the item with a 9% vinegar solution (a spoon per glass of water) will also add shine. The effect of painting will be temporary in any case. Once a season, it’s worth touching up the item so that it doesn’t lose its shine and always looks attractive!

Coating methods

The technique of applying decorative plaster coat can be done either manually or mechanically. Manual methods are used when the amount of work to be done is small. But what to do if you have to process a lot of “squares” of the wall.

In this case, preference should be given to the mechanical method of applying plaster, which is ideal for working with large areas.

Brush and board

The first method, which has been known to our grandparents for a long time. The tool required is a stiff brush and a small board. Dip the brush into the plaster mixture and turn it upside down with the bristles, placing it in a horizontal plane. Next, we begin to move the board along the surface of the brush in the direction from the wall towards us. Under the influence of the board, the hairs of the brush bend, and then, when the board moves further, under the influence of elastic force they straighten and shoot pieces of the mixture along the wall.

This method is more suitable for applying thin, decorative layers of plaster under a fur coat and is not used to create thick sound and heat insulating layers.

Net

Not very common, but quite valid, is the method of applying plaster under a fur coat through a mesh. To do this, a fine mesh netting is fixed at some distance in front of the wall, and then, using a construction trowel, you begin to throw small portions of the plaster mixture through it. Flying through the mesh, they break and form quite interesting patterns on the surface of the wall. After finishing work, do not forget to remove the mesh.

With a broom

When using this method of applying plaster under a fur coat, you will need, as is clear from the name of the method, a broom and a stick. Take a stick in one hand and place it horizontally at ground level next to the surface of the wall that you will be covering. Next, dip the broom into the plaster mixture and apply it with a light, sharp blow to the stick. Under the influence of centrifugal force, particles of plaster fly off the surface of the broom, splash onto the surface of the wall and “stick” to it.

This method is quite labor-intensive and time-consuming. With one portion, you apply a small amount of the mixture to the wall surface.

Therefore, a fairly large number of such movements will be needed, as a result of which it is used when processing small areas. By the way, we do not recommend using a sorghum broom when performing this type of work, since the sand-plaster mixture has a fairly large mass, which, combined with blows on the stick, will quickly lead to damage to the broom. It is advisable to make a broom yourself from thin branches of a tree.

Roller

Using this method, we can get a thicker layer of plaster in less time spent on work. This is a more modern way of making fur coat plaster. The principle of its operation is similar to painting walls with paint using a roller. We take a shallow rectangular container, fill it with the plaster mixture, then dip a roller into it and then roll the mixture onto it along the wall.

You can also apply a portion of the mixture to the surface of the wall being treated and roll it out using a roller.

Manual sprinkler

Using a machine to apply plaster under a fur coat is considered a semi-professional method. The container is filled with the prepared mixture, after which the master begins to rotate the sprinkler handle. The handle rotates the shaft located under the mixture container. On this shaft there are many metal tendrils, which, rotating, will shoot particles of the mixture towards the surface being treated. This method is somewhat reminiscent of working with a roller.

Gun with compressor

Professional option. Plaster mixture under the influence of high pressure air flow,

which the compressor creates is directed from a hose to the surface of the wall. This method allows you to quickly and efficiently process large surfaces. Plaster under a fur coat applied in this way is more textured and durable compared to all previous methods. One of the obvious disadvantages of this method is the high cost of the equipment necessary for it.

Surface preparation

In order for the fur coat paint for facades to stick firmly, it is necessary to properly prepare the surface of the walls before applying it. This finishing material is suitable for walls made of the following materials:

- foam concrete blocks;

- plastered surface;

- bricks;

- tree.

First, any surfaces must be cleaned of dirt and old cladding. If there are gaps and cracks on the surface of the walls, you need to plaster them. After this, you should treat the work surface in such a way that the adhesion to the applied solution is good, and the decorative plaster lasts a long time and is quite durable. To do this, you need to take into account the degree of adhesion of each material in order to properly prepare the surface for plastering.

