Even the most stylish bathroom interior will look ridiculous if the space under the plumbing fixture is not covered. You can decorate it using different methods, but installing a screen is considered the best and most reliable. With it, you can not only improve the room, but also create a comfortable work area, hidden from prying eyes. Under such panels in the free space you can place household chemicals, small buckets and other things.

DIY installation

If the acrylic screen was purchased after purchasing the bathtub, then there is a need to install it yourself. There is no need to be afraid of it. It is easy to install, although it differs from installation under a regular bathtub.

How to install a screen under an acrylic bathtub? This can be done in several stages:

To begin with, it is important to make the correct markings and transfer them to the bathtub. To do this, the middle of the structure is calculated mathematically - its length is divided by two

Next, the found value is plotted along the ruler and marked with a marker on the side of the bathtub. Using a special fastener, a pin with an angle is installed. The panel is slipped under the edge of the bathtub rim and secured with self-tapping screws screwed into the previously installed mounting bracket. The heads of the screws are closed with special decorative caps.

Preparatory work

A sliding screen under the bathroom, installed independently, is a multifunctional invention that provides attractiveness to the interior, additional protection to the bathroom, and comfortable storage of household chemicals for the bathroom owner. But such an element of the bathroom interior will be easy to use and durable only if its installation was carried out without errors and with high quality.

Installing a screen under a bathtub with your own hands begins with purchasing the screen itself. You can purchase a design that is designed for a standard rectangular bowl, or you can find a design for a curved bowl. It all depends on the bathtub installed in your bathroom. The characteristics of sliding screen models that are present in a wide range on the domestic plumbing market today are described in the table.

| Structure length, cm | Structure height, cm | Screen material | Number of bowl legs, pcs |

| 150 | 50 | Plastic (PVC) | 2 |

| 160 | 52 | Metal | 3 |

| 170 | 54 | Aluminum | 4 |

You can also make such a design yourself, but it will require more time and effort. Yes, and experience in such matters must be present, otherwise the result of the work may not be as good as necessary.

When all the tools and the screen itself are prepared, you can proceed to the preparatory work. Clean your bathroom of unnecessary furnishings so that they do not act as an obstacle to comfortable work.

What and how can you make a screen with your own hands?

You can make a screen with your own hands. The technology is simple:

The bathtub is being tied up. The material can be brick, wooden beam, metal profile. At the same time, any of the above materials are suitable for rectangular bowls; for semicircular corner baths, brick and a special aluminum profile (it can be given any rounding)

During the work, it is important not to forget to make a harness under the hidden hatch through which the bathtub siphon will be serviced;

- You can immediately attach ceramic tiles to the brick, and cut-to-size sheets of gypsum plasterboard are screwed onto the frame with self-tapping screws;

- a finishing finish is applied to the drywall (mostly ceramic tiles).

In conclusion, choosing the right screen will make the task easier: no need to adjust anything, just install. The instructions for all types of fastenings are simple and easy to follow on your own.

Foot niche

When installing a screen, the comfort of using the bathtub for washing and servicing the inner surface of the bowl is reduced. In other words, the feet rest against the wall, preventing you from getting close, for example, to clean or wash large items that do not fit in the washing machine.

There are four design options to make this task easier:

- a cutout 5–10 cm high between the screen and the floor;

- niche at the same level;

- screen surface beveled downwards;

- a niche with a beveled plane in the middle part of the screen.

The video shows the technology for assembling a frame with a niche for the feet:

The main disadvantage is the accumulation of dust/dirt at the junction of the niche with vertical surfaces and floor coverings. It is possible for horizontal tile joints to shift due to an increase in the length of the inclined surface. It is also considered bad design practice.

Factory fasteners and frame

Providing the ability to secure an acrylic bathtub against shifting in a horizontal plane, manufacturers complete the plumbing fixtures with metal brackets or polymer fasteners of a similar shape.

Factory-made bracket for attaching the side of the bowl to the wall.

A staple is a curved steel strip, one plane adjacent to the supporting surface, the other forming a hook. Plastic fasteners are formed in extruders or cast entirely.

Plastic factory fasteners for bathtub

The step-by-step installation method to the supporting structure is as follows:

- the frame elements are attached to the bowl with self-tapping screws from below;

- the bathtub is installed at the place of use, the sides are aligned in a horizontal plane due to height-adjustable legs;

- the upper edge of the bowl and its adjacent sides are marked on the walls;

- the bathroom is moved, the height of its side is measured, the markings on the walls are moved lower by this value;

- staples or plastic fasteners are mounted along the line;

- the bowl is raised above the hooks and placed on the sides.

The standard supports for the height-adjustable legs of the power frame of an acrylic bathtub usually do not have holes for attaching them to the floor. The most inexpensive option for fixing a plumbing product in a horizontal plane is to make such holes, marking them after adjusting the height, removing the bathtub, and drilling blind holes in the floor.

If the bathtub is installed after the walls are covered with tiles or PVC panels, then the gap remaining between its sides and walls is sealed with sealant by default.

This material is actually an adhesive with high adhesion to plastic and ceramics. Therefore, the bathtub bowl is guaranteed not to wobble, even without additional measures to stabilize the spatial position.

Install mortgages

If the bathtub comes with a factory-installed screen, then the design already includes all the necessary fasteners. If not, you will have to install embedded parts into the front side, to which the screen frame is then attached.

YouTube channel “Ruslan Viktorovich”

To do this, you need to cut a piece of a wooden block and glue it to the inside of the side with silicone sealant or polyurethane foam. If the bowl is adjacent not to three walls, but to only two, another block should be secured to one of the free sides.

Some acrylic bathtubs already have ready-made embeds in the form of pieces of timber along the perimeter of the sides. If you see such pieces of wood, it means you can do without additional inserts.

Procedure for installing a screen for an acrylic bathtub

There are several options for installing a screen on an acrylic bathtub. The easiest way is to fix a blind, non-opening panel. The most durable construction will be required for pivoting sashes. A purchased or self-made structure can be attached to:

- self-tapping screws;

- magnets;

- springs;

- clamps;

- against a rigid frame.

