Of the various types of posts used to build fences in summer cottages, pipes are used in most cases. Firstly, the material is from a moderate price category, durable, easy to use. Secondly, it combines perfectly with other materials.

Depending on the type of barrier, different types of pipes are selected. Use round, rectangular and square. Round ones are a little cheaper, but square or rectangular ones are stronger and easier to work with.

Painting fence posts will not only give the fence an aesthetic appearance, but will also protect the pipes from corrosion. Regardless of whether the material was used or new, the preparation requirements are the same.

To pre-treat pipes you will need:

- metal brush;

- brushes for power tools;

- grinding wheels;

- sandpaper;

- personal protective equipment.

The treated surface is thoroughly cleaned of rust and dirt. A suitable tool for this purpose is selected. Washing may be necessary to remove old paint. The stores offer a wide range of removers for old paint.

How to treat metal fence posts

- Bitumen mastic

- Bitumen varnish

- Paint treatment

- Paint "Special Forces"

- General rules for painting work

Of the various types of posts used to build fences in summer cottages, pipes are used in most cases.

Firstly, the material is from a moderate price category, durable, easy to use. Secondly, it combines perfectly with other materials. Depending on the type of barrier, different types of pipes are selected. Use round, rectangular and square. Round ones are a little cheaper, but square or rectangular ones are stronger and easier to work with.

Painting fence posts will not only give the fence an aesthetic appearance, but will also protect the pipes from corrosion. Regardless of whether the material was used or new, the preparation requirements are the same.

To pre-treat pipes you will need:

- metal brush;

- brushes for power tools;

- grinding wheels;

- sandpaper;

- personal protective equipment.

The treated surface is thoroughly cleaned of rust and dirt. A suitable tool for this purpose is selected. Washing may be necessary to remove old paint. The stores offer a wide range of removers for old paint.

Tool selection

The most popular tool for painting fences and posts is a standard paint brush. First of all, this choice is dictated by the need to paint in hard-to-reach places and on raised areas of the structure. For most types of materials, a natural hair brush is considered the best choice. Before starting work, the brush should be fluffed - this is necessary to get rid of loose bristles, otherwise they will remain on the painted surface during painting.

For a smooth surface, a roller with medium or long pile is suitable. Foam rollers are not the best choice because they leave small air bubbles on the surface.

Another option is a spray gun. To treat hard-to-reach areas, it is necessary to change the spray angle and paint supply power. Modern models of spray guns allow you to work not only quickly, but also economically, in terms of paint and varnish composition consumption.

Note! It is recommended to prime and paint using different tools. If this is not possible, the instrument must be thoroughly washed and dried between different operations.

If the post is covered with a layer of old paint, the surface will need to be cleaned before painting can begin. To mechanically clean the post, you will need a metal brush, scraper and spatula. A more advanced cleaning method is a special attachment for an electric drill. You can also use sandpaper, a rag or chemicals. The thermal cleaning method requires the presence of a hair dryer, gas burner or soldering iron.

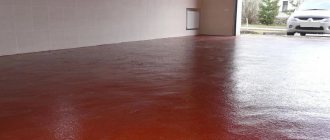

Bitumen mastic

Bituminous mastic is widely used in various construction works as a protective and waterproofing material. In the case of support pillars, it is necessary to process that part of the pipes that will be buried or cemented. This will help protect the metal from water and salts dissolved in it. Fence support posts can be painted prior to installation. At the same time, the drying time increases, since the lower plane is not painted, and it is simply difficult to work with round material. In addition, the finished surface can be damaged quite easily. Therefore, it is better to apply paint after installation.

If welding work is expected, then the coating must be applied after completion, carefully cleaning the weld seams!

For ferrous steel, solvent rinsing is used without subsequent water rinsing. What kind of fence posts should I use? To degrease, you can wipe it with a rag soaked in white spirit and let it dry. It is not recommended to use solvent for degreasing galvanized surfaces.

It is better to wash the posts and joists with soap and water. Then rinse with clean water and wipe dry.