The sand-cement mortar should be applied to flat surfaces where the height difference does not exceed 2 cm. There is no need to carry out preparatory work on a flat and undamaged wall. If the concrete or brick walls in the cracks are uneven, then first they need to be rough-plastered, after which you can lay the fur coat.

Before applying such decorative plaster, wood must first be treated with lime-gypsum mortar and then primed. If the old wall peels off, it must first be treated with an antiseptic. The plaster will lie firmly on such a surface.

If the wall is brick

If facade paint coat is applied to brickwork, then you need to make notches on the bricks with a chisel to increase the adhesion of the brick surface. After this, you can apply the sand-cement mortar.

Descriptions of popular brands, photos

Plaster compositions designed to create mixtures with a “fur coat” effect are sold by many renowned manufacturers . To make your choice more informed, it is worth familiarizing yourself with the brand names and their key features.

Knauf

This brand has long established itself in the construction materials market. The company's assortment includes a product that allows you to obtain a “fur coat” coating. It is called Knauf Diamant Shuba and is sold in 25 kg bags in the form of a dry mixture for self-breeding. Its key advantages:

- suitable for façade and interior wall decoration;

- a diluted mixture allows you to obtain plaster that, when dried, forms a structure characterized by pronounced graininess and roughness;

- plaster can be repeatedly repainted;

- the composition can be applied to the surface being processed either using hand tools or using professional spray compression equipment;

- textured surface allows you to create a spectacular design of a room or facade;

- has water-repellent properties and protects walls from getting wet;

- not affected by adverse weather and atmospheric factors.

Specifications:

- Dry density: less than 1400 kg/m3.

- Compressive strength: more than 3.5 MPa.

- Vapor permeability index: 0.04 mg/m·h·Pa.

- Water absorption rate: less than 15%.

- Withstands more than 50 freeze-thaw cycles.

- The shelf life, while maintaining the integrity of the packaging, is 12 months.

The mixture consumption rate per square meter of surface (excluding possible losses) is 3.8 kg/m2. The water consumption level for this composition is 0.28 liters per 1 kilogram of dry mixture.

Lakra

Lakra is a domestic brand producing dry and ready-made mixtures, paint and varnish compositions and other materials for home repair and decoration. The composition in question is sold completely ready for use and is manufactured on the basis of an acrylic water dispersion. Decorative plaster with a relief in the form of a “fur coat” is characterized by increased whiteness.

Other advantages of the composition include:

- high-quality coating that can eliminate minor unevenness and defects in the base;

- can be applied using a roller and does not require the use of expensive professional equipment;

- the coating is resistant to moisture and atmospheric factors, as well as loads during operation;

- the plaster layer is highly durable and permeable to steam, which allows the walls to “breathe”;

- excellent adhesion to surfaces made of various materials - concrete, brick, chipboard, plaster, natural stone, etc.;

- contains no solvents;

- no smell;

- the painted surface can be washed.

The ready-made composition of the Lakra brand can be used for plastering both external and internal surfaces, which must be pre-prepared before applying the plaster as follows:

- The plane must be cleaned of traces of dust, dirt and remnants of the old coating, if any.

- All surface defects must be eliminated by knocking down sagging and filling cracks and depressions.

- The plane must be treated with a water-dispersion based primer to increase adhesion.

- Application is carried out at an air temperature of at least 12°C and a humidity of about 80%.

- Before applying the plaster mass to the surface, it is recommended to mix thoroughly without diluting.

- Plastering is done using a roller; the type of texture formed will directly depend on the length of the pile on it and the thickness of the mixture layer.

- Uniform distribution of the composition is possible within 20 minutes, otherwise visually noticeable joints between sections may occur.

- To finish large areas, it is recommended to involve several workers.

- If the master performs the treatment alone, the coating is applied to a small area and then structured.