Sometimes you can see non-removable screens made of moisture-resistant plasterboard or brick and lined with tiles. Such non-removable structures can be beautiful, but they satisfy the owners until the first plumbing failure or siphon clogging.

Self-tapping installation

To secure the decorative screen with self-tapping screws, you will need a set of special fasteners. These can be pieces of plastic or aluminum corners. They need to be secured at the top to the stiffening rib of the acrylic bathtub, and at the bottom to the supports of the supporting frame or a horizontal profile, if there is one.

After installing the fasteners, attach the screen and apply a mark against each of them.

Drill holes in the panel in the marked places and use a conical bit or a large-diameter drill to select a countersunk hole for the screw heads.

Screw the hardware to the fasteners, and install decorative plugs into the cuts in the caps. If you couldn’t find plugs on sale, you can cut them out yourself and attach them with glue.

On magnets

In order for the magnets to firmly hold the decorative panel, there must be a steel frame or vertical stops that are connected to the supporting structure of the bathtub. The magnets themselves need to be glued to the back surface of the panel and then applied to the installed steel profile. To finally fix the screen, 2-3 clamps should be screwed to the stiffening rib of the bath.

On springs

Attaching the screen to an acrylic bathtub using springs is simple and reliable. Its device is based on the fact that springs are attached to the elements of the supporting frame of the bathtub, which will lift the screen, pressing it against the stiffener. The work is performed in the following sequence:

- place the screen over the side and lift it up until it stops;

- on the frame posts, make marks for the lower level of the panel;

- move the marks 30 mm higher;

- attach the lower part of the spring to the new marks and then the top will show on the rack the place for drilling a hole for the hook;

- on the back side of the screen, glue a piece of corner with a drilled hole for the hook of the lower part of the spring;

- Glue wooden blocks to the side wall of the bathtub, which will prevent the panel from moving towards the bowl;

- install the springs, press the screen down, place the top over the side and release.

The dimensions of the bars must be selected experimentally, taking into account the thickness of the panel material.

For clamps

Floor spring clamps are used for rounded or asymmetrical bathtubs. In addition to the clamps, you will need locking latches to complete the job. The procedure for this method of fastening is as follows:

- using a plumb line or bubble level, mark a line on the floor corresponding to the edge of the bathtub rim;

- place the corner clamps on the floor along the drawn line and mark the places for drilling;

- drill holes in the floor, install clamps and fix them on dowels;

- Screw the latches to the stiffening rib of the bath opposite the clamps;

- On the back of the panel, mark the locations of the clamps and screw the fastening tabs there;

- Place the bottom of the screen in the clamps, and press the top of the screen tightly against the board until it clicks into place.

The main thing in this method is not to make a mistake with the markings in order to ensure that all fastening elements match.

By surprise

To install the screen on an acrylic bathtub by surprise, you will need to make a strong frame, at the ends of which locking spacer screws are installed on the support legs.

The decorative panel is fixed to this frame using self-tapping screws or glue. You need to fill the bath with water. This is necessary to take into account possible subsidence and more accurately determine the moment of emphasis.

To install it in place, place the finished screen over the side and, turning the screws, lift it until the top edge rests against the edge.

Drain the water and check the installation is secure.

How to quickly remove the screen without damaging it

It is almost impossible for an untrained home craftsman to remove the screen from an acrylic bathtub without damaging the panel. You need to know the type of fastening. However, not everything is so complicated in the end if you know some of the nuances.

- If there are no supports between the bottom of the screen and the floor, then the panel is secured in one of three ways: self-tapping screws, magnets or using springs.

- The supporting legs of the screen frame indicate that it is installed sideways.

- Direct fastening of the panel to the floor indicates the presence of spring clips.

With this information, you can easily remove the screen.

Fastening with self-tapping screws. The panel hanging above the floor should first be inspected for the presence of plugs. If they exist, then the problem is solved in two steps:

- decorative plugs are carefully removed using a sharp blade;

- Use a screwdriver to unscrew the screws.

Magnets. If there are no plugs, the panel quietly pulls down. If a little effort is not enough to tear the screen out of place, it means it has magnets on the bottom and latches on top. It's easy to remove - just pull the top towards you. In this case, it is advisable to perform the operation with several hands, so as not to distort the screen too much.

Springs. Pull the panel down and out from under the side. After this, disconnect the springs from the hooks.

Attention: if there are no plugs, and attempts to remove the panel by other methods were unsuccessful, it means that the screen is still on screws, and the heads of the hardware are skillfully masked with sealant by a good craftsman. In this case, a needle will help - in the supposed locations of the screws you need to carefully prick the acrylic (plastic). Acrylic (plastic) will resist, but the sealant will puncture easily. Then it’s simple: the homemade plug is removed, the hardware is unscrewed.

Installation by surprise. The presence of a frame is indicated by the legs. In such options, the screen is attached to the acrylic bathtub by surprise. To remove the panel, simply screw the legs into the frame and then pull them towards you.

Spring latches. The panel is removed from the spring clips in two steps:

- the upper edge of the panel is pulled towards itself until the clamps are released;

- the screen is raised up to release the latch tab from the clamp attached to the floor.

Installing a rectangular bathtub on a factory frame

Acrylic bathtub Cersanit

Acrylic bathtub with frame

Step 1. We print out the purchased bathtub and the factory frame and lay it out on a clean floor, having previously laid it with soft cloth or cardboard. In the set of fasteners you will find short and long metal profiles, self-tapping screws, legs and pads for them (thrust bearings), dowels, studs, washers, nuts, stands. Depending on the configuration, the number of parts may be different, for example, the reinforced frame contains more metal profiles, or the bathtub is supplied immediately with an all-welded frame.

Typically, holes are already drilled in the reinforcement and dowels are inserted. This eliminates the need to mark and drill holes yourself.

