The garage is a separate room with its own microclimate. Therefore, its interior design must be suitable. Painting the walls and ceiling in the garage is carried out using compositions that are suitable for buildings with a low degree of thermal insulation. The quality of the resulting surface is also influenced by the choice of methodology and tools for carrying out the work.

Garage paint and room operating conditions

The decorative design must create an antistatic surface and be immune to the formation of pathogenic microorganisms. Before deciding what to paint the walls in the garage with, it is important to understand the essence of the use of the room itself:

- Garage is a poorly heated room;

- Based on the first point, the appearance of mold under such conditions is inevitable;

- The composition must include bactericidal components;

- First, the walls are coated with antiseptic agents.

The garage is rarely cleaned. That’s why there is a large accumulation of dust and dirt here.

The decorative design must create an antistatic surface and be immune to the formation of pathogenic microorganisms.

Important points

Nowadays, there is a wide variety of paint and varnish products that are made for different types of surfaces. Therefore, first you should decide what kind of paint you would like to use for the walls in the garage. When choosing paint you need to consider the following points:

Article on the topic: Is it possible to store drywall in a garage?

- As a rule, the garage contains flammable materials that can easily ignite, which is why the paint for the walls, ceiling or even floor must meet all fire safety requirements.

- Wall paint must be resistant to abrasion, as well as other mechanical stress.

- The finishing material you choose must be resistant to various chemicals and not absorb any odors.

Types of paint coatings suitable for garages

The choice of paint for the inside of a garage is based on the properties of the composition, as well as cost. Paints can be universal or intended for use in certain climatic conditions. The presence or absence of heating, and the material from which the structure itself is directly constructed are also fundamental factors.

Paints can be universal or intended for use in certain climatic conditions.

Pentaphale

The base is pentaphalic resin. It includes dyes, oils and other components. Pentaphal paints are divided into two types depending on their functional purpose.

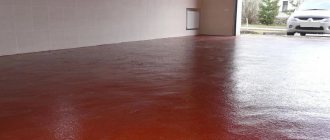

Painting the walls in the garage with pentaphale paints is carried out in various ways: rollers, brushes, and a spray gun. After application, it forms a protective, hydrophobic film with a high degree of density, which prevents the formation of pathogenic bacteria. There are several varieties of this type of paint.

After application, it forms a protective, hydrophobic film with a high degree of density.

Acrylic

The base of acrylic compositions is polyacrylates. Among the active components are organic solvents, which is why they are an environmentally friendly product that does not release toxic substances into the atmosphere.

Acrylic paints can be used to paint a garage made of any material. They are resistant to sunlight, have good hiding power and color fastness. At the same time, they have a long service life and low price.

Acrylic paints can be used to paint a garage made of any material.

Alkyd

Despite the apparent variety of alkyd paints, their composition remains unchanged: pentafal or glypthal varnishes, colors and solvents. The resulting indicators are achieved by adding various excipients. They stand out for their wear resistance and so on. Paints can have a glossy or matte finish. At the same time, this indicator does not affect their technical characteristics.

They stand out for their durability.

Epoxy

Garage paint based on epoxy resin is durable, has a wide choice of palettes, patterns, and is primarily resistant to abrasion. Thanks to the latter circumstance, epoxy compounds are ideal for decorating rooms with small space.

They are divided into:

- Powdery;

- In the form of sprays;

- Consisting of two components.

When working with such finishing materials, constant ventilation is necessary.

Garage paint based on epoxy resin is durable, has a wide range of colors and patterns, and is highly resistant to abrasion.

Polyurethane

This type of paintwork material is characterized by increased strength, wear resistance, and moisture impermeability. They are suitable for processing any type of surface, extending the service life of the material. They do not react to the influence of an aggressive environment, forming a strong thickened layer. A high hiding power will help hide minor unevenness on the surface.

This type of paintwork material is characterized by increased strength, wear resistance, and moisture impermeability.

The best way to paint a metal garage

Painting a metal garage requires the most effort. The main task of the work is to eliminate and prevent the occurrence of corrosion. It is important to protect the room from atmospheric influences, give it a neat appearance, and create a unique design.

Exterior painting

When choosing paint for exterior painting of a metal garage, you must give preference to products that can withstand temperature changes, precipitation, and gusty winds. Poor-quality paintwork can quickly peel off, losing its beautiful appearance and color saturation. The ideal solution for exterior painting is water-based enamel. The advantages of this material include:

- Brightness and durability of the applied coating.