Recommendations from the experts

In order to paint the fence once and not return to this issue for many years, it is recommended to follow the indicated tips:

- It is not recommended to prime metal surfaces with a roller, due to its ability to drive excess air and moisture into the primer - as a result, the fence will quickly rust.

- The optimal temperature for performing work is +5+40°C, humidity level is from 80 to 85%;

- You cannot add too much solvent to the paint - the paint layer will cover the fence with a thin transparent layer.

- A roller and brush will not be able to provide an equally shiny and smooth layer on par with a spray gun.

Before choosing what paint to paint a fence with, it is worth remembering the most important thing: the process of covering a metal fence with a protective and at the same time decorative layer requires studying the types of materials and technologies for their application. Fence paint can prevent metal corrosion or improve the physical parameters of the structure in cases where it makes sense to go over previously formed rust.

Paint treatment

When choosing paint, the main thing is to decide on the color scheme and buy material from one manufacturer. This will guarantee that the color scheme will not change. In case of special wishes for color, you will have to use different types. When purchasing for mixing, consultation with a specialist is necessary, since not all paints can be mixed. They can curdle like milk, which can ruin the whole process. And since we are talking about a dacha, here we are talking about more economical options. When painting, oil, acrylic, alkyd and other paints are used. It all depends on your wishes: a matte or glossy finish will be the final product. Oil paints are considered the most economical, but have a number of disadvantages: they take a long time to dry, cannot withstand high temperatures, and do not protect well from corrosion. Enamels harden faster, hold better and are more resistant to temperatures.

The ideal option would be acrylic paints. They are non-toxic, water soluble, and can withstand high temperatures.

Before painting, the metal surface should be primed. For this purpose, GF-021 or similar ones are most often used. Its color is gray and red-brown. To reduce the amount of paint used, a more suitable primer is selected. It is applied to a dry, clean surface with a brush, roller or using a spray gun in 1-2 layers. After the primer has dried, begin painting. To prevent the primer from showing through, the paint will have to be applied in two layers.

- Choose a color. To do this, you must be guided, first of all, by your own preferences. It is desirable that both the fence and its supports do not stand out, but serve as a beneficial addition to the harmonization of the entire space.

The process of painting poles and wooden fences

- Choosing a tool. It is very important to prepare the tool for applying paint.

- Brushes, classic tools that are used to paint hard-to-reach places;

- Rollers. You can immediately process a large area, provided that the surface is flat and wide;

- A spray gun, a lightweight and high-quality tool with which you can quickly paint poles.

You can use:

Painting the European fence posts

In this case you can use:

- Varnish that reliably protects thanks to its reliable film;

- Oil paint is a budget option;

- Acrylic paint, it is UV resistant.

Don't forget about impregnation, which will protect the pillars from high humidity.

Painting wooden poles

This process requires special care. It is necessary to work with them before installing the pillars. The part of the pillars that will be in the ground should be treated with bitumen impregnation. All operations should be aimed at extending the service life of structures.

Bitumen impregnation will contribute to the resistance of the fence base to water, alkaline and acid reactions. It is advisable to repeat this procedure twice with a break of a day.

The bitumen layer must be hard. Also, try to dry the posts before painting. Humidity should reach 15%. Why should this be done?

Because the wood will always be in contact with moist soil. And so, when painting dry wood, the moisture content of the wood is adjusted. Be sure to sand the surface of the wooden fence. This will reduce the amount of impregnation used and better protect the wood being treated.

Corrosion

Metal corrosion is a natural phenomenon that cannot be completely prevented, but this destructive process can be significantly slowed down. The oxidation process occurs with the participation of oxygen and aqueous solutions containing acid, alkali or salt.

Iron is not found in nature in its pure form, but is found in iron ore. Humanity invented the production of steel and came up with ways to preserve it. Factories use methods of phosphating steel by immersing it in various solutions, as well as electrochemical treatment. This coating is in the nature of a primer and requires subsequent painting. Steel is coated with other metals. Cheaper ones are aluminum and zinc.