Most acrylic bathtubs are installed not only on the frame, but are also fixed along the line adjacent to the walls with metal hooks and hangers.

If the kit does not include drain fittings, it must be purchased, taking into account the height of the legs and comparing it with the dimensions of the siphon.

For work you will definitely need screwdrivers, wrenches and pliers. Also don’t forget about silicone-based sealant, a bubble level, a tape measure and a pencil.

Step 2. We start by assembling the frame and legs. We turn the bathtub over without removing the protective film from the inner surface. We provide easy access to any side of the bowl.

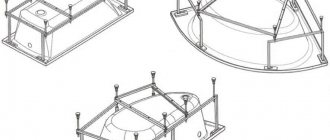

Frame diagram for installing a bathtub

Using long self-tapping screws, we connect the profiles. We rely on the instructions attached to the acrylic bathtub and the correspondence of the holes in the longitudinal reinforcement with the dowels installed in the transverse strips.

We place the assembled frame exactly in the center of the bottom of the bathtub.

Installing a bath yourself

Step 3. Let's move on to installing the legs. We will install three pieces on the front edge of the bathtub, two under the bottom of the bowl and two more at the edge that will be adjacent to the wall.

We begin to fasten the racks to the profile and side of the bathtub. We install the stand on the side, screw the first long pin into it, and a nut onto the pin. We insert the resulting pin with a stand into the hole of the longitudinal metal profile. Secure the stud with a nut and locknut. We screw a plastic support on top.

We assemble the remaining support legs in the same way. We adjust the height of the legs depending on the dimensions of the decorative screen. The approximate height from the floor to the edge of the side should be 60 cm.

Short studs are intended for the legs located under the bottom of the bathtub. We insert them into the holes of the transverse profiles, secure them with nuts and screw on the plastic supports.

How to install an acrylic bathtub

Installation of a bathtub frame

Step 4. Check the assembled frame with a bubble level.

Checking the position of the bath

If necessary, tighten the studs with a wrench to level the position.

Turning the bath over. If necessary, adjust the position of the legs

We take short self-tapping screws and fasten the racks to the sides of the bathtub.

Step 5. Turn the bath over. We take a level and once again double-check the horizontality of the sides. There is no need to make slopes for better water flow.

Step 6. Now you can connect the siphon with overflow, based on the manufacturer's instructions. The general principle for connecting inspection siphons (piping) of the knee type is as follows:

Installing a homemade screen

Homemade screens, subject to high-quality installation, are more reliable and durable, and therefore many craftsmen prefer this option. The most common method is to make a screen from plasterboard and a metal profile, followed by tiling. As in the previous case, all work on finishing the bathroom must be completed, the space under the bowl must be cleared of dust and construction debris, and communications must be connected.

For installation you will need:

- galvanized profile 75x40 mm and 60x27 mm;

Galvanized profile

- moisture-resistant drywall;

Drywall

- level and ruler;

- metal screws;

- dowel-nails;

- drill with a set of drills;

- metal scissors.

Since this screen will be stationary, you need to take care in advance about the presence of a technical hatch for inspecting communications under the bathroom. You can also make it yourself, but it is much easier to buy ready-made, because the cost of such products is very low. This will save you both effort and time on making the screen. In addition to the usual ones, on sale there are hatches for tiles, which, after cladding, do not stand out at all against the background of the screen.

Step 1. Determine the location of the outer frame post. To do this, step back 1 cm from the outer edge of the side towards the bathtub and put a mark. Next, add up the thickness of the drywall, guide profile, tiles and adhesive layer, measure the resulting value from the first mark and place another one.

Determine the location of the outer frame post

Marking

Step 2. Measure the exact distance from the floor to the side of the bathtub and cut the rack profile according to the measurements. A section of the profile is applied to the wall at the level of the second mark, set vertically and draw a line with a marker to the very bottom.

Step 3. The profile is laid on the floor and one hole with a diameter of 6 mm is drilled in its lower and upper parts. Place the stand against the wall again and mark the locations of the fasteners through the holes.

Profile attached to the floor

Step 4. At the marked points, drill the tile with a spear-shaped drill with a diameter of 6 mm, then insert the drill into the concrete, turn on the hammer drill mode and go deep into the wall to the length of the dowel.

Step 5. Place the profile in place, level it and fix it to the wall with dowel nails. On the other side of the bath they do the same.

Step 6. A horizontal guide is laid on the floor between the side posts. It is also attached to the floor using dowel-nails in increments of 30-40 cm.

Step 7. At the top of the rack they are fastened with a guide made of two 60x27 mm profiles. For reliability, the profiles on the sides are fixed with self-tapping screws with press washers every 40-50 cm. The guide should be 30-40 mm below the side of the bathtub.

Double profile

Profile fixed under the side

Step 8. Install intermediate posts. The lower edge of the racks is inserted into the groove of the guide, the upper edge is cut off on the sides with scissors, leaving only the central part. This ensures a tight fit of the profile to the guide. The distance between the posts is approximately 30 cm.

The photo shows how to cut the profile for the stand

Trimming excess with metal scissors

Attaching the intermediate post from below

Attaching the intermediate post from above

Racks

Step 9. From the side where the drain is located, additional sections of the profile are attached to the frame, forming a frame for the technical hatch.

Technical hatch

Step 10. The sheet of drywall is cut exactly to size, and if necessary, cutouts are made for water pipes. Apply the canvas to the frame and fix it with metal screws to each rack and both guides. The fastening pitch is about 15 cm.

Holes for pipes are cut in a sheet of drywall

Fixing drywall

Advice. To more securely fix the screen in the upper part, you can drill a couple of through holes in the drywall and blow a little foam through them. After hardening, the foam will firmly connect the screen to the wall of the bathtub, and the structure will not move.

Foam blowing

At this point, the main work is completed and all that remains is to complete the cladding. Before gluing the tiles, the drywall must be well primed and wait until the surface dries. Find out the plumbing drain by following the link.