- Anti-corrosion effect.

- High water resistance.

- Fast polymerization (within 4 hours).

- High level of elasticity.

- Increased adhesion.

- Not afraid of temperature changes and direct sunlight.

Interior work

For interior decoration, it is worth choosing acrylic paints, as they can be cleaned dry and wet and do not accumulate dust and dirt. You can choose any shade of paint from a huge selection.

How to choose the right coating

How to paint the walls in a garage if it is not heated? Materials for outdoor work that have improved performance. The optimal choice here is polyurethane mixtures, which can be applied in a wide temperature range from -10 to +35 degrees. Acrylic mixtures are no less reliable than polyurethane ones, but at the same time they are the most affordable. The choice is wider for the design of a heated garage. All of the above compositions are suitable for it.

The optimal choice here is polyurethane mixtures, which can be applied in a wide temperature range from -10 to +35 degrees.

Preparing the car surface before painting

Having prepared the garage for painting work, you should move on to preparing the car itself. First of all, you need to thoroughly wash and dry the car, and, if necessary, carry out repair work.

Removing paintwork

To remove old paint and varnish coatings, mechanical and chemical methods are most often used.

For mechanical cleaning, tools are used: scrapers, metal brushes, scrapers, emery stones. The mechanical method is the simplest, but it is labor-intensive and inconvenient in hard-to-reach places. Rinse-off compositions are used for preliminary softening of durable paint and varnish coatings.

Auto repair plants use the method of immersing the body in a hot caustic solution and then rinsing it with hot water. To remove coatings from certain parts of the body, car enthusiasts use washes based on organic solvents.

You can prepare the simplest wash yourself. Dissolve 10 parts of finely planed paraffin at 70-80 ° C in 45 parts of xylene. After this, cool it to 45-55 ° C and, while stirring, add 45 parts of acetone. Cool the mixture to room temperature.

Preparing the wash is a fire-hazardous process, so it must be done in a water bath and not over an open fire.

Degreasing and putty

Before applying the primer, any uneven areas or dents on the surface should be filled. To eliminate deep defects, use a fiberglass-based product. Before application, it is necessary to clean the area with sandpaper and degrease with a solvent.

After this, sanding is done using a grinding machine or sandpaper. They degrease the car with a solvent and obtain an ideal surface on which primer and paint can be applied.

Padding

Scheme of painting work.

The primer is used to prevent corrosion, improve adhesive properties and level out small irregularities. Before application, the primer is filtered and the working surface is degreased.

Priming is done with a spray gun. First of all, the putty areas are primed, and then the entire surface is coated in several layers. Each layer must be thoroughly dried before applying the next. Avoid smudges and uneven spots when priming as they will be visible after painting.

Tips for choosing colors

This is a space in which there is little natural light, so light shades are advantageous. Here color will help in zoning the area. Considering that the garage is a place with sacred significance, where men spend a lot of time, when choosing the color of the walls in the garage, its “psychology” should be taken into account. See how it affects a person’s well-being and mood.

This is a space in which there is little natural light, so light shades are advantageous.

Ceramic tile finishing

This is the material that ideally meets all the stated requirements that we talked about earlier. The material is fireproof, beautiful, reliable, durable, easy to wash, and resistant to moisture. Such a wall will be able to withstand various types of loads.

To decorate the walls and floor of the garage, it is recommended to use clinker and porcelain tiles. They have high strength, scratch resistance and excellent wear resistance. And due to the matte coating, you will get a non-slip surface. If you want to save money, you can use regular tiles.

Advice! To save money, only the lower part of the walls, which is especially exposed to load and external factors, can be treated with clinker tiles. You can paint the top part or apply decorative plaster.

As for the disadvantages of the material, it is worth noting the heavy weight and high cost of both the tiles and their installation.

Tools for work

The speed and quality of work carried out is influenced by correctly selected work equipment: roller, spray gun, brushes, containers.

Spray gun

Working with a spray gun is easy for experienced craftsmen. The device allows paint to penetrate even small cracks, sealing them well. However, only people with experience can work with it.

The device allows paint to penetrate even small cracks, sealing them well.

Paint roller

For alkyd compositions, a tool with a velor coloring part is suitable. For water-dispersed ones - foam rubber, polyamide or with a soft part made of natural materials.

For alkyd compositions, a tool with a velor coloring part is suitable.