- After this, you can begin immediately finishing the next fragment of the surface.

- To wash instruments, the manufacturer recommends using only clean water, without adding solvents.

The shelf life of the finished composition is 2 years from the date of manufacture. It is recommended to store the plaster mixture that is not immediately used in the manufacturer’s container and cover it tightly with a lid to prevent drying out, at an air temperature in the range from +5 to +35 degrees. The composition is able to withstand up to 5 freeze-thaw cycles, fully retaining its consumer qualities.

The product contains:

- water-based acrylic dispersion;

- mineral supplements;

- titanium dioxide;

- functional fillers and ethylene glycol.

Manual tinting using universal or water-based colorants is allowed, in a concentration not exceeding 5%.

Elbrus

White decorative plaster is sold in buckets weighing 15 kg, and is immediately ready for use. The composition can be applied to brick, concrete and other types of surfaces, creating an ideal, snow-white coating. Thanks to the texture of the composition, the surface looks optically voluminous. The “fur coat” effect can be achieved by applying it with a regular long-haired roller. This composition can be used for internal and external work.

Among the advantages of the material:

- affordable finishing cost;

- low material consumption: with one 15 kg bucket you can process about 25 m2 of surface;

- high strength indicators, good resistance to atmospheric factors;

- perfect for finishing wall finishing work;

- may be subject to frequent wetness, suitable for washing with a damp cloth.

KNAUF-Diamant

A line of cement decorative plasters for exterior and interior use. Structure (bark beetle 1.5/2.5 coat 1.5/3.0).

Cement-based mineral structural plaster with modifying additives and water-repellent properties.

Main color: white.

More details

Advantages

- Variety of designs. The surface structure of Knauf-Diamant plaster is textured, in the form of a “fur coat or bark beetle”.

- The optimal solution for decorating the facade and interior spaces

- Thanks to its water-repellent properties, it protects the wall surface from getting wet

- Resistance against adverse weather conditions

- The working solution can be applied manually or using continuously operating high-performance mortar mixing pumps G4, G5, Monojet (PFT)

Application

KNAUF DIAMOND is designed for exterior and interior use.

It is used for plastering building facades on the surface of cement plasters (for example, KNAUF-Unterputz, KNAUF-Grünband) and concrete, in external thermal insulation systems of buildings "KNAUF-Teplya Stena", indoors on gypsum plaster, KNAUF plasterboard sheets/gypsum building boards and etc.

During processing, depending on the type of mixture, a rough granular (fur coat) or grooved structure (bark beetle) is formed; the surface can be painted.

Application is manual or automatic using continuously operating high-performance mortar mixing pumps G4, G5 (PFT). The machines must be equipped with a D4-3 screw pair and a Rotomix-D stirrer.

The application process includes the following stages of work:

- Preparing the base surface: removing old coating, removing dust

- Preparation of the solution

- Application of the solution

After the plaster has dried, it is necessary to apply paint with high vapor permeability, appropriate for the operating conditions (facade or interior).

- During the work, fresh plaster should not be allowed to freeze or dry quickly before it hardens.

- Application of KNAUF-Diamant decorative plaster to the surface of KNAUF-Grünband, KNAUF-Unterputz plasters can only be done after the plaster layer has dried.

- To ensure uniformity on continuous surface areas, it is recommended to use plaster from the same production batch.

- Structuring of bark beetle plaster is done after partial drying (when the mixture stops sticking to the tool).

- Structuring of the “shuba” plaster is carried out immediately after applying the mixture.

- The structure is created using a plastic grater.