The surface of the drywall must be primed before finishing.

Applying adhesive to tiles

Screen tiling

Selecting a screen model

Before you install the finished screen under the bathtub, you must select it.

Today, construction markets have a wide selection of models that differ not only in size and color.

Main features of screens

- frames made of different materials - steel, plastic, aluminum;

- sliding doors or a fixed panel that tightly covers the lower part of the bathtub and the space under it, an option is a fixed panel with an observation window;

- sash or panel material – plastic, MDF, organic mirror glass, metal;

- fastener

Choose a model that suits your requirements. You should not settle for cheap options with a frame made of fragile plastic or neglect the choice of color - the screen will become a prominent element of the decor, its breakage or an inappropriate color scheme will cause inconvenience.

Acrylic is a capricious material; bathtubs made from it are usually equipped with a ready-made screen. Installing an unsuitable fixture can damage your plumbing.

Bath screen models have a wide range of sizes. There are standard options designed for the dimensions we are used to, but if necessary, there are also non-standard ones. If possible, choose exactly the appropriate standard size, but if you cannot find a suitable one on sale, some materials (plastic, metals) can be cut with an angle grinder (“grinder”). Therefore, it is worth choosing a larger rather than a smaller size.

We select a convenient design

Screens consist of a frame (usually aluminum) and panels. They can be blind or equipped with doors for access to communications and items stored under the bathroom.

There are also models with removable panels; they are usually installed under acrylic bathtubs.

The advantages of blind panels are high aesthetics and durability. The smooth surface can be decorated in any way or left plain.

It will look nice regardless of the presence or absence of additional decor. Due to the absence of moving parts, these bath screens last much longer.

The disadvantages of solid stationary structures include the inconvenience that arises in the event of breakdowns of the plumbing system. To access it you will have to remove the entire panel.

This takes a lot of time, which can cause problems if a leak develops and water accumulates under the bathtub.

In some interiors, screens perform a style-forming function. A luxurious bright model looks very attractive if the rest of the design elements are monochromatic or made in the same style

Designs with doors are more practical than blind ones. The doors themselves can be hinged or sliding. Both options have their own advantages and disadvantages.

In most cases, bathroom owners opt for sliding models.

Hinged doors conveniently open and close, providing access to shelves with necessary small items.

However, you should not choose a screen with such doors for a small bathroom. Open, they occupy useful space and make it difficult to manipulate the elements of the plumbing system.

The doors of the sliding screens for the bathtub open, sliding along the guides. When purchasing such a system, you should pay special attention to the quality of the metal.

The stronger it is, the longer the bath screen will last. It is better to give preference to steel or aluminum.

There are models with plastic frames. They are less reliable, but are quite suitable for apartment owners who do not intend to store frequently used items such as washcloths, towels, shampoos, hygiene products, and household chemicals under the bathroom.

If doors are needed only for access to communications, then you can buy a plastic system.

Doors can swing open not only to the left or to the right. There are models with folding elements. They have the same advantages and disadvantages as swing screens

Kinds

The modern market offers a large number of different models, made of various materials, and differing in cost, performance characteristics and appearance.

- Screens made of plastic. The models are characterized by hygiene and the ability to apply any pattern, relief or photo printing to the surface. The frame of plastic screens is made of aluminum, which gives the structure lightness, strength, corrosion resistance and durability. The service life of the models is up to 30 years, during which the material perfectly retains its performance properties and original appearance. The advantages of plastic screens also include low cost, ease of maintenance and ease of installation.

- Plexiglas screens. The material is hygienic and aesthetically pleasing. The wide range of glass screens is due to the wide variety of colors and textures. The structures are made of thick organic glass with a transparent, matte or mirror surface. The models look harmonious in combination with a sink made of glass and chrome-plated sanitary ware, and also visually increase the area of the room and do not hide the space. The disadvantage of glass screens is the high cost of the products, heavy weight, complexity of installation and the need for regular maintenance.

- Models from MDF. Inexpensive, beautiful and easy to care for, the material is often used to make screens. It is available in the form of laminated panels with a wide variety of colors and textures. Models with imitation patterns of wood fibers, natural stone and tiles are very popular. The design may have sliding doors, a service hatch or hinged doors. The disadvantages include the low moisture resistance of the models, due to which the elements absorb moisture, swell and deform. To prevent this from happening, the bathroom must be equipped with a working exhaust ventilation system. The service life of MDF screens does not exceed three years.

- Acrylic screens. Lightweight, hygienic and practical acrylic harmoniously combines with bathtubs and sinks, is highly resistant to household chemicals and has high moisture and heat resistance.

- Aluminum models. The products are characterized by low cost, durability and corrosion resistance. The low weight of the screens facilitates quick transportation and easy installation of the structure, and a wide range of colors allows you to choose products to suit any color and style of the room.

- Drywall. A popular material for making screens, which allows you to independently form a curved structure for a non-standard bathtub. The front part can be covered with ceramic tiles or mosaics.

- Tree. Practical, environmentally friendly and durable material. Wooden screens are made in a monolithic, sliding or hinged design. They are distinguished by their elegant appearance and practicality. The disadvantages of these models include the heavy weight and high cost of some products.

What are they?

Modern manufacturers offer a wide range of products to suit every taste.

There are different types of protective panels:

- deaf;

- with sliding doors;

- with accordion doors;

- with hinged doors;

- with shelves.

- with fabric curtain.

Which option to choose is up to each person to decide for himself. If you want to save free space, you should choose the option with accordion doors, which fit best into small spaces. For a comfortable location of household chemicals under the bathtub, it is better to choose a product with shelves. But blank panels are distinguished by their aesthetics. They are very simply attached to the frame, but their installation limits access to plumbing connections, since not all models can be easily and quickly removed.

Find a full overview of all screens in our special article.

The most popular options among users of acrylic bathtubs are:

- front panel.

- continuous screen made of ceramic tiles;

- sliding

In our article we will take a closer look at installing an acrylic panel, because consumers most often prefer this method of decorating the space under the bathroom.