Paint brushes

Brushes are divided into two categories: those with natural fibers and those with artificial fibers (polyester). With all the advantages of natural pile, it quickly loses its original, working shape. On flat surfaces it is more convenient to work with flat brushes, in corners - with round ones. It is advisable to choose products with a wooden handle.

On flat surfaces it is more convenient to work with flat brushes, in corners - with round ones.

Plasterboard finishing

Instead of doing “wet plastering” to level the walls and prepare them for further finishing, you can use the “dry” method, which involves covering the walls with plasterboard. Thanks to the sheets, you will achieve a perfectly flat surface that will match any finish.

It is better to use moisture-resistant and fire-resistant drywall, which will be attached directly to the wall with glue or to a metal frame. The second option provides the opportunity to insulate the walls by filling the space with mineral wool or polystyrene foam.

Pros of drywall:

- Light weight.

- Easy installation.

- No dirt or construction debris during work.

- Affordability.

- Possibility to sheathe even arched structures.

- Versatility. Subsequent finishing can be very diverse.

Painting methods

The coloring method is selected based on the working conditions. In an empty room, it is better to work with a sprayer, giving preference to compositions with a thick texture. Where there is furniture, it is easier to work with a brush or roller. Seams and brickwork are easier to work with a brush.

In an empty room, it is better to work with a sprayer, giving preference to compositions with a thick texture.

General information

Please note that coating for garage walls and ceilings (the same applies to workshops) should not be too expensive, but it should be durable.

And yes, there is one more condition - resistance to the formation of mold, mildew and antistatic surface in general. But which paints and varnishes will meet all the necessary conditions?

Operating conditions in the garage

Before deciding what paint to paint the walls in the garage, first consider the conditions under which the painting compositions will be used:

- According to statistics, only 5% of garages are constantly heated. The remaining rooms are heated only during the cold and snowy season, or are not heated at all. But what kind of garage paint can you use? We'll talk about this a little later.

- If there is no regular heating, mold can form, and the likelihood of its occurrence is quite high.

- Because of this, it is very important that the coating materials contain special additives (namely bactericidal components).

- If a special composition with an antiseptic effect is applied to the surface of the walls and ceiling in the garage before applying paint, this provides a guarantee of durability.

What other points should you pay attention to before painting the walls in your garage?

A garage is a special-purpose room where cleanliness is not particularly monitored. This means that there is often dust, dirt and even soot from exhaust gases that appear due to heating.

Interestingly, because of this, when choosing what color to choose for painting the walls of the garage, it is better to opt for non-staining, but not very dark shades. Simply put, you should be clear on when to clean the surface.

Besides:

- If you frequently clean your garage, choose a coating that will withstand abrasion well, both wet and dry.

- When selecting a composition for future repairs in the garage, remember that you are choosing a coating for concrete walls.

- This should be taken into account when purchasing paint and varnish materials, as well as when you are going to prepare the garage for painting.

Article on the topic: Where is the garage in watch dogs 2

Technology of work execution

The plane is first primed. This improves subsequent grip. The primer helps reduce paint consumption. You need to choose it based on the base material.

Vertical surfaces subject to condensation are additionally coated with an appropriate primer. A primer with a matting effect will help to achieve an even coating on the old one.

The primer helps reduce paint consumption.

Tools and materials

To perform these works, you will need the following materials:

- beauty;

- putty;

- primer;

- masking tape;

- sandpaper with fine and coarse grains.

In addition, you must have the following tools:

- paint container;

- drill with attachment;

- wide and narrow spatula;

- individual protection means;

- roller tray;

- roller and several brushes of different sizes;

- container for putty.

Preparatory work

Painting the inside of a garage involves a number of preparatory works. Initially, you need to prepare the walls by removing the old decoration. Then they are primed.

Initially, you need to prepare the walls by removing the old decoration.

Stages of preparation of brick and concrete surfaces

First, the walls are inspected for unevenness and chips. Then all cement stains are removed. Check the quality of the brick plaster. If necessary, loose elements are fixed using a cement-sand mixture. The seams are filled with cement mixture.

Oil stains should be removed as they will bleed through the paint over time. If possible, the walls are washed or at least vacuumed.

If possible, the walls are washed or at least vacuumed.

Stages of preparation of metal surfaces

The old coating is removed from the surfaces using a suitable method. Then, solvents are used to remove oil stains. Rust is removed with a special remover. Irregularities are eliminated with metal putty.