Specifications

- Density: 3 (dry)

- Compressive strength: > 3.5 MPa

- Vapor permeability coefficient: 0.04 mg/m h Pa

- Water absorption: 2 wall surfaces excluding losses:

- KNAUF-Diamant “fur coat” 3.0: 3.8 kg/m2

- KNAUF-Diamant “bark beetle” 1.5: 2.5 kg/m 2

- KNAUF-Diamant “bark beetle” 2.5: 3.5 kg/m 2

- KNAUF-Diamant “fur coat” 1.5: 2.5 kg/m 2

- KNAUF-Diamant “fur coat” 3.0: 0.28 l/kg

- KNAUF-Diamant “bark beetle” 1.5: 0.24-0.28 l/kg

- KNAUF-Diamant “bark beetle” 2.5: 0.24-0.28 l/kg

- KNAUF-Diamant “fur coat” 1.5: 0.24-0.28 l/kg

vote

Article rating

Where to order and buy?

You can purchase dry and ready-made mixtures for plastering the facade of a house and interior walls of premises both in large retail chains - Castorma, Leroy Merlin, and on the official websites of manufacturers of these materials, their distributors, as well as in small retail outlets.

Plaster finishing of facades and interior walls with a fur coat has been and remains in demand due to its affordable cost, high decorative effect and speed of work execution. Buildings finished using this technology look unusual and neat. It is important to choose the right shade of plaster to create a holistic composition , as well as to ensure the compatibility of this material with the base on which it will be applied.

Source

What is home decoration with fur coat?

This type of home decoration is used quite often in the individual construction of one-story and two-story country houses and cottages.

This is an inexpensive but decoratively effective method. This decorative plaster is used on flat surfaces - brick, concrete, facade putty, plaster. The fur coat is applied manually and mechanically. Solutions and mixtures for plaster:

- For plastering a fur coat, the simplest solution of cement M300 and M400 and sand in a ratio of 1:3 is quite suitable. If a colored shade of the solution is needed, then the cement should be taken white, since gray cement absorbs the color of the paint;

- A dry ready-made mixture for finishing facades, which is diluted with water to the consistency of mashed potatoes and whipped with a construction mixer or electric drill. A denser mixture fits better on the wall surface and shows its texture more clearly. Dry compositions are made based on cement. Their color can be light or colored;

- Ready-made mixtures in the form of solutions. Their chemical composition is different from the other two because they contain acrylic copolymers. The addition of polymers to the mixture gives the solution plasticity and adhesive properties. They fit perfectly on the wall surface, and due to their elasticity, they fill all the cracks on the surface of the treated walls of the house;

- A solution based on enamel paint, which is mixed with dry putty. This method gives a durable coating of the desired color.

Fur coat façade finishing technology

Textured plaster has been used in construction since the times of Ancient Greece, therefore, there are quite a few ways to perform it.

But any of them requires preparatory work. Cleaning the walls of the house from dirt, dust and large irregularities;

- Treating walls with an antiseptic;

- Applying a primer to the walls to better retain the plaster layer on them;

- Performing rough plastering. This work is carried out even with a flat wall surface. Rough plaster will improve the quality of the textured finish of the house and will require less mortar, time and effort.

Decorating a house with fur coats in various ways:

- The most modern way to decorate a house with fur coats is using a compressor. When spraying the solution with pebbles, it gives a high-quality, uniform layer on the wall surface. The size of the droplets can be adjusted, which allows you to control the quality of the texture;

- Applying the solution using a machine. The solution is sprayed onto the wall using rotating drum blades. The method is more labor-intensive, but the high quality is worth the effort;

- Automatic production machines for applying mortar to walls are used when it is necessary to work on large areas. The automatic machine itself prepares the mixture to the desired consistency and delivers it to the walls under pressure through a sprayer. This technique has high productivity, economical use of the solution and high speed;

- The manual method is the most labor-intensive, but also quite popular. The textured roller leaves the original surface. But hand plastering requires special skill and skill. If there is no experience in performing this method, then sharp edges may remain in the surface texture, which subsequently break off and damage the plaster.

With any method of applying fur coat plaster, there is a rule that must be followed - the begun section of the wall must be treated in one go with the same composition at a continuous pace. Compliance with this rule gives a high quality finish.