For detailed information about installing a screen made of tiles and sliding panels , see the relevant articles

Options for a homemade bath frame

What material is most often used to make a bathtub frame? Regular profile for drywall. It is coated with zinc, which means it is quite durable and reliable. And it will last a long time. It can be used under the frame of acrylic and steel bathtubs.

Before starting installation work, you need to level the walls, separate the sewer and water supply pipes.

Let us follow step by step the entire procedure for constructing this structure.

We prepare the equipment and make markings

First of all, turn the bathtub over. We attach the profiles for the legs to the self-tapping screws. For this purpose, the design of the bathtub includes reinforcement of the bottom with a plywood sheet. And now we attach the legs to the profile. Without moving far from the bathtub, we install a drain and overflow system.

Now you can bring the structure into the room and, after adjusting the legs in height, install it in place. Along the lower edge of the side we apply markings for mounting the frame.

Next, you again need to pull the bathtub out of the room and start assembling the frame.

Frame assembly

To make a frame from a metal profile, it is enough to perform several manipulations:

- Cut the profile according to the marks. Holes are made in the cut pieces so that they can be mounted on the wall.

- Apply sealant to the shelf adjacent to the wall. Next, following the marks, screw the profile to the wall. If the wall is made of brick or concrete, then drill holes and insert dowels. No dowels are needed in the gypsum board; the screws hold perfectly.

- Next you should install the side posts and the bottom guide of the screen.

- Apply sealant to the top of the profiles. Bring the bath back, install and connect it.

Now you need to make a stand on which the bottom of the bowl will rest. You can take brick or cinder block for these purposes. We place them in several rows and secure them with ordinary cement mixture.

After the foam has hardened, we proceed to install the frame under the screen and hide it with a sheet of drywall.

Wood frame

Wood is not as suitable for creating a bathtub frame as metal. In rooms where people bathe: in bathrooms, baths, saunas, it is always very humid. As you know, moisture is the worst enemy for wood. To protect our structure from the destructive effects of moisture, we should take care of protection.

The material must be impregnated with an antiseptic or other protection that will repel water and protect against fungus and mold. We assemble the frame from bars with sides 50 by 50 millimeters. We do this in the same way as assembling a frame from a metal profile. Let's go over the main points:

- We level the walls and prime them, after which you can attach the frame;

- to give additional rigidity, we supplement the horizontal slats with vertical slats;

- as soon as the frame is assembled, we cover the beams with a waterproofing solution; If the walls located behind the bathroom are not planned to be covered with tiles, then it is better to cover them with waterproofing.

When the waterproofing compound has dried, you can install and connect the bathtub. To make it more stable, a support is made from brick underneath it. A foam layer is placed between the support and the bottom of the bowl. Next, the screen and its casing are mounted.

Welded metal frame

Naturally, you can weld a metal frame. A profile pipe is suitable for this design. Essentially, it is a metal rectangular object that does not even look like a pipe. Such a frame can be arranged for an acrylic bathtub, as well as for a cast iron or steel one. Its strength is such that it can withstand any weight. This design allows, in addition to the bath itself, to install a glass screen for the shower.

How to make a frame using welding? Let's look at the main points:

- first you need to take all the measurements and draw a diagram of the future structure;

- cut blanks to the required length;

- connect the base of the frame by welding - these are three supports, with two guides attached to them; the bottom of the bathtub will “rest” on the guides;

- installing the legs - selecting small sections of profile pipe and welding them to the support legs;

- at the lower end we weld a washer and a nut to it, matching the diameter of the screw;

- when all the elements are assembled, the frame can be adjusted in terms of horizon and height;

- Now you need to weld a rack located vertically, and install horizontal crossbars on it, on which the lower part of the side will rest;

- To be able to cover the front side of the bathtub, we weld on the front pillars.

We install the assembled structure in the room, level it and install the bathtub itself. We connect and test the operation of the drain and overflow systems. We cover the frame with a sheet of plasterboard.

Two in one: aesthetics and functionality

Entering the bathroom, a person sees a bathtub. If the screen is not installed, then the legs of the bathtub and elements of the plumbing system are visible.

They seem unsightly and make the entire bathroom look untidy. The screen can become an excellent decorative element that will cover everything unnecessary and help decorate the room in a single style.

During Soviet times, it was difficult to find a worthy alternative to brick walls under the bathroom. Now there are designs made of light and beautiful materials, but brick screens are still installed in some apartments

The design will protect the pipes from moisture and damage, and will become an additional cabinet where you can store household chemicals, household supplies, plumbing tools and other useful items.

Screens are not only beautiful and practical, they can act as a reliable barrier that prevents children and animals from accessing household chemicals

Installation stages of finished models

Ready-made bath screens are completed with frames, fittings and fasteners. All this must be indicated in the technical documentation for each specific model.

Installation instructions should also be included. Before purchasing, make sure everything you need is included.

If the dimensions are chosen correctly, then for installation you will need a minimum of tools: a tape measure, a building level and a screwdriver. Before starting work, it is recommended to fill the bath with water.

If the bathtub and screen are installed at the same time, this is not necessary.

Screens may vary in shape and design, but their installation scheme is always approximately the same:

- Measurements and markings. Before installing the frame, you need to once again measure the niche under the bathtub and mark the mounting locations for the frame. If the panels do not fit slightly due to the curvature of the walls or floor, they are trimmed with a grinder.

- Installation of the frame. The frame is mounted under the bathtub and secured in accordance with the instructions; the W-shaped guide profile for sliding models is also installed and aligned.

- Adjustment of legs. If the model has adjustable legs, they are unscrewed so as to achieve maximum fixation of the frame between the floor and the side of the bathtub. To ensure that the supports hold more firmly and the screen does not shake when water is poured into the bath, you can apply a little sealant under each leg and press it to the floor.

- Fastening the frame under the side of the bathtub. When the frame is firmly fixed, the space between the edge of the frame and the side of the bathtub is filled with foam. This will add additional rigidity to the structure.