There are silicate coatings - these are different types of enamel. Enamel is fragile and not entirely suitable for a fence. Cement has approximately the same expansion temperature as steel and serves as an insulator against aggressive environments. Good insulation is a polymer film applied in several layers in the factory.

How and with what to paint metal poles

The use of paint compositions for finishing and protecting metal load-bearing elements of fencing

This is one of the most affordable and affordable options for fence posts. These are usually just old water pipes. Sometimes, new, primed posts, cut to size. In any case, their preparation for painting, as well as the painting itself, are quite similar. The main stages of bringing such pipes into operational condition are as follows:

- they are cleaned of rust (especially loose) in any way, for example, with a large emery cloth glued to a mitten, a metal brush, a hand brush (for cleaning files) or a brush for power tools;

- an option is possible using a rust converter, but with subsequent cleaning in accordance with the previous paragraphs;

- with a water-based solvent similar to “9-151” or “Ferrario”, it is necessary to degrease the cleaned surface;

- Apply the selected primer to the pipe surface prepared for priming. As a primer, you can use the composition “GF-021”, “Spray-Zinc”, “Stabiterm-022”, “Rust Beater N o1” from Hammerite ;

- As an additional option, in preparing the pipe stand for painting, it is recommended to coat the inner surface of the workpiece with primer. This can be done by dipping into a plugged section of pipe of larger diameter;

- After the soil has dried, paint the surface with the main paint composition. This could be Spetsnaz paint or the shipbuilding composition KO-42T;

- when using anti-rust paints such as Nerzhamet, Hammerite or similar enamel, exclude the use of points 5 to 9;

- It is useful to cover the section of the pipe directly intended for contact with the ground with bitumen mastic.

Subsequent drying completes the process of painting future pipe blanks. They, and existing poles repaired in a similar way, will continue to perform their functions properly for many years to come.

How to paint fence posts

If the color of the primer is not very attractive, the metal fence posts are painted in a suitable shade. Here it is more important not so much to choose a color as to choose the appropriate composition. There are many options, but you need to take into account that the street fence is subject to high loads and the fence will have to be painted often.

The most famous include the following compositions:

- Oil-coloring pigments are dissolved in drying oil. Oil paint, when dried, forms a dense waterproof film and protects against corrosion. However, the composition does not tolerate temperature changes well, cracks and needs frequent renewal.

- Alkyd – based on alkyd resins. This paint is resistant to ultraviolet radiation, although it also does not tolerate high temperatures. Alkyd enamels have high hiding power and adhere well to galvanized surfaces. The paints are toxic; work must be done in a protective mask and clothing.

- Acrylic - non-toxic, non-flammable, elastic compounds. But in order to paint a profile pipe for a country fence, you need to buy compounds marked for metal. Regular acrylic paint is not suitable.

There is also a group of universal coatings. This paint can be applied to any surface without prior preparation. The mixtures are quite expensive, but suitable for painting black steel, cast iron, and concrete pipes.

Anti-corrosion or anti-rust

You can paint metal fence posts to prevent them from rusting, or if they are already rusty. These include universal and special powder paints.

Unlike conventional ones, they are solid compositions of pigments, hardeners, film-forming ingredients and other things. The film is formed due to the fusion of particles and a chemical reaction, so the resulting coating is very strong and durable.

Owners of summer cottages most often prefer the following compositions:

- Forge paint - used for painting steel, galvanized steel, iron, non-ferrous metals. Easy to apply, does not fade in the sun, and is completely insensitive to moisture or temperature changes. It attracts with its decorative effect: the composition easily reproduces the shine and color of old gold, bronze, and silver.

- Hammer - forms an original texture, reminiscent of a riveted surface, with traces of hammer blows. Paint can be applied without primer to any surface, including rusty ones. The manufacturer provides a 25-year warranty on the coating.

When painting fence posts, you need to choose paints for outdoor use.

Is it possible to paint over rust?

When the fence at the dacha has been standing for a long time and is old, the owners are often faced with the presence of rust on the surface. The desire to remove corrosion usually does not arise due to the laboriousness of the process, but this stage should not be skipped.