Rust is removed with a special remover.

Stages of preparing wooden surfaces

The old coating is removed. The surface is degreased, and the existing depressions are sealed with a special wood putty. Then, the surface is sanded, cleaned of dust and primed.

The surface is degreased, and the existing depressions are sealed with a special wood putty.

Selection of paint and varnish material

Previously, it was easier to choose paint, since the assortment was scarce. There are many paints on store shelves today, but not all of them can be used on concrete. It all depends on the operating conditions. Having considered the features, advantages and disadvantages, you can choose what to paint your concrete floor, ceiling or walls.

Oil-based paints and varnishes

The products are made on an oil base. It has long been used for painting interior and exterior surfaces. However, due to the toxic composition due to solvents, it is better not to use it inside. Has a pungent odor. Advantages:

- Affordable price.

- Withstands the negative impact of the street, is not afraid of moisture and other atmospheric factors.

- A durable and beautiful coating is created.

- Oil-based paint can be susceptible to dust and dirt, but it is easy to clean with gentle products.

- Long service life.

- Good adhesion.

- Large selection of colors.

Flaws:

- Strong smell. Requires waiting for weathering before moving in.

- Toxicity.

- Long drying time, 24 hours or more.

- Has low elasticity, if the concrete cracks, the paint will tear.

- The color is unstable. The drying oil will turn yellow as it is used.

To conclude, oil paint for concrete walls is good if you need to repaint a storage area or other exterior surfaces. After all, it is cheap and practical. But it is better not to use it for work around the house or garage.

Water based paint

Water emulsion and dispersion are an excellent option for interior painting. It is water-based, so it has many advantages. There are no harmful substances in the composition. It can be used to paint concrete walls, ceilings and interior floors. There are façade paints for exterior use. The packaging indicates for what purposes the composition can be used.

Advantages:

- Environmentally friendly.

- Not afraid of moisture.

- Dries quickly.

- Has no smell.

- Easy to use.

- Paints can be sold in white and tinted by hand.

As for the disadvantages, the only thing we can note is the cost. It is low, but oil formulations are cheaper.

Acrylic paint

A universal option, it can be used to paint concrete ceilings, floors, walls inside and outside. It is based on acrylates, which give the composition special properties. The packaging indicates for what purposes it is used: “Ceiling”, “Facade”, “For walls”. Acrylic compositions are also used for artistic painting.

Advantages:

- Environmentally friendly.

- Not afraid of mechanical impact.

- Elastic.

- Vapor permeable, the walls will breathe without condensation.

- Has a stable color throughout its entire service life.

- Possibility of tinting.

- Long service life.

- Not afraid of moisture.

The downside is the cost. It is high. But if you consider the benefits, the price is justified. When choosing what to paint a concrete wall with, you can safely buy alkyd compounds.

Silicate based

It is also called glass paint, as it is based on liquid glass. Thanks to this, a durable film is created on the surface after painting, protecting the structure of the concrete surface. Suitable for indoor and outdoor surfaces.

Advantages of silicate paints:

- Not afraid of chemical exposure.

- Has stable color.

- Strong and durable.

- Protected from fire.

- Not afraid of moisture.

- Resistant to biological factors (development of mold and other microorganisms).

- Very wear-resistant.

Their disadvantages are that they are expensive, and contain toxic substances, so when working with them, it is important to take care of respiratory protection

Impregnations for concrete

Painting walls requires preparation. Before the process, it is better to coat the surface with a special impregnation. This will preserve the surface from dirt, moisture and aggressive environments. The impregnation will penetrate the concrete structure and strengthen it. The compositions are made on an acrylic base, polyurethane or epoxy resins. In addition, preliminary application will reduce paint consumption. After all, concrete has a porous structure and absorbs liquids well.

After applying the impregnation, the wall will dry in a few hours (exact time on the packaging). After this, the wall, floor or ceiling will be ready for painting. The impregnation itself is transparent and may also have additional properties, for example, antiseptic. Having considered the features of paints, you can choose what to paint your concrete floor with.

Features of painting on plaster

The process of preparing previously plastered surfaces is similar to the pre-treatment of any others. All uneven surfaces are also puttied. Then the surface is dried, a layer of primer is applied, after which the walls must dry well for at least six hours.

Taking into account the porosity of the material structure, paint consumption for treating plastered surfaces doubles.

The surface is dried, a layer of primer is applied, after which the walls must dry thoroughly for at least six hours.