- Installation of panels. Decorative panels are installed on the frame. If the doors are hinged, they are hung on hinges; sliding doors are inserted into the guide profile. Handles are screwed to the doors.

- Seam processing. It is advisable to treat the joints with sealant. This will help protect the niche under the bathtub from moisture.

Installing screens for acrylic bathtubs has its own characteristics. Most often, these baths are pre-equipped with screens that are suitable in shape and size. Models are usually made of plastic. The kit includes frame, panels, handles, brackets, dowels, screws.

The pictures show the entire process of installing a screen under an acrylic bathtub. Installing screens under bathtubs made of other materials has some differences. For example, in cast iron models you cannot drill holes at home, as there is a risk of splitting the cast iron

If the bathtub is not equipped with a screen, then you can make it yourself from a wooden block and ready-made plastic panels. The frame is attached to the side of the bath using liquid nails, the joints are additionally strengthened by cold welding.

To secure the bottom brackets, drill holes in the floor and install dowels. After installing and adjusting the frame to size, the screen panels are inserted into the guides.

A characteristic click is a sign that they are in place.

Installing decorative panels for a corner bath may pose some difficulties. The sequence of correct installation of a corner acrylic bathtub with a screen is shown in the video:

https://youtube.com/watch?v=deZXHjpgBh4

How to choose the right size?

Any bath panel is selected for a specific size. It is very important to check whether it fits your plumbing model. The length of acrylic panels varies from 120 to 180 cm for standard hot tubs. And the height is 55-60 cm, but it can change if there are legs.

Most often, acrylic panels come complete with plumbing fixtures and have the same tone as the bathtub, which allows the overall design to look organic. They are made of plastic coated with an acrylic layer.

The advantages of panels purchased complete with a bathtub include the fact that they fit as tightly as possible to the sides of the bathtub, eliminating unsightly gaps. Experts do not recommend purchasing such screens separately, since they do not always fit exactly in size.

If the screen is purchased separately from the bathroom, then in order not to make a mistake with the choice of size, you should carefully measure the plumbing from all sides.

“How to fix an acrylic bathtub so that it doesn’t wobble” - Yandex.Connoisseurs

In order to make an acrylic bathtub stable, you need to install it correctly.

There are 3 ways to install it:

- On support legs and mounting frame

- On a brick frame

- Combined method (legs and brick frame).

Method 1 is suitable if the bathtub is rectangular. The installation should begin by preparing the floor; it is enough to cover it with packaging film, for example. Build a mounting frame (this can be done using the frame assembly guide) and fit it to the bathtub, which should already be upside down.

Measure the holes for the fasteners (note that the frame is attached no closer than 17 cm from the drain). Drill holes according to the marks.

Now you can start attaching the legs. Screw adjusting nuts and plastic plugs onto the threaded studs. Secure the legs to the bathtub with locknuts.

Try on the bathtub with frame and legs at the installation site horizontally and levelly, using a building level, install the mounting strips. Now you can finally install the bathtub in place and connect the water.

The 2nd method involves the construction of a brick frame. It will make the bath as stable as possible. You need to lay out the frame half a brick wide, having taken all the measurements before doing so. Provide a hole in it in order to then have easy access to the siphon. Leave a gap between the base and the bottom of the bathtub so that it can be filled with foam for a tight fit.

Water drawn into it will help ensure a tight fit of the bathtub to the frame.

In the place where the bathtub is adjacent to the wall, install mounting strips.

Plasterboard frame. To ensure proper installation, place the bathtub directly in the location where the frame is planned. To make the frame, moisture-resistant drywall, profiles and aluminum slats are required. Before starting all work, take measurements of the length and width.

Drywall, cut to size, is attached to the installed frame of slats and profiles. And this entire box is finished with the materials used to decorate the room.

Features of installing different types of bathtubs

The technology for installing any model has few differences. But there are some nuances. How to install a cast iron bathtub yourself? When installing it, you cannot install the siphon in advance. This plumbing fixture is too heavy and impossible to fit into place in a confined space.

Typically, cast iron models have special holes for the legs. Therefore, the bathtub is placed on its side and the legs are screwed on. No additional fastenings are needed. If the floor is tiled, it is better not to place a cast iron bathtub on tiles, as the tiles may collapse from the weight.

How to install a steel bathtub? Its installation is carried out in exactly the same way as acrylic, but there are some small features. It necessarily requires grounding, as it has high electrical conductivity.

Also, steel models are too noisy, so they need to be soundproofed. Since the metal bathtub is very thin, it is better to place brickwork underneath it to provide stability. Rubber pads should be placed under each leg to prevent it from moving out of place without water.

Installation of acrylic bathtubs

The most common type of bathtub in homes around the world is acrylic. How to install an acrylic bathtub? Its installation is not easy, since acrylic is a very sensitive material and can be easily damaged. It is better not to buy acrylic plumbing fixtures in advance; they may become deformed during long-term storage.

If the model is produced in the basic configuration, it comes without additional fasteners. How to properly install an acrylic bathtub? If you bought a model without legs, it can be installed on a brick frame. But it is advisable to buy in an expanded configuration, with a frame or legs for installation, a drain-overflow, and installation kits.

The corner design has its own specifics. The choice of brick supports for corner models depends on their shape and features. How to install a corner acrylic bathtub on bricks? Brick frames are laid out:

- a triangle repeating the shape of the bathtub;

- in the form of the letter “P” in the direction of expansion;

- a simple monolithic rectangle;

- in the form of two pillars covering the entire length of the structure;

- a solid box, on which the bath is then “put on”. The frame installed in this way is very durable.

Knowing how to install a corner bathtub made of acrylic, it is easy to apply these methods to steel products.

How to install a bathtub yourself to the desired height? Usually it is placed at a standard height, but if you decide to make it to suit your height, you can place it on brickwork and decorate the bottom with a special screen.