Otherwise, corrosive formations will very quickly break through the painted layer, and the layer will simply collapse. You will have to re-paint and still remove the rusty areas.

Even good paint for a metal fence may not hold up over time and become rusty, because moisture remains underneath it, which will restart the process of rusting the base. It is necessary to remove the formations efficiently; special products have been created for this purpose, or a brush with metal bristles is used.

What types of metal poles are there?

Pipes having the following types of sections are usually used as metal fence supports:

- round;

- square;

- rectangular.

Pipes with a round cross-section have a low cost. The height of this type of pipe varies from two and a half to four meters, and the diameter ranges from 57 to 108 millimeters.

Pipes with a square cross-section are easier to install, and due to the presence of stiffeners, they are more reliable. For them, you do not need to purchase plates that act as a stabilizer. The wall thickness of such pipes is 2–4 mm.

Pipes with a rectangular cross-section have the same properties as pipes with a square cross-section; they differ only in their design.

In the production of metal poles, the method of internal and external hot-dip galvanizing can be used, which increases the service life of these products. The thickness of galvanizing is usually 135 microns. The thickness of the polymer coating most often ranges from 65 to 90 microns.

The strongest and most durable are metal poles that are both zinc and polymer coated.

For waterproofing, metal caps are attached to metal pipes.

The cost of metal supports directly depends on its quality and service life of the product and is calculated per linear meter.

Asbestos-cement structures

Pillars made of this material are the cheapest option for such products. They do not have an attractive appearance, and they also do not have very good characteristics. But they are not at all afraid of high humidity. It is not necessary to paint these structures, because they can already last for more than ten years.

But painting will give a better appearance to such structures, which is exactly what they lack. If such pillars are filled with concrete, their service life will increase several times more. Below we will describe some paintwork materials that are suitable for painting poles made of this material:

- Coatings for Shikril slate. They can only be painted on a completely dry and clean surface. This product must be diluted with a solvent according to the manufacturer’s instructions. You will have to wear personal protective equipment to work, as this composition is toxic. This material is not afraid of moisture, frost, very durable and elastic.

- Kilpi products from Tikkurila. It has many positive qualities, but it is especially worth highlighting that it is not at all afraid of low temperatures. The consumption of such a product will be approximately 500 g per 1 sq.m.

- TM Dachbeschichtung from the manufacturer Dufa. An important feature is that it has the best level of adhesion (adhesion to the surface). And the consumption is no more than 150 g per 1 sq.m.

- Akrilakma product from the manufacturer Lakma. The consumption of this paint is 170 g per 1 sq.m. And it dries in about one hour.

- TM Polifan from the manufacturer Polifan-L. The consumption of this substance is about 350 g per 1 sq.m.

Metal poles

Preparatory and painting work consists of the following:

- Cleaning from traces of corrosion (sandpaper, wire brush, electric tool, rust converter). Chemical cleaning methods can be used, but the toxicity of the chemicals must be taken into account. Rust is easily removed by heating, which is facilitated by the difference in expansion coefficients.

- Degreasing the surface with a solvent.

- Metal priming. If the product is hollow, then it is advisable to apply primer to the internal surfaces. You should not skimp on the choice of primer, since films formed by cheap materials are short-lived. For oil paints it is recommended to use glyptal primers. For acrylic compounds and auto enamels, phenol-formaldehyde primers are best suited. There are also specialized primers that convert rust into an anti-corrosion coating.

- Treatment of the underground part of a metal column with a bitumen-containing substance (mastic).

- Applying paint.

Review of popular manufacturers

There is definitely less doubt about the quality of products from famous foreign companies. But turning to a little-known name can turn into a risk. In such cases, you never know what to expect from the acquisition. Why take the risk?

It is worth mentioning the names that have been known on the market longer and more than others:

- "Prospectors". From a domestic company that began operating in 1992. We started with simple putties, and over time moved on to other types of building mixtures. They offer a range of universal formulations and highly specialized ones with specific properties. Painting is guaranteed to be of high quality;

The painting is guaranteed to be of high quality.