Painting a cinder block garage

A garage made of brick or cinder block has several options for paint application technology. Each of them will have a completely different result, so it is important to determine the desired result. The main rule is the mandatory application of a primer. This procedure will help increase the adhesion of the paint to the surface and improve the quality of the final result. IMPORTANT: after painting, all wall defects (chips, cracks, unevenness) will remain visible. Therefore, it is necessary to prepare the area for painting as much as possible.

Many experts recommend applying putty to brick and cinder block. When plastered, the wall will become perfectly smooth and the seams between the materials will be hidden. You can also be satisfied with a double layer of primer: in this case, you will have the opportunity to give the room an original design by painting the seams in a contrasting color.

To paint a brick garage, it is better to use:

- Epoxy primer enamels.

- Polyurethane paint.

- Water-emulsion acrylic compositions.

- Perchlorovinyl paints.

Dyeing process

Following simple “steps” will help make the process easier. By following these recommendations, you can save material consumption:

- The base layer should not be thick;

- Painting begins from any of the corners.

Paints based on polyurethane or alkyd resin are applied in strokes, which are then rubbed over the surface.

Painting begins from any of the corners.

What should you pay attention to?

As a rule, fuels and lubricants are stored inside garages. Therefore, paints for interior decoration must meet safety requirements and resistance to open fire. Resistance to abrasion and most mechanical damage is important.

Finally, the composition must absorb various odors to a minimum and be resistant to aggressive chemicals.

How to care for painted garage walls

Not only painting, but also subsequent proper care will help keep the coating in good condition for a long period. If oil stains appear, they can be removed immediately using water and detergent.

Industrial stains are removed with a solvent. Cracks that appear are immediately puttied, leveled and repainted. Clean the walls with a soft cloth soaked in soapy water.

If oil stains appear, they can be removed immediately using water and detergent.

Material requirements

A garage is a specific room with an increased fire hazard and a high level of pollution. You should not choose paint that contains flammable elements. It is better to give preference to a material that is resistant to fire. It is equally important that the product has a durable structure: temperature changes and dampness will negatively affect the interior and exterior finishes.

A plus will be the presence of antifungal components in the coating: they will help to avoid a dangerous problem - the appearance of mold on the walls and ceiling. An alternative would be to apply additional anti-fungal agent to the walls and ceiling before painting. Garage paint must be resistant to chemicals, and also easy to clean with detergents and not wear off. An improved ventilation system will help the paint look impressive for a long time.

Useful tips from the experts

Experts advise choosing the right paint. The service life of the coating depends on this. Attention is paid to characteristics. It is important to remember that the garage is not a place where flammable coatings are used. It is not necessary to paint the garage walls with expensive compounds. Budget options are suitable.

Experts advise choosing the right paint.

Painting a garage is not a very different process from painting other spaces. And paints are not a particularly demanding finishing option. The main thing is to take into account the standard recommendations: choose the right coating material, its color, and also take the time to prepare the surface and tools.

Aftercare

Applying the composition beautifully is the initial stage of the “life” of the paintwork. It is important to provide care for painted surfaces, which depends on the type of paint and the method of application.

There are several rules that help maintain an attractive appearance:

- To remove oil and grease stains, use wipes soaked in anti-greasy cleaning solutions.

- White Spirit is used to remove chemical contaminants.

- If several defects are identified, they need to not only be puttied, but also dried and sanded.

- Every 2 weeks, painted surfaces should be wiped with a cloth soaked in an aqueous solution.

With proper use, this coating will last for decades.

Important nuances for organizing an inspection pit

A functional area such as an inspection pit is intended for construction in modern garages. This facility will help if there is a need for independent technical inspection or car repair:

- The pit should be organized at the stage of foundation construction, having previously studied the groundwater level.

- The walls must be lined with bricks. This will prevent them from collapsing during operation.

- A shallow niche should be built inside the pit at elbow level. It will serve for temporary storage of tools that will be useful in work.

- To ensure your own safety, you need to purchase a grate for the pit itself. You can weld it yourself from fittings and stylish corners.

- The dimensions of the inspection pit must correspond to the height and body shape of the person. Moreover, in this case you cannot do without stairs and steps.

Wood finishing Source remoo.ru

Garage for sports equipment Source raphaeldesign.ru

Beautiful interior Source remoo.ru

Classification of garage structures by material

Modern garage structures can be made of different materials, both classic and more modern, which are less common. The most common options for these buildings today are:

- capital;

- temporary;

- combined;

- wooden;

- metal;

- foam concrete.