Installing a bathtub on bricks

No factory frame? No problem! We can install an acrylic bathtub on bricks. This option is even more reliable compared to the method of installing a bathtub on a factory-made frame.

The support can be solid or columnar.

Installing a bathtub on a solid brick base

Example of installing an acrylic bathtub on a brick

First step. We temporarily install the bathtub in the place of its future installation and project a drain hole onto the base. This will give us the opportunity to leave a gap in the substrate to connect the drain.

Second step. We lay out the bricks over the entire supporting part of the container. We select the height so that the sides of the bath rise above the floor by no more than 600 mm. At the same time, we take into account that we will still have a 2-3 cm pillow made of polyurethane foam.

The bricks are laid on traditional cement mortar.

Third step. We assemble a frame made of sheet plywood around the perimeter of the brickwork. The height of such sheets should exceed the masonry by the thickness of the foam substrate. Don't forget to leave the drain hole unfilled.

Fourth step. We evenly foam the surface of the substrate with polyurethane foam, without going beyond the boundaries of the frame. We immediately apply pre-prepared sheet plywood onto the foam. We use moisture-resistant sheets 10 mm thick.

Installing a bathtub on a brick

Fifth step. We tightly plug the drain of the acrylic bathtub. At the same stage, we prepare about a liter of water and wooden supports to regulate the level of installation of the container.

Sixth step. We pour the previously prepared water into the container and place the bath on the substrate according to the building level.

Seventh step. While the polyurethane foam has not hardened, we adjust the evenness of the installation of the bathtub using supports. As a result, the water in the container should be evenly distributed around the drain, and the level should show “0”.

Eighth step. Having aligned the bathtub, pour water into it to about half the volume. Under the weight of water, the foam will not be able to lift the container, and the bath itself will take on the required slope.

Ninth step. Let the foam dry and remove the bath. If the edges of the container must be recessed into the wall, first outline the outline of the edge on the surface, and then make a recess in the wall for the edge of the bath. A hammer drill will help us with this. If a groove is not provided (this is not recommended if the walls are made of blocks, plasterboard or other lightweight material), at the level of the lower cut we simply fix a beam impregnated with an antiseptic, or a steel corner. We will additionally strengthen the supporting bar at the end with stops.

Tenth step. We return our container to its place and connect it to the sewer. We fill the gaps between the container and the bricks with foam. We install a decorative screen and baseboards.

Example of a bathtub installed on bricks with mosaic finishing

Installing an acrylic bathtub on brick supports

Installing an acrylic bathtub on brick supports

First step. We bring the container into the bathroom.

Second step. We mark the base at the location where the brick supports are installed. The most correct option is to erect the pillars closer to the edges of the bend of the acrylic bathtub. If the container is long, an additional support can be erected in the middle.

Third step. Having outlined the places for laying the supports, we begin to prepare the cement mortar. We don’t prepare too much - we have to lay out no more than 20 bricks, so we don’t need any extra expenses.

Fourth step. Let's start laying. We place the support for the back of the bathtub at a height of 190 mm, and the pillar for the front edge of the tank is erected at 170 mm. The height of the middle support, if needed, is selected according to the situation, depending on the design of the bathtub being installed. The difference in height of the pillars will provide conditions for efficient drainage of water from the container.

Fifth step. We give the masonry about a day to dry and install the bath. We place the container slowly, moving it tightly towards the walls. We fill the gaps between the bricks and the bathtub with sealant.

If desired, you can additionally fix the bath to the wall using dowels and a metal profile. This type of fastening is used quite rarely, but still occurs.

Having made sure that the installation of the bathtub is correct, stable and even, we connect the sewerage system, install the mixer, mount the decorative screen and lay the baseboard on the bathtub.

Decorative tiled screen on a brick base

The advantage of a decorative screen on a brick base is reliability and durability. Disadvantage - the monolithic structure consists of difficult-to-replace elements. Instead of tiles, you can glue plastic panels.

Make markings on the floor surface.

- Lay the first row of bricks. The second row is laid after 24 hours. During this time, the cement mortar will completely set and dry. Shift each subsequent row 1-2 cm to the side.

- Place a brick wall under the edge of the bathtub. Leave space for a technical opening.

- Cover the finished structure with a primer mixture.

- Apply adhesive over the primer.

- Lay the tiles on the glue and leave to dry.

- Treat the joints with sealant.

- Insert the decorative plug into the technical opening.

How to install on corner models

For corner bathtubs, mounting is most often provided not with self-tapping screws, but with special magnets and metal plates. Such magnets are initially attached to the legs of the font.

STEP 1. Height adjustment. Just as in the case of the rectangular model, we adjust the height of the legs based on the screen parameters.

STEP 2. How to attach the plates? On the back side of the panel, in the places where the magnets will rest, we glue the metal plates from the kit with double-sided tape or silicone sealant. While drying, you can secure them with regular tape.

STEP 3. Installation. We apply the front panel and check that the magnets grab the metal plates.

This installation option is convenient because the question: how to remove the screen and then put it back on again does not arise. Everything is extremely simple, you need to apply a little force by pulling the panel towards you, and you can just as easily return it to its place. The previous method is no different from this simplicity; there you will first need to unscrew the screws.

Conclusions and useful video on the topic

Detailed video instructions from the manufacturer:

How to install the screen assembly:

Review of budget homemade products:

The variety of screens allows you not only to create a convenient storage space under the bathroom, but also to stylishly decorate the screen outside using mosaics, 3D panels, mirrors, tiles and other materials. Installing a factory model is easy and takes a minimum of time; with a self-made screen you will have to tinker a little longer.

Are you assembling a purchased screen and have any questions during the work process? Ask our experts in the comments section, add a photo with instructions from the manufacturer - we will try to help you.

Or maybe you successfully completed the installation of the screen yourself and modified it a little by placing convenient stands or a cabinet with shelves to comfortably place it inside a package of detergents? Share the results of your work with other users - add a photo of the improved screen design.