- IVSIL. The same applies to domestic developments. The company focuses not on deep penetration primers and universal varieties;

The company focuses on deep penetration primers and universal varieties.

- Weber. One of the constituent branches of the Saint Gobain groups. It produces primers under the Vetonit brand. If necessary, colors are added to primers for interior and exterior work;

If necessary, colors can be added to primers for interior and exterior work.

- Caparol. The activities of this company began in Germany, in 1885. Black primers are produced for metal for work inside and outside; in addition, they have antiseptic and adhesive properties;

They have antiseptic and adhesive properties.

- Tikkurila. A company from Finland, operating since 1862. Of the entire assortment, it is worth highlighting adhesive compounds, moisture-proofing, universal, with acrylic as a base. Penetration into the metal will be sufficient;

Penetration into the metal will be sufficient.

- Knauf. A company from Germany, founded in the 30s of the last century. The craftsmen focused on improving construction work, introducing innovation wherever possible;

The craftsmen focused on improving the construction work.

- Ceresit. In terms of the production of building mixtures, the manufacturer has long become a leader, having been operating for more than 100 years. Expansion of the range, advanced technologies with quality control - this is what the representatives of this production decided to focus on. Even if they produce a simple transparent primer.

In terms of production of building mixtures, the manufacturer has long been a leader.

We recommend: Primer for walls under wallpaper: choose which primer is best for walls under wallpaper

The cost of products is reduced without loss of quality, including due to the location of factories in Russia. The range includes compositions with deep penetration, for mineral compounds with the ability to absorb everything, for decorative materials. It also cannot be done without classic universal compositions.

Purpose and operating conditions are the main difference between the produced compounds. For example, in the case of car finishing, certain characteristics are required. There are universal mixtures that can be combined with various problem areas.

When purchasing any primer for non-ferrous metals, it is important to study the manufacturer's recommendations in advance. The retention time of compounds on surfaces is an example of information from manufacturers. Equally important are the properties associated with anti-corrosion properties. A wise choice contributes to durability and reliability. It is important not to save on such a purchase and to purchase from well-known manufacturers.

Painting technology: from preparation to drying

If you decide to install the fence yourself, or plan to update the supporting structure, then you need to paint the posts and supporting elements correctly. Not only the appearance, but also how long the paint will stay on the base depends on compliance with the technology.

For different pole materials and for different paints, the technology may differ, but the general algorithm will remain unchanged:

- In any case, you need to start by cleaning the surfaces. For wooden and concrete structures, dust removal is sufficient; the metal pole should be cleaned of loose rust.

Important! Old profiled or round pipes can rust quite badly, so removing all the rust will simply be impossible. In this case, a rust modifier is applied to the surface or a special paint is used, which holds the oxidized layer together and prevents it from crumbling, and also stops the corrosion process.

- Next we apply the primer. Before priming a concrete or brick surface, they should be treated with a stiff brush to open the maximum number of pores. In the case of wooden posts, impregnation acts as a primer.

- After the primer has polymerized, we begin painting. We apply the paint in several layers, painting each pillar from top to bottom. We try to avoid drips: they lead to pigment detachment.

- Apply each next layer only after the previous one has completely dried. When drying paint on support poles, it is advisable to protect them from moisture and dust. Therefore, if possible, either paint the parts indoors before installation, or at least partially cover them.

General rules for painting work

It is recommended to paint metal products after applying a primer.

Step-by-step instructions for painting are the same for all compositions. When using universal or powder paint, preparatory work can be neglected.

- Support posts, gratings, and corrugated sheets are cleaned of dirt, dust, and grease stains. The latter are removed with acetone or solvent.

- After drying, the surfaces are treated with a primer. The next day the procedure is repeated. Primer is carried out only in dry weather.

- The paint is applied with a brush, roller, or a spray gun. In this case, the face is protected with a mask and goggles, gloves and an apron are put on.

- It is recommended to apply the coloring composition a second time after the first layer has completely dried.

- The coating dries from 4 hours to 2 days depending on the type.

Painting the metal elements of a fence not only increases its attractiveness. Paint protects iron from rust and extends its service life.