The garage can be made of brick, metal, wood or foam concrete

Distinctive features of capital, temporary and combined buildings

Capital. The main material used in the construction of such a garage is brick. The decor of such a building can be different and depends on the individual preferences of the owners.

The advantages of a permanent garage include a presentable appearance and a long service life, which amounts to several decades. In addition to lighting, a heating system is often installed in a brick garage (photos of this design allow you to appreciate its obvious advantages).

Brick is used for the construction of permanent garage structures

Temporary. Such a structure for a car is most often assembled from scrap materials. This can be a wooden board or metal sheets. A popular option is to use corrugated sheets. A temporary garage can be made with or without walls. In the second case, it is a regular canopy, the dimensions of which should be sufficient to protect the car from precipitation.

This design is used when temporary parking for a car is needed. It is designed for 1-2 years and is most often performed during the construction of a residential building. In the future, the temporary structure will be replaced with a more reliable structure. Temporary garages include a type of garage called a prefabricated garage. You can buy a garage of this type on the Internet by placing an order on any specialized website.

As a rule, temporary garages are designed for 1-2 years of operation

Combined. Such buildings combine the features of the first and second types of garages. The construction time of the combined structure is only a few days (if everything is calculated correctly). For such a construction, you will need to purchase a metal frame, which is installed on a ready-made permanent foundation. Siding, corrugated sheeting, as well as a block house - all this is used to decorate the exterior design of the garage. Inside such a structure, lighting is provided and racks or shelves are installed to allow you to store tools and other items.

Characteristics of wooden, metal and foam concrete garages

Wooden. Garages made of wood are extremely rare. This is due to the fact that wood cannot compete with other materials. Structures made of foam concrete or brick have many advantages, so wooden buildings are gradually disappearing. The main advantage of such garages is their presentable appearance. A wooden structure can decorate any area.

Wooden garages have a presentable appearance and look good on the site

Helpful information! When choosing the material from which the future construction will be made, it is necessary to take into account the climatic conditions in your region.

Metal. The most popular garage option today. This is due to the fact that it is simple and practical, and its cost is quite attractive, especially when compared with permanent buildings. The metal group includes quite interesting types of garages, made of shells, and a pencil case garage. Buying these protective structures is quite simple, but they do not have the same list of advantages as permanent buildings.

Today the most popular are metal garages.

Foam concrete. Such garages have many advantages and are recommended as permanent structures to protect the car. In addition to a long service life, it is worth noting that these structures are resistant to fire and also retain heat well. The second property allows you to protect a car located inside a foam concrete structure from the negative effects of low temperatures. Photos of houses with garages made of foam concrete indicate the solidity of these structures.

Having decided on the type of garage and the material from which it will be built, you can begin to create a plan for the future structure. You can do it yourself or order it from specialists. You can also easily download the plan on the Internet, where many ready-made projects are offered. When using a ready-made scheme, remember that it must correspond to the individual characteristics of your site.

Foam concrete garages are durable, fire-resistant and retain heat well

Features of a floor with an inspection hole

The arrangement of the floor in a garage with an inspection hole has some features. There must be good waterproofing, otherwise it will simply be impossible to use. If the car sits in damp conditions for a long time, its parts will deteriorate and rot much faster.

Before digging a hole for inspection, it is necessary to measure the groundwater level.

It is necessary to make a strong iron frame along the edge of the pit. It will restrain the pressure of the machine in statics and dynamics. Otherwise, the wheels will push through the screed, and its crumbs will fall directly into the hole. As additional stops, special channels are placed in the area of the wheels.

It is possible to provide lighting into the pit, powered by 36 volts. If the value is higher, an accident may occur if fuel vapors ignite.

Garage interior

The optimal design of a garage should not only be visually attractive, but also convenient for its owner. Various decor and all sorts of little things would be out of place here. To emphasize your individuality and create a pleasant environment for your stay, you can decorate the walls with posters, placards, and tool stands. Minor details should not take up much space.

After completing your garage renovation, it is important to keep it tidy. The ease of use will depend on this. In a cluttered room it will be difficult to find the things you need. To hide open shelves and racks from view, use tarpaulin screens or water-repellent curtains.

To quickly sweep away debris, it is necessary to provide special holes on the shelves.