How to install a screen under a bathtub - instructions

The procedure will depend on the type of screen - sliding or solid without the ability to access communications without removing the panel. But both options will not cause problems if you have a ready-made screen with mounts included.

You will need the bare minimum of tools - a tape measure, a screwdriver, a building level. For models with height-adjustable legs, the parts of the adjustment mechanism can be secured with nuts; then a wrench of the appropriate size will be required.

First of all, make sure that the product is selected correctly - take measurements. Next, follow the simple instructions:

How to secure the screen if it does not have viewing windows or sliding panels?

The installation procedure for such a product is even simpler - there is no need to insert moving parts into the grooves. It is enough to install the finished screen and secure it, placing it at a standstill.

How to attach the screen to an acrylic bathtub?

To install and fix the screen in the bathroom with an acrylic product, the tool kit will be replenished with a drill.

Unlike a cast iron bathtub, an acrylic bathtub itself serves as a base for attaching a decorative panel. How to install a screen on an acrylic bathtub without damaging it?

After trying on the screen, drill holes for the pins in the acrylic. This must be done carefully, try not to damage the stiffeners of the product, this will weaken the structure of the bathtub. After this, the decorative panel easily falls into place and is fixed with the included fasteners.

If the bath screen is made of MDF, organic glass or other materials, then the process itself is not much different from installing a plastic screen. The main stages of work are the same.

To install the screens, you do not need to call a specialist or contact familiar plumbers. You can do this yourself at any time, you just need to carefully study the model and read the simple instructions - in this article or supplied with the product.

Materials and tools

Before starting work on installing the factory panel, you need to buy the screen itself and select a set of tools (buy, rent, borrow from friends or neighbors).

The kit should include:

- sashes - 2-3 pcs.;

- frame consisting of 2 (preferably 3) vertical posts and 2 horizontal ones;

- legs;

- pens;

- screws for fastening handles (2 per handle);

- self-tapping screws for attaching the frame to the bowl.

Attention: manufacturers increasingly began to supplement kits with screwdrivers for screws and self-tapping screws, and wrenches for legs, and therefore they will be superfluous in the tool kit.

Tools you will need:

- screwdriver with drill and bits: slotted and cross-shaped. The tool will be needed for drilling holes for handles, and also as a replacement for screwdrivers;

- roulette;

- construction pencil or marker;

- level;

- wrench, if not included;

- silicone sealant.

Benefits of use

Installing panels covering the space under the bath bowl helps solve several problems:

- create a unified space in the bathroom;

- hide household chemicals;

- cover communication pipes;

- reduce the likelihood of water and objects entering hard-to-reach places under the bathtub bowl.

The solution to these problems is facilitated by diversity - both in designs and in screen design.

Aesthetics

The screen allows you not only to hide the legs of the bathtub and water supply and sewerage pipes, but also to decorate the bathtub. Such products made of plastic look especially attractive. Such panels are often decorated with various designs, which are applied using photo printing technology.

Functionality

Screens perform several functions. The main thing is to hide utility lines. However, this is not the only task that such structures perform. Screens prevent water from penetrating under the bathtub, thereby creating additional protection against leaks. In addition, these products hide household chemicals from pets and children.

Materials for making the screen

The screen for the bathtub is made with your own hands from:

- galvanized profile covered with sheet material: moisture-resistant plasterboard;

- moisture-resistant or laminated plywood with a thickness of at least 10 mm;

- GVL (a good choice, as it is absolutely not afraid of moisture and does not deform);

All of these structures, except the last one, require finishing. Most often this is porcelain stoneware or ceramic tiles, the same as those laid on the walls of the bathroom.

The most common version of a homemade bath screen is made from profiles and drywall. In order for the structure to be reliable and not sag under loads, the profiles must be taken with a thick wall, or reinforced ones can be used. Also a prerequisite is good quality galvanization. If possible, you should take branded profiles so that there are no problems later - after all, high humidity in the bathroom is the norm.

Frame made of galvanized profile for sheathing with sheet material

Sheet material for the frame must be moisture resistant. This is a must. And even in this case, before installation, it won’t hurt to prime it with a compound that increases water-repellent properties. It’s not bad if this composition is also antibacterial - protection against mold and fungi will not hurt.

Brick screens are made mainly for acrylic bathtubs - so that part of the load can be transferred to the brick wall. Although, if desired, the profile frame can be made with sufficient load-bearing capacity - double reinforced racks can be made.

If you decide to make a screen for a bathtub from brick, you should use a red ceramic one. It is better not to take silicate because of its hygroscopicity. Ceramic brick is also hygroscopic, but its absorbency is less. To minimize possible problems (painting due to high humidity), it is advisable to cover the inside of the masonry with a layer of plaster. This is not easy, but if desired, it is possible to apply the solution as the screen is being erected. No special care is required, the main thing is to protect the brick from moisture.

Brick bath screen ready for tiling

Another option for a bathtub screen that you can make yourself is from aerated concrete. This material is easy to process. The required relief is formed easily, even with a sharp piece of iron, and the block is cut with a regular saw. With all this, the blocks have good load-bearing capacity. So this material can also be used for a homemade screen for an acrylic bathtub. In addition, the blocks are large, so this small wall folds up very quickly.

Laying a screen under a foam concrete bath

Plastic screen for bathtub

Mount the wall mount

Massive cast iron bathtubs stand confidently on legs and do not require additional fixation. But light steel and especially acrylic ones are also attached to the wall for reliability.

Installation of a homemade structure

Tile design

You can make a screen yourself as follows:

- Mark the attachment points.

- They take all the necessary measurements.

- A frame is made of metal and its elements are secured according to the markings.

- Panels are cut from a suitable material and secured to the frame.

- They carry out the cladding.

If the installation process takes place on an acrylic bathtub, then the fasteners are mounted directly on the side, but a cast-iron bathtub cannot be drilled, as this will damage the product.

When installing a sliding screen, you can use removable suction cup handles. This is an additional safety measure that will help hide household chemicals from children.