Types of construction

Many owners of private houses are thinking about building a garage if they don’t have one in the first place. For residents of multi-storey apartments, this will be a little more difficult, because for so many residents it is difficult to allocate space for a car for everyone, and not everyone has one.

To know what exactly is best to build, you need to have a clear idea of what type of structure is best suited for a particular home. It is believed that the most successful option is a built-in garage, which is a single building along with the house. It is easy to supply light and water and is much more convenient to use, but it also has its drawbacks. Due to the entry and exit of cars in this room, exhaust gases are released that enter the house. This in itself is of little use, but there are also people who are especially sensitive to odors.

The way out of the situation can be considered a good hood or ventilation, but it can be noisy, which will create discomfort, or ineffective, and money and time on its installation will simply be wasted. In this regard, in houses where people live permanently, they try not to build a house with a built-in garage.

Another type is the garage under the house. This is a rarely used option due to the risk of fire. In addition, the cost of constructing such a building will be approximately equal to a residential building, which is completely unprofitable.

You can make an extension to the house so as to use one of its walls for a garage, but do not combine it with a residential building. This option will make it easy to carry out all communications and not harm household members with harmful fumes from the garage. Essentially, he is building separately, only using one wall of the house.

You can build a garage separately from the house. This is done if an extension is impossible or the location of the house does not allow convenient and quick access to the garage. A separate room can be made of different materials. The simplest would be a metal garage; sometimes it can be purchased ready-made and simply installed on a prepared foundation. In addition, you can build it from brick or cinder block so that the construction is permanent.

A metal garage can also be lined with masonry to be able to insulate it, and maybe even add a second floor. It will be easier with brick options, they are initially ready for the fact that you can add a meter of masonry to them, install a roof and there will be a second floor in the form of an attic room, which can be used as a pantry, warehouse or corner of the owner of the house.

Buildings finished with metal sheets are easy to install, but they are very cold in the winter. In addition, it can be easily hacked and there is a high risk of fire. If you build a building from corrugated sheets, then the positive aspect will be its cost and simplicity of design, and the negative aspect will be the cold in winter.

Sandwich panels, which can be easily assembled, are frost-resistant, aesthetically pleasing and environmentally friendly - are an excellent option for creating a motorhome.

A wooden garage is considered a budget option, but is environmentally friendly and durable. It also has significant disadvantages - it is afraid of moisture and fire, and also strongly absorbs odors.

You can build a garage from polycarbonate, which in the right hands looks great, is lightweight, has good heat and sound insulation, does not burn, is durable and wear-resistant. The only downside is that it can be hacked.

As for garage designs, the following options are distinguished:

- frame rooms - made of wood;

- collapsible - made of metal;

- Shell garages and pencil case garages are small spaces exclusively for a car;

- awning structures;

- construction from a sea container.

What tools help with coloring?

The following devices are used for application:

- Roller. It is most successfully used for large areas, smooth surfaces. The type of tool is selected depending on the material to be processed. For example, foam rubber is best used with aqueous dispersions. For water-emulsion ones, a fur version with medium pile is more suitable.

- Brush. It will be useful in the case of reliefs and surfaces of small areas. In addition, brushes go well with paintwork materials that contain organic solvents.

- Spray gun. It is indispensable if someone wants to figure out how to paint a garage. The high speed of work in this case becomes the main advantage. The spray gun will apply the material in just a few minutes, although a brush may take hours. It is better to choose models that can work with dense compounds. They will be the best choice for garages. Compared to other modifications, the nozzle diameter of these models will always be larger. Free spraying is guaranteed with thicker paint. But the high cost makes tools a less common solution.

In the video: painting garage walls with a spray gun.

How to paint a garage with your own hands inside and outside: Gates and walls: description of the process + Video and Photo

Construction of a garage is another half of the work; after that, the building is brought into decent shape, finishing is done inside and outside. The assortment of finishing materials will delight those buyers who are planning to decorate their garage. Painting a garage can be done in 2-4 days if you do it yourself. This finishing method does not require large labor and financial investments. You can cope with the task yourself, since no special skills are required in this matter.

When choosing paint and varnish materials, be guided by knowledge of the characteristics of the material from which the garage is built. This is due to the fact that for each material, standards for working with it are established. For example, in a garage built of brick or foam block, the walls are first plastered, and only after that paint is applied.

Simple puttying of the wall will not give the expected result, since it disrupts the degree of adhesion of the paint to the